-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Agriculture and Forestry

p-ISSN: 2165-882X e-ISSN: 2165-8846

2014; 4(1): 19-23

doi:10.5923/j.ijaf.20140401.03

Infestation, Population Density and Sterilization Effects on Rice Weevils (Sitophilus oryzae L.) in Stored Milled Rice Grains in Sierra Leone

Joseph Sherman Kamara1, Sheku Max Kanteh2, Sahr Marvin Bockari-Gevao1, Sheku Jalloh1

1Department of Agricultural Engineering, School of Technology, Njala University, Freetown, +232, Sierra Leone

2Department of Crop protection, School of Agriculture, Njala University, Freetown, +232, Sierra Leone

Correspondence to: Joseph Sherman Kamara, Department of Agricultural Engineering, School of Technology, Njala University, Freetown, +232, Sierra Leone.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

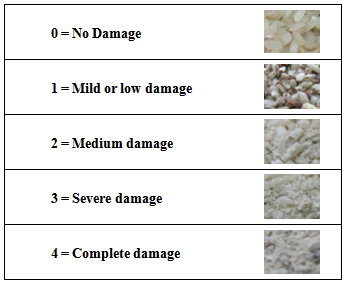

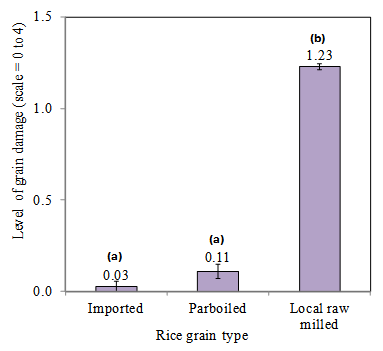

Sitophilus oryzae (L.) is one of the most important insect pests infesting stored food grains. The level of infestation, population density, the relationship between damage level and weevil population in stored rice grain samples were investigated. The effect of hot air sterilization on weevil population density was also examined. Samples (including; 29 imported, 16 parboiled and 62 raw milled rice) were randomly collected from markets across Sierra Leone and subjected to storage treatments under laboratory conditions at room temperature (with and without prior sterilization). The results show a significantly higher number of rice weevils in raw milled rice (156.0) with correspondingly higher level of grain damage (1.28); than the imported (3.2 and 0.03), and parboiled (21.7 and 0.11) rice grains, respectively. This suggests that locally produced raw milled rice may be more prone to rice weevil infestation, than either parboiled or imported rice grains. Results of pre-storage sterilization treatment suggest that hot air sterilization eliminates weevils in stored rice, where as the unsterilized rice grains remained prone to rice weevil infestation. These results lead to the conclusion that the nature of rice grain products and pre-storage treatment influence the degree of rice weevil infestation during storage and that heat sterilization could be a useful option in the management rice weevil in stored rice grains.

Keywords: Rice weevil infestation,Sitophilus oryzae, Imported rice, Parboiled rice, Stored grain pests

Cite this paper: Joseph Sherman Kamara, Sheku Max Kanteh, Sahr Marvin Bockari-Gevao, Sheku Jalloh, Infestation, Population Density and Sterilization Effects on Rice Weevils (Sitophilus oryzae L.) in Stored Milled Rice Grains in Sierra Leone, International Journal of Agriculture and Forestry, Vol. 4 No. 1, 2014, pp. 19-23. doi: 10.5923/j.ijaf.20140401.03.

Article Outline

1. Introduction

- Rice, Oryza sativa L. (Gramineae), is one of the main food sources for most people all over the world[1, 2, 3]. In Sierra Leone, rice is the staple food and per capita consumption is among the highest in the world; estimated at 104 kg per person per year[4]. Availability of rice is therefore crucial to the wellbeing of Sierra Leoneans. Fundamental challenges affecting the national productivity of rice and high postharvest losses impose a strong negative impact on the national economy, since deficits in national rice demand must be met through importation, a situation that warrants the regular use of substantial amounts of scarce foreign exchange. In particular, high postharvest losses are believed to be among the primary causes of food shortages and rural poverty. Generally, it is believed that understanding the pathways to postharvest loss reduction will pave the way to poverty reduction and increased food security in many developing agrarian economies, like Sierra Leone[1, 5]. Traditionally, rice processing in Sierra Leone targets either parboiled or raw milled rice products[4]. Parboiled rice undergoes initial hydration (soaking), followed by hydrothermal treatment in hot water or steam[6], before drying and milling, unlike raw milled rice which is dried and milled directly. Milling may be done manually by smallholder farmers or with the use of simple mechanical rice mills by small cooperatives, albeit in less common circumstances. Whichever way they are produced, the two types of rice products are made available in the local markets along with various kinds of imported rice mainly from Asia and South America. It is obvious that due to the facilities and opportunities available to rice exporting companies, harvesting, milling, storage and handling operations will be conducted more efficiently compared to rice produced locally by smallholders or cooperative farms. After harvest, rice grains become exposed to risk of quantitative and qualitative losses posed by the physical, biological and chemical conditions of the production, processing, storage and handling environments. The ability of grains to survive these risks will very likely depend on the level of preparation and protection they receive prior to and during distribution and marketing. In this regard, the storage quality of rice may be measured in terms of ability to survive inherent threats in the storage environment. Biological threats become the most critical after milling and between the stages of storage and marketing. Some of these include threats posed by micro-organisms, insects, mites, birds and rodents. Threat of damage to grains due to micro-organisms may be controlled simply by properly drying the grains and keeping vertebrate pests out of their reach. However properly dried grains kept under rodent proof conditions still face the threat of insects, which are capable of surviving in grains over a wide range of moisture levels. The level of insect infestation is an important quality factor of food grains and represents a serious and continuing problem for the grain and milling industries[7]. In rice insects can cause major economic losses because of their ability to infest paddy, milled rice and the by-products of milling material that accumulates in structures and equipment where rice is processed. Rice weevil (Sitophilus oryzae (L.), Angoumois grain moth (Sitotroga cerealella (Olivier), and the lesser grain borer (Rhyzopertha dominica (F.) were identified[8] as the most common insect pests of stored food grains. The rice weevil and maize weevil look similar. Although the maize weevil, usually found in corn, is somewhat larger and darker than the rice weevil, it is more often found in small grains[8]. Both are small snout beetles, about 1/8-inch long, and are reddish brown to almost black. The wing covers are usually marked with four reddish or yellow spots. Eggs are laid within individual kernels, and the grub-like larvae consume the grain from within. Pupation occurs in the kernel, and adults emerge through a small round hole, leaving behind a hollow kernel. During warm weather, an entire generation may be completed within 26 days; thus, stored grains may be severely damaged within a month of harvesting. Infestations may start near the top of a storage bin (because of insects that fly in from outside, entering underneath the eaves) or near the bottom (caused by insects that migrate up through the perforated floor). Rice weevils are very mobile and may be found anywhere within the grain mass[9] and capable of infesting all kinds of rice products. This study was conducted to investigate the influence of grain type and pre-storage thermal sterilization on the level of weevil infestation and grain damage in stored milled rice grain samples.

2. Materials and Methods

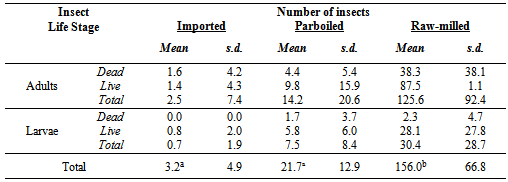

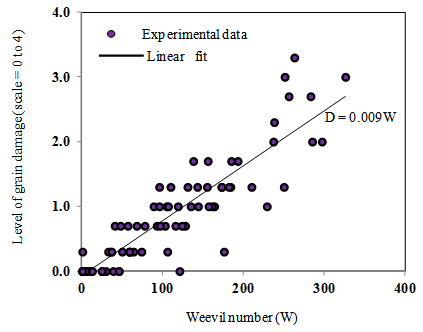

- The study was a laboratory storage experiment, conducted at the Department of Agricultural Engineering, School of Technology, Njala University, Sierra Leone. A total of 107 samples; including 29 imported, 16 parboiled and 62 raw milled rice samples collected at random from selected markets in Bo, Kenema, Makeni and Freetown were used during the study. Twenty (20) grams of each sample was put in small white polythene bags, and carefully tied for storage test in an open shelf at room temperature (25 to 30℃) for a period of six months. About 5 grams samples of each of the three grain types (i.e., imported, local parboiled and local raw milled) were heat sterilized in an oven at 105℃ for 10 minutes and allowed to cool at room temperature. All samples were then carefully put in transparent polythene bags, and stored in an open shelf at room temperature for a period of six months. At the end of the storage period, the test samples were analyzed to determine the level of rice weevil infestation, in terms of the number of live or dead adults and larvae. The damage level due to insect infestation was also assessed for all samples through visual inspection using a five-point ordinal scoring system (Figure 1). Data collected were analyzed to determine the means and standard deviations of insect counts and associated damage levels. Grain types were compared using one-way analysis of variance and significantly different treatments were separated by Fisher’s Least Significant difference (LSD) at α = 5%.

| Figure 1. Assessment scale used to estimate grain damage levels associated with weevil infestation |

3. Results

3.1. Distribution of Rice Weevils (Sitophilus oryzae) and Associated Grain Damage Level in Test Rice Grain Samples

- The distribution of adult and laval forms of rice weevils (Sitophilus oryzae) in tested milled rice samples were determined for local raw milled, local parboiled and imported raw milled rice grain samples collected in selected markets across Sierra Leone, and stored in open shelves for a period of six months. Table 1 shows the distribution of live and dead insects (including adults and larvae) found in test grain samples. Generally, there were more adult weevils than larval forms in all three grain types. The average number of rice weevils (both adults and larvae) found in raw milled rice (156.0) was highly significantly greater (P < 0.01) than that estimated for parboiled (21.7) and imported rice grains (3.2). Though numerically different, the average numbers of rice weevils found in local parboiled and imported rice were not statistically different. A key observation noted was that whereas in imported rice grains there were evidently more dead adult weevils than live ones (dead = 1.6, live = 1.4 ), for the local products there were more live than dead adult weevils in parboiled (dead = 4.4, live = 9.8) and raw milled (dead = 38.3, live = 87.5) milled grain types. Unlike the adults, there were consistently more live than dead larvae in all three grain types; with the imported grains recording the least number of live larvae (0.08), followed by parboiled (5.8) and raw milled grains (28.1).

|

| Figure 2. Column chart of average damage levels for the three rice grain types; Columns labeled with the same letter are not significantly different at α = 5% |

| (1) |

| Figure 3. A scatter plot of total insect count against grain damage level; showing the linear fit (line) and experimental data (small dots) |

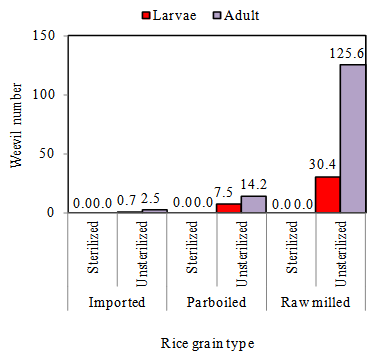

3.2. Effect of Sterilization Treatment on Number of Rice Weevils Counted on Three Different Milled Rice Grains Collected from Selected Markets in Sierra Leone

| Figure 4. Average number of insects found in sterilized and unsterilized samples test rice grain samples stored over a period of 6 months |

4. Discussion

- The study demonstrates the economic importance of grain storage insect pests to rice grains. Several studies have identified a number of insect pests of stored products, and the consequent level of damage if left unattended[8, 7]. Results obtained from the study suggest that imported rice products are less susceptible to rice weevil (Sitophilus oryzae) infestation than locally produced rice (raw-milled and parboiled). Among the local rice products, a greater number of rice weevils were recorded in the raw milled rice grains parboiled rice products, which had statistically comparable levels of rice weevils as the imported rice products. For the imported rice products, these results tend to suggest that a low incidence of weevils might be linked to the origin of the grains. Imported rice grains may have come from more improved grain postharvest systems with comparative better processing, handling and storage systems than the local rice grains. It is quite likely that most of the imported rice grains, come from large rice mills where grains are processed in high capacity rice mills consisting of artificial dryers operating at high temperatures, multistage mills with multiple stages of shearing, friction and abrasion to produce highly polished grains. Such mills are often operated with large warehouses where the use of pesticidal fumigants to control storage pests is a common practice. The duration in the field, the variety of rice, polishing and post polishing processes, etc., have been identified as factors that affect grain susceptibility to insect pests[10, 11]. Some studies have shown that kernel pre- and post-polishing size and proportion of broken kernels affect the grain attraction and susceptibility to insect infestation[12, 13]. The rice weevil, (Sitophilus oryzae L.) has being identified as the most common coleopteran pests of stored white and brown rice[14]. Adult weevil feed on rice and female lay their eggs inside rice kernel where the larvae develops to the adult stage[15]. Evidence shows that the rice weevil is capable of infesting grains in the field[16]. So it may be speculated that locally produced rice grains may have been infested with rice weevil by the time of harvest, probably due to the undeveloped harvesting and handling practices. Several studies have shown the effects of rice milling operations (especially polishing) on its subsequent susceptibility to the rice weevil[14]. Other studies have shown that weevil reproduction was higher and the developmental period was shorter in brown rice[13, 16], and that an increase in polishing reduced rice susceptibility to weevil infestation[13]. This situation could be due to the presence of the bran on brown rice grains. The abundance of this bran on local raw milled rice grains, may explain the high proliferation of weevils, greatest level of infestation, and hence the greater level of grain damage observed. In was not surprising to note that the level of infestation was positively correlated with the level of insect damage since more weevils would require more grains to feed on. Similar results were obtained by[17] in their work on wheat grains, leading to the development of a model relating grain damage and insect infestation level. Many control methods have been reported for storage insect pests[18, 19]. Among these, heat treatment has been recognized as an effective ecologically based technique that can be used as an alternative to pesticides for the control of stored-product insect pests[20, 21]. The thermal stage of parboiling can therefore serve as a possible means of sterilizing grains against field infestations. In addition to this parboiling also alters the mechanical properties of rice grains making them less penetrable by weevils. Chemical fumigation, for example, using methyl bromide and phosphine is commonly applied throughout the world as an effective method of controlling infestations by storehouse pests. However, this method has led to serious environmental and safety implications. For these reasons, world leaders adopted a plan for the phasing out of methyl bromide[22]. Phosphine fumigation is also faced with the problem of increasing pest resistance. Thus, there is an urgent need to develop new, safe methods of controlling infestations storage insect pests. Results of this study indicates that weevil population generally increased in unsterilized grains, unlike the sterilized grains, which exhibited high level of resistance, indicating that heat sterilization and parboiling of rice may be critical in improving the storage quality of locally produced rice. However, more research is required to establish the optimal conditions for use of thermal sterilization to protect food grains against postharvest losses in Sierra Leone.

5. Conclusions

- The most important implication of this study is the indication that grains marketed in Sierra Leone might be contaminated with rice weevils, which continue to develop and proliferate to varying degrees depending on the type of rice grain and prevailing storage or handling conditions to which the grains are subjected. The results also suggest that imported rice grains were less prone to rice weevil infestation and damage than the local rice products (i.e., parboiled and raw milled rice). It is speculated that the low presence of rice weevils in stored imported rice may have originated from the better processing, handling and storage systems through which such grains pass, unlike the local rice grains, which are produced and handled using traditional practices. It was also noted that among local rice products, parboiled rice products appeared to be more resistant or tolerant to rice weevil infestation, proliferation and consequent grain damage. Additional results from sterilization experiment show that hot air sterilization eliminates weevils in stored rice grains. These results lead to the conclusion that the nature of rice grain products as well as pre-storage treatment influence the degree of rice weevil infestation during storage and that heat sterilization could be a useful control for rice weevil in stored milled rice grains.

ACKNOWLEDGEMENTS

- The authors extend profound thanks and gratitude to the technical staff in the Department of Agricultural Engineering, Njala University, for making available laboratory space and facilities to conduct experiments in this study.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML