-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Agriculture and Forestry

p-ISSN: 2165-882X e-ISSN: 2165-8846

2015; 5(2): 166-175

doi:10.5923/j.ijaf.20150502.11

The Import Substituted Poultry Industry; Evidence from Ghana

Kwamina Ewur. Banson 1, 2, Gobinath Muthusamy 3, Ebenezer Kondo 4

1Department of Technology Transfer Centre (TTC), Biotechnology and Nuclear Agriculture Research Institute (BNARI), Ghana Atomic Energy Commission (GAEC), Legon-Accra, Ghana. BSc, MSc Agricultural Economics

2Department of Marketing and Management, School of Business, University of Adelaide, Adelaide, Australia

3Faculty of Business, Kaplan Business School, Adelaide, Australia

4Department of Nuclear Agriculture, Biotechnology and Nuclear Agriculture Research Institute (BNARI), Ghana Atomic Energy Commission (GAEC), Legon-Accra, Ghana, BSc, Agricultural Economics

Correspondence to: Kwamina Ewur. Banson , Department of Technology Transfer Centre (TTC), Biotechnology and Nuclear Agriculture Research Institute (BNARI), Ghana Atomic Energy Commission (GAEC), Legon-Accra, Ghana. BSc, MSc Agricultural Economics.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Rapid growth in Ghana’s poultry imports revealed the weaknesses of the domestic industry in competing with imported products. Establishment of an intensive poultry system as a benchmark for examining the performance poultry production and marketing in addition to interviews with poultry stakeholders revealed the constraints in the poultry industry in Ghana. Results emphasized that Feed Conversion Rate is a major factor in reducing production cost and improving the broilers growth efficiency. The BNARI feed conversion rate for the broiler is 1.56 Kilogram of feed needed to produce 1 kg live weight compared to 2.12 kg of feed to produce 1 kg live weight by other poultry farmers engaged in the study. Feed costs represent more than 70% of the total cost of broilers production, and feed utilization efficiency, are critical for the growth rate of broilers. A major constraint is the lack of protection on the infant poultry industry by the Ghana government leading to unfair competition with cheap imported poultry products, which is 30-40 percent cheaper and undermines the growth of the local industry. Other constraints are high feed cost, high chick mortality as a result electricity power outage for brooding, feed and water contamination and consumer preference for imported poultry meat. There is still 74% demand market share to be fulfilled. The Ghana poultry industry is insecure because poultry farms are collapsing faster than new farms are being established or old farms are being expanded. There is a need for serious intervention by the government through policies and enforcements to reverse this trend.

Keywords: Import substitution, Marketing poultry, Poultry imports, Feed formulation, Feed conversion rate, Chick mortality rate, Domestic poultry industry

Cite this paper: Kwamina Ewur. Banson , Gobinath Muthusamy , Ebenezer Kondo , The Import Substituted Poultry Industry; Evidence from Ghana, International Journal of Agriculture and Forestry, Vol. 5 No. 2, 2015, pp. 166-175. doi: 10.5923/j.ijaf.20150502.11.

Article Outline

1. Introduction

- Rapid growth in imports revealed the weaknesses of the domestic industry in competing with imported products [1]. The poultry sub-sector of Ghana can be broadly categorized into backyard production systems (also referred to free range birds) and commercial systems. The backyard production system is the most prevalent in Ghana with poultry playing a very important role in the livelihoods of farmers. According to various estimates they account for 60-80 percent of the national poultry population [2-4]. Backyard chickens include turkey, duck and other local poultry varieties. For example the Frizzle, Barred, Naked neck including guinea fowls (Pearl helmeted) are kept as a source of protein and as a means of sustaining or improving household livelihoods both in the rural areas and urban towns. These birds are sometimes given kitchen waste to supplement the feed scavenged in the surroundings of their homestead to survive and to reproduce [5-7]. The commercial enterprises can be categorized into small-scale (50-5,000 birds), medium scale (5,000 – 10,000 birds) and large-scale (>10,000 birds) operations [4, 8]. Presently in Ghana, there are less than twenty large-scale commercial poultry operators, producing mainly eggs with limited production of broilers (meat). Broiler birds are often produced to meet demand at festive seasons such as Christmas or Easter, when most consumers would normally purchase live birds. Most of the poultry producers also sell off spent layer chickens during these festive occasions. But after the festive occasions, farmers fully focus on producing eggs again. The large commercial poultry farms are privately owned by individuals or a family. Ninety five percent of the poultry farmers (about 1500 in number) are small-to-medium-scale and they depend on the supply of both local and imported day-old chicks. They also depend on feed mills for their feed. The medium sized enterprises also produce primarily eggs [8]. The small-scale enterprises (including backyard poultry producers) mainly produce broiler birds. The medium and small-scale operators practice minimal bio-security. One of the major constraints in the poultry industry is competition with foreign imports [9, 10]. One concern has been that surges in food imports are disrupting local markets, with negative effects on prices, production and food security in the importing country [1]. Import surges and associated negative effects, notably on farmers or other producers in Ghana cannot be over emphasized and hits headlines. The surge in poultry imports in Ghana is caused by two factors: the lowering of trade barriers as a result of regional integration and economic liberalization; and the domestic producers’ inability to meet consumer demand because of structural constraints to efficient production [11]. As a result, Government has put in place import quotas and import tax to protect the infant poultry industry, yet still prices of imported poultry is so low that local production cannot compete. Import surges have become more common as West African countries lowered tariffs as part of their regional trade agreements in the late 1990s. As part of the World Trade Organization, most West African countries have the right to impose tariffs ranging from 79 percent to 230 percent. However, as signatories of regional trade agreements committed to establishing common external tariffs, West African countries have dramatically lowered their tariffs [12] In Ghana, the poultry farmers are among those that have been severely affected by the globalization process and trade liberalization which has resulted in structural changes [13]. The non-economists are likely to hear the terms import substitution industry. What impact does the import substitution industry means for the market and the economy? Assume two families living apart, “A” and “B”. Family “A” has two children and Family “B”, has six children. Both families depend mainly on what they produce and trade the surplus if any. Assuming all children of the two families are maize farmers and each farmer can produce two bags of maize per year. We also assume that each person needs one bag of maize per year to live satisfactorily when all conditions are favorable and at least half a bag of maize for unsustainable conditions. So, let also assume that in family “A”, the children; “Kofi” grows maize but his brother “Kweku” does not and in family “B” all the six children grow maize resulting in 4 bags of maize as a surplus. In family “A”, maize is sold at 15 Dollars per bag and in that of family “B”, is equivalent to 5 Dollars per bag. “Kofi” makes good profit and can expand his business within the next few years which will lead to more bags of maize at lower price. However his brother “Kwaku” decided to trade with family “B” by buying their surplus maize and sells them at a lower price compares to his brothers. Their parent also decided to buy “Kweku’s” maize since its far cheaper than “Kofi’s”. “Kofi” then decides to close down his business since there is no market for them.A wise parent will prevent “Kweku” from buying maize from family “B” or tax him higher percentage to protect “Kofi’s” infant farming business to grow. Import substitution, therefore entails an attempt to replace commodities that are being imported, with domestic sources of production and supply. It includes a number of industrialization policies based on a very little degree of international openness. By doing so, local communities can put their (hard-earned) money to work within their boundaries. Import substitution, involving the development of the domestic industry through varying forms of protection and is pervasive element of economic policy in todays less developed or developing countries including Ghana. Developing countries such as Ghana should temporarily protect its domestic poultry industry with high tariff barriers (and / or quotas) on the importation of poultry goods and then try to promote the local farmers to produce these goods. The hope is that producers will be able to produce for the domestic market without a tariff wall and also export low-cost poultry goods [14]. Concerns about the negative effects of Ghana’s poultry imports on domestic poultry prices have raised the concern of local farmers, consumers and governments. Import surges of poultry products in Ghana have risen to a mainstream debate at the national level in recent years undermining domestic poultry production. An import surge case for poultry was identified for study from MOFA, the University farm at Nungua, FAO and USDA available data. Industry stakeholders have pressed policy makers to raise tariffs, claiming that import competition threatens local industries. According to the FAO, (2006) approximately 50 percent of the poultry surges registered in developing countries have occurred in Africa, with 24 percent reported in West Africa, 11 percent in central Africa and 10 percent in southern Africa. Ghana has witnessed an increasing prevalence of poultry import surges over the past 6 years with imported quantities far exceeding domestic once. The incidence of these surges increase occurred in 2002 where imported quantities for the first time exceeded domestic levels and since then, import quantities keep skyrocketing yearly due to domestic poultry enterprises operating at low capacities. Poultry imports grew from 4000 tonnes in 1998 to 124 000 tonnes in 2004 (FAO, 2006). With production growing significantly less than imports, imports accounted for more than half of consumption gains over the past few years.As a result the local market has become uncompetitive and lots of local poultry farmers have already left the industry for alternative business. The traditional poultry sector, characterized by backyard operations of small producers who sell live chickens in local markets, appears not to be affected by rising imports. The apparent lack of substitutability between commercially grown broilers and these farm-grown chickens can be inferred from price developments in the industrial and local markets. This study therefore examines the impact of poultry imports on local poultry production, stakeholders and their markets. In addition, this paper examines poultry production performance, consumer attitude towards the poultry markets and the challenges involved in production and marketing by stakeholders. From a theoretical and policy perspective, this research fits into the current debate on the poultry imports surges to agricultural improvement in Ghana and aims to provide useful lessons for neighboring countries that are engaged in a peer learning process with Ghana as an example. The limitation of this research is that, it involved only stakeholders within the greater Accra region of Ghana and data is limited by the fact that it rarely can be independently verified. In other words, researchers accepted what the poultry farmers and consumers say, whether in interviews, focus groups, or on questionnaires, at face value. The counterfactual performance study and examination among 5 selected farmers in the greater Accra district with all things being equal did not have similar feed formulation strategy, housing and maintenance culture thus there may be bias in performance comparison.

2. Materials and Methods

- The research method used in this study includes the establishment of an intensive poultry system by the Biotechnology and Nuclear Agriculture Research Institute (BNARI) to use as a benchmark for examining the performance of poultry production and marketing. This was done to model the performance and real impact of imports on farmer’s profitability and sustainability. Secondary sources of data were also reviewed. It also involves stakeholder surveys through standard interviews based on a set of questions by the Technology Transfer Center of BNARI of the Ghana Atomic Energy Commission (GAEC). The stakeholder theory of organizational management and business ethics that addresses morals and values in managing an organization originally detailed by Freeman (2010) was adapted. A Stakeholder approach identifies and models the groups which are stakeholders of a corporation, and both describes and recommends methods by which management can give due regard to the interests of those groups (Donaldson and Preston, 1995). "The interview questionnaire began with introductory and explanation of the purpose of the research which examine the poultry production performance among Ghanaians poultry farmers and market access. Consumers and wholesalers were also interviewed to elicit their perception of the local poultry industry. The study location was within and around the peri-urban areas of the Greater Accra region due to the presence of both medium and small-scale poultry farmers.BNARI adopted the deep litter system for a broiler intensive system for a period of 42 days with more than seven cycles produced within a year. The biological material used is the commercial broiler hybrids “Ross-308”. The growth system was on the deep litter with a density of 10 chicks per square meter. In the growth period of day 1 to the 42nd day, microclimate factors such as temperature and relative humidity values conformed to the recommendations found in the 2014 Broiler Management Manual for “Ross-308’[15]. The lighting schedule varies depending the age of the birds. 24 hours of light were provided from day 1 d to day 7; 23 hours of light and 1 hour dark provided from day 8 to day 35-with dark periods on the night time and 24 hours light from day 36 to day 42. BNARI formulated feed mixed with protein and energy levels which closely conforms to the recommendation of the Aviagen Group [15] for “Ross-308” hybrid. The main feed ingredients include maize (white or yellow) wheat bran, cotton-seed cake, kernel cake, soybean cake, copra cake, fish meal, soybean meal; vitamin-mineral premixes, shell grit, RE3, salts, methionine and lysine. The main poultry feed inputs such as fishmeal, premix, concentrate and soybean, are imported [4]. The counterfactual performance study and examination among 5 selected poultry farmers within the respondents with all things being equal did not have similar feed formulation strategy, housing and maintenance culture. However, they all follow the vaccination programme recommended by the Veterinary Services Directorate of the Ministry of Food and Agriculture against Gumboro, Newcastle Disease (HB1, Lasota & Newcavac), and Fowl Pox [4]. BNARI provided three recipes of compound feed depending on the age of birds during the growth period: starter, grower and finisher. Performance parameters investigated during the experimental period were: body weight dynamics, average daily weight gain, feed conversion ratio, and mortality. Data collection occurred from 23rd January 2014 to December 2014. Stakeholders interviewed are poultry farmers, feed producers, retailers, consumers, and local restaurants. A total of 52 small-scale broiler and layer producers were interviewed in addition to 50 traders and consumers. This research outlines the key findings obtained from the BNARI Poultry Project established by the Biotechnology and Nuclear Agricultural Research Institute (BNARI) under the Ghana Atomic Energy Commission. Additional information was obtained from the Poultry Unit of the Ministry of Food and Agriculture, MOFA), University of Ghana Farms, Abundant Grace farm at Dodowa, as well as personal interactions with experts on production, marketing and information on the benefits of production. Raw data obtained from measurements were processed using methods of biostatistics with Microsoft Excel spreadsheet application and SPSS.

3. Results and Discussions

- Of the 150 respondents, 60 were farmers (40.0%) between the ages of 28-65 years. Also 40 (27%) were wholesalers and retailers between the ages of 21 to 40 while 50 of them (33%) were consumers from the age 17 to 70. All the farmers had a minimum of high school education with 80% among them having a higher degree ranging from bachelor to PhD. This implies that small and medium scale layers poultry farmers are literate and are among the economic active force the population. Majority (91%) of the respondents have more than 4 people in a household and the poultry business is an important source of income to supplement the family maintenance [16-18]. For the 20% of farmers with up to high school literacy, the poultry business is their only source of job security and main source of finance for family up keep. However, the rest of the respondents with the minimum of degree certificates see it as an alternative way of investing their hard-earned income (20%), others also see it as security for their job (45%) and to generate more income to provide a better quality of life (35%). Ninety eight percent of respondents engage their family labour in their poultry business [19].

3.1. Productive Performance

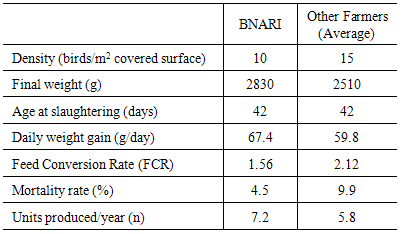

- The Arbor Acres, Ross 308 and Cobb 500 are the common breed of broilers produced among the respondents due to their robust, fast growing and feed efficiency with good meat yield [15]. The data obtained in the BNARI study were compared to the average standard values of selected poultry farmers engaged for the study using hybrids Ross-308 [15]. The productive performances gained by the intensive system employed by BNARI showed large differences for the final weight, age at slaughtering, feed index and mortality rate (Table 1) compared to that of the average poultry farmers of the same breed.

|

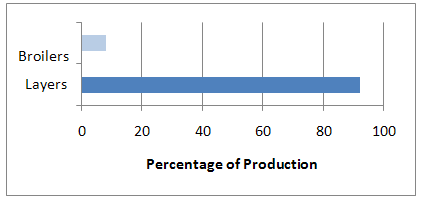

| Figure 1. Ratio of broiler to layer production |

3.2. Production and Markets Systems

- All farmers interviewed indulge in deep litter system of poultry production. Aside the Arbor Acres, Ross 308 and Cobb 500 breed of broilers produced by the interviewed poultry farmers, layers primarily constituted more than 90% of poultry production unit in Ghana as shown in Figure 1.Ghana’s poultry feed industry has also shifted to producing layer feed as a result of this trend. About 90 percent of feed produced by commercial feed millers is layer feed. According to the correspondents, the main reason is the good unchallenged market for the demand and sales of eggs. None of the interviewed small-scale farmers including BNARI has a cold store to slaughter and preserved birds when they get to their finished weight.This leads to high cost of feeding till the birds are sold. This has resulted in a major producer shift from broiler (meat) production towards the production of layer birds for table eggs. According to farmers, average industry egg production is 230-250 eggs/layer/year after which birds are sold as spent poultry. However these birds exceed their average eggs producing age unless markets are found for them leading to sometime poor quality eggs. Of the wholesalers interviewed, 60% are meat importers and usually operate cold storage capacities of 1000-2000 tons and sell products to retailers in cartons and in bulk. Wholesalers are considered a key player in the success of the chicken out-grower scheme initiated in 2003 when they were encouraged to stock and distribute local chicken [4]. The other 40% mainly buy from domestic poultry farmers and retail them directly in the market or redistribute to organizations or catering companies. However majority (90%) complaints that, selling live birds are less profitable since they must be fed at a cost till they are completely sold. The poultry industry is developing on a limited scale due to lack of significant import limitations and lax border enforcement. As a result major shipments of poultry meat are imported from Europe the U.S., Canada and Brazil. More than 95% of eggs and live poultry are sold by farmers at their farm gates to retailers and wholesalers. Figure 2 revealed that interviewed consumers were more concern with the faking of expiration date of imported poultry product and what these birds are fed with.

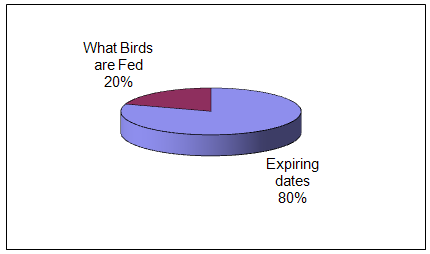

| Figure 2. Consumer main problems with importer poultry products |

3.3. Production and marketing challenges

- The first 14 days of the broiler’s life is the most sensitive period for effective brooding because the bird is changing from an immature thermo regulation system to a mature one [28]. BNARI and all the farmers involved in the studies stated that unannounced electricity power outage and inconsistence pipe born water supply are their major constraint to production as shown in Figure 3.

| Figure 3. Production constraints of poultry farmers (n=60) |

3.4. Imports Trends and the Local Poultry Industry

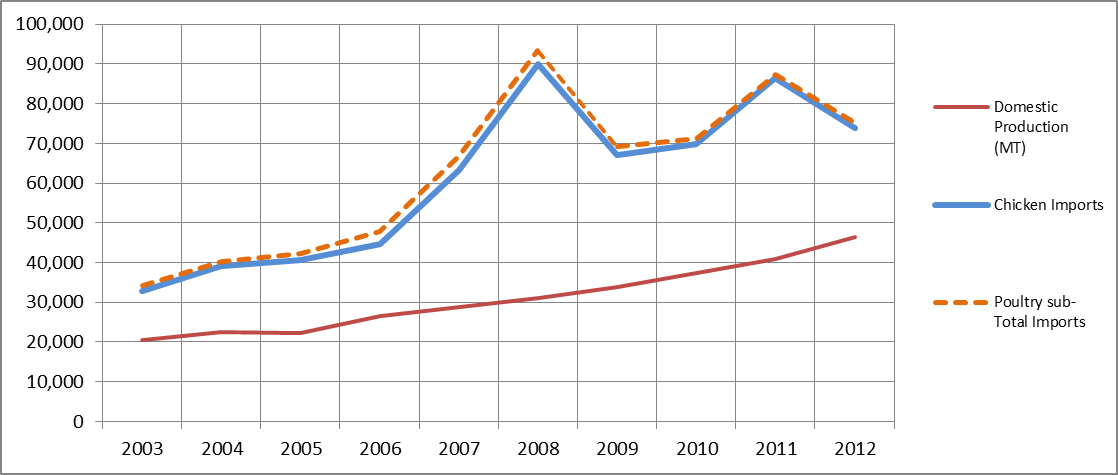

- Ghanaian imports of poultry have grown dramatically over the past decade, rising from 32,939 metric tons in 2003 to 73,788.4 metric tons in 2012 (Figure 4). Figure 4 shows a negative impact on the growth of the poultry industry in the country as a result of the impact of the avian influenza (H5N1) viruses which posed the greatest pandemic threat to millions of birds and man between 2008 to 2009 [32, 33]. Aside causing economic losses to poultry farmers, this led to a large scale socio-economic impart around the world export and imports. The rise in import growth, in conjunction with the inability of domestic production to meet demand, has increased the share of imports in domestic consumption to about 75 percent [34, 35].

| Figure 4. Domestic production and imports of poultry products from 2003 to 2012 [36] |

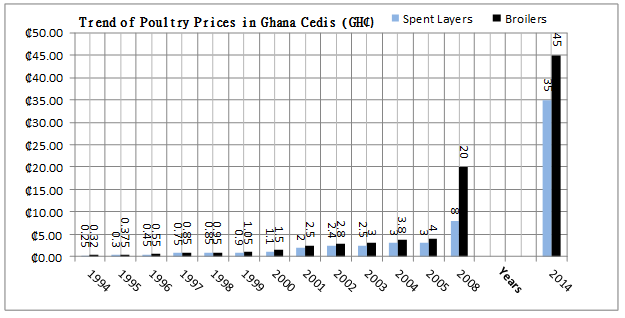

3.5. Poultry Prices

- Unit costs of production for poultry meat and eggs have increased since at least 2001 without comparable increases in sale prices [39]. Figure 5 depict the prices of both broilers and spent layers since 1994. The price of domestic live chicken had increased by over 1000% since 2005 to 2014 (Figure 5). Figure 5 shows the trend of price/bird of both spent layers and broilers from 1994 to 2008 and to date in Ghana Cedis. Currently spent layer and broiler are selling between 35-45 ($11-$14) Ghana Cedis respectively.

| Figure 5. Trend of Poultry Prices in Ghana (1994-2008 & 2014). Source: [40] |

4. Conclusions

- The Ghana poultry industry is insecure because poultry farms are collapsing faster than new farms are being established or old farms are being expanded. This is largely due to the unprotected domestic infant poultry industry having to compete with cheaper imports, high poultry feed prices, expensive veterinary drugs and the lack of cold storage facilities and interrupted power supply cuts leading to spoilage especially for wholesalers who have invested in deep freezers. As a result of a lack of consistent electricity and water supply and lack of deep freezers by farmers to store domestic processed frozen birds, the import substitution of frozen birds can barely be sustained with domestic production. Higher imported meat drives down farm gate poultry prices, and there is a need for serious measures to limit meat imports. This can be done by registering all meat importers to acquire license and also the introduction of reasonable level of meat tariff rate quotas which will make imported meat prices same as domestic prices. This can be seen as an attempt to level the playing field for the domestic poultry or meat farmers. Although consumers buy imported chicken as a result of convenience, it also had an impact on consumer buying behaviour as a result of taste, origin and production processes. Most of the interviewed poultry farmers depend solely on poultry trading as their main source of income. Poultry production is an important socio-economic and household livelihoods activity in Ghana. Controlling importation and animal feed costs is critical to the future of the Ghanaian poultry industry. Since these represent 82% or more depending on the time birds are sold on variable production costs. The survey notes that costs have been rising in response to rising global maize costs. It is clear that lower tariff rates lead to increasing shipments of low priced poultry, keeping inflation lower and increasing the availability of meat on the domestic market. However it undermines the domestic poultry industry. Its disadvantages far outweigh the benefits. Therefore there is the need to protect local poultry industry by enforcing strict phytosanitary policy relating to the importation of fresh meat and introducing higher tariff barriers as soon as possible. If this is not done, Ghana will be forever dependent on imported meat while our domestic poultry industries collapse. There is a need for the local government to invest in research and development in the poultry industry. For example, the government of Australia charges 0.02 Australia dollars per bird mainly for research and development to boost productivity in that industry. The Government can also put in place another source of water supply mainly for agricultural development purposes using recycled water and rain harvesting at a fee for interested farmers. The electricity power outage problems must also be taken care of if productivity of the poultry industry is to be boost. The local government can also set up standardized poultry sheds (housing minimum of 20 thousand birds) to support local investors and increase production. And last but not the least, the government can attract investors to site pockets of centralized poultry processing plant of any scale of operation to process poultry at a price which farmers can afford under hygienic, wholesome, attractive and saleable conditions. Attention also needs to be paid to current practices of transshipping product through duty-free third country such as Togo ports. Weaknesses in border control can also contribute to the meat supply. Metric tons of meat can be imported illegally into Ghana as a direct result of lax border enforcement. The importance of poultry industries to the Ghanaian economy and livelihoods cannot be over emphasized, particularly in the context of employment and as a major source of protein. Policies must support the full attention of domestic farmers and protect industries. The authors recommend the use of a systems thinking approach to investigate the root causes of the collapse of the industry and the poor productivity of the domestic poultry industry of Ghana.

ACKNOWLEDGEMENTS

- I thank God for his favour which made this work possible. The corresponding author would like to take this opportunity to express a very sincere thanks and appreciation to the team at the Nuclear Agriculture Center of the Biotechnology and Nuclear Agriculture Research Institute (BNARI) who helped to make this study successful. My gratitude also goes to BNARI for providing funds for this research. In the latter category I am particularly grateful to Malcolm Robert Pattinson of the University of Adelaide for his constructive comments and my parents and family members for their love and support.

References

| [1] | Sharma, R., et al., The impact of import surges: country case study results for Senegal and Tanzania. FAO commodity and trade policy research working paper, 2005(11): p. 27. |

| [2] | FASDEP, I., Food and Agriculture Sector Development Policy. Ministry of Food and Agriculture, Republic of Ghana, 2002. |

| [3] | Gyening, K., The future of the poultry industry in Ghana. Ghana Veterinary Medical Association, Accra, 2006. |

| [4] | FAO. Livestock country reviews; Poultry sector Ghana 2014 [cited 2015 17/03]; Available from:www.fao.org/3/a-i3663e.pdf. |

| [5] | Islam, S.F. and M. Jabbar, Scavenging Poultry for Poverty Alleviation: A review of experiences with. 2003. |

| [6] | Ekue, F., et al., Survey of the traditional poultry production system in the Bamenda area, Cameroon. Characteristics and parameters of family poultry production in Africa, 2002: p. 15-25. |

| [7] | Kitalyi, A.J., The Scope and Effect of Family Poultry Research and Development. |

| [8] | USDA. Ghana poultry report: Annual’, GAIN Report No. 1303. 2013 8/6/2013 No. 1303]; Available from: http://gain.fas.usda.gov/Recent%20GAIN%20Publications/Ghana%20Poultry%20. |

| [9] | Banson, K.E., et al., A Systems Thinking Approach to Address the Complexity of Agribusiness for Sustainable Development in Africa: A Case Study in Ghana. Systems Research and Behavioral Science, 2014. In Press (http://onlinelibrary.wiley.com/doi/10.1002/sres.2270/pdf). |

| [10] | Banson, K.E., N.C. Nguyen, and O.J. Bosch, Using systems archetypes to identify drivers and barriers for sustainable agriculture in africa: A case study in Ghana. Systems Research and Behavioral Science, 2014. In Press (http://onlinelibrary.wiley.com/doi/10.1002/sres.2300/pdf). |

| [11] | Johnson, M.C., Why Did the Chicken Cross the Border? An Investigation of Government Responses to Import Surges in Senegal, Cameroon and Ghana. An Investigation of Government Responses to Import Surges in Senegal, Cameroon and Ghana, 2009. |

| [12] | Dorémus-Mege, C., et al., Chicken Exports: Europe plucks Africa. Brussels: SOS Faim, 2004. |

| [13] | Chisenga, J., C. Entsua-Mensah, and J. Sam. Impact of globalization on the information needs of farmers in Ghana: A case study of small-scale poultry farmers. in 73RD IFLA General Conference and Council. Durban: World Library Information Congress. 2007. |

| [14] | Todaro, M.P. and S.C. Smith, Economic development. England: Pearson Education Ltd, 2009. |

| [15] | Aviagen Group. Performance Objectives for the Ross 308 2014 [cited 2015 14/03/]; Available from: http://en.aviagen.com/home/TechDocSearchForm. |

| [16] | Alabi, R., A. Esobhawan, and M. Aruna, Econometric determination of contribution of family poultry to women’s income in Niger-delta, Nigeria. Journal of Central European Agriculture, 2007. 7(4): p. 753-760. |

| [17] | Gueye, E., Employment and income generation through family poultry in low-income food-deficit countries. World's Poultry Science Journal, 2002. 58(04): p. 541-557. |

| [18] | Aboe, P., et al., Free-range village chickens on the Accra Plains, Ghana: Their contribution to households. Tropical animal health and production, 2006. 38(3): p. 223-234. |

| [19] | Sonaiya, E., Family poultry, food security and the impact of HPAI. World's Poultry Science Journal, 2007. 63(01): p. 132-138. |

| [20] | Aggrey, S.E., et al., Research Genetic properties of feed efficiency parameters in meat-type chickens. 2010. |

| [21] | Okoli, I.C., et al., Assessment of the mycoflora of poultry feed raw materials in humid tropical environment. Journal of American Science, 2007. 3(1): p. 5-9. |

| [22] | Ampofo, J.A. and G.C. Clerk, Diversity of bacteria contaminants in tissues of fish cultured in organic waste-fertilized ponds: health implications. Open Fish Science Journal, 2010. 3: p. 142-146. |

| [23] | Osei-Somuah, A. and P. Nartey, Microbial flora of Anchovis spp. used in poultry and livestock feed preparation in Ghana. Ghana Journal of Agricultural Science, 1999. 32(2): p. 185-188. |

| [24] | Banson, E.K., Consumer Acceptance of Irradiation for Sterilisation; A Systemic Approach to The Case Of Medical Items And Food In Ghana. Int. J. Markets and Business Systems, 2015(In Press): p. http://www.inderscience.com/info/ingeneral/forthcoming.php?jcode=ijmabs. |

| [25] | Bal, A. Ghana is balancing on the table egg market. 2013 [cited 2015 14/03/2015]; Available from: http://www.worldpoultry.net/Layers/Eggs/2012/2/Ghana-is-balancing-on-the-table-egg-market-WP009959W/. |

| [26] | Woolverton, A.E. and S. Frimpong, Consumer demand for domestic and imported broiler meat in urban Ghana: bringing non-price effects into the equation. British Journal of Marketing Studies, 2013. 1(3): p. 16-31. |

| [27] | Halal Food Authority (HFA). Origin of halal food authority. 2013 [cited 2015 14/03]; Available from: http://halalfoodauthority.com/origin-of-halal-food-authority/. |

| [28] | Henrique, F. and C.-V.S. America, How to give chicks the best start in the brooding period. International Poultry Production, 2013. 20(5): p. 11-13. |

| [29] | Kwakye-Nuako, G., et al., Sachet drinking water in Accra: the potential threats of transmission of enteric pathogenic protozoan organisms. Ghana medical journal, 2007. 41(2). |

| [30] | The Poultry Site. High Feed Prices - Reevaluating Turkey Slaughter Ages and Weights. 2009 [cited 2015 20/03]; Available from: http://www.thepoultrysite.com/articles/1286/high-feed-prices-reevaluating-turkey-slaughter-ages-and-weights/. |

| [31] | Banson, K.E., et al., Economic and Market Analysis of Swine Rearing and Pork Production in Ghana. Journal of Life Sciences, 2014. 8(8): p. 699-708. |

| [32] | CDC. The 2009 H1N1 Pandemic: Summary Highlights, April 2009-April 2010. 2010 [cited 2015 16/03]; Available from: http://www.cdc.gov/h1n1flu/cdcresponse.htm. |

| [33] | FAO/WHO/OIE/AU-IBAR, Republic of Ghana Avian and Human Influenza Integrated National Action Plan Aid Memoire. , 2008. p. 2-3. |

| [34] | Aning, K., P. Turkson, and S. Asuming-Brempong, Pro-poor HPAI risk reduction strategies in Ghana: Background paper. Draft Report. International Food Policy Research Institute/International Livestock Research Institute, 2008. |

| [35] | Schmitz, C. and D. Roy, Potential impact of HPAI on Ghana: a multi-market model analysis, 2009, DFID-funded project for Controlling Avian Flu and Protecting People’s Livelihoods in Africa/Indonesia. HPAI Research Brief. |

| [36] | MOFA. Agricultural facts and figures. 2015 [cited 2015 16/03]; Available from: http://mofa.gov.gh/site/?page_id=6032. |

| [37] | The Poultry Site. President Pledges Adequate Funding to Poultry Farmers. 2014 [cited 2015 16/03]; Available from: http://www.thepoultrysite.com/poultrynews/32180/president-pledges-adequate-funding-to-poultry-farmers/. |

| [38] | USDA, Russian Federation Livestock and Products Poultry and Meat Prices 2007, E. Hansen, M. Maksimenko, and A. Mustard, Editors. 2007, USDA: US. |

| [39] | SRID/MoFA, Agriculture Statistics 2010, Statistical Research and Information Directorate, Ministry of Food and Agriculture, Editor 2011, MOFA: Accra. |

| [40] | University Farms, Price trends of poultry, 2011, University Of Ghana Accra. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML