-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Frontiers in Science

p-ISSN: 2166-6083 e-ISSN: 2166-6113

2011; 1(1): 16-20

doi: 10.5923/j.fs.20110101.03

Development of Automatic Alkaloid Removal System for Dioscorea hispida

Hudzari R. M. 1, Ssomad M. A. H. A. 1, Rizuwan Y. M. 1, Asimi M. N. N. 2, Abdullah A. B. C 3

1Faculty of Agriculture and Biotechnology

2Faculty of Innovative Design and Technology

3Faculty of Food Technology, Universiti Sultan Zainal Abidin (UniSZA), 21300, Gong Badak, Kuala Terengganu, Terengganu, Malaysia

Correspondence to: Hudzari R. M. , Faculty of Agriculture and Biotechnology.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Dioscorea hispida (D.hispida) is a poisonous plant which their tuber contains toxic poison and can be consumed after the poison or dioscorine is removed. The tubers were peeled, sliced and soaked in flowing water (river) up to 7 days during traditionally detoxified process. Due to the traditional processing methods for removal of dioscorine is difficult to practice, we develop two types of equipment (wavy and spin) based on their water circulation operations. This project consisted the stages of design, fabricate and testing for the development of stand alone dioscorine removal equipment. Survival of Cyprinus carpio fish in slicing tuber of D.hispida extraction was used as a tool for detection of dioscorine removal. Results indicate that water circulation of spin operation was more effective compared to wavy type based on their capability of increasing pH activity and survival of fish as in D.hispida tuber during 6 hours of detoxified process. Therefore, this unique equipment can reduce the preparation time and also handling process of detoxified D.hispida thus making it to be more hygienic as compared to the traditional method in which river is used as a medium for dioscorine removal. The manual operation for water inlet and outlet for dioscorine removal system will replace for automatic operation by using On / Off solenoid valve while the Peripheral Interface Controller (PIC) is use for controlling input and output signal from sensor, solenoid valve and motor pump. Conceptually, the system will enhance with automatic timer which will pour out the dirty water and refill new water from inlet automatically.D.hispida which entitle Ubi Gadong in Malaysia is a poisonous plant where methodical studies have shown that its rhizome contains toxic poison. It can only be consumed as a food after the poison of dioscorin is removed. Approximately, over 600 Dioscorea species are consumed in various parts of the world (Agbo and Treche, 1995). These edible starchy tubers are important for cultural, economic and nutritional aspects in tropical and subtropical region (Salam, 1990). D.hispida is a wild tuber species and commonly found in secondary forest (Hahn, 1995). The common names of D.hispida in Malaysia include Gadog, Gadong, Gadong lilin, Gadung mabuk, Gadung, Ubi akas, Ubi arak, Taring pelanduk and Sulur gadung (Nashriyah et al., 2010). These tubers are known to be consumed by people especially during rainy season in lean period. The consumption of raw tuber can be harmful since it contains of toxic alkaloids (Tattiyakul and Naksriarporn, 2010). Traditionally, it takes for up to 7 day of soaking D.hispida tubers in flowing water for detoxified process before it safe for human consumption (Udensi et al., 2008; Hudzari et al., 2011a).

Keywords: Dioscorea hispida, Alkaloid, Dioscorine, Agriculture Mechanization, Automation Technology

Cite this paper: Hudzari R. M. , Ssomad M. A. H. A. , Rizuwan Y. M. , Asimi M. N. N. , Abdullah A. B. C , "Development of Automatic Alkaloid Removal System for Dioscorea hispida", Frontiers in Science, Vol. 1 No. 1, 2011, pp. 16-20. doi: 10.5923/j.fs.20110101.03.

Article Outline

1. Introduction

- Agriculture is the backbone of human civilization. It evolved with human history whereas in the righteous book; Al-Quran there are verses of agriculture significance invariably in many societies agriculture integrates into various socio-religious practices. Refer to Imam Nawawi on Kitab Sahih, the best work or effort for the human being is agriculture.In Malaysia, agriculture was, and is always an important government agenda to ensure the country’s food security for all the people.Because of traditional detoxified methods is difficult to practice, we develop two different types of equipment (wavy and spin) based on their water circulation operations. The application of this equipment based on Bernoulli’s principle as in equation (1) where increase in the speed of a fluid produces a decrease in pressure and a decrease in the speed produces an increase in pressure. A common form of Bernoulli's equation, valid at any arbitrary point along a streamline where gravity is constant, is (Mulley, 2004):where:

is the fluid flow speed at a point on a streamline,

is the fluid flow speed at a point on a streamline, is the acceleration due to gravity,

is the acceleration due to gravity, is the elevation of the point above a reference plane, with the positive z-direction pointing upward – so in the direction opposite to the gravitational acceleration,

is the elevation of the point above a reference plane, with the positive z-direction pointing upward – so in the direction opposite to the gravitational acceleration, is the pressure at the chosen point, and

is the pressure at the chosen point, and is the density of the fluid at all points in the fluid.Besides that the kinetic energy of water can also produce the spin and wave movement. Therefore, the objectives of the study were to develop new dioscorine detoxified equipment by enhancing the quality and time of detoxified process compared to the traditionally detoxified method.

is the density of the fluid at all points in the fluid.Besides that the kinetic energy of water can also produce the spin and wave movement. Therefore, the objectives of the study were to develop new dioscorine detoxified equipment by enhancing the quality and time of detoxified process compared to the traditionally detoxified method.2. Material and Methods

2.1. Stand Alone Dioscorine Removal Equipment (Wavy Type of Water Circulation Operation)

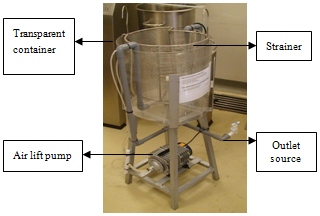

- Figure 1 show the equipment that was developed to enhance traditionally detoxified method is based on wavy types of water circulation operation. This equipment consists of transparent container, air lift pump, strainer and piping system. Inside the transparent container, the piping systems which include two input pipes were placed opposite each. The air flow from the air lift pump (Electromagnetic air pump) with a power of 120 watts will be passed through the pipe and move to the bottom of the container in order to more oscillate the sliced tuber. The strainer was used to prevent slices of D.hispida tuber from moving out through the output pipe or stuck in the pipe. This equipment includes an output pipe which used to remove out the water which contained toxic alkaloid (dioscorine) from the transparent container. The advancement of technology should introduce in most important area; agriculture, as for benefit of mankind. The farm mechanization for ubi gadong is help to produce the good quality and output in this new exploration of wildlife food for commercialization (Hudzari et al., 2011b).

| Figure 1. Stand alone dioscorine removal equipment (wavy type of water circulation) part |

2.2. Stand Alone Dioscorine Removal Equipment (Spin Type of Water Circulation Operation)

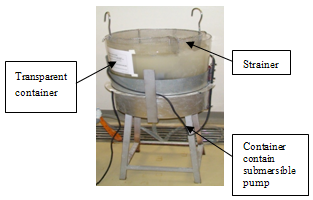

- Figure 2 show the second equipment we developed to enhance traditionally detoxified method is based on spin types of water circulation operation. This equipment used air lift submersible pump (Multi system pond pump) to produce water circulation. This pump produce 230 watt of power, 7.0 meter of maximum high and 16000 L/ hr of flow rate. Inside the transparent container, an input pipe was placed at the bottom to produce spin type of water circulation. The air flow from this pump can make movement of slices tuber of D.hispida circulates around the system. The tubers are washed by using replacement of water to remove the dioscorine alkaloid. The vortex water circulation moved the sliced tubers up and down.

| Figure 2. Stand alone dioscorine removal equipment (spin type of water circulation) part |

2.3. Removal of Dioscorine in D.hispida Slices Tuber by Using Wavy and Spin Types of Water Circulation Equipment

- Two ± 0.5 kg of slices D.hispida tuber (0.3 cm of thickness, 1.5x1.5x1 cm) were detoxified with 26.5 liter and 40.0 liter of water in wavy and spin types of water circulation equipment respectively. The mixture was homogenized and soaked for 6 hours, during which time the water was changed on every 60 minutes. The mixtures were then filtered using colander. The pH activity of residual D.hispida detoxified tuber was measured every 0, 2, 4 and 6 hour of processing fine. For the residue, 5 ± 0.1 g of sample was homogenized using Weddgen Houser homogenizer () and mixed with 50 ml of distilled water. The mixture was homogenized and stirred for 5 minutes before filtered with muslin cloth and Whatman filter paper. Then, the mixture was centrifuged for 10 minutes at 9500 rpm. The supernatant was used for the fish lethality assay using Cyprinus carpio fish. Each Cyprinus carpio fish was placed in small container which contained 20 ml of supernatant sample. The survival of fish was observed every 60 minutes for 24 hour exposure. Fish was considered dead if they did not show any movement during several seconds of observation.

3. Results and Discussion

3.1. Development for Automatic System

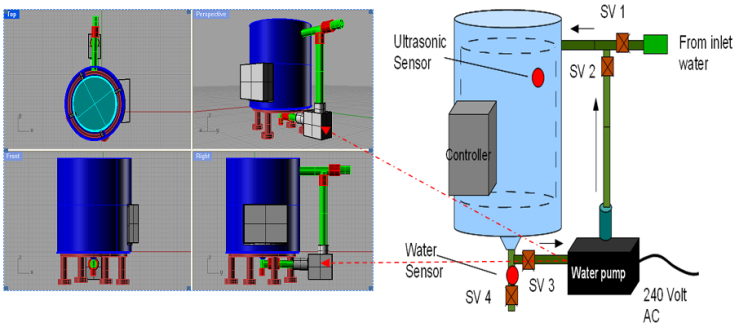

- The manual water inlet and outlet for wavy type operation as shown in Figure 1 and 2 can replace for automatic operation using On / Off solenoid valve while the Peripheral Interface Controller (PIC) are use for controlling input and output signal from sensor, solenoid valve and motor pump. The system will propose to have automatic timer which will pour out the dirty water and refill new water from inlet on each 2 hours operation as shown in figure 3. As in figure 3, the water pump will put at the outside tank to avoid the increase of temperature in water on tank. The bottom of the tank will be modifying to make sure all the water flow out from the tank without any leakage.

| Figure 3. Conceptual design and modeling of automatic controller for dioscrine removal system |

3.2. Electronic Components

- The electronic componet of circuit breaker would install to cut off the water pump supply during operation. Figure 4 show the PIC Circuit and the driver circuit that used for solenoid valve and water pump to be use in this prototype. Ishak et al., (2011a) and Ishak et al., (2011b) use the same concept of computer automation for controlling the positioning of agriculture mechanism device which will be use for this alkaloid removal system.

| Figure 4. Controller and driver circuit for to be use in this prototype |

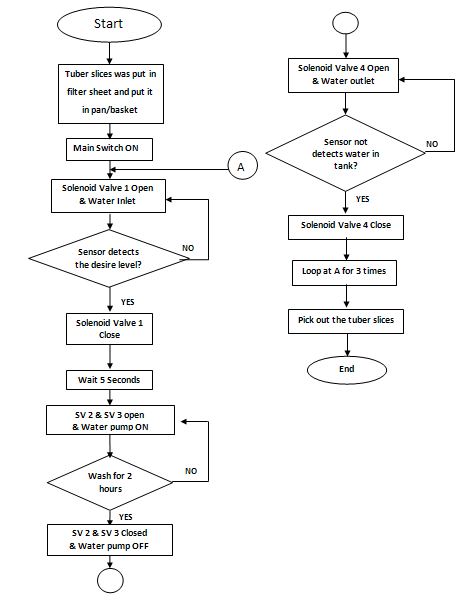

3.3. System Process Flow

- Figure 5 show the flowchart for the process development of automatic dioscorine removal system. A few (kg) of slices D.hispida will put in the pan/basket. The basket then insert to the wash tank. The Solenoid valve 1 was open while Solenoid valve (SV) 2, 3 and 4 are closed. The water inlet to the wash tank will stop when the ultrasonic sensor detect the desire level of water then the SV1 is closed. After 5 seconds the SV2 and SV3 open, the water pump is ON. The concept of waterways will used where the water from the wash tank is pump in by water pump at the bottom side then pump out at the upper side. The process will operate for 2 hours. After 2 hours, the PIC (Peripheral Interface Controller) will send the command to water pump to switch OFF. The Solenoid valve 2 and 3 closed while solenoid 4 is open. The toxic water flow out thru the pipe out at the bottom side of tank. The water sensor is used to detect the water in the tank. If the sensor detects no water, SV4 will be closed. Then the process will repeat for four times of 8 hours.

| Figure 5. Reconstruction of flowchart for the process development of automatic dioscorine removal system |

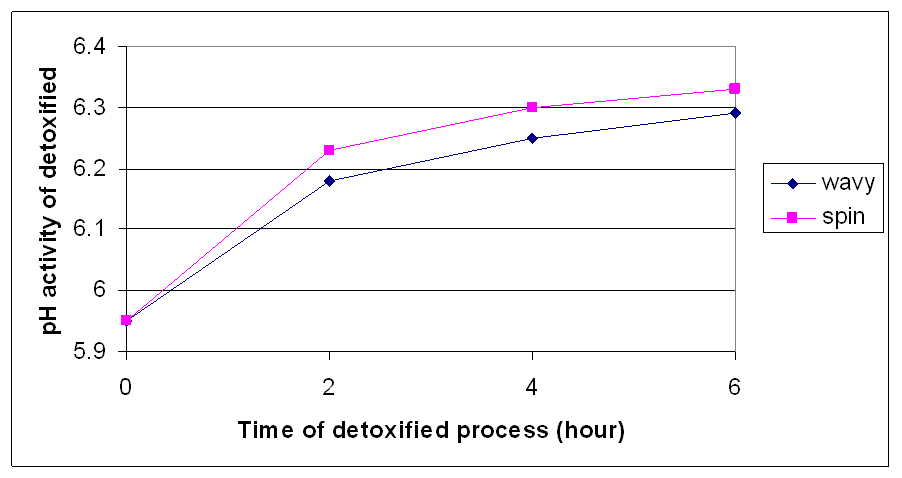

3.4. Dioscorine Removal Efficiency

- As shown in figure 6, the pH value of D.hispida increase in all types of removal dioscorine equipment including wavy and spin types of water circulation. Increasing pH activity of D.hispida slices tuber increase with time of detoxified process. For instance, the pH activity of spin type water circulation increase at initial stages with 5.95 to 6.23 at 2 hours of detoxified process. And it slowly increases at 6.30 and 6.33 at 4 and 6 hour of detoxified process respectively. These indicate that extraction process of dioscorine occurred and it was removed from D.hispida slices tubers make it become low level of acidity. This might be due to volume of water during detoxified process and different types of pump power used in those equipments.

| Figure 6. pH activity of slices tuber of D.hispida during detoxified process |

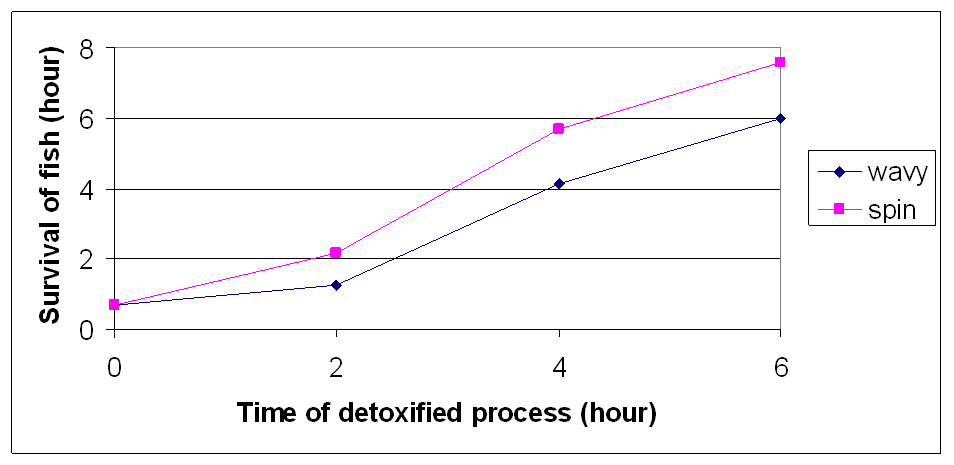

| Figure 7. Time for survival of fish during detoxified process |

4. Conclusions

- Water circulation of spin operation in dioscorine removal equipment is the more effective as compared to wavy and spin. The usage of powerful pump motor and movement of D.hispida slices up and down caused of dioscorine become easily to remove at the short time of processing. Therefore, this unique device can reduce times of preparation for D.hispida compare to traditional method which is used river as a medium for removal of dioscorine. The development of food product from D.hispida via this technology and future work makes it safe to consume by people. Moreover, soaked water of D.hispida which contain dioscorine can be reused for other invention such as in application of pesticides.

ACKNOWLEDGMENTS

- The authors would like to thank all staff from Faculty of Food Technology and Faculty of Innovative Design and Technology, Universiti Sultan Zainal Abidin and the Unit Perancangan Ekonomi Negeri (UPEN), Terengganu, Malaysia for their valuable assisting, financing the project and for the laboratory facilities.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML