-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Agriculture and Forestry

p-ISSN: 2165-882X e-ISSN: 2165-8846

2015; 5(3): 177-181

doi:10.5923/j.ijaf.20150503.01

Production, Conservation and Health Assessment of Acid Silage Vicera of Freshwater Fish as a Component of Animal Feed

Everton Oliveira Vieira1, Osvaldo Juliatti Venturoso2, Felipe Reinicke2, Caio Cézar da Silva2, Marlos Oliveira Porto2, Jucilene Cavali2, Nayche Tortato Vieira2, Elvino Ferreira1

1Department of Agronomy, Universidade Federal de Rondônia, Rolim de Moura, Brazil

2Department of Veterinary Medicine, Universidade Federal de Rondônia, Rolim de Moura, Brazil

Correspondence to: Elvino Ferreira, Department of Agronomy, Universidade Federal de Rondônia, Rolim de Moura, Brazil.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

The acid silage of fish waste is a source of generating feed simply process and at low cost and sustainable alternative to the disposal of this waste now docked in the environment. This work aims to evaluate the method of production of silage made with muriatic acid (hydrochloric acid commercial) for the process of production, conservation in acidic medium, health assessment, job burnout for the production of animal feed and chemical profile. The experiment was conducted at the Experimental Farm of the Federal University of Rondônia, Campus Rolim de Moura with viscera tambaqui (Colossoma macroponum) were obtained from fish farms in the county. They were passed on meat grinder, reserved in plastic drums which was added the acid. After three weeks of incubation samples were sent to a specialized laboratory in this resulted in negative for the presence total coliform, fecal coliform and heterotrophic bacteria. It can be seen that 210 days after the material showed no visible changes or odor, color and consistency. To achieve a pH of around 6.0 was used 6.4 g of commercial caustic soda. This time added sodium levels represented 2.9 % in the silage. The silage neutralized or made with pH levels around 4.0 provided the occurrence of fungi of the genus Mucor and Rhyzophus. Regarding the chemical profile obtained levels of 30.81 % crude protein, 26.73 % ether extract, 0.62 % calcium and 0.73 % phosphorus in the dry matter. The process can be simple and potentially considered for use as animal feed.

Keywords: Colossoma macropomum, Fish filleting residues, Raw food

Cite this paper: Everton Oliveira Vieira, Osvaldo Juliatti Venturoso, Felipe Reinicke, Caio Cézar da Silva, Marlos Oliveira Porto, Jucilene Cavali, Nayche Tortato Vieira, Elvino Ferreira, Production, Conservation and Health Assessment of Acid Silage Vicera of Freshwater Fish as a Component of Animal Feed, International Journal of Agriculture and Forestry, Vol. 5 No. 3, 2015, pp. 177-181. doi: 10.5923/j.ijaf.20150503.01.

Article Outline

1. Introduction

- The use of fish waste in the form of silage can be a source of nutrients for good quality composition of concentrates for animals of economic interest. The waste refers to the disposal of the fishing industry, low economic value, ie, head, fins, skin, scales and guts [3], and its recommended use because of its high amount of organic matter [2].Among the options is to silage which is obtained by autolysis acid residue of the protein from the fish, or even by the action of enzymes present in fish [25] producing a pasty liquid form which can be incorporated in the diet as a protein source [20]. The conventional silage is acidified to a pH between 3.9 and 4.2 in three days at an ambient temperature of 27C to 30C, which is sufficient for the product with a liquid and homogeneous feature [27].Oxygen, light, heat, the presence of metals, pigments and the degree of unsaturation of fatty acids influence the oxidation reactions, the main feature oxidative rancidity. This causes deterioration of fish silage when exposed to atmospheric oxygen, due to its high content of polyunsaturated fats, such as omega 3 fats present in fish [12]. Lipid oxidation is a chemical change and causes unpleasant taste and odor of fat from food. The exclusion of oxygen or the addition of an antioxidant slows the process. This material has adequately preserve the high nutritional value and digestibility of the protein, because it be hydrolysed enough, however an extention of storage period to avoid it’s because excessive hydrolysis [21].After industrialization process of filleting fish there are approximately 67% of waste [24], which, with its disposal incorrectly can cause major environmental, health and economic problems [17].Globally, to have to order production of 126 million tonnes of fish an increase of 100 million tonnes by 2030 [11]. Brazil is one of the few countries that is able to meet this demand, with increases estimated at $ 200 million and more than 300 million workers directly or indirectly involved in the activity [14].In this scenario, Brazil in 2010 showed significant growth in this activity, from 278 thousand tons in 2003 to 415 thousand in 2009, which equates to 35% increase in less than one decade [19]. The production of fish farming reached only 60.2% growth between 2007 and 2009. Isolation tilapia production increased 105% in just seven years (2003-2009). Together, aquaculture grew 43.8% between 2007 and 2009 making fish production increased the most in the domestic meat market in the period [19]. The activity generated a fishing gross domestic product $ 5 billion, mobilizing 800,000 professionals among fishermen and fish farmers and provided 3.5 million direct and indirect jobs [19]. To Rondônia, in particular with the breeding of large-scale fish in the lakes of the Santo Antônio hydroelectric and Jirau, it is estimated that production could reach about 100 000 tonnes of fish per year [5, 9], highlighting the State in such activity.The production of fish silage offers economic advantages, since it requires simple and independent scaling technology, besides using low cost materials, unlike fish meal, for example, which requires high investment for their production [13]. This is important because spending on feed sometimes reaches 65% or more of production costs [1] and that the profit margin for the business is small. However should be checked as barriers to processing, manufacturing conditions evaluate both silage as feed in order not compromised its quality or even the performance of animals fed diets composed for her. In the development of this study was to evaluate yield, the occurrence of microorganisms in relation to manufacture, storage time of silage with different levels of acidity and bromatologic profile of this product.

2. Material and Methods

- The study was conducted at the experimental farm of the Federal University of Rondônia, Campus Rolim de Moura, located at km 15, line 184, north of the city of Rolim de Moura - RO. The municipality lies at 277m above sea level, in latitude 11° 34' South and longitude 61° W, in the period January to December 2013, where it was produced silage with fish waste (skin, remains of muscles, bones, viscera) tambaqui (Colossoma macropomum), coming from the local trade, i.e., fish farms Rolim de Moura and Santa Luzia d'Oeste. These wastes were processed in a commercial meat grinder for the purpose of homogenization of fish waste.This pasty, homogeneous mixture was transferred to plastic containers (silos) with a capacity of 50 liters, in three replicates, muriatic acid, commercial product based on hydrochloric acid, which presented the following composition was added hydrochloric acid 54-83%; ethyl alcohol 7 to 13% and ammonia solution (28%) of 0.1 to 1.0%.The concentration of acid used was 175 ml kg-1 residue, which afforded the amount of 324.07 mL of product to be added per kg of crushed waste fish.Daily silage was mixed twice a day (morning and evening) and the supernatant (fat) was dropped, with the aid of a spoon, while presenting excessive since high levels of both animal fat intake undertake as the conservation of the product [12].The silage process was considered finished, three weeks after the addition of acid to obtain absence of total coliforms counts [4]. Monitoring aimed at observing the changes in color, aroma and consistency was achieved. Three weeks the samples were subjected to microbiological analysis in a specialized laboratory. Elsewhere silage was produced with an initial pH of 4.0, using a lower amount of acid in three replications. Also conducted sampling to bromatologic analysis, so the product is used in feed composition.The pH of the silage was determined on portable digital pHmeter, always preceded by mixed mass. For the neutralization of the ensiled mass aiming to use in diets was used soda ash (96-99% NaOH), pH to be obtained around 6.0, compatible with the physiology of domestic animals.

3. Results and Discussion

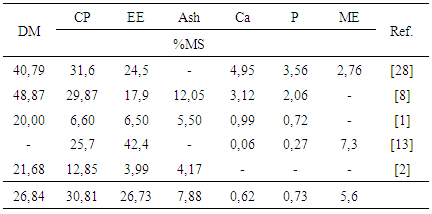

- Production and Conservation in the manufacturing processFor the manufacture of silage depending on the concentration range provided by the manufacturer, it was decided to use the lowest level of concentration of hydrochloric acid (54%) referred to in the literature extrapolation, 175 mL of hydrochloric acid, which afforded the amount 324.07 mL of residue per kg of fish. The process need not be used in other methods as anaerobic silage, since the microorganisms no longer have the major role in the transformation of the material, the process being carried out at acid [4].After the 21 day period of adding the acid, some characteristics of the silage changed as the characteristic aroma of fish disappeared from the early moments giving rise to the aroma of the acid product used. With the addition of acid produced a brown color in the reddish mass, but not the time of visual and olfactory changes that indicate the involvement of the silage was observed. The initial texture became less viscous due to addition of the commercial product (liquid).In the production process flotation was observed with a layer of fat which has been removed periodically with the aid of a spoon. The daily tickler (twice a day, morning and afternoon) allowed the remaining fat to get in touch again with acid and, therefore, did not occur to oxidative rancidity, thus compromising the quality of the silage. This was evidenced by the absence of consistent flavor to the process of rancidity generated by the presence of unsaturated fatty acids of the lipids which react with oxygen by breaking the double bond and produce peroxides and free radicals, which are chemically very reactive [12, 18].In relation to fat, it has to tambaqui (Colossoma macropomum) reared in tanks with industrial food has higher fat content than fish in natural environment or even as catfish and trout used in reference to other research work.Health evaluation and conservationThree weeks three samples, each silo acidified in the proportion of 324.07 mL of the commercial acid residue per kg of fish waste were sent to specialized laboratory to be checked for the presence of pathogenic microorganisms. Report was registered in the absence of coliforms, fecal coliforms, heterotrophic bacteria or thermotolerant.This result is important since, if confirmed the presence of these microorganisms shall be the invalidate of the material its food use. These microorganisms can promote the deterioration of silage by perceived differences in their color (darker) and the occurrence of unpleasant odors. The process of deterioration begins (in the flesh) with scores ranging from 106 colony forming units (CFU g-1) of aerobic mesophilic, being succeeded by strange odors (107-109 CFU g-1), change in taste (108-109 CFU g-1) and surface slime (109 CFU g-1). With the presence of microorganisms in initial counts 104-105 CFU g-1, the shelf life of the product can reach 3 to 4 days when stored at 5°C [22].The addition of acid was effective in sterilizing the ensiled mass, since the viscera, by itself, provides a suitable means for the establishment and development of a number of microorganisms. With its fragmentation by using the meat grinder, the release of cell juice is increasing even more favorable conditions for the proliferation of microorganisms [22] which entails compromising its conservation and its use in the feeding of domestic animals, which was prevented by the addition of acid.Neutralization of the ensiled massIn the manufacturing process the pH of the silage was measured after the acid has stabilized, that is, the color was uniform, homogeneous mass, and lack of perception of the odor given off from the acid initially crushed mass. With the measurement of pH levels in this opportunity, it was found that the amount of acid added mass of viscera ground provided with amount of Hydrogen (H+) in addition to the scaling limit of the apparatus (pHmeter). Such a viscera is related to the absence of microorganisms as previously reported.For the inclusion of this material aiming its use in feed composition the addition of a base in order to raise the pH, leaving it near neutrality is needed. Was used for both commercial caustic soda (NaOH 96-99%). To assess the amount of soda needed to be employed made a study of addition levels with the goal of pH close to 6.0 is obtained. For it became 100mL flasks silage where increasing amounts of soda (two replicates) were added, pH meter readings taken two hours after the addition of caustic because of the lack of heat given off to its addition.The amount that is adapted to adjust the pH to 6.4 g of sodium hydroxide in 100mL of silage, which increased silage pH around 6.1 to 6.4 (average 6.25). The mass participating sodium neutralization represented 2.94% (2.94 g 100 mL-1). It is important to remember that levels greater than 1% in concentrated sodium diet is not recommended for animal feed in general. With increasing sodium intake, there is an increase in blood osmolarity and by means of neurohormonal mechanisms, develops the feeling of thirst, which stimulates water intake by the animal to excrete excess sodium [16]. For example, in pigs poisoning can occur by excessive salt intake being aggravated by this period of water deprivation, which can lead to death of the animals [6].Evaluation as to the storageThe high level of acidity before the addition of sodium hydroxide was responsible for preservation of the silage with the incidence of not occurring fungi or bacteria. Three samples were undisclosed in plastic silo evaluated periodically until 210 days showed no changes as the smell and the occurrence of microorganisms.With the use of four levels of hydrochloric acid 75, 100, 150 and 175 ml kg-1 in 2kg acid added fish waste, for 3 weeks, resulted in low bacterial count and coliforms at 45°C, making it suitable for animal consumption product [4].The literature also has as a reference the acid process developed silage pH 4.0 [3]. Thus the pHmeter was used to manufacture other amounts of silage minor amounts of acid used for this purpose. After three days at ambient conditions, the ensiled material showed fungal growth conducive to microbiological growth. The same happened with the silage pH 4.0 maintained at 30°C in a forced air oven after 10 days.In the literature that has this level of pH (3.75 ± 0.24) temperature of 26.2 ± 2.8°C prevents the proliferation of pathogenic and spoilage microorganisms in addition to promoting the activity of some enzymes [13], however this result was observed regarding the use of formic acid and citric acid in the ratio of 1:0.75 for preserving viscera silage catfish [13].Impaired quality of ensiled mass can be realized by differences in color (darker) and odor (strong and unpleasant). The deterioration process starts with counts in the range of 106 CFU g-1 of aerobic mesophilic and lower initial counts (104 CFU g-1), their shelf life is restricted 3-4 days even when stored at 5°C [22]. For the mechanisms of contamination should be considered that the meat grinder there is a possibility of formation of bacterial biofilms, or when there is a minimum of 107 cells per square inch and adhering considering the occurrence of filamentous fungi and yeast (104 CFU g-1) these can accelerate the spoilage as a result of production of various enzymes [22]. For the case where the silage were produced with pH around 4.0 after microbiological assessment showed the occurrence of fungi of the genus Mucor and Rhyzophus belonging to the phylum Zygomycota.Silage produced only with inorganic acids should have pH 2.0 to prevent bacterial action [10], which agrees with the results of this work for acidified silages at lower levels, however, is recorded also that the pH more favorable to fungal growth is between 5 to 7, however, filamentous fungi can develop in the pH range from 1.5 to 11 [26]. Regarding the occurrence of these microorganisms can be reported that the species of the genera Mucor and Rhizopus are saprophytes in foods stored, may also be present in animal feces, among others [23].Profile bromatological of silage vicera tambaquiIn order to employ the silage for animal feed use in a sample of silage and adjusted to pH 6.0 Material was sent for analysis to be evaluated bromatological analysis. The results of the analysis were: Dry Matter 26.84%, Crude Protein 30.81%, Ether Extract 26.73%, Calcium 0.62%, Phosphorus 0.73%, and 5.6 Mcal kg-1 Metabolizable Energy. This last value is intermediate to other data found in the literature data [13, 28] (Table 1).

|

4. Conclusions

- High concentrations of hydrogen (H+), promote the preservation of the silage with no occurrence of pathogenic microorganisms.The silage neutralized with soda (NaOH) for generating pH 6.0 promoted the occurrence of fungi was observed in the same (non-neutralized) when the silage processing occurred at pH 4.0.The silage viscera of tambaqui fish have potential use to make concentrates for animals of economic interest.

ACKNOWLEDGEMENTS

- To CNPq (National Council of Scientific and Technological Development) for providing financial support (proc. 476654/2011-A). The authors also thanks Patricia Ferreira Miranda review to the manuscript.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML