-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Frontiers in Science

p-ISSN: 2166-6083 e-ISSN: 2166-6113

2017; 7(1): 23-26

doi:10.5923/j.fs.20170701.03

Detection of Environmentally Hazardous Nitrogen Oxide Pollutants using Polythiophene Derivative/Carbon nanotube-based Nanocomposite

Ayesha Kausar

Nanoscience and Technology Department, National Centre for Physics, Islamabad, Pakistan

Correspondence to: Ayesha Kausar, Nanoscience and Technology Department, National Centre for Physics, Islamabad, Pakistan.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This article reports a novel effort towards the detection of environmentally hazardous NO and NO2 gas pollutants. The required nanocomposite sensor was designed using poly(thiophene-3-[2-(2-meth -oxyethoxy)ethoxy]-2,5-diyl) (PThME), multi-walled carbon nanotube (MWCNT), and 3-thiopheneacetate additive. Simple dispersion route was opted in this case. Gas sensing properties towards nitrogen oxides NO and NO2 gases were measured. The response of PThME/MWCNT-based sensor for NO and NO2 gases in the concentration range of 2-5 ppm was studied. The resistance change was found to increase with the increase in gas concentration. Moreover, the sensitivity of PThME/MWCNT 3-based gas sensors for 2 ppm NO gas was increased with rise in temperature. Time derivative of resistance for PThME/MWCNT was also observed higher for NO2 gas. In a nutshell, novel PThME/MWCNT gas sensors possess high efficiency to distinguish NO and NO2 based environmental pollution.

Keywords: Polymer, MWCNT, NOx, Sensor, Environment, Polluant

Cite this paper: Ayesha Kausar, Detection of Environmentally Hazardous Nitrogen Oxide Pollutants using Polythiophene Derivative/Carbon nanotube-based Nanocomposite, Frontiers in Science, Vol. 7 No. 1, 2017, pp. 23-26. doi: 10.5923/j.fs.20170701.03.

Article Outline

1. Introduction

- By definition, an air pollutant is any material which may harm human beings, animals, vegetation or other materials [1, 2]. In the case of humans, air pollutants may cause or add to mortality or serious illness. Therefore, air pollutants may cause potential hazard to human health. The determination of hazardous substances in atmosphere has, therefore receives an immense research attention [3]. Carbon nanotube (CNT) is a talented material with range of exclusive properties such as surface area, aspect ratio, mechanical strength, and electrical conductivity [4, 5]. Uniqueness of carbon nanotubes has rendered them competitors for specific applications. Research on CNT-based materials have pointed to range of probable applications in electronic devices, sensors, field emission devices, supercapacitors, batteries, actuators, membranes, and drug delivery systems [6-10]. It has also been an attractive material for the sensing and detection of gases [11]. CNT possess wide specific surface area and fine adsorption ability, therefore can be used as a gas sensing material. Nitrogen oxides such as nitrogen monoxide (NO) and nitrogen dioxide (NO2) are typical air pollutants causing serious environmental problems. The demands for low cost gas sensors have been rapidly grown NOx detection. Consequently, highly sensitive and inexpensive NOx gas sensors have been developed to detect low concentration of NO and NO2 gases. In this regard, polymer and CNT-based gas sensing materials have outstanding high sensitivity at low temperature with fast response and selectively [12-18]. NO2 sensors for environmental applications have been developed using chemical vapor deposition (CVD) technique [19]. The sensors showed good response to low NO2 concentrations and fine selectivity. Such sensors have also been prepared using pulsed laser ablation (PLA) method. The sensitivity of CNT-based gas sensors was dependent on the deposition methods [20]. Similarly, various types of gas sensors have been prepared using polymer and carbon nanotube [21]. The mechanism of CNT-based gas sensors depends on the p-type semiconducting properties of nanotubes. The electron transfer between CNT and oxidizing or reducing gas molecules adsorbed on nanotube surface may affect the electrical conductance [22, 23]. In this paper, gas sensors of a polythiophene derive polymer and multi-walled carbon nanotube (MWCNT) have been developed for the first time. The objective of study was to see the effect of MWCNT loading on the performance of sensors towards the detection of toxic nitrogen oxides. The sensor was developed on ceramic substrate. The response of the prepared gas sensors to NO and NO2 gases were measured and analyzed.

2. Experimental

2.1. Materials

- Ethyl 3-thiopheneacetate (98%), poly(thiophene- 3-[2-(2-methoxyethoxy)ethoxy]-2,5-diyl) (PThME, sulfonated solution), multi-walled carbon nanotube (MWCNT, 97-98%), and tetrahydrofuran (THF, anhydrous, 99.9%) were obtained from Aldrich.

2.2. Poly(thiophene-3-[2-(2-methoxyethoxy)-ethoxy]- 2,5-diyl)/MWCNT (PThME/MWCNT)-based Sensor Film

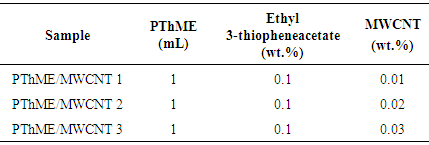

- First, MWCNT materials were ultrasonically dispersed in THF (0.5 mg/mL). Then, 1 mL of sulfonated solution of PThME was added along with the 0.1% ethyl 3-thiopheneacetate. The sensor films were deposited by dispersing 4 mL of THF ethanol dispersions on the substrates. Alumina substrates were used to prepare the required materials [19, 23]. The materials tested are listed in Table 1.

|

3. Results and Discussion

3.1. Sensor Resistance Measurement

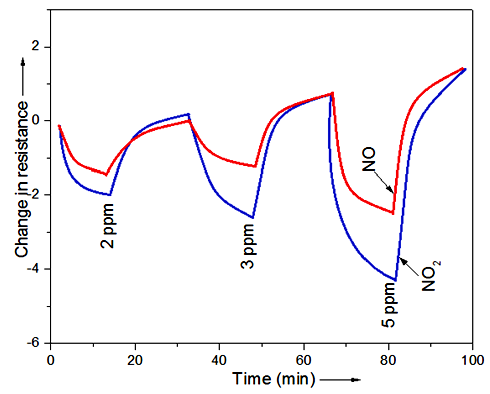

- The sensor resistance was measured using digital multimeter (Keithley 2000). The fully automated measurement system was used for the purpose. Fig. 1 shows the response of PThME/MWCNT-based gas sensor to NO and NO2 gas in the concentration of 2-5 ppm. Initial resistances (R0) of the sensor were 200 Ω for NO gas detection and 210 Ω for NO2 gas detection. The change in sensor resistance (ΔR/R0) was measured to evaluate the sensor sensitivity. The resistance was measured by exposing PThME/MWCNT to NO gas and NO2 gas. The amount of resistance change of the sensor was increased with the increase in NO and NO2 concentration [24]. The sensor revealed larger response to NO2 gas relative to NO gas. As p-type semiconducting CNT adsorb oxidizing molecules, electric resistance of nanotube decreases with the increase of the adsorbed gas molecules. The overall sensor resistance measurement depicted fine performance of sensors.

| Figure 1. Resistance changes of PThME/MWCNT 3 sensor in NO and NO2 gas at 100°C |

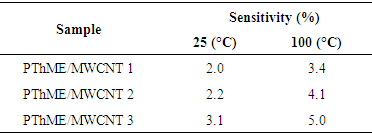

3.2. Sensitivity of PThME/MWCNT

- The sensitivities of PThME/MWCNT-based gas sensors for 2 ppm NO gas was measured at different temperature. The results are tabulated in Table 2. The gas sensor showed higher sensitivity at higher temperature as compared to room temperature. The PThME/MWCNT 3-based gas sensor was found promising for the detection of NOx. The sensitivity was found to have direct relation ship with temperature. It was found to increase with increase in temperature. This result can also be beneficial for high temperature execution of gases.

|

3.3. Measurement of Gas Concentration

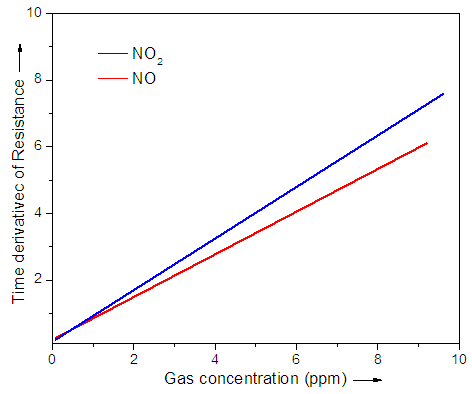

- Time derivative of the resistance was used to measure gas concentration. The differential values at t = 1min after introduction of gas (NO or NO2) vs. gas concentration is plotted in Fig. 2. The values seem to be proportional to the gas concentration. A direct relation ship was observed between the time derivative and gas concentrations. The increase in NO2 concentration was more pronounced as compared to that of NO. The performance of novel sensor was also better than the reported gas sensors for NO or NO2 detection [25]. Several other polymer nanocomposites can also be used to fabricate such type of gas sensors [26-31]. Such type of sensors can be promising for the removal of noxious gases from atmosphere.

| Figure 2. Time derivative of resistance for PThME/MWCNT 3 at t = 1min |

4. Conclusions

- In this effort, poly(thiophene-3-[2-(2-methoxy- ethoxy)ethoxy]-2,5-diyl) and MWCNT sensor was successfully developed using ethyl 3-thiopheneacetate additive. The sensor was prepared using simple dispersion route. The resistance of the PThME/MWCNT sensor was increased with increase in NO2 gas concentration. The larger response was observed for NO2 gas relative to NO gas. The sensitivity of PThME/MWCNT 3-based gas sensors for 2 ppm NO gas was also found to increase with rise in temperature. Moreover, time derivative of resistance for PThME/MWCNT was observed higher for NO2 gas. Results revealed that the novel PThME/MWCNT gas sensors had high efficiency to detect NO and NO2 based environmental pollution.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML