-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Frontiers in Science

p-ISSN: 2166-6083 e-ISSN: 2166-6113

2014; 4(1): 1-7

doi:10.5923/j.fs.20140401.01

Prioritization of Agro-industrial By-products for Improved Productivity on Smallholder Dairy Farms in the Lake Victoria Crescent, Uganda

Andrew M. Atuhaire 1, 2, Swidiq Mugerwa 1, Samuel Okello 2, Kenneth Lapenga 2, Fred Kabi 3, George Lukwago 4

1National Agricultural Research Institute (NARO), National Livestock Resources Research Institute, P. O. Box 96, Tororo, Uganda

2Department of Livestock and Industrial Resources, College of Veterinary Medicine, Animal Resources and Bio-security, Makerere University, P. O. Box 7062, Kampala, Uganda

3Department of Agricultural Production, College of Agricultural and Environmental Sciences, Makerere University, P. O. Box 7062, Kampala, Uganda

4East African Agricultural Productivity Project: National Agricultural Research Organization, P.O. Box 295, Entebbe, Uganda

Correspondence to: Andrew M. Atuhaire , National Agricultural Research Institute (NARO), National Livestock Resources Research Institute, P. O. Box 96, Tororo, Uganda.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Livestock feed fluctuations in quality and quantity is a major constraint to dairy cattle production in Uganda, particularly, in smallholder dairy cattle production. Studies on prioritizing agro-industrial by-products in dairy cattle feeding are central to formulation of sustainable feed management strategies. This study was thus conducted to investigate farmers’ knowledge of agro-industrial by-product management as dairy cattle feed to build logical ideology required in development of appropriate feed management strategies. Focus group discussion and individual interviews were conducted in Lake Victoria Crescent agro-ecological zone to capture information on farmers’ knowledge of the factors enhancing agro-industrial by-products utilization, temporal and spatial variability, and limitations to utilization in smallholder dairy farming system. Chi-square test at p<0.01, df = 3 showed a significant difference among farmers rankings of utilization and factors limiting utilization (p<0.01, df = 4) of agro-industrial by-products across all the study districts. There was no significant difference (p>0.05) in spatial and temporal variability of agro-industrial by-products. The study provided basic information about farmers’ knowledge on importance of agro-industrial by-products that could aid the development of sustainable and socially acceptable dairy cattle feed management strategies.

Keywords: By-product, Dairy cattle, Farmers knowledge

Cite this paper: Andrew M. Atuhaire , Swidiq Mugerwa , Samuel Okello , Kenneth Lapenga , Fred Kabi , George Lukwago , Prioritization of Agro-industrial By-products for Improved Productivity on Smallholder Dairy Farms in the Lake Victoria Crescent, Uganda, Frontiers in Science, Vol. 4 No. 1, 2014, pp. 1-7. doi: 10.5923/j.fs.20140401.01.

Article Outline

1. Introduction

- Shortages and fluctuating quality and quantity of animal feed resources impose major constraints to productivity on smallholder dairy farm in Uganda. However, from the production and processing of plants for human food production, agro-industrial by-products are generated and are potentially suitable for the feeding of dairy cattle [1],[2] reported that agro-industrial by-products play an important role on smallholder dairy farms in sub-saharan Africa for supply of metabolisable energy (ME) and crude protein (CP) which are key components in feeding dairy cattle for optimum productivity. Smallholder dairy farming, where 1 to 5 head of cattle are reared on less than 0.5 to 5 acres of land, is an integral part of livestock production systems that provides food, manure for crop production, income and employment[3]. In Uganda, development strategy and investment plan (DSIP) clearly recognize the role of smallholder dairy farmer in economic growth and poverty reduction [4]. Under the Eastern Africa Agricultural Productivity Project (EAAPP) there has been a deliberate effort aimed at increasing smallholder dairy productivity. However, smallholder dairy farming system in Uganda often fails to attain maximum production limit of their potential, because of inability to obtain adequate required amounts of ME and CP [5]. It is documented that smallholder dairy farmers in Uganda provide only 59% and 36% of the required ME and CP, respectively [6]. According to [7], Uganda has the potential to produce enough agro-industrial by-products for dairy cattle feeding, especially in Lake Victoria Agro-ecological Zone (LVZ) to provide adequate nutrition to match the present trend. Therefore, exploring the potential to prioritize agro-industrial by-products will lead to economically feasible as well as socially acceptable feed management strategies for improved sustainable productivity of smallholder dairy farm. Despite the potential of agro-industrial by-products, their utilization in smallholder dairy farming system is limited. Therefore understanding utilization, spatial and temporal variability, and limitation to utilization will give an insight on prioritizing agro-industrial by-products. This will build coherent principles required to develop appropriate feeding strategies for sustainable productivity on smallholder dairy farms. The objective of the study was therefore to establish utilization, variability and limitations to utilization of agro-industrial by-products in smallholder dairy farming system.

2. Materials and Methods

2.1. Description of the Study Area

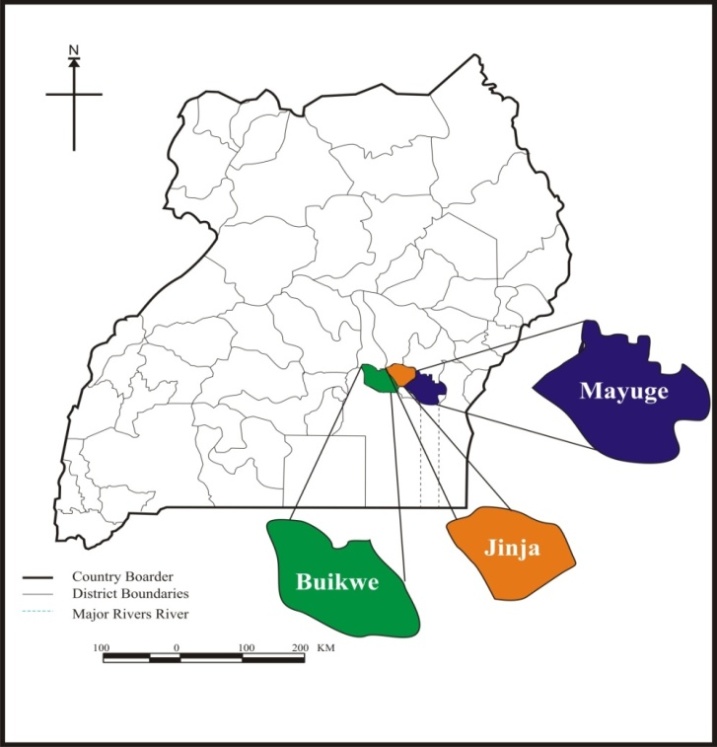

- The study was conducted in the Lake Victoria Agro-ecological Zone (LVZ) of Uganda which hosts the majority of smallholder dairy farmers [4]. Three districts namely Buikwe (0018’4.32 N and 3303’6.63 E), Jinja (0025’28 N and 33012’15 E) and Mayuge (0027’35 N and 33028’49 E) were selected for the study based on the intensity of smallholder dairy farms (Figure 1). The mean daily temperature ranged between 16-28℃, 18-28℃ and 17-27℃ for Buikwe, Jinja and Mayuge Districts respectively. The mean annual rainfall ranged between 1279 to 1544 mm, 1200 to 1500 mm and 1100 to 1500 mm for Jinja, Mayuge and Buikwe, respectively. The districts experienced tropical climate bimodal rainfall pattern characterized by two rainy seasons (March to May and September to November) with dry spells (December to February and June to August). According to the Population and Housing Census of 2002, the estimated mean population density was 256, 66, and 92.55 people’s km-2 for Buikwe, Jinja and Mayuge, respectively [8]. Agriculture is the main economic activity in the zone, and the level of agricultural productivity at farm level greatly influences household’s social- economic status.

| Figure 1. Map of Uganda showing the location of Buikwe, Jinja and Mayuge districts |

2.2. Sampling Procedure, Sample Size, Data Collection and Analysis

- A purposive multi-stage sampling design was employed in this study. In the first stage, the country was stratified into ten (10) strata (Agro-ecological Zones) on the basis of geographical demarcations. In the second stage, one out of the ten agro-ecological zones was purposively selected. In the third stage, three administrative districts were randomly selected as domain of analysis from the agro-ecological zone. In the fourth stage, three sub-counties per district were randomly selected, in the fifth stage three parishes per sub-county were randomly selected and a list of smallholder dairy farmers was developed per parish from respective extension officers in these three administrative districts. Finally, 7% of the farmers were randomly selected, 126 smallholder dairy households were interviewed across the agro-ecological zone. Primary data were collected through structured and semi- structured questionnaires administered by way of one-on-one direct interviews. Focus group discussions (one per sub-county) were also held to corroborate the information gathered in direct interviews. Secondary data were collected from document reviews at the district headquarters.In order to establish differences among farmers’ ranking on utilization, variability and limitations to utilization of agro-industrial by-products, farmers’ ranking were pooled and subjected to nonparametric statistics analysis (Kruskal–Wallis one-way analysis of variance) using [9]. Using multiple pair-wise comparisons, the computed mean of ranks were used to establish if there were significant differences in utilization levels, variability, availability and limitations to utilization of agro-industrial by-products [10], [9] was used to generate descriptive statistics for the variables.

3. Results

3.1. Utilization of Agro-industrial By-products

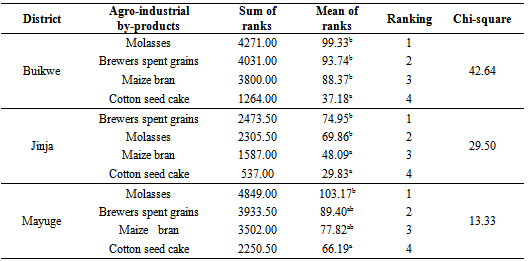

- Farmers supplement their animals with various types of agro-industrial products (Table 1). Four agro-industrial by-products were identified and ranked based on their utilization by farmers using a scale of 1 to 4 with four being the most utilized agro-industrial by-product and l the least utilized. Chi-square test at p < 0.01, df = 3 showed a significant differences among farmers’ ranking on utilization of agro-industrial by-products.

3.2. Factors Enhancing Utilization of Agro-industrial By-products in LVZ, Uganda

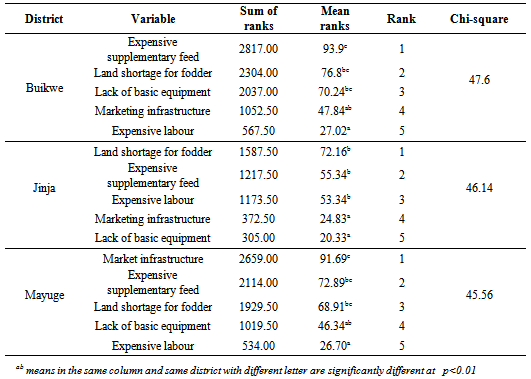

- Factors enhancing utilization of agro-industrial by-products in LVZ were ranked by farmers and analyzed. Chi-square test at p<0.01, df = 4 showed significant differences among the farmers’ rankings.

3.3. Spatial and Temporal Variability on Availability of Agro-industrial By-products

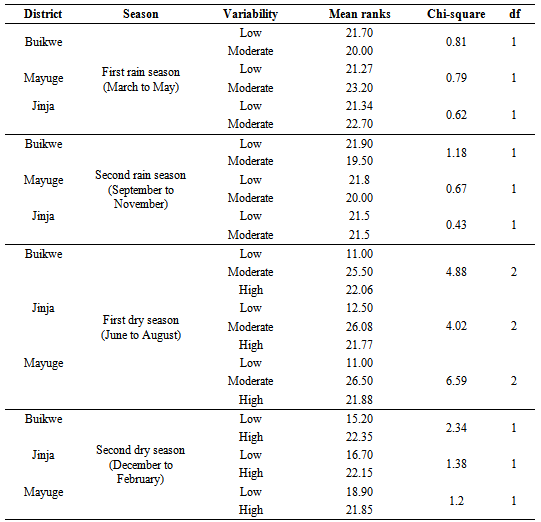

- The variability of agro-industrial by-products were ranked by farmers basing on their memory of past experience. Chi-square test at p<0.05 showed no significant difference in variability of agro-industrial by-products generally in all the seasons throughout the year across LVZ, in Uganda.

3.4. Smallholder Dairy Farmers’ Rankings of Limitations to Utilization of Agro-industrial By-products in LVZ, Uganda

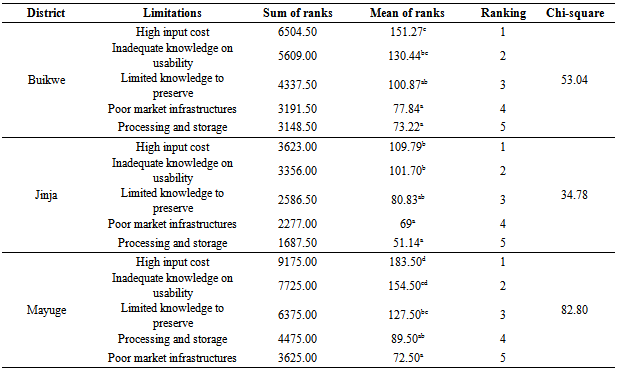

- Limiting factors to utilization of agro-industrial by-products were identified and ranked by smallholder dairy farmers as presented in Table 4. Five limiting factors were identified and ranked using a scale of 1 to 5, with 5 being the most limiting factor affecting utilization of agro-industrial by-product and 1 the least limiting factor. Chi-square test showed a significant difference at p<0.01, df = 4 among farmers rankings across the LVZ.

|

|

|

|

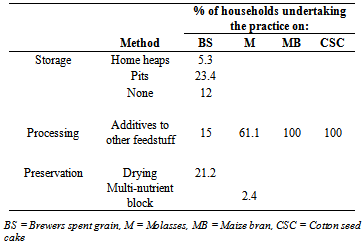

3.5. Methods Practiced by Smallholder Dairy Farmers to Store, Process and Preserve Agro-industrial By-products

- Table 5 shows the different methods used by the farmers to process and store agro-industrial by-products. While 23.4% of the farmers’ stored brewers spent grains in ground pits, 21% preserved it by drying and 12% used it directly. It was also observed that 61.1% of the farmers mixed molasses with fodder especially in dry season to improve dry matter intake, while 2.4% used it in home-made multi-nutrient block. Maize bran and cotton seed cake were utilized as additive to the basal feed.

|

4. Discussion

4.1. Utilization of Agro-industrial By-products

- The possible explanation for significant utilization of agro-industrial by-products in the study area was because of geographic comparative advantage that made most of agricultural processing industries such sugar factories, maize milling, brewery and oil manufacturing factories to be situated in this area. For this reason, smallholder dairy farmers in the study area have access to most of the agro-industrial by products. Utilization of agro-industrial by-products in LVZ is still limited to only four by-products implying that there could be some other factors limiting their integration. On the other hand, there is limited literature on utilization of agro-industrial by-products by farmers in smallholder dairy farming system in the zone in particular and generally in Uganda, unlike in other developing countries [7]. The current dairy cattle feeding regimen that heavily depends on elephant grass as the major source of nutrients to dairy cattle confirms earlier studies by [3], which indicated that elephant grass is the most dominant and more frequently used source of energy in Uganda. Such poor supplementary regime does not lend itself into good husbandry for highly yielding dairy cattle, which probably explains the low productivity in smallholder dairy farming system in LVZ, of Uganda. Although molasses was ranked number one agro-industrial by-product utilized by smallholder dairy farmer in the study area, it was reported to face stiff competition from alternative use in other cottage and commercial industries like ethanol production, local brew production and thermal power generation [1]. The potential of brewers spent grain to provide economical viable feed supplement to dairy cattle in the study area remains credible since there was no significant difference between molasses and brewers spent grain across all districts (Table 1).

4.2. Factors Enhancing Utilization of Agro-industrial By-products in LVZ, Uganda

- Most of the smallholder dairy farmers in the area of study own between 0.5 to 5 acres of land which limits them in forage production. As such, the available forage is usually deficient to meet the nutritional requirements of their animals paving way for high levels of supplementation. The smallholder farmers largely keep cross-breed animals whose response to supplementation with high value protein is significant compared to local breeds as earlier reported [11]. Given the fact that natural pastures are usually deficient in protein, it was not surprising to note that smallholder farmer whose animals depend mostly on natural pasture were supplemented with molasses, brewers spent grain, dairy meal and home-made concentrates to augment the protein and energy deficient pastures. Limited use of agro-industrial by-products to make home-made concentrates despite its high affordability by farmers was probably because the farmers had limited expertise to formulate the concentrates suggesting a need for more farmers’ training. The findings imply that in Mayuge district farmers urgently require immediate solutions on how to process home made concentrates for dairy cattle from agro-industrial by-products than any other district.

4.3. Spatial and Temporal Variability of Agro-industrial By-products

- The spatial and temporal variability of agro-industrial by-products in area of study was not significant and indicated low levels of variability in utilization. Farmers in LVZ ranked utilization of agro-industrial by-products as high in the dry seasons and slightly low in wet season. In a related study, similar relationship between utilization levels and season was earlier reported by farmers in Tanzanian western rangeland zone, Morogoro peri-urban area [12]. This is consistent with [13], who stated that peak agro-industrial by-product utilization occurs during dry season. [14] noted that periods of intense utilization of agro-industrial by-products reflect the dynamics of dairy cattle nutrient requirements. During the dry season, forages are low in essential nutrients such as nitrogen, energy, minerals and vitamins required for optimal rumen microbial growth [12]. Thus it is very important to supplement with agro-industrial by-products for supply of deficient nutrients in poor quality forage during the dry period. During focus group discussions farmers reveled that supplementing dairy cattle during dry season improves productivity in terms of milk yield and calving interval. This suggests that supplementing during dry season meets the high physiological nutrient demands for lactating animals hence improving on their productivity.

4.4. Limitation to Utilization of Agro-industrial By-products in LVZ, Uganda

- The generally high cost of inputs ranked as the main limitation across all the districts (Table 1) irrespective of season was attributed to scarcity of supplementary feeds due to limited knowledge by farmers in value addition to the abundant agro industrial by-products. Similarly, poor marketing infrastructures that limited value addition to the highly perishable milk were a bottle neck to farmers to fetch reasonable prices. Therefore, in agreement with earlier observation [2], inadequate knowledge usability, limited knowledge on preservation, unstable supply, inadequate processing and storage of agro-industrial by-products were identified as very important limitations that need urgent attention if challenges that limit dairy cattle productivity are to be eliminated. Furthermore, lack of infrastructural development such as milk coolers in the area to preserve milk which is not immediately consumed locally especially during the wet season coupled with lack of equipment to reduce on drudgery of labour was reported to negatively impact on smallholder dairy productivity. It was evident in the study that although to some extent farmers were aware of the nutritive attributes of agro-industrial by-products to dairy cattle, they did not fully exploit the resource.

4.5. Storage, Processing and Preservation of Agro-industrial By-products

- Based on storage, preservation and processing skills, farmers identified three methods of storage, two methods of preservation and two methods of processing, which were remarkably consistent with scientific methods. Such knowledge is worth documenting, promoted and where possible improved on to facilitates communication between farmers, extension staff and scientists on agro-industrial by-product utilization. The quantity and time period during which they are available, storage properties, cost of transport, preparation, and preservation are determinants for their utilization [15]. In view of the reported shortages of conventional feeds for dairy cattle, there is a need to develop technologies that are already known to farmers, using more social economic efficient scientific strategies to obtained protein and energy supplements for improved productivity.

5. Conclusions

- It was evident in the study that farmers are aware of the importance of agro-industrial by-products in dairy cattle feeding. Although a number of factors were fronted to explain variations in dairy cattle productivity, majority of smallholder dairy farmers attributed the challenges to social-economic deterioration associated with inadequate knowledge to processes, preserve and store agro-industrial by-products. Utilization of agro-industrial by-products was high during dry periods when natural pastures and forages are low. Sustainable agro-industrial by-products management strategies on smallholder dairy farm should not only target dry season, but also focus on ensuring sustainable nutrient supply for optimum productivity. Prioritizing agro-industrial by-products management strategies that enhance sustainable nutrient supply will help meet physiological nutrient demands by productive animals and thus mitigate productivity surges. It is also necessary to conduct scientific experimental investigations to establish appropriate economic inclusion levels of agro-industrial by-products. Such information would assist to guide management decisions in an attempt to maintain viable productivity equilibrium between nutrient supply and other farm input components. The study has also provided some basic information about farmers’ knowledge of the utilization and limitations of agro-industrial by-products that could aid the development and promotion of sustainable and socially acceptable feeding strategies for smallholder dairy farming system. Smallholder dairy farmers demonstrated knowledge of the importance, limitation, spatial and temporal distribution of agro-industrial by-products. The study revealed that efforts aimed at prioritizing integration of agro-industrial by-products into dairy cattle feeds in LVZ should focus on technologies of processing, preservation and storage.

ACKNOWLEDGEMENTS

- We are grateful to East African Agricultural Productivity Project (EAAPP) Uganda for funding this study. We are also thankful to the Director National Livestock Resources Research Institute for facilitating the smooth implementation of the project activities.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML