-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Agriculture and Forestry

p-ISSN: 2165-882X e-ISSN: 2165-8846

2013; 3(1): 16-28

doi:10.5923/j.ijaf.20130301.04

An Exergeticcold Chain Methodological Analisys Onhorticultural Productive Chains to Evaluate Productivity and Competitiveness: Study Case Andean Blackberry

Flórez Martínez Diego Hernando 1, 2, 3, Cifuentes Aya Héctor 4, 5, 6

1Chemical Engineer, MSc in Industrial Engineering, National University of Colombia

2Professional specialized in competitive intelligence at Colombian Agricultural Research Corporation, Corpoica, Colombia

3Professor of Industrial Engineering, FundaciónUniversitaria San Martín

4Specialist in Quality Management MSc. In Higher Education

5Ph.D. in Materials Science and Technology, National University of Colombia

6Teaching Assistant, National University of Colombia Faculty of Engineering Research Group productivity, competitiveness and quality

Correspondence to: Flórez Martínez Diego Hernando , Chemical Engineer, MSc in Industrial Engineering, National University of Colombia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This research has resulted in a methodology of exergy analysis of main requirements to implement cold chain models in agribusiness productive chains, which improve the productivity and competitiveness indicators that contribute to accomplish demands on product quality for minimally processed and processed products for domestic and international markets. Based on the model of links and segments, which in the case of the agricultural sector involves activities from the primary producer to the end user, are analyzed in a cross-linked and their current status, the requirements in terms of product distribution logistics of the cold chain, as a mechanism for keeping quality of the products to the end consumer. Given the requirements of the cold chain, the models proposed in the literature were analyzed, from conceptualization and identification of critical control points. Finally methodology evaluates the product exergy losses along the production chain for scenarios in which contemplates the use and non-use of the cold chain, from a thermodynamic analysis, interpretation contemplating thermoeconomics and its impact on productivity and competitiveness indicators considering fresh Andean Blackberry (RubusGlaucus) as a study case.

Keywords: Production Chain, Cold Chain, Exergy, Thermoeconomics, Productivity, Competitiveness, Andean Blackberry

Cite this paper: Flórez Martínez Diego Hernando , Cifuentes Aya Héctor , An Exergeticcold Chain Methodological Analisys Onhorticultural Productive Chains to Evaluate Productivity and Competitiveness: Study Case Andean Blackberry, International Journal of Agriculture and Forestry, Vol. 3 No. 1, 2013, pp. 16-28. doi: 10.5923/j.ijaf.20130301.04.

Article Outline

1. Introduction

- Farming and agroforestry from the perspective of developing countries, should be benefited from the processes of Research, Development and Innovation (R&D&I) in order to increase productivity and competitiveness, given its great social, political and economic incidence, constituting one of the pillars on which the country develops economically and which involves much of its rural and industrial human resources. In this context, the ultimate aim of all productive sector is to offer differentiated products with quality standards consistent with the requirements demanded by the specific market of interest, based on the time variable as the critical factor that limits the performance of supply chains but not the only one that should becontrolled within the distribution process from the producer to the end customer. In what is known as the logistic distribution system of products and services, joins a range of factors to consider, which, permanently affect productivity, becoming part of the strategic direction that allows the chain to adapt to changes market[1].Within the agriculture and agroforestry in Colombia, diversify a large number of subsectors each with specific problems within their strategic direction needs focus on increase their technological and non-technological, capacities being a particular case study horticulture[2], which seeks to meet fluctuating demand in quantity and quality ([3]).Narrowing the specific processes that involve the formation of foodstuffs at horticultural production chain within the degrees of transformation to which a product is subjected to cool, the successful integration of the supply chain in terms of product quality, falls in effective management of the "cold chain"[4], a logistics network system within a production system, equipped with transport and storage technology that ensures the quality of fresh and frozen food in nature, from the producer to the consumer[5], to extend the useful life of products[6], that in low temperature conditions for the particular case of fresh or refrigerated varies between 0℃ and 10℃, whereas for frozen products must be below 0℃.This leads to the need for an evaluation methodology supported by an analysis of critical control points in a concatenated integration of a cold chain model intoa productive chain which characterize the potential and actual risks in the handling, transport and disposal product based on a model that integrates logistics distribution chain model with a model based cold chain temperature and critical control points for food products in fresh, minimally processed and processed from the system guidelines Hazard Analysis and Critical Control Points (HACCP).

2. Methods and Materials

- The structuring methodology is developed in four phases that allow reaching integrative assess changes in indicators of productivity and improving competitiveness against material loss by exergetic evaluation in a model of integrated production chain technological and non-technological inputs cold chain from the HACCP regulations. These phases are adapted to the Andean Blackberry productive chain as a case study.● Phase I: Structuring the supply chain model of links and segments.● Phase II: Analysis of cold chain models, selection based on the supply chain and the chain link.● Phase III: Rating exergy losses of product through the production chain with and without cold chain.● Phase IV: thermoeconomics evaluation of productivity and competitiveness indicators.

2.1. Phase I: Structuring the Supply Chain Model of Links and Segments

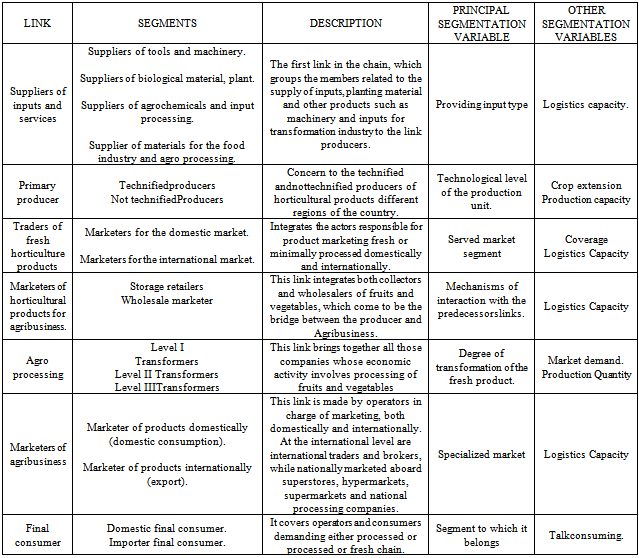

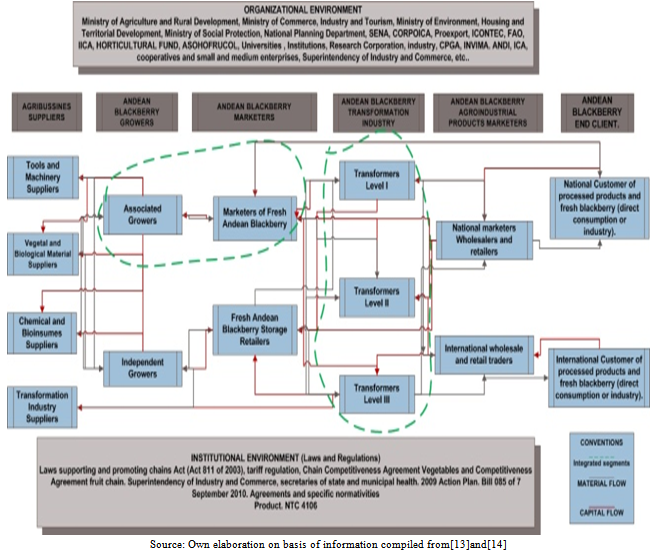

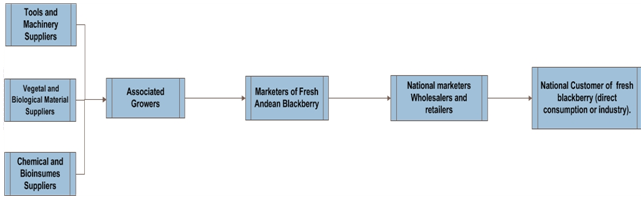

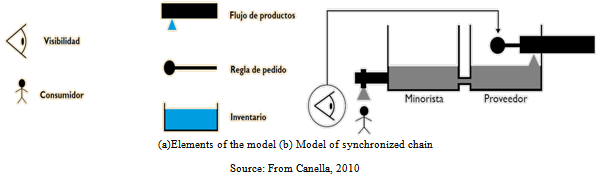

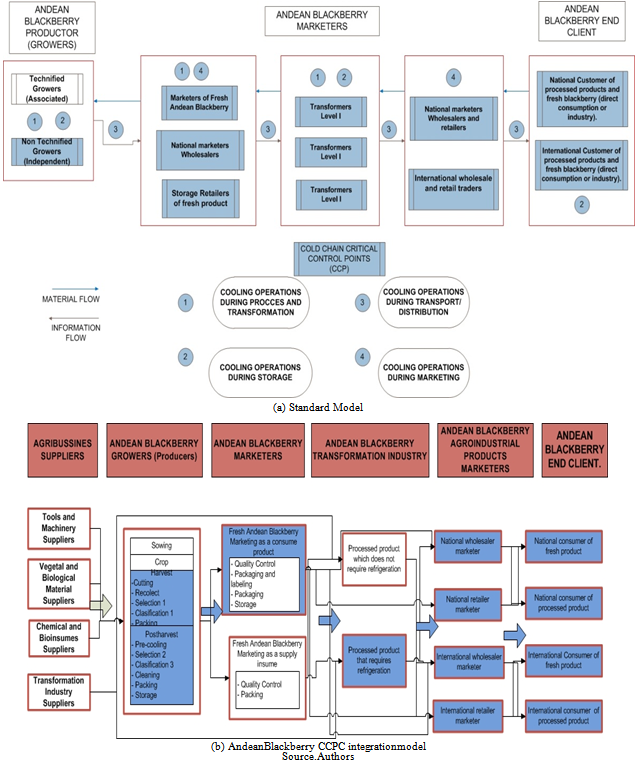

- Modern analysis of global value chains emphasizes the relationship between actors as a mechanism to reduce uncertainty, improve access to key resources and increase the efficiency of the system[7]cited by[8]. Coordination is therefore a key source of competitiveness that is sometimes called "collaborative advantage" or "comparative advantage of cooperation"[9]cited by[8].The model of the horticultural production chain design, provides the conceptual and methodologies established in sectoral characterization studies, which comprehensively covers the interaction of actors throughout the production process[10]. According to[11], the supply chain is the set of components interacting in the agribusiness environment of a country or region, including production systems, suppliers of inputs and services, production and processing industries , distribution and marketing agents and consumers, where the flows of material, information and capital are the mechanisms linking the various actors in the chain (production units), which seek to provide and ensure to the consumer market products with a high quality degree[12]. These mechanisms (supply chain, logistics methodologies, specific brands such as cold chain, etc.), Differentiating to become competitive with peer environments in the world market.The productive chain (PC), is articulated in terms of activities for product development, structuring links or clusters. The link is the unit of analysis defined as groups that include a set of actors relatively homogeneous in terms of their characteristics, production techniques, common raw materials, intermediate or final uses common and similar production technologies. Table 1, presents a description of the links and segments that make up the horticultural production chain. Figure 1 shows the standard model adapted to Andean Blackberry which allows its use as an analysis tool that will address the integration of the cold chain as a key element in the distribution of products from the producer to the end customer.Understanding the current dynamics of the production process chain of blackberry, represented linkage model has clear interactions between blackberry growers, marketers directly and indirectly to the end customer, but there is no detailed information the way they handled the delay in the production units of agro processing link. In this sense the approach of the cold chain (CC) joint with productive chain(PC) will focus on integrated links growers, traders, wholesalers and retail traders and end customers.The supply chain model that is constructed to analyze and depicted in Figure 1, where there are six links through which the final product is developed. The product chosen for the methodological study is fresh or minimally processed Andean Blackberry commercialized in the national market. Theproduct flow to analyzeacross the PC is presented in Figure 2.An important factor in the management of the cold chain in the selected route, is to record the temperature of fresh product throughout the distribution process[15]which contributes to an optimal level of traceability, integration with policies and quality standards of the food industry (such as HACCP) compliance and tolerance limits[16],[17];[18],[19] cited by[15], where the activities of monitoring and control of temperature throughout the distribution process logistics cold chain horticultural directly influence economic, technological and non-technological requirements, focused on the end customer.

| Figure 1. Standard model of the production chain for Andean Blackberry |

| Figure 2. Fresh Andean Blackberry Road in the productive chain |

|

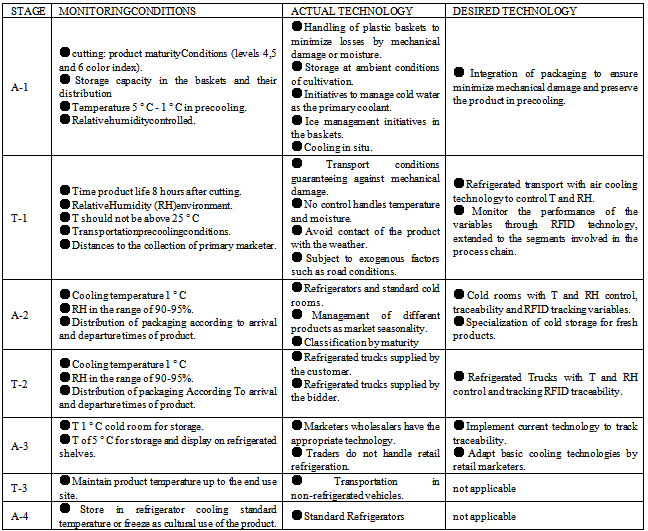

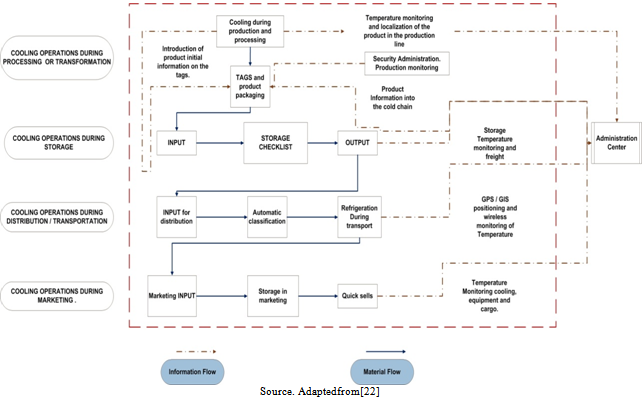

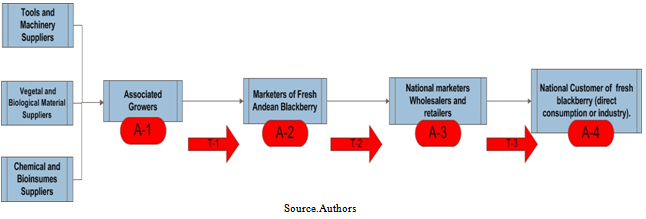

2.2. Phase II: Analysis of Cold Chain Models, Selection based on the Supply Chain and the Chain Link

- The analysis conditions of the cold chain, starting from the concept of customer perceived quality compared to the products and the quality offered by the producer, in relation to the conservation process to which they are subjected[20], since the post-harvest handling of product, as final product or as an input for the processing industry, handling affects differentiated and specific criteria in the same way it is contextualized with the cost management and the energy crisis[21].The articulation of the cold chain (CC) with the productive chain (PC), starts from the temperature monitoring and control of times, both in storage and transport, is part of the fulfillment of norms explicit focus to the product itself, in standards quality in each link that are testable, verifiable and traceable through the system of hazard analysis and critical points (HACCP) should be adaptive to the specific product and the chain link that is applied, taking into account that the link in which the product remains in a longer time is marketing.9 models were evaluated for cold chain (1) traceability model for production units, (2)traceability of the cold chain systems, (3)radio frequency identification (structured frameworks), (4)Model Security System for cold chain, (4)Integration model of the consumer or end customer to cold chain monitoring model CF food from RFID and integration with the client, (5)Model cold chain logistics based on focus just in time (JIT), (6)Traceability of products for smart RFID TAGS, (7)Direct distribution model and node, (8)Model of multi-temperature distribution nodes and (9)RFID integrative model for the links in the chain of distribution and production, the latter being selected for horticultural PC (See Figure 3).

| Figura 3. Integración de la tecnología RFID a la cadena de frio para productos alimenticios |

| Figure 4. Analytical model for supply chain |

| Figure 5. Integrated cold chain to productive chain model |

| Figura 6. CPCF para mora en fresco |

|

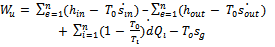

2.3. Phase III: Rating Exergy Losses of Product through the Production Chain with and without Cold Chain

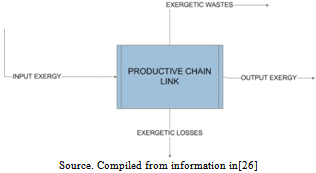

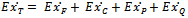

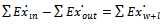

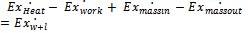

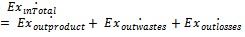

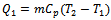

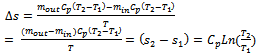

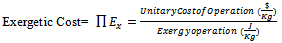

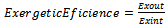

- The exergy concept is based on the first and second laws of thermodynamics, which in contrast to the energy, this is exempt from the law of conservation, since the availability input exergy into a system always exceeds the output exergy. All actual process has lost exergy or irreversibilities, associated with the first process exogenous and endogenous factors other, this energy or work available is called exergy, which measures the ability of a power source to produce useful work. In accordance with[26] cited by[27], is defined as the maximum work that can be obtained from a system.Exergy analysis, did not include the law of conservation of energy, since its purpose is to estimate the maximum amount of work that can be obtained in each of the links, where the irreversibility of the process is directly related to the CCP and potential losses ofproduct. In accordance with[28], cited by[27], the flow exergy per link should include the inputs and outputs described in Figure 7.

| Figure 7. Exergy flows provided by link in the CPHF |

|

|

(2)

(2)  (3)

(3)  (4)

(4)  (5)

(5)  (6)

(6)  (7)

(7)  (8)

(8)  (9)

(9)  (10)

(10)  (11)

(11)  (12)

(12)  (13)

(13)  (14)

(14)  (15)

(15)  operation to operation (16)

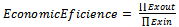

operation to operation (16)  For Andean blackberry productive chain exist country indicators to assess their competitiveness by specialized government agencies in agriculture estimates those in order to generate competitiveness and productivity indicators assuming for the particular case of this product two scenarios, one without and one with cold chain Competitiveness indicators to evaluate are:●Trade Balance: The trade balance is the registration of imports and exports of a country during a period. The balance of it is the difference between exports and imports.●Apparent consumption (Yij+Mij-Xij): Apparent consumption expressed product availability consuming a region, country or countries in a given period of time. Is estimated based on domestic production plus the trade balance and the inventory consumption. In the case of perishable goods, apparent consumption is being equal to its availability as no inventories or stocks are present.●Tradability (Xij-Mij)/(Yij+Mij-Xij): This indicator is a relationship between net exports (exports minus imports) to apparent consumption (domestic production plus imports minus exports). For foreign trade, the indicator is used to keep track of the gain or loss of the export capacity of the country that produces the good. When the indicator is above zero, the export sector is considered, because there is excess supply, ie, is a competitive sector within the country. When the indicator is less than zero, it is possible that this is an import substitution industry, or non-competitive with imports, as there is excess demand. ●Relative Trade Balance (Xij-Mij)/(Xij+Mij): It measures the relationship between a product's trade balance (exports minus imports) and the total sum of exports and imports of a country.When the RTB is between -1 and 0, indicates the strength of the nature of the importing country, the value -1 being the end where the country imports all of the product and does not export anything. When not in the extreme value, there is a greater amount of import what is exported. When the indicator for a product in this range, it is said that the country is a net importer of this product. When the indicator value is zero, indicating that the country exports the same amount of product that matters. It may also be that the country is producing the amount consumed domestically. When the indicator value is between 0 and 1, indicates that this product exports are greater than imports. When the value is equal to 1, but no matter exporting country significant amounts of product. When the RTB for a product is in the range of 0 to 1, says the country is a net exporter of the product.●Comparative Advantage (Product Exports / Exports Country) / (World exports of product / total world exports): Measures the performance of trade in selected countries for a product in relation to the goods and the rest of the world.●Specialization Index (Xij-Mij) / Exp country's total: For a certain period (set of years, or a given year), this indicator shows the degree to which the net flow commercial (trade balance) of a product from a country participating in the quantum of exports of that product in the world, or for a specific market, in this case the world market. That is, expresses what percentage of exports of the product made by the world, it is up to each producer.Productivity indicators are:●Sales price●Utility●Number of dwelling in optimal state to market●EarnedValue●Total value of production●EconomicEfficiency

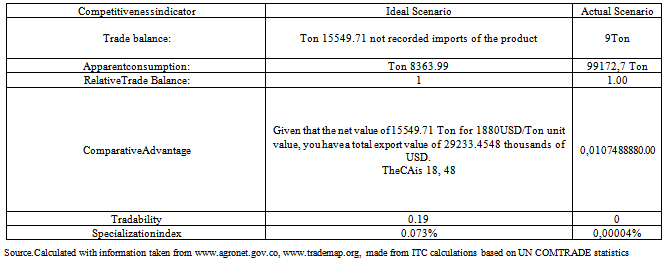

For Andean blackberry productive chain exist country indicators to assess their competitiveness by specialized government agencies in agriculture estimates those in order to generate competitiveness and productivity indicators assuming for the particular case of this product two scenarios, one without and one with cold chain Competitiveness indicators to evaluate are:●Trade Balance: The trade balance is the registration of imports and exports of a country during a period. The balance of it is the difference between exports and imports.●Apparent consumption (Yij+Mij-Xij): Apparent consumption expressed product availability consuming a region, country or countries in a given period of time. Is estimated based on domestic production plus the trade balance and the inventory consumption. In the case of perishable goods, apparent consumption is being equal to its availability as no inventories or stocks are present.●Tradability (Xij-Mij)/(Yij+Mij-Xij): This indicator is a relationship between net exports (exports minus imports) to apparent consumption (domestic production plus imports minus exports). For foreign trade, the indicator is used to keep track of the gain or loss of the export capacity of the country that produces the good. When the indicator is above zero, the export sector is considered, because there is excess supply, ie, is a competitive sector within the country. When the indicator is less than zero, it is possible that this is an import substitution industry, or non-competitive with imports, as there is excess demand. ●Relative Trade Balance (Xij-Mij)/(Xij+Mij): It measures the relationship between a product's trade balance (exports minus imports) and the total sum of exports and imports of a country.When the RTB is between -1 and 0, indicates the strength of the nature of the importing country, the value -1 being the end where the country imports all of the product and does not export anything. When not in the extreme value, there is a greater amount of import what is exported. When the indicator for a product in this range, it is said that the country is a net importer of this product. When the indicator value is zero, indicating that the country exports the same amount of product that matters. It may also be that the country is producing the amount consumed domestically. When the indicator value is between 0 and 1, indicates that this product exports are greater than imports. When the value is equal to 1, but no matter exporting country significant amounts of product. When the RTB for a product is in the range of 0 to 1, says the country is a net exporter of the product.●Comparative Advantage (Product Exports / Exports Country) / (World exports of product / total world exports): Measures the performance of trade in selected countries for a product in relation to the goods and the rest of the world.●Specialization Index (Xij-Mij) / Exp country's total: For a certain period (set of years, or a given year), this indicator shows the degree to which the net flow commercial (trade balance) of a product from a country participating in the quantum of exports of that product in the world, or for a specific market, in this case the world market. That is, expresses what percentage of exports of the product made by the world, it is up to each producer.Productivity indicators are:●Sales price●Utility●Number of dwelling in optimal state to market●EarnedValue●Total value of production●EconomicEfficiency3. Results

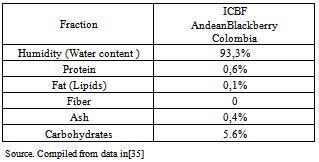

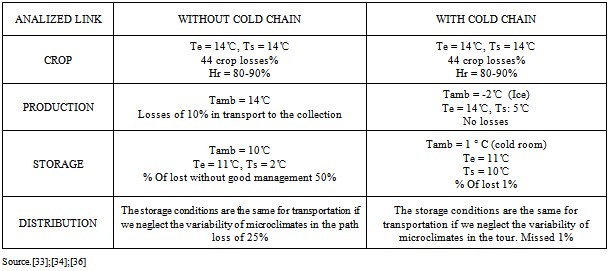

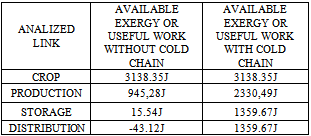

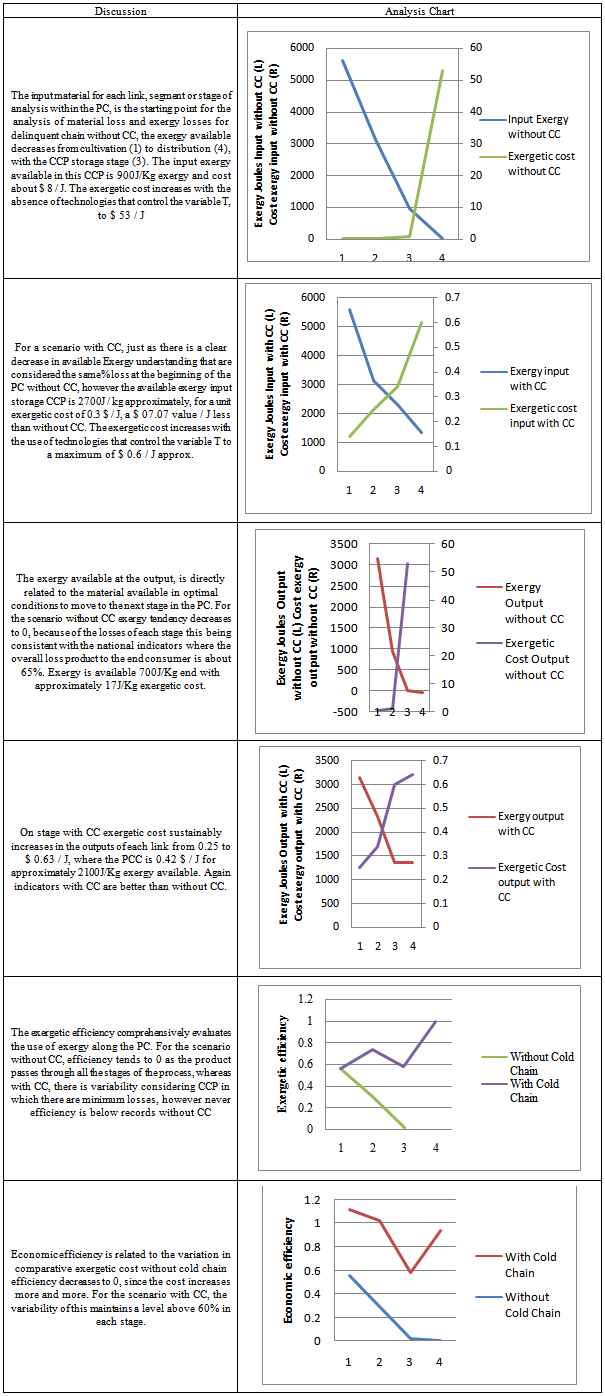

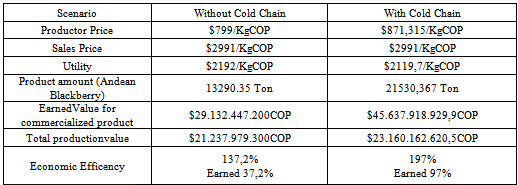

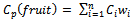

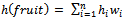

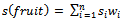

- The estimation of entropy and enthalpy as a function of the specific heat (Cp), is done with an evaluationsoftware of thermophysical properties designed by the Ibero-American Science and Technology for Development, and Treatment applet in Food Preservation XI version associated with the Polytechnic University of Valencia, which includes developments estimation of thermodynamic properties of fruits and vegetables developed by[31] cited by[32] and are considered inputs for analysis cited[27] and[36].The results are recorded in Table 6.Table 7 is a comparative analysis of exergy and economic results for the chain for both scenarios with cold chain and without cold chain for Andean blackberry.Considering that average losses in Colombian crops of Andean Blackberry are 30-40%, the transportation and handling losses of 50% to reach the wholesale marketer when not handled cold chain for the product, is necessarythat comparison scenarios contemplate a significant decrease in the% loss allowed to the implementation of technology in storage and transport within the joint of the cold chain, and the final destination of the product that can be domestic consumption or export to markets and potential. Table 8 shows the competitiveness indicators for the two scenarios and Table 9 productivity indicators.

|

|

|

|

4. Conclusions

- ●Temperature, humidity and time are key control variables of horticultural products, these can be controlled, monitored and modified through the cold chain as an integration tool in process and product technology directly linked to the activities of proper storage and transportation logistics distribution models and inventories.●The consolidation of the PC model, the identification of synchronous chain archetype, to adapt optimum cold chain models identified for food handling and perishability grade products for temperature, through the joint CCP allows to formulatethe integration model of the CCPC.●The results for PC with CC show increasing link by link exergetic cost sustainably by minimizing product loss due to the T, while for the PC without CC fixed costs increase and are increasingly representative in the unit value of the product, which leads to the conclusion that the implementation of cold chain in horticultural production chains affects overall quality and economic efficiency of these●It is important to consider establishing an integrative scheme between chain model and a model of technology transfer, under the current guidelines established and directed against technology gaps

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML