-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Geosciences

p-ISSN: 2163-1697 e-ISSN: 2163-1719

2014; 4(3): 51-53

doi:10.5923/j.geo.20140403.01

Geotechnical Properties of Some Selected Beach Sands in Lagos, Southwestern Nigeria

Alao David Afolayan1, Adeoye Adeyinka Olumayowa2, Abioye Olayinka Oyeronke3

1Folaina Nigeria Limited, 14 Dasuki Road, Tanke GRA Ilorin, Nigeria

2Edmonton, Alberta, Canada

3Department of Geology and Mineral Sciences, University of Ilorin Nigeria, Nigeria

Correspondence to: Alao David Afolayan, Folaina Nigeria Limited, 14 Dasuki Road, Tanke GRA Ilorin, Nigeria.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The geotechnical properties of selected beach sands in Lagos, Dahomey basin have been investigated. Representative samples were subjected to standard engineering tests [1]; and used the Terzaghi’s shallow foundation formula for strip and square footing. Beecroft sand has the highest angle of internal friction of 33 with cohesion (c) of 10kPa.It has the highest compressive strength of 3.67KN/mm2. Shear strength for the beach sands (0.18 to 3.67KN/mm2); specific gravity (2.57) bulk density (1.95g/cm3)) dry density (1.70g/cm3); moisture content (14.6%). Gradation (0.063mm-16.00mm) some with, 10% sil; 30% gravel and 60% sand with Cc and Cu of 0.30 and 16.00 respectively. The bearing capacity of each sample was deduced at depths of embedment (0-2m) and width of footing (0.0475-3m). The ultimate bearing capacity of Beecroft is the highest followed by Suntan beach, Bar-beach and Banana-Island in decreasing order.

Keywords: Bearing Capacity, Compressive Strength, Concrete – Aggregates, Embedment

Cite this paper: Alao David Afolayan, Adeoye Adeyinka Olumayowa, Abioye Olayinka Oyeronke, Geotechnical Properties of Some Selected Beach Sands in Lagos, Southwestern Nigeria, Geosciences, Vol. 4 No. 3, 2014, pp. 51-53. doi: 10.5923/j.geo.20140403.01.

Article Outline

1. Introduction

- The Dahomey Basin is a combination of inland / coastal / offshore basin that stretches from south-eastern Ghana through Togo and the Republic of Benin to south-western Nigeria. It is separated from the Niger Delta by a submarine basement high referred to as the Okitipupa Ridge. Its offshore extent is poorly defined. Sediment deposition follows an east-west trend. In the Republic of Benin, the geology is fairly well known [2, 3]. According to Omatsola and Adegoke [3]. The Lagos coastline has prominent beaches whose sandy materials are harnessed for construction purposes, and as Lagos develops into a Mega - city under the current civilian administration with external funding by the World Bank and other external financiers civil engineering projects have sprung up, correspondingly, demand for construction aggregates have increased in recent times .Our study of beach sands for a better understanding of the engineering properties of these sands is justified.The demand from construction companies, for the use of concrete aggregate, especially cohesion-less soils such as; sand and gravel and rocks has increased. The construction industry accounts for 96 percent of all the domestic consumption of cohesion-less soil. The composition of sand is the presence of silica which is chemically inert and is therefore resistant to weathering. The geotechnical properties include: shear strength, grain size, moisture content, specific gravity, bulk density, dry density and compressive strength some of which were tested and reported in this paper.

2. Field Methods and Laboratory Analyses

- The investigated beach sands of Suntan beach (latitude N6° 25’ 62” and longitude E3°25’ 7”), Bar-beach (latitude N6°25’2” and longitude E3° 25’ 7”), Banana-Island (latitude N6° 27’ and longitude N3° 26’) and Beecroft (latitudeN6° 26’ 2” and longitude E3° 2’ 1”) are located at Victoria Island and Marina in Apapa respectively; north eastern Dahomey basin and it is a coastal environment has shown in figure 1 below. At these locations, sands occur along the coast which is an accreting coastline (Suntan) and eroding coastline(Bar-beach) which is evident in the position of the coconut trees along the shoreline; sands are carried by longshore drift at high tide and are willowed therefore the sands at Suntan beach and Bar-beach are clean sands while that of Banana Island and Beecroft are lagoonal environment with low tide and has dirty sand due to organic matter present and is responsible for the grey –black coloration of the sand and the water body. The sea flows in the northeast to southwest direction. Four fresh representative samples were obtained from selected locations whose coordinates are shown above. A summary of geotechnical properties determined are shown in Table 1.

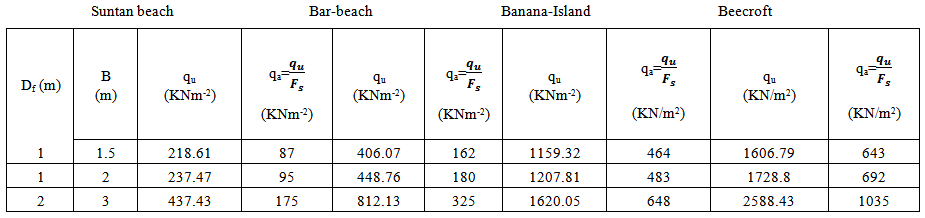

| Table 1. Shows the ultimate bearing capacity and allowable bearing capacity for square footing at the four locations |

2.1. Geotechnical Properties of Lagos Beach Sands

- From the grain size analysis, the following results were obtained; Suntan beach has particle size distribution ranging from 0.063mm to 4.0mm with 3% gravel and 97% sand nd Bar-beach has 0.09mm to 4.0mm with 2% gravel and 98% sand; according BS1377, it is therefore classified as slightly gravelly sand and the coefficient of gradation and coefficient of uniformity are1.60 and 1.83 and 1.31 and 2.2 and in accordance to Bolwes [7, 8], if Coefficient of gradation, Cc is between 1-3 and Cu <6; it is poorly graded. Therefore the samples are poorly graded while Banana-Island and Beecroft have 0.075mm to 8.00mm with20% silt, 30% gravel and 50% sand and 0.063mm to 16.00mm with 10% silt, 30% gravel and 60% sand respectively and it is therefore classified as gravelly sand and the coefficient of gradation and coefficient of uniformity of1.07 and 2.14 and 0.3 and 16.00 respectively; it is therefore classified as poorly graded. From the compressive strength and shear strength parameters the compressive strength of the sample at Suntan when stabilized with Portland cement at 10%, 15% and 20% are 0.18KN/mm2, 1.22KN/mm2 and 2.63KN/mm2 and the cohesion is 0KPa and angle of internal friction is 23°and Bar-beach has cohesion of 0KPa and angle of internal friction of 28° which shows that the samples are purely cohesionless soil and are prone to local shear failure according to Pecke et al., [7] while that of Banana-Island and Beecroft has compressive strength of 0.09KN/mm2, 0.58KN/mm2 and 1.35KN/mm2 and 0.18KN/mm2, 2.09KN/mm2 and 3.67KN/mm2 respectively and the shear strength parameters are cohesion 17KPa and angle of internal friction of 28° and cohesion of 10KPa and angle of internal friction of 33° respectively. The angle of internal friction (ф) at Beecroft is the highest amongst the four locations and is therefore classified as loose sand according to Peck et al., [7] and are susceptible to both local and general shear failure; and has the highest compressive strength while Banana Island has the lowest compressive strength and the highest cohesion of 17KPa amongst the four locations. From the shear strength parameters and the unit weight of the soil, the bearing capacity for each soil was obtained for shallow foundation applying Terzaghi’s formula for shallow foundation for strip and square footing:qu= cNc+ qNq + 0.5ϒNϒ (strip footing)qu = 1.3cNc + qNq + 0.4ϒNϒ (square footing)qa = qu /Fswhere qu is the ultimate bearing capacity of the soil, qa is the allowable bearing capacity of the soil, Fs is the factor of safety (2.5 was used for this study), c is the cohesion, Nc, Nq and Nϒ are the Terzaghi bearing capacity factors for cohesion, surcharge and the unit weight of the soil, ϒ is the unit weight and q = ϒDf where Df is the depth of embedment.The following results were obtained for pillars (0.475m) and normal loading at varying depth of embedment (Df) pillar)s (0m to 2m) and width (B)(1m to 3m). For shallow foundation the depth of embedment must be less than the width of footing that is; Df <B (Braja, M.D. [8]. From the values of the bearing capacity of the samples obtained; the bearing capacity of the soil increases as the base of the footing increases and there is slight increase in the bearing capacity of soil for square and strip footing pillar).

3. Discussion

- From the various geotechnical analysis data of the samples, the following deductions were made: The beach environment contains sands ranging from very loose sand to loose sand based on their shear strength parameters (cohesion and angle of internal friction); the Bar-beach, Suntan and Banana –Island are very loose sand and Beecroft beach is loose. Bar – beach and Suntan beach sands are purely cohesion-less and are liable to localised failure due to the absence of cohesive materials which can serve as adhesive material but Banana Island and Beecroft have cohesion values which reflected in their bearing capacity. The bearing capacity of Beecroft is the highest among the four location with ф = 33° and has a compressive strength of 3.67 N/mm2 even when stabilized with Portland cement. Bar-beach sand has compressive strength of 3.16N/mm2 and therefore can be serve as good concrete aggregate while that of Suntan beach has low ф = 23° and will not be strong enough for concrete aggregate. Due to the presence of organic matter present in Beecroft despite its high ф value will not be suitable for concrete aggregate because it can react with other elements it is deleterious to Portland cement and thereby reducing the strength of the concrete to be used. Beecroft and Banana Island have more bearing capacity than that of Bar-beach and Suntan beach which are very loose sands. The high pH of sea water was not included, but we know it also is a factor that must be considered to use the beach sands.

4. Conclusions and Recommendations

- In order to solve the problem of soil failure, and destruction civil structures in Lagos, occurring frequently nowadays, there is need for proper site investigation because all the beach samples tested in this research can only support small structures. Large scale, high- rise buildings intended for these sites would need soil improvement procedures of stabilisation such as vibro – compaction and grouting. Beecroft and environs may require piling of foundation in order to meet the specifications for design and construction of civil structures in the emerging mega – city (new Lagos) in the 21st century.

ACKNOWLEDGEMENTS

- Osmo- Geotech Engineering Company of Ijanikin, Lagos provided logistic support for the field -work, when we studied the sites and collected pertinent earth resistivity data (not in this article).The efforts of Mr Femi of Unilorin Soil Engineering Laboratory is also recognized.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML