Imranul Huda 1, Sanaullah Panezai 2

1Department of Geography and Regional Planning, University of Balochistan, Quetta Balochistan, Pakistan

2Department of Geography, Government Postgraduate Science College, Quetta, Balochistan, Pakistan

Correspondence to: Sanaullah Panezai , Department of Geography, Government Postgraduate Science College, Quetta, Balochistan, Pakistan.

| Email: |  |

Copyright © 2021 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Background: Chromite is a metallic mineral composed of chromium, iron, and oxygen (FeCr2O4). Pakistan is bestowed with numerous economic minerals and chromite is one of them. It has major deposits in Muslim Bagh Ophiolites, Muslim Bagh area of Balochistan province, Pakistan. Objectives: The objectives of this study are to analyze the chromite ore mining and the associated factors in the Muslim Bagh area of Balochistan province and to suggest viable strategies to boost-up the production of chromite ore in the area. Methods: For this case study, the primary data were collected through convenient sampling from fifty-one mine owners by using semi-structured questionnaires. Results: The results indicated that the majority of mine owners were local. Almost one-thirds (35.5%) of them were having primary education with 17.6% uneducated. Only two-thirds (39.2%) had a lease and they had a five-year lease. Three-fourths (76.5%) were extracting chromite ore through partnerships, 45.1% of them had four partners. The leased area extended from less than 1 acre to 875 acres. All mines were located in the hilly area and chromite was extracted through underground mining. Four-fifth (82.4%) of the mines were working in two shifts and wages for labourers extended from 10000 PKR to 22000 PKR based on their skills. The important factors that affect chromite production include; mining disputes, disputes over the mining area, lack of finances for extracting chromite ore, unstable and low price of chromite ore, and unavailability of explosives for mining. Due to the unavailability of medical aid in emergent situations, the lives of labourers were found to be at risk. Conclusion: The findings unveiled significant factors that affect chromite ore production and suggest that government should facilitate the mine owners by providing basic infrastructure, emergency health services, the easy availability of explosives, electricity, and scientific and technical guidance for the exploration of chromite ore in the study area.

Keywords:

Chromite, Chromite ore, Chromite ore mining, Muslim Bagh ophiolite, Chromite deposits, Mining lease, Muslim Bagh, Balochistan, Pakistan

Cite this paper: Imranul Huda , Sanaullah Panezai , Chromite Ore Mining and Associated Factors in the Muslim Bagh Ophiolite of Balochistan, Pakistan, Geosciences, Vol. 11 No. 1, 2021, pp. 43-54. doi: 10.5923/j.geo.20211101.03.

1. Introduction

Chromite is an oxide mineral composed of chromium, iron, and oxygen (FeCr2O4). Chromite is the only ore mineral of chromium (Edwards, 2012). Further, in Balochistan, Pakistan, it occurs in in a rock series called the Muslim Bagh Ophiolite (Ahmad and Abbas, 1979). The major application of chromite is in production of stainless steel. As chromium is a highly corrosion resistant element, it is used to increase the resistance of steel against the corrosion and discoloration. Moreover, small proportion of chromite is also used in foundry, chemicals, and pigments. The well-known major deposits of chromite ore are found in South Africa, Kazakhstan, India, Turkey, Brazil and Cuba. The total estimated chromite reserves are 30400 thousand metric tonnes in the world. According to US Geological Survey (USGS), South Africa has the largest reserves of the chromite. Moreover, South Africa also accounts for the highest Annual production of Chromite Ore as well. In addition, United States of America (USA) has 5% of overall chromite consumptions, highest in the world (Papp, 2007). Pakistan is bestowed with numerous economic minerals ores while chromite is one of the most significant mineral ore which is found abundantly in Pakistan. Even though Pakistan being very rich in the mineral resources, mining and quarrying industry only contributes to 2.51% of GDP of Pakistan (Aziz & Khan, 2020). Th estimated chromite ore deposits in Pakistan are to be 2.5 million tones, having low to medium grade (Shah, 2018). Unfortunately, there is no production unit for ferrochrome deposit of undying demand for stainless steel production. Chromite ore mining initially started in 1903 in Khanozai, Balochistan. In addition, chromite is also found and mined on large scales in Qilla Saifullah, Nisai, Zhob, Gawal, Kharan, Wadh, Khuzdar and Sonaro areas in Balochistan (Shah, 2018). Moreover, its deposits are also found in Chillas, Sawat, and Malakand districts of Khyber Pakhtunkhwa province (Umar et al., 2013). The significant factors that affect ore mining are the production capacity of the mines, ownership of mines, the method of mining, the working conditions including roof and floor condition in the mines, quality of raw material (richness of ore), finished product, the sue of mining techniques and equipment (Malhotra, 1975). Moreover, other factors that affect the ore mining include the geographic features of mining site (climate, terrain and accessibility), the transportation facilities, the level of technological advancements for exploration, industrial developments for processing of the raw material, governmental policies, labour costs and to some extent, demographic issues such as disputes over ownerships in underdeveloped countries also effect the production of ore mining (Liberary, 2020). Research studies have reported that Balochistan has the highest grade of chromite ore, particularly in Muslim Bagh area. The grades of chromite ore (Cr2O3) ranges from 28% to 56%. (Shah, 2018). The exploration and development of mineral industry in the far-flung areas of Balochistan have not been paid attention due to financial limitations, lack of infrastructure and heavy risk investment (Pakistan Economic Survey, 2016). It clearly shows the barriers that are responsible for poor performance of mining industry in Balochistan. Due to the unviability of modern processing and value addition facilities, the entire chromite ore is exported to China from Balochistan in raw form. The chromite ore shares a considerable part in the mining sector of Balochistan. The local investors are involved in chromite ore mining majority of the areas of the province. Generally, research shows an increase in the chromite production 100516 million tons to 121, 435 million tons in the country (Pakistan Economic Survey, 2021). However, only the increase in production cannot bring prosperity, unless the cost of production remains low and continuous. So far, no study has been found that has empirically assessed the chromite ore production and associated problems in Balochistan. There is a dire need to analyze the production of chromite ore at domestic level. Therefore, this study aims to assess the chromite ore mining in Muslim Bagh ophiolites, to analyze the factors affecting the production of chromite ore, and to suggest the viable strategies to boost-up the production of chromite ore. Furthermore, the study also suggests ways to overcome the problems regarding fragile chromite production in Balochistan particularly in Muslim Bagh area.

2. Methods

2.1. Research Type

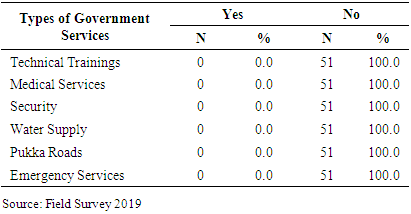

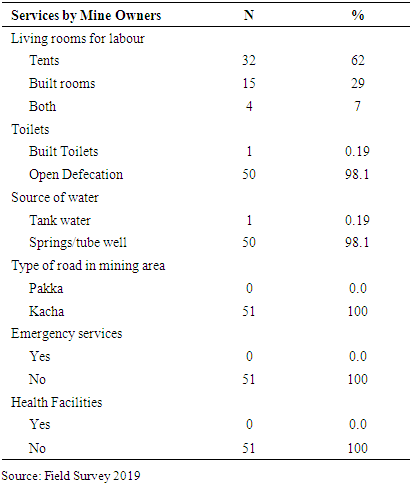

Mixed method research has been used in the study. Mixed methods research is a methodology for conducting research that involves collecting, analyzing and integrating quantitative (e.g., experiments, surveys) and qualitative (e.g., focus groups, interviews) research (FoodRisC, 2016). | Figure 1. Map Showing the area of Chromite Despites in Muslim Bagha Ophiolites, Balochistan |

2.2. Research Design

A case study design was selected as research design for this study. In a case study design, the area which is chosen becomes the basis for a thorough and comprehensive investigation of the aspects which are to be investigated (Chakraborty et al., 2011).

2.3. Study Area

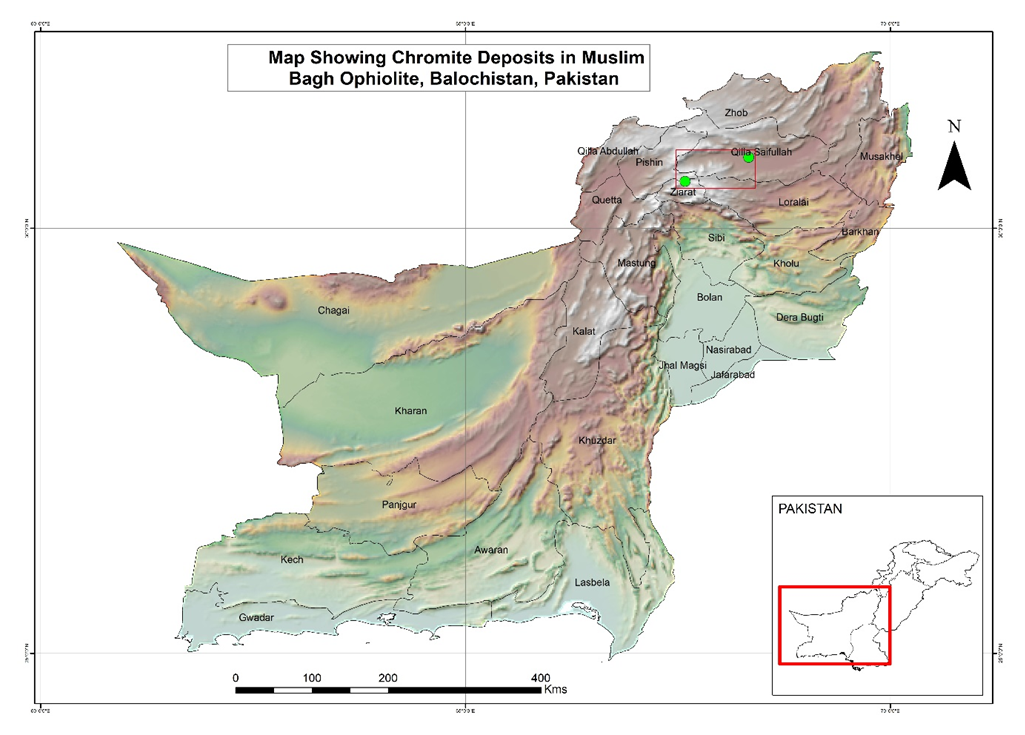

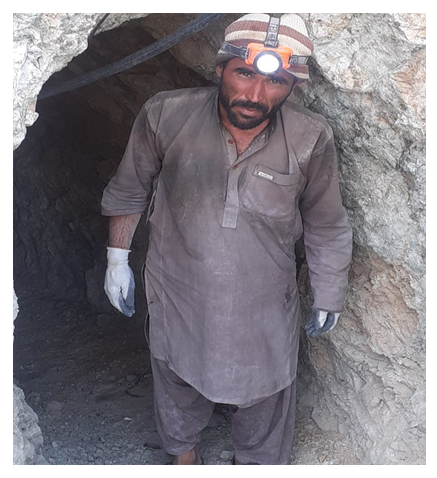

Muslim Bagh is a town and a tehsil (an administrative unit) of Qilla Saifullah district in the Balochistan, a largest province by area of Pakistan (Bazai & Panezai, 2020). Balochistan has borders with Afghanistan and Iran (Khan et al., 2020), rich in mineral resources (Shah et al., 2019), however with most the population due to poor socioeconomic conditions live below the poverty line (Ashraf, 2019; Rehman et al., 2019). The chromite in Muslim Bagh is located at 30°33´N to 30°50´N and 68°35´ E 68°20´ E. According to Census of 2017, the population of Muslim Bagh is 78,597, with a total area of 1,453 km². The area is mostly inhabited by the ethnic Pashtun tribe. The climate of Muslim Bagh ranges from very cold winters to moderate summers. Moreover, this area contributes significantly to the mining sector of Balochistan. Muslim Bagh is known for its chromite production and is the largest chromite ore producing area, as huge amount of chromite (200, 000 tons) is extracted annually of the total chromite ore production (121,435 million tons) of the country (Bureau of Statistics Balochistan, 2019; Economic Survey of Pakistan, 2021). | Picture 1. Haulage to the mine in Muslim Bagh area |

| Picture 2. A labourer at the entrance of haulage |

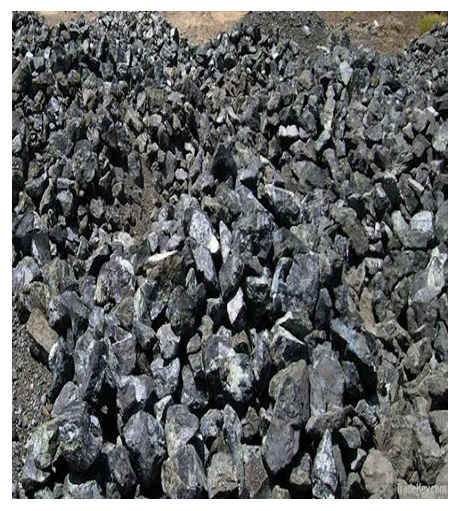

| Picture 3. Chromite ore lying on the ground outside mine |

| Picture 4. Donkey used for extracting Chromite Ore |

Chromite deposits of the Muslim Bagh area occur in a suites of rock association called the Muslim Bagh Ophiolite (reference of Ahmad, 1979). The Ophiolite is a geological term used for the blocks of oceanic crust that have been emplaced over the land due to tectonic activities. Ophiolites in Pakistan are exposed from Bela to Muslim Bagh, then extend northward into Dras Ophiolite in Khyber Pakhtunkhwa province. The Muslim Bagh Ophiolite is the richest in chromite occurrence among all ophiolites within Pakistan. It also contains rich deposits of asbestos and magnesites having million tons estimated reserves. Chromite ore deposits are hosted by a rock called ‘dunite’, which is an ultramafic rock that had been formed within mantle beneath the ocean floor. Other rocks associated with dunite are harzburgite, pyroxenite and wehrlite in the mantle section of the Muslim Bagh Ophiolite (Kakar et al., 2014).

2.4. Data Collection

For this study, the primary data was collected through semi-structured questionnaires, personal meetings, observations and interviews with miners and lease holders.

2.5. Convenient Sampling

Convenient sampling was used in the study where the respondent who were willing to provide data were selected. Further, the interviews were also taken based on their willingness. The major concern of respondents was about the declaration of the production as well as income even though the confidentiality of data had been insured during data collection. A sample size for data collection was fifty-one (51). Keeping in view the hesitation and unwillingness of the respondents for data provision, easily accessible and willing respondents were selected randomly in the study area.

2.6. Data Analysis Methods

The data was collected and analyzed through the Statistical Package for Social Sciences (SPSS) and MS Excel. The descriptive techniques such as frequency distribution, mean, median, range etc., and Chi square test were used for data analysis.

3. Results

3.1. Socio-Demographic Characteristics of Respondents

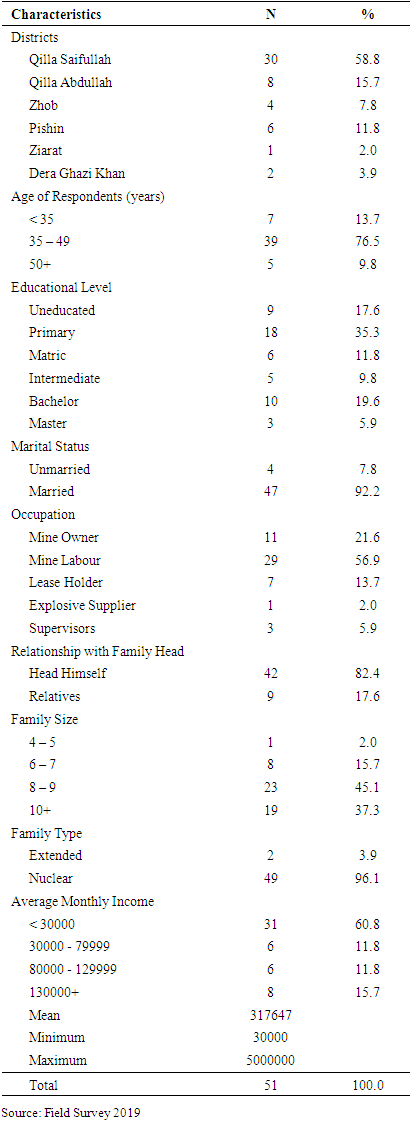

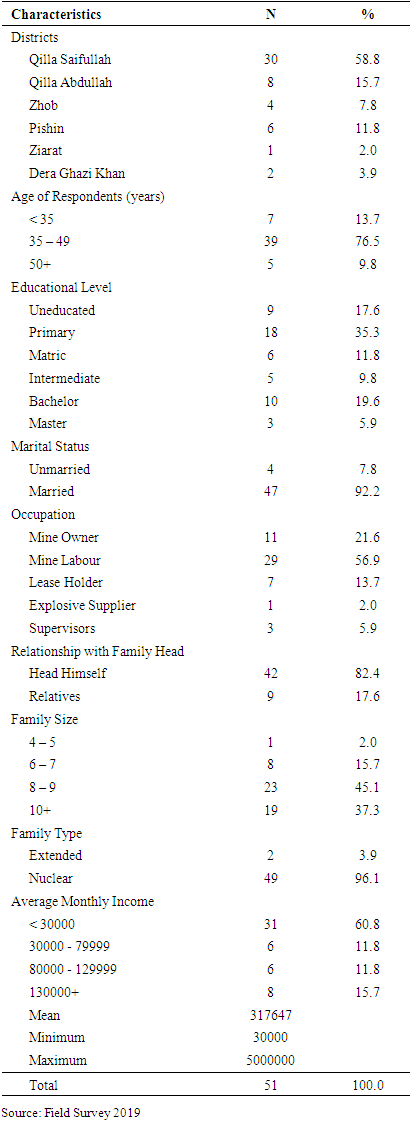

The findings in Table 1 show the that 30 out of 51 mine owners belonged to only Qilla Saifullah district, whereas the rest are from other parts of the country including from Qilla Abdullah, 8 respondents, Zhob (7.8%), Pishin (11.8%), Khanozai (4%), Dera Ghazi Khan (4%) while only 1 mine owner belonged to Ziarat district. The respondents belong to different age groups and most of them belonged to age group of 35-49 years (76.5%), were aged and belonged to the age group of 35-49 years. Moreover, 7 respondents were also younger than 35 years. Only 5 respondents, however, were elder than 50 years. The data overall shows that mining sector belongs to mature and well-experienced age group mine owners. As education can be a good prospect in any field including mining sector as well. the data was further categorized into the different levels of education from uneducated to master degree holders. The findings showed that the respondents with primary education level of education were highest with 35%. Moreover, 9 mine owners were also uneducated. In addition, matric and intermediate degree holders were 6 and 6 respectively. Quite surprisingly, 10 out of 51 mine owners were graduates. Only 3 of the mine owners were master degree holders. Broadly speaking, two third of the respondents were either uneducated or matric degree holders which is quite low level of the education. In the case of marital status, data showed that apart from only 4 of the respondents, all were married. Quite obviously, the dominate age group of the respondents was over 35 years which seems justifying for the high rate of marital status. As the culture dominates the social life in tribal areas, it influences the family size and its types as well. The data showed that 49 out of 51 respondents lived in the nucleated family while only 2 respondents belonged to an extended family. As far as size of family is concerned, the different categorizes had been formed to assess their family size. Overall average of family size was 10.43 members per family. As far as status of respondent within a family is concerned, the respondents were asked either they themselves are family heads or their relationship with the family head. The findings showed that 42 respondents themselves were heads of the family. Moreover, the ones who were not the head, their relation with family head was mostly reported to be grandfather, father, uncle and even elder brother as well. As the target population is mine owners, the income varies as per the number of haulages and workers owned by them. As findings depict that the average monthly income of the mine owners was PKR. 317,647 with average workers of 19 per mines. Almost half of the respondents earned between PKR. 100,000 to 200,000 per month while 15 out of 51 mine owners’ income was under PKR. 100,000. In addition, 9 respondents’ monthly income was above PKR. 200,000. The minimum monthly income of the mine owners was PKR. 30,000 while maximum was up to PKR. 5,000,000.Table 1. Socio-demographic characteristics of respondents

|

| |

|

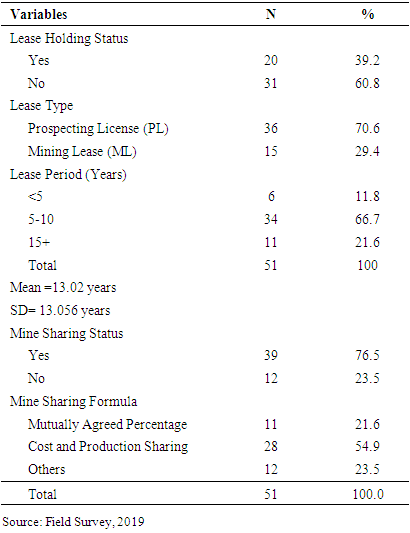

3.2. Lease Details of Mine Owners

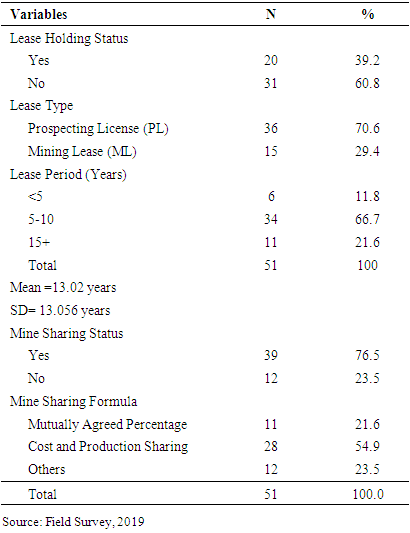

The findings in Table 2 show that only 20 out of 51 mine owners are lease holders while 31 of the respondents don’t have any lease at all. The rate is quite low as per the policies of governments and concerned department. As far as type of lease hold by the mine owners is concerned, the findings of study show that 36 out of 51 respondents have Prospecting Lease (PL) while 15 respondents had Mining Lease (ML). For the assessment of the lease period, the respondents were asked about the time period of the lease they have been mining. The data shows that the average lease period was 13 years which seems quite reasonable. Moreover, around two-third (34) of respondents reported to have lease period from 5-15 years, while 11 of them reported to have lease period of over 15 years. Quite surprisingly, only 5 respondents reported to have less than 5 years lease period. The longest lease period reported was as long as 70 years, starting exactly 3 years after the independence of Pakistan while the shortest period was less than even a year as well. The data showed that sharing mines were also an effective practice that was exercised to improve productivity. Findings showed that 39 out of 51 respondents shared their mines, while 12 of them had no one to share mines with. In the case of mine sharing formula, 28 out of 39 mines sharing owners reported to have cost and production sharing formula, while 11 mine owners reported to have carried mutual agreed percentage of production of chromite ore as formula of sharing. However, 12 mine remained unshared at all. Table 2. Lease Details of Mine Owners

|

| |

|

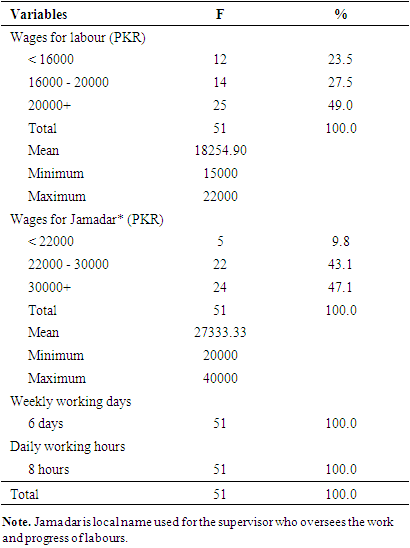

3.3. Wages Structure for Labour

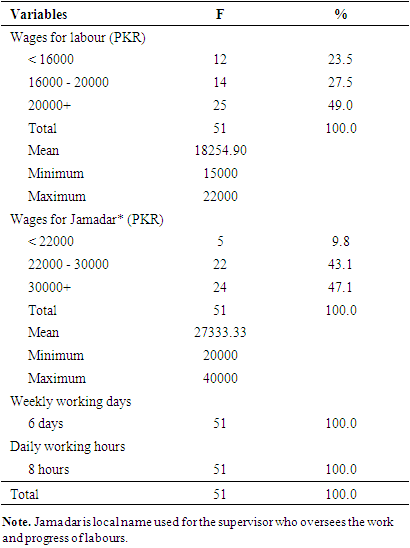

The findings in Table 3 showed the wages structure for labours working in mines in the study area. As far as the monthly wages of the labour are concerned, the labour is paid on the basis of the skill and the experience, either gets maximum or minimum wages. The data in Table 3 demonstrates the wages of labour per month. The average wages paid to the labours was PKR. 18352 which is less than the minimum wage rate of the Government of Pakistan i.e., PKR. 20000 per month (Minsitry of Finance, 2021). As far as range of maximum monthly wages are concerned, the maximum wage was reported to be PKR. 22000 while minimum was only PKR. 15000 only. Moreover, 25 respondents reported the maximum wages to be over 20000 per month while remaining were almost equally distributed in the class of either less than 16000 or between 16000 to 20000 per month. Moreover, the Jamadar1 are the supervisors in the mines which are responsible for all the related affairs in the mines. The findings show that the average monthly income for Jamadars was PKR 27333, the maximum wage to be paid was PKR. 40000 and the minimum was PKR. 20000 per month. Furthermore, 24 of the mine owners reported to pay more than 30000 per month to jamadars while 22 of them paid between 22000 to 30000 per month. Only 5 of them, however, paid less than 22000 per month to Jamadars who are the highest paid workers among the labours. The labours work 6 days a week and 8 hours a day with only one day off i.e., Friday. | Picture 5. A Trolley used for Extraction of Chromite Ore |

| Picture 6. Diesel Engine used for dewatering of mine |

Table 3. Wages structure for labour

|

| |

|

3.4. Availability of Explosives for Mining

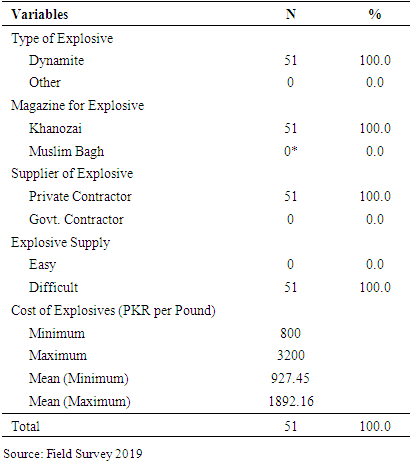

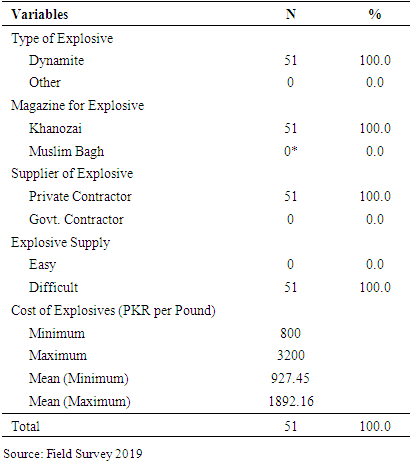

The findings in Table 4 explain the availability of explosive for chromite ore mining. As all of the mine owners reported the use of explosives in mining process, the information about the explosives is quite significant. All the mine owners used dynamite for in the excavation process. Moreover, the magazine where the dynamite is stored were owned by the private contractors where there was no check and balance over the price of explosives. Magazine of dynamite was, however, only located in Khanozai and mine owners of Muslim Bagh had to buy the explosives from Khanozai which is located about 40 kilometers from Muslim Bagh area. As far as supply of explosives are concerned, all the mine owners reported that explosive supply was quite difficult in the study area. As far as cost of explosives are concerned, Table 4 shows the minimum and maximum cost of explosives per pound. The findings also show the huge difference between minimum and maximum cost of the explosives due to the seasonal shortage and no check and balance on the rates. In result the price always fluctuates. The findings revealed the minimum and maximum cost of explosives as PKR. 800 and PKR. 3200 per pound respectively. The findings show that the average minimum average cost was PKR. 927.45 and the maximum average cost of the explosives was PKR. 1892 per pound. Table 4. Availability of explosives for mining

|

| |

|

*The magazine for dynamite was closed in Muslim Bagh area due to local conflicts and political interventions, therefore, the mine owners used to get the dynamite from Khanozai.

3.5. Quality of the Chromite Ore

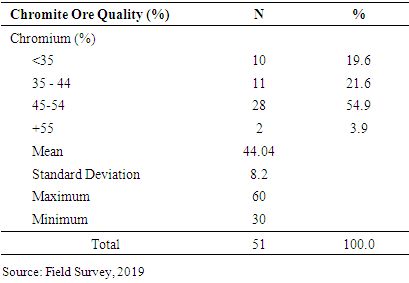

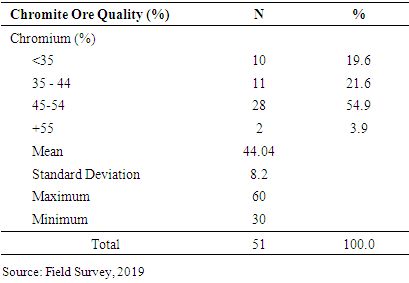

The quality of the chromite ore is usually calculated on the basis of the availability of percentage of chromium oxide (Cr2O3) in the ore. To be more specific, the data is further categorized into maximum and minimum percentage of chromium in chromite ore being mined from Muslim Bagh area. The minimum percentage of chromium in chromite ore was 30%, and the maximum was 60%. As far as maximum percentage of chromium oxide (Cr2O3) in chromite ore is concerned, it was up to 60%. The average percentage of chromium was 44.04%. According to geological interpretation, the ‘disseminated variety’ has the least percentage of Cr2O3 while the ‘massive variety’ has the highest percentage of Cr2O3. Therefore, it can be concluded that the quality of Chromite ore in Muslim Bagh area was ranged from 30% to 60%. Table 5. Quality of the Chromite Ore

|

| |

|

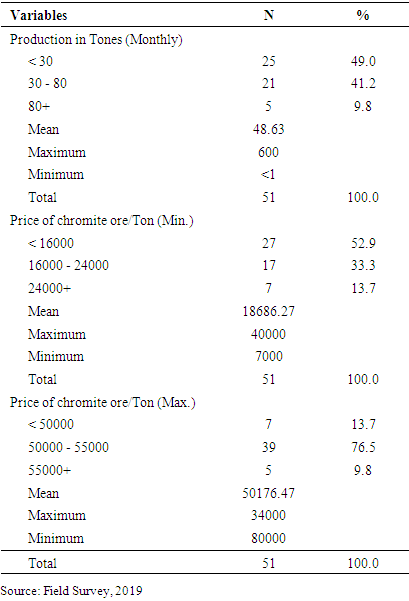

3.6. Monthly Chromite Production in Tones

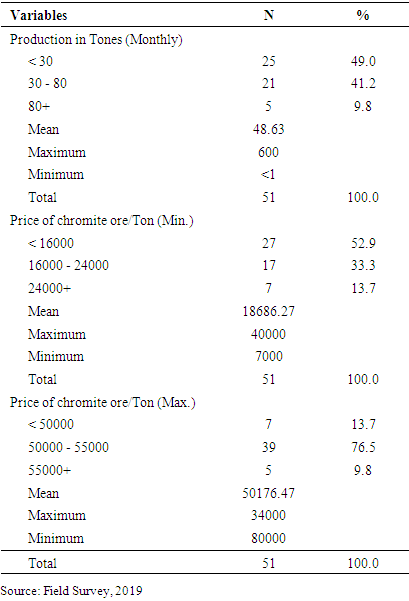

The average monthly production of chromite ore of the Muslim Bagh area is 48.63 tons while the maximum production was reported up to 600 tons, and, the minimum monthly production was less than one ton. The price of chromite ore in the market is a significant factor which accelerates and decelerates the chromite mining. The minimum price of chromite ore was PKR.7000 per ton whereas, the maximum rate was PKR. 80,000 per ton. The minimum average price was PKR. 18686.27 and the maximum average price was reported at PKR. 50174 per ton.Table 6. Price of Chromite Ore

|

| |

|

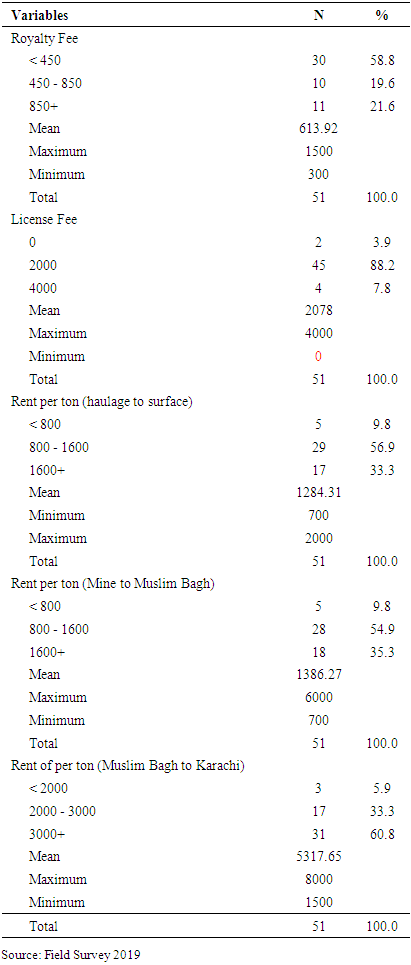

3.7. Loyalty, License Fee and Rent Details of Chromite Ore

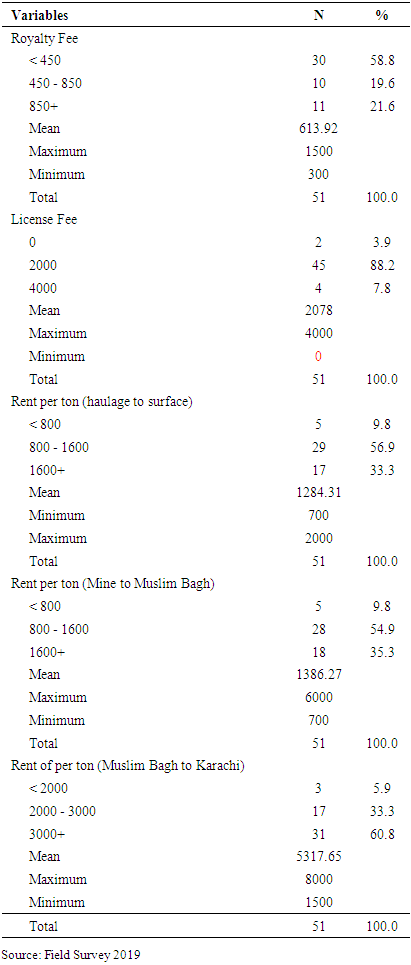

The royalties, license fee and rent paid by mine owners for production and transportation in Muslim Bagh area are most significant economic factors in the mining sector. The data shows that average royalty fee paid by the mine owners was PKR. 613 per ton while the maximum royalty fee was reported to be PKR 1500. The minimum royalty was, however, only PKR. 300. As far as the license fee is concerned, the maximum was PKR. 4000 and minimum PKR. 2000 and the average license fee was 2078 rupees. In the case of rent paid by mine owners for transportation of the chromite ore from place of production to outside and then to market, the average rent per ton of chromite ore is PKR. 1284 from bringing the ore to outside of mine. As far as rent per ton of chromite ore to Muslim Bagh is concerned, the average rent per mine was PKR. 1386 rupees. Whereas, the average transportation cost from Muslim Bagh to Karachi is PKR. 5317 per ton with minimum to be PKR. 1500 and maximum at PKR. 8000 depending on the demand and supply of transportation. Table 7. Loyalty, license fee and rent details of chromite ore

|

| |

|

| Picture 7. Chromite Ore is accumulated outside mines for transportation to Karachi |

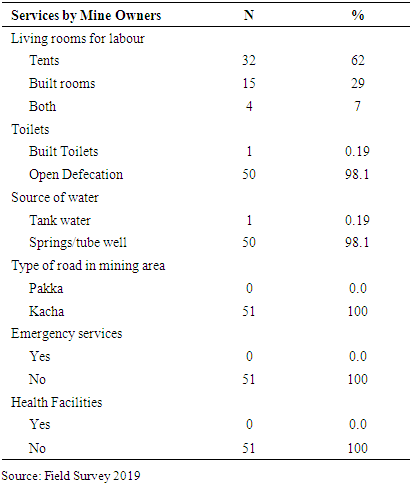

3.8. Provision of Services for Labours by Mine Owners

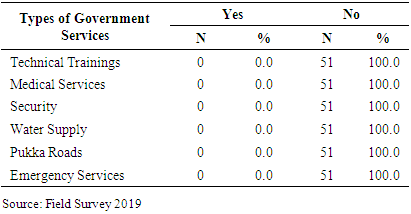

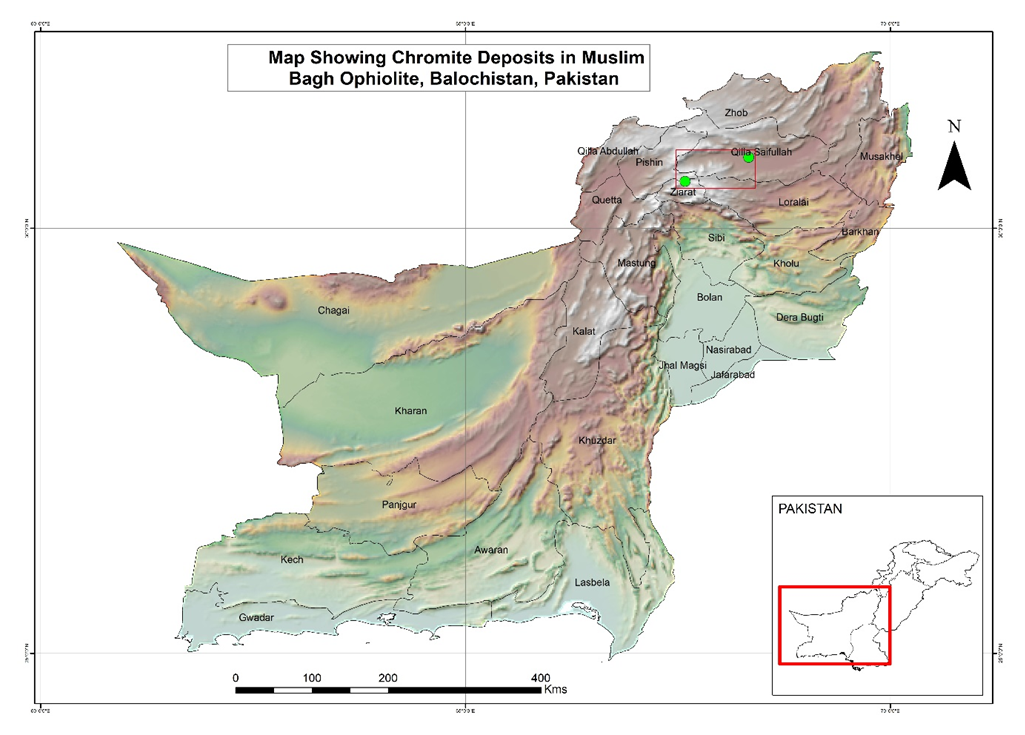

The findings revealed the provision of services to labours by mine owners. The living standards of labour was quite worse. Most of the labour lack basic facility of housing. is concerned, out of the total 51, 32 mine owners reported that their labours live in tents only. While 15 of the mine owners reported to have built rooms for the housing of labour while only 4 respondents reported both the means of housing; tents as well as built rooms. Similarly, the basic facility of toilets was provided only at a single mining site, whereas labour of the remaining 50 mines practiced open defecation. Moreover, the water used by 50 of the mining sites was that of spring water, while only at one site it was provided through water tanker. The transportation system was totally fragile as all the roads in mining sites were Kacha2. As far as health care facilities including emergency services such as first aid boxes as well as ambulances were totally unavailable in mining sites. Table 8. Provision of services for labours by mine owners

|

| |

|

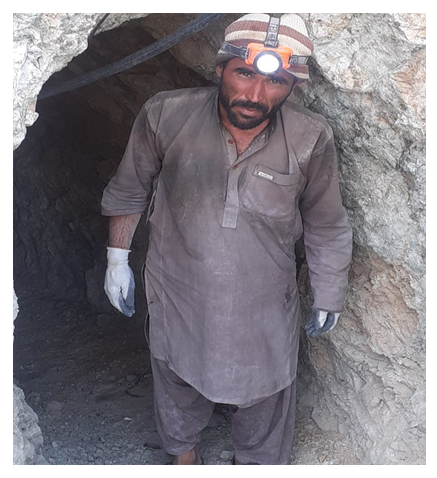

3.9. Availability of Government Services

The findings in Table 9 show that the summary of government services available for mining sector in Muslim Bagh, Balochistan. The data show that Government has failed to provide any services for the chromite ore mining sector in Muslim Bagh. The data reveals that government has not conducted any sort of technical trainings for mine owners or workers at all. Neither any medical services nor any security is provided by the government or relevant authorities. The provision of public water supply was almost to zero in mining sites. Most importantly, government has failed to facilitate the mining sites with proper means of transportation as all the road in the area were Kacha. Moreover, emergency services hold base importance in the mining sector yet government as well as relevant stakeholders squarely failed to provide them the basic emergency services at the mining sites. Table 9. Availability of Government Services

|

| |

|

3.10. Factors Affecting Chromite Ore Production

Several factors were affecting the production of chromite ore in Muslim Bagh area of Balochistan province. The analysis of the data collected through semi-structured questionnaire revealed that local disputes over the ownership of lands and shortage of finances were the major factors that caused decrease in production. Other factors include unstable and low price of chromite ore in market, miserable working conditions for mine workers, lack of basic health care services, lack of private investment, notoriety of the area, lack of financial initiatives by the governments, lack of technical surveys and use of digital tools, fragile infrastructure and shortage of the explosives ultimately affected the chromite ore production severely. Moreover, chromite ore mining being risky enterprise was also reported by mine owners. As far as market for chromite ore of Muslim Bagh is concerned, all the respondents reported that Karachi is the only market for chromite ore of Muslim Bagh area. This makes the mine owners financially vulnerable.Major Problems of Chromite Ore Mining The mine owners of the chromite ore mining revealed during interviews that several problems hamper the chromite ore production in the study area. Following were the major problems pointed by the respondents; § Lack of financial support in terms of credit through formal sources from the government. § Lack of technical surveys for exploitation of subsurface chromite ores.§ Shortage of explosives specially during peak times. § Lack of technical training for labours which have increased cost of production due to unskilled labour in the sector. § Outdated methods of mining, particularly manual mining.§ Fluctuations in the market price or ore which cause uncertainty among mine owners.§ No security and safety are provided for the remotely located mines.§ Unavailability of basic health and emergency services in mining sites due to which great human losses occur. § Lack of basic physical infrastructure including transportation network as well as sewerage system. As the roads are mostly Katcha and slippery in the rainy seasons.§ Local disputes affect mine production as these dispute cause closure of the mining in most of the cases.§ Fluctuations in the demand also affects supply and ultimately the production.

4. Discussion

This study was aimed to assess the chromite ore mining and associated factors in Muslim Bagh area of Pakistan and to suggest viable strategies to improve the chromite ore production. The findings revealed that two-third (60%) of the mine owners had no lease documents. Moreover, the findings of study also showed 61% of the respondents had Prospecting Lease (PL) while 39% had Mining Lease (ML). This shows that majority of the mine owners lack proper documents and were involved in illegal production of chromite ore. On the one hand, this causes huge financial losses to government revenues whereas on the other hand, local disputes over the ownership of mining areas. It is pertinent to mention that on Prospecting Lease (PL) the commercial production of ore is not allowed. Only Mining Lease (ML) can be used for commercial extraction of chromite ore. The larger number of miners were involved in commercial production through ML that causes huge financial losses to the Government of Balochistan in terms not paying royalties, license fee and land rents. Thus, the proper documentation of leasing is mandatory for increasing government revenues. The findings of current study revealed that availability of explosive for chromite ore mining has been problematic. All the mine owners use dynamite for chromite ore extraction from hard rocks. The unavailability of dynamite had severely affected the production process. The smooth supply of dynamite is extremely important for keeping the production alive and saving mine owner from the catastrophic production costs. Both supply and price of dynamite is important to be stable. The magazine for storing the explosives was non-functional in Muslim Bagh. There are different reasons of non-functionality of magazines in Muslim Bagh as revealed by the mine owners. Many of the respondents reported the tribal disputes and local conflicts as the big reason for non-functional magazine in the area. Others reported the security issue as a basic reason of non-functionality of the magazine in the area. Besides that, some respondents also reported elders’ interference in using the explosives. In addition, brokers monopoly also was reported as brokers can create the shortage of explosives the magazines. In the same regard, political influence cannot be neglected where the owners with high political influences can get the maximum supply. The government must establish and rehabilitate the magazine for storage of explosives and take serious steps for the smooth supply of explosives with regular check on its prices. As mining in Muslim Bagh is underground, the selection of site becomes highly significant. The haulages were quite deep as lack of electricity and improper exhaust system make labour at very high risk of poisonous gas traps as well as the mine subsidence. Only one mine had an engineer as an expert while other had no technical assistance. The unavailability of the technical expertise mostly results in form of site failure which cause huge human and financial losses. Moreover, the average minimum monthly income of labour was as low as PKR. 13490, whereas the Government of Pakistan has set minimum labour wage of PKR 17500 per month in National Budget 2020-21(Raza, 2020). This needs attention of the social welfare department and mines and minerals department to ensure the minimum salary in mining sector. In the chromite mining area at Muslim Bagh, the mining is carried out with the traditional and outdated methods as spade or shovel “Belcha”, pickaxe “Kuddal”, wedges, hammers and chisels. The use of these tools is quite risky and are not even productive. Exposure to advanced tools and skills through trainings by the mines and mineral department can surely improve the efficiency of labour and ultimate improve production. In addition, assistance of the national and multinational organizations can be availed for the provision of advanced mining tools along with trainings. Further, the dewatering tools are submersible which due to the shortage of electricity are ineffective. Overall, the increase in the chromite production can’t be attained until modern techniques and tools are used.As explosives are the basic need of extraction in mining sector but its availability is a huge concern for the mine owners in Muslim Bagh area. Khanozai is the only market of explosives. Moreover, the explosives are provided by private brokers without any check over the price and the availability by government. The shortage and increase in the price are very common when the season is at the peak. Therefore, government must ensure the sufficient provision of quality explosives so that the production can be maintained.Besides that, the quality of chromite in Muslim Bagh ranges from as high as 60% to as low as 30%. Low quality chromite, however, can be disastrous for mine owners due to very low financial gain. This difference can be minimized through conducting proper advanced and digital surveys to assess the quality of chromite before initiation of mining. Similarly, as Karachi is the only market of chromite ore where mine owners pay high rents form Muslim Bagh to Karachi. Moreover, price of chromite also fluctuates regularly along with the handsome amount being paid in rents which always is a huge cut on the net profit. These all the factors can be encountered by establishing iron smelting and crushing plants as near to mining region as possible. Moreover, Government can assist the large businessmen to establish steel industry as well which can ultimately change the fate of Muslim Bagh by creation of large-scale employment opportunities. In addition, the living standards for mine workers are very low including unavailability of basic facilities of water, shelter, toilets, basic health facilities and security. Therefore, the government needs to insure the provision of basic facilities. As these mine owners are lease holder and pay the government in terms of lease, royalty and license fee, it becomes the responsibility of the government to provide them basic facilities. Initially, Chapter V of Mines Act, 1923 namely, “Provisions to Health and Safety” ensures the availability of water, toilets and all the medical facilities of supply of ambulances and stretchers, splints, bandages and other medical requirements including the First Aid box. Moreover, the administration, tribal chiefs and law enforcement agencies are needed to solve out the local disputes so that mining industry in the region can be more prosperous and productive.Limitations of the study In this study, we have summarized the problems extracted through qualitative interviews. However, due to word limit, we could not state their actual statements. The market prices of the chromite ore are highly volatile. Therefore, the prices of chromite reported in our paper should not be generalized as static and to other part of Pakistan.

5. Conclusions

The findings of this survey revealed that the government has totally neglected the local chromite ore “Black Gold” mining sector. Government must focus to provide technical support, better transportation network, emergency care services, trainings, sufficient electric supply as implementing the policies affectively to boost up the complete sector of chromite ore mining. Most importantly the chromite ore mining is the sector that provides employment to the locals and can contribute to not only the local economy but also to the regional economy given that proper attention is paid by the government. Government of Balochistan has approved several projects in the Public Sector Development Program (PSDP) for the year 2021-22. These include the establishment of mines rescue and safety training centre and mines surveyors institute at Quetta, integrated development of mining sites (shelterless schools, dispensaries, of mines labour welfare organization, purchase of machinery for maintenance of shingle road to access mining areas, automation of royalty regime in mining sector, construction of mineral complex in Balochistan at Quetta. mineral resource mapping in Balochistan, capacity building of the officer of the Mines & Mineral Development Department, construction of new mineral check post at Noshki, Pishin, Loralai, Mastung., installation of digital weight bridges at Hanna, Degari, Rakhni, Zhob & Lung Lohaar (Hub), establishment of mines rescue centre in Duki, geo resource survey of Balochistan, establishment of mineral testing laboratory (Government of Balochistan, 2021). If these projects are successfully executed, then the mining sector can improve in Balochistan.

6. Recommendations

Following are the strategies through which chromite production in Muslim Bagh can be increased; § Extending financial support to lease holders including low markup or interest free loans, government and private sector investments, minimizing the taxes through mining sector friendly policies and finances for the infrastructural development, equipments availability as well as giving training to labours. § Ensuring timely supply of explosives can boost up the chromite ore production. Particularly, the supply on regular basis and on the optimal prices should be ensured to help mine owners continue mining. § Up-gradation of existing infrastructure and provision of the basic facilities to the labours to ensure their welfare.§ Implementation of labours safety laws through the provision of water, canteen (food), shelter, medical facilities including first aid kits, doctors as well as ambulance availability in case of the medical emergency to ensure that workers get least risky working conditions. § Provision of security for workers as local conflicts and remoteness of the area leave mine workers at high risk. Proper security must be provided for the workers by law and enforcement agencies. § Surveys for exploration of new sites should be conducted on regular basis by relevant authorities as most of the mines are too old. New sites through proper surveys can surely increase the production in mining sector.§ Provision of training to labours for their capacity and skill building so that more skilled labour can be produced.

ACKNOWLEDGEMENTS

The authors pay cordial thanks to Sanaullah Khan, GIS Specialist for making map of the study area. We also pay regards to the reviewers of this manuscript whose invaluable comments significantly improved the quality of manuscript. Moreover, we are also thankful to Mr. Anis Khan Kakar from Muslim Bagh who helped us in conducting field survey and provided accommodation in the study area.

Notes

1. Jamadar is a word of Urdu language used for the supervisor. 2. Katcha is a word of Urdu language used for unpaved road.

References

| [1] | Ashraf, M. (2019). Farmers’ coping and adaptive strategies towards drought in Pishin district, Balochistan. Journal of Geography and Social Sciences, 1(1), 1-16. |

| [2] | Aziz, W. A., & Khan, T. Z. (2020). Untapped Mineral Resources and Economic Development of Pakistan. https://www.globalminingreview.com/exploration-development/15072020/untapped -mineral-resources-and-economic-development-of-pakistan/#:~:text=In%20contrast %20as%20per%20Economic,of%20Pakistan%20(Figure%203). |

| [3] | Bazai, M. H., & Panezai, S. (2020). Assessment of urban sprawl and land use change dynamics through GIS and remote sensing in Quetta, Balochistan, Pakistan. Journal of Geography Social Sciences, 2(1), 31-50. |

| [4] | Bureau of Statistics Balochistan. (2019). Developemnt Statistics of Balochistan Planning and Development Department (P&DD), Government of Balochistan. |

| [5] | Chakraborty, S., Kumar, S., & Basu, S. (2011). Conformational transition in the substrate binding domain of β-secretase exploited by NMA and its implication in inhibitor recognition: BACE1–myricetin a case study. Neurochemistry international, 58(8), 914-923. |

| [6] | Economic Survey of Pakistan. (2021). Manufcaturing and Mining. Ministry of Finance, Government of Pakistan Retrieved from https://www.finance.gov.pk/survey/chapters_21/03-Manufacturing.pdf. |

| [7] | Edwards, R. (2012). Ore deposit geology and its influence on mineral exploration: Springer Science & Business Media. |

| [8] | Food Ris C. (2016). Mixed methods research. http://resourcecentre.foodrisc.org/mixed-methods-research_185.html. |

| [9] | Government of Balochistan. (2021). Annual Budget of Balochistan for the Year 2020-21: Mines and Mineral Department Finance Department, Government of Balochistan Retrieved from https://balochistan.gov.pk/wp-content/uploads/2021/06/BC12236-MINERAL- RESOURCES-SCIENTFIC-DEPARTMENT.pdf. |

| [10] | Khan, Z., Saeed, A., & Bazai, M. H. (2020). Land use/land cover change detection and prediction using the CA-Markov model: A case study of Quetta city, Pakistan. Journal of Geography Social Sciences, 2(2), 164-182. |

| [11] | Library, Y. A. (2020). Factors Affecting Exploitation of Mineral Resources around the World. https://www.yourarticlelibrary.com/essay/factors-affecting-exploitation-of- mineral-resources-around-the-world/25483. |

| [12] | Malhotra, R. (1975). Factors Responsible for Variation in Productivity of Illinois Coal Mines. |

| [13] | Ministry of Finance. (2021). Pakistan National Budget. |

| [14] | Pakistan Economic Survey. (2016). Mining Sector. Retrieved from https://www.finance.gov.pk/survey/chapters_17/03-Manufacturing.pdf. |

| [15] | Pakistan Economic Survey. (2021). Mining Sector. Retrieved from https://www.finance.gov.pk/survey/chapters_21/03-Manufacturing.pdf. |

| [16] | Papp, J. F. (2007). Chromium, a National Mineral Commodity Perspective: US Geological Survey. |

| [17] | Raza, H. (2020). Minimum Wage. The NEWS. Retrieved from https://www.thenews.com.pk/print/679654-minimum-wage. |

| [18] | Rehman, T., Panezai, S., & Ainuddin, S. (2019). Drought perceptions and coping strategies of drought-prone rural households: a case study of Nushki District, Balochistan. Journal of Geography Social Sciences, 1, 44-56. |

| [19] | Shah, S. A. H. (2018). Strategy for Mineral Sector Development in Pakistan. Retrieved from https://www.pc.gov.pk/uploads/pub/FIRST_05_PAGES_STRATEGY_FOR_ MINERAL_SECTOR_DEVELOPMENT_IN_PAKISTAN.pdf. |

| [20] | Shah, S. T. H., Tariq, M., Khan, N. G., Iftikhar, A., Farid, A., & Naseer, S. (2019). Chromite deposits of Pakistan: a short review. International Journal of Research-GRANTHAALAYAH, 7(7), 70-78. |

| [21] | Umar, M., Waseem, A., Sabir, M. A., Kassi, A. M., & Khan, A. S. (2013). The impact of geology of recharge areas on groundwater quality: a case study of Zhob River Basin, Pakistan. CLEAN–Soil, Air, Water, 41(2), 119-127. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML