-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2020; 10(4): 88-96

doi:10.5923/j.fph.20201004.02

Received: Sep. 16, 2020; Accepted: Oct. 15, 2020; Published: Nov. 15, 2020

Influence of Inulin and Pumpkin Powder Addition on Sensory and Rheological Properties of Low-Fat Probiotic Yogurt

Al-Zahraa Mohamed Darwish

Dairy Science and Technology Department, Faculty of Agriculture, Assiut University, Egypt

Correspondence to: Al-Zahraa Mohamed Darwish, Dairy Science and Technology Department, Faculty of Agriculture, Assiut University, Egypt.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Pumpkin (Cucurbita sp.) is a natural ingredient with health benefits because of its rich contents of vitamins (A, B1, B2 and C) minerals (K, P, Mg, Fe and Se), β‐carotene, pectin and dietary fiber. In this study, low-fat probiotic yogurt samples enriched with pumpkin powder (1% YPP1, 3% YPP2 and 5% YPP3) and inulin (1%) were produced to achieve the potential health benefits of pumpkin and inulin. Results showed that the addition of pumpkin powder and inulin slightly increased acidity and increased viscosity of low-fat probiotic yogurts with increasing pumpkin powder and during cold storage period. Also, addition pumpkin powder and inulin was improved the survival of yoghurt cultural and Bifidobacterium lactis Bb-12 to 7.28 log cfu g−1 YPP2 comparison with plain (-) yogurt 6.33 log cfu g−1 after 14 days of storage period. The sensory evaluation revealed that there was statistically significant difference (P ≤ 0.05) between yoghurt with addition pumpkin powder and plain (-) yoghurt especially in color and flavor. So, according to present results addition of inulin and pumpkin powder can be used as a fat replacement to improve the texture profile analysis during the cold storage period, and to increase the yoghurt shelf life of low-fat yoghurt. Also, the addition of powder pumpkin (3%) and inulin (1%) to low- fat probiotic yogurts could be an alternative to incorporate the fat and texture improvers in dairy products. Therefore, adding pumpkin (3%) and inulin (1%) to low-fat yogurt is an alternative to adding artificial texture improvers and fat alternatives to low-fat probiotic yogurt as a new functional dairy food.

Keywords: Pumpkin powder, Inulin, Probiotic, Low-fat yoghurt, Rheology, Sensory evaluation

Cite this paper: Al-Zahraa Mohamed Darwish, Influence of Inulin and Pumpkin Powder Addition on Sensory and Rheological Properties of Low-Fat Probiotic Yogurt, Food and Public Health, Vol. 10 No. 4, 2020, pp. 88-96. doi: 10.5923/j.fph.20201004.02.

Article Outline

1. Introduction

- In Egypt, yoghurt is one of most popular products for all ages. Sometimes, the manufacturers used to add synthetic color and artificial texture improvers to provide the color, texture and taste of low-fat probiotic yoghurts. Yoghurt is produced by milk fermentation with a mixture of lactic acid bacteria (LAB). Quality and sensory acceptance of manufactured yoghurt ensured its physical properties like perceived viscosity and lack of visible wheying-off [1]. Rheologically, yoghurt is a viscoelastic, pseudoplastic fluid which exhibits highly time-dependent shear thinning in flow [2]. Vegetables present a valuable source of nutrients and are also low in calories. They are rich in dietary fiber, minerals as well as many bioactive compounds, such as antioxidants, e.g. carotenoids, ascorbic acid, tocopherols, phenolic substances [3]. The therapeutic and prophylactic effect of cultured dairy products containing vegetable and fruit powders (beetroot, carrot, pumpkin, marrow and apple) for patients with gastrointestinal disorders was reported by Arkhipova, Krasnikova [4]. Pumpkins are a good source of carotenoids, mineral salts, vitamins, and other bioactive substances, such as phenol compounds [5]. Pumpkin is one of the well-known edible plants and has substantial medicinal properties due to the presence of alkaloids, flavonoids, and palmitic, oleic and linoleic acids [6]. Processed pumpkin into flour can be used in products as wheat-pumpkin composite flour blend for fiber enrichment and other functional purposes [7]. Fiber can give texture, gelling, thickening, stabilizing, and emulsifying effects on certain foods [8]. As well high dietary fiber intake regulates promotes the level of serum insulin, provides protection against diseases such as diabetes, cardiovascular disease, constipation, and colon cancer [9,10]. Fortification of dairy products with dietary fiber is of increasing interest in creating functional foods with health benefits and improving their initial functionality [11]. The fruit and vegetable fibers can improve the fatty acid profile of probiotic yoghurts and point out the suitability of using fruit and vegetable fibers to develop new high value-added fermented dairy products [12]. Inulin is used as a low-calorie sweetener and a nondigestible fiber to form gels, increase viscosity and improve organoleptic attributes in the food industry. In dairy products, it is mostly used as sugar and fat replacer and as a prebiotic [13] For example, inulin is used as fat replacer and texture modifier in low-fat dietary yoghurt to enhance the textural and sensory properties of the final product due to its functional characteristics [14]. Yoghurt containing inulin had a stable color and water activity and syneresis did not prevail during storage [15]. The aim of this study, it was investigated that the effect of supplementation yogurt with pumpkin powder at different levels (1% (YPP1), 3% (YPP2), 5% (YPP3)) and 1% inulin as a low-calorie sweetener, fat replacer and prebiotic for probiotic bacteria.

2. Materials and Methods

2.1. Materials

- Skim caws milk was obtained from Assiut University herd. Pumpkin was purchased from the local market. Thermophilus yoghurt culture (Sreptococcus salivarious ssp. thermophilus and Lactobacillus delbrueckii ssp. bulgaricus) in the form of freeze dried-direct Vat set (FD-DVS) was obtained from Rodia food, France, Bifidobacterium lactis Bb-12 was obtained from Chr. Hanseh's' Laboratories, Copenhagen, Denmark. Chemicals used were obtained from Sigma-Aldrich Chemie, Steinheim, Germany, Sigma Chemical Co. St. Louis USA. The inulin used was that of Hopkin and Williams Ltd were used.

2.2. Methods

2.2.1. Preparation of Pumpkin Powder

- Fresh pumpkin was washed, manually peeled and seeds were removed. The pulp was cut into small slics and dried at 60°C in the laboratory drying oven. Dried slices of pumpkins were grinded using the grinder (DeLonghi Grinder, 110 w made in Chania). The dried pumpkin was sieved through cotton gauze pads to produce flours, which was kept chilled in an air-tight container.

2.2.2. Experimental Procedure

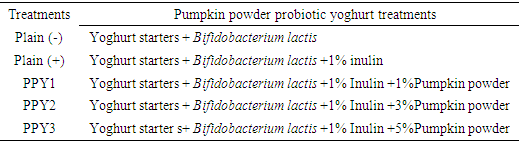

- After preliminary experiments, the appropriate concentration of pumpkin powder was 1%, 3% and 5% (w/w) the most preferred color, taste and texture to consumers. Preparation of plain and pumpkin powder yoghurt from cow's milk (lactose 4.6%, protein 3.3%, fat 0.8%. Total solids 12.5%. and acidity 0.18%). The amount of six kg of milk was divided into five equal portions. The first portion was kept without addition of pumpkin powder and inulin as a control sample (Plain (-)). The second portion was added 1% inulin (Plain (+)). The inulin 1% and pumpkin powder were added to the rest of three portions of cow's milk at 1% (PPY1), 3% (PPY2) and 5% (PPY3) pumpkin powder (Table 1). The percentage of inulin was 1% according to Srisuvor, Chinprahast [14] which suggested that additive of 1% inulin is suitable amount to have low- fat yoghurt. All samples were heated up to 90°C for 15 min. then cooled to 42°C and inoculated with 2% yoghurt culture (Sreptococcus salivarious ssp. thermophilus and Lactobacillus delbrueckii ssp. bulgaricus) and 2% Bifidobacterium lactis Bb-12 culture. Yoghurt was picketed in 100g plastic cups and incubated at 42±2°C for 4 h, then transferred to refrigerator at 6±1°C to be kept for 14 days for chemically, rheologically, microbiology and sensory evaluation analysis.

|

2.2.3. pH Value

- pH value was measured by a digital pH meter (Wissenschaftlich- technische Werkstätten weilheim, Germany). Acidity, total solids, fat and protein percentage was determined according to Horwitz and Latimer [16].

2.2.4. Viscosity

- Viscosity was measured at room temperature using a Brookfiled digital viscometer (Middleboro, MA 02346, USA). The sample was subjected shear rates ranging from 3-100 S-4 for an upward curve. Viscosity measurements were expressed as centipoise (cP.s) and were performed in triplicate [17,18].

2.2.5. Texture Profile Analysis

- Texture measurements were carried out with universal testing machine (Cometech, B type, Taiwan). Provided with software 35 mm diameter compression disc was used. Two cycles were applied, at a constant crosshead velocity of 1 mm/s, to 40% of sample depth, then returned. From the resulting force–time curve, the values for texture attributes, i.e. Firmness (N), gumminess (N), chewiness (N), cohesiveness, springiness and resilience were calculated from the TPA graphic [19].

2.2.6. Color Measurements

- The color of yoghurt samples was measured using a Hunter Lab, Easy MatchQC according to Abonyi, Feng [20]. The Hunter L*, a*, and b* values correspond to lightness, redness (+a), and yellowness (+b), respectively. Hue angle (H value: Eq. (1)), and chroma (C value: Eq. (2)) were calculated using Hunter L, a, and b values. (1) H value = arctan (b/ a) (2)

2.2.7. Microbiological Analysis

- Sreptococcus thermophilus count was enumerated using M17 ager Terzaghi and Sandine [21]. Count of Lactobacillus bulgaricus was determined using MRS ager/broth as reported by Dave and Shah [22], while count of Bifidobacterium lactis Bb-12 was determinate according to Vinderola, Bailo [23].

2.2.8. Sensory Evaluation

- The tests were conducted in laboratory conditions with 15 consumers randomly recruited. They were between 19–55 years of age with,7 males and 8 females. Consumers using a sensory rating scale of 1 (poor) to 10 (excellent) for some sensory parameters (the color, odor, texture, flavor and overall acceptability). Samples were placed on white plates and identified with random numbers. Panelists evaluated the samples in a testing area and were instructed to rinse their mouths with water between samples to minimize any residual effect [24].

2.2.9. Statistical Analysis

- Data obtained from analysis of the samples was evaluated statistically using analysis of variances (ANOVA) and the differences among means were compared using the Duncan’s multiple range tests (using SPSS statistical software program version 13 (SPSS Inc., Chicago, IL). The statistical significance was determined at level of P ≤ 0.05.

3. Results and Discussion

3.1. Chemical and Rheological Properties

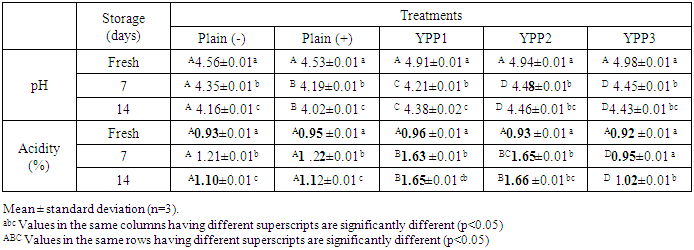

3.1.1. pH Value and Titratable

- pH value and titratable acidity of yoghurt samples with different amounts of pumpkin powder to yoghurt and after the different storage days, the results were shown in (Table 2). Despite the influence of inulin on a chemical attribute of products, it is found that it has no remarkable effect on acidity and pH values in yoghurt [25-27]. Addition of pumpkin powder lead to increase the pH value in fresh yoghurt samples after that pH value was significantly decreased (P ≤0.05) during the storage period vice versa for titratable acidity. The increase of pH levels in pumpkin probiotic yoghurts with added pumpkin powder, maybe due to the presence of several protein-pound polysaccharides in the pumpkin [28] which may increase its viscosity and cause coagulation at higher pH. The percentage of added pumpkin flour increased the pH of yoghurts decreases which confirms their stimulation effect on starter microorganisms and Bifidobacterium lactis Bb 12 [29].

|

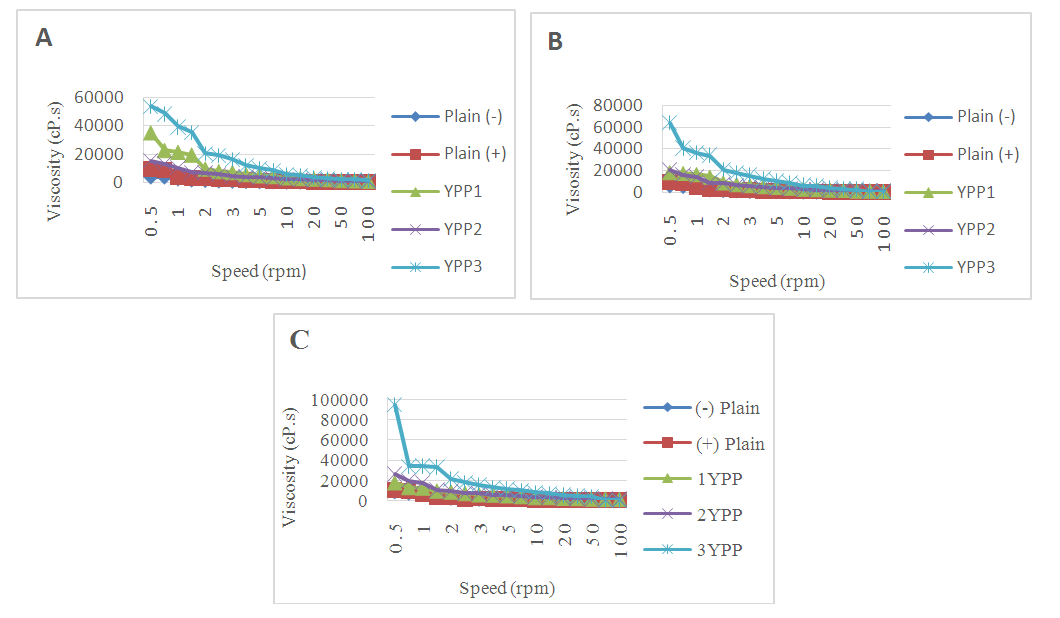

3.1.2. Viscosity

- Viscosity can be affected by the processing methods, type of starter cultures, heat treatment, and formulation composition [30]. The results in Fig.1 show that addition of pumpkin powder significantly increased the viscosity of the yoghurt after fourteen days of cold storage. As can be seen Fig. (1) the viscosity trend in all yogurts shows the following order: YPP3 > YPP2 > YPP1 > Plain (+)> Plain (-). The highest viscosity recorded for addition pumpkin powder may be due to the presence of stabilizer agents (dietary fibers) in pumpkin which has the ability to bind water tending to increase the consistency of the products by increasing the water-binding capacity [28] which leading to the formation of viscous gels and consequently promoting higher viscosities [31,32].

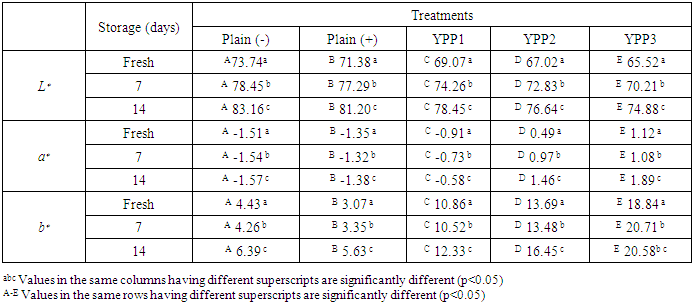

3.1.3. Color Properties

- Products acceptance and preference are functions of product quality. Color is the first sensory characteristic perceived by the consumer and color tends to modify other perceptions such as flavor and aroma [9]. Pumpkin provides a valuable source of β-carotene [33] so added to the yogurt samples had a strong effect on the color properties .Value of L* indicating brightness added powder pumpkin it shows a tendency to decrease significantly as the amount added increases (P<0.05), and tends to increase gradually as the storage period increases. (P<0.05). For a value a*, the value of foliage or redness in yogurt samples increase significantly as the amount of pumpkin powder added increased. (P<0.05) and gradually increases as the storage period increases. The trend was shown (P<0.05). The pumpkin had the distinction of own yellow color in yogurt. So, the yellow value of b* is also determined and it showed a tendency to gradually increase as the amount of powder pumpkin added increased. Gradually, the brightness of yogurt increases as the amount of pumpkin powder increases. Redness and yellowness increased as the amount of added pumpkin powder increased. it is believed to be due to the contained carotenoids-based pigment. [33]. The color properties (L*, a*, b*) of yogurt samples changed [34]. It was also pointed out that the color properties of yogurt were influenced by the pH [35].

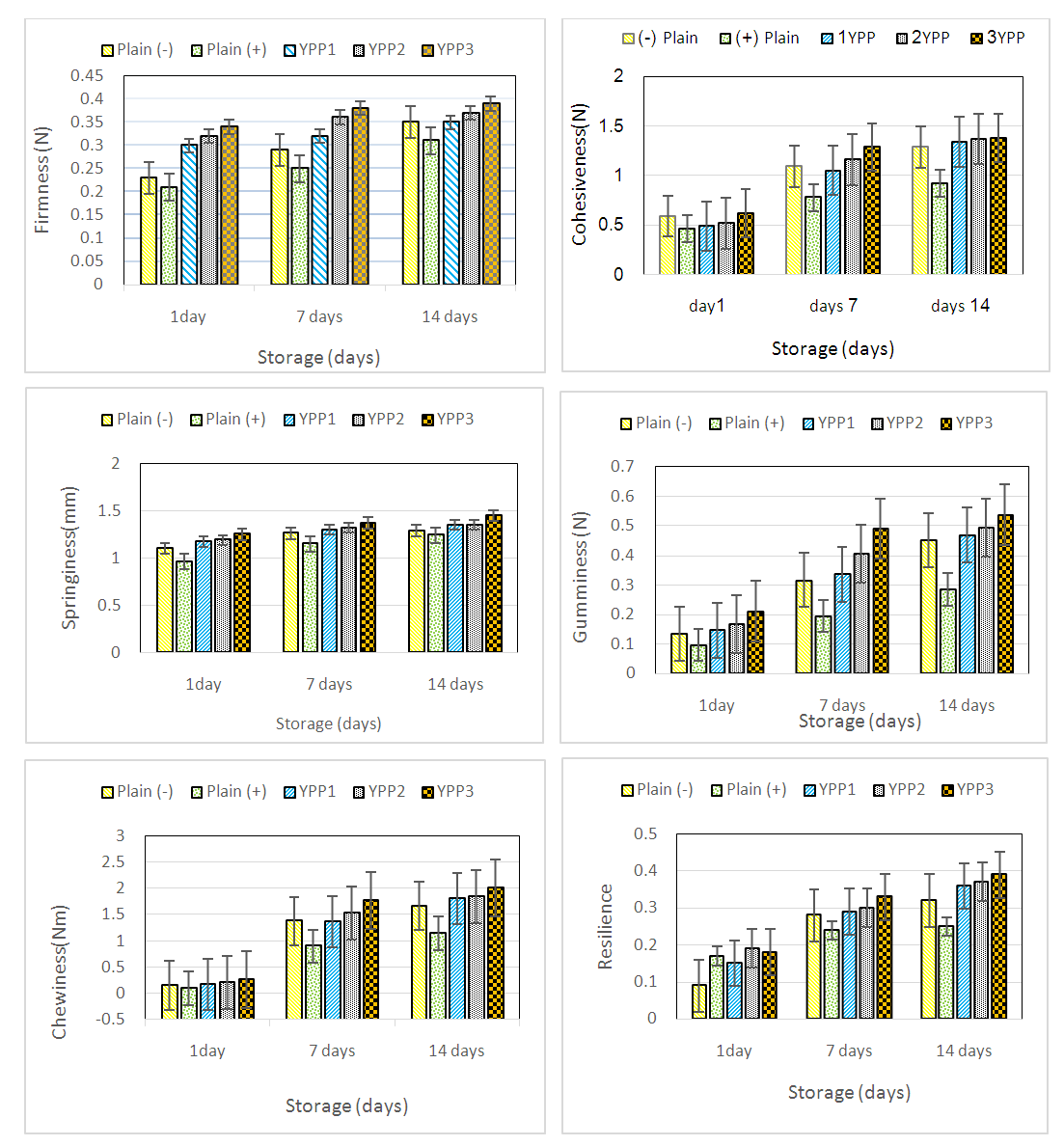

3.1.4. Texture Profile Analysis (TPA)

- Texture profile analysis (TPA) imitates the conditions in the mouth by twice compressing a product [36]. The TPA of probiotic yoghurt were analyzed for the various treatments and during the storage period the results shown in Fig (2). The results represent firmness, cohesiveness, springiness, gumminess, chewiness, and resilience respectively. Firmness is defined as a force that needs to be applied in order to ensure a certain deformation in the composition of foods. Firmness is a parameter that plays a key role in determining the quality of yoghurt [37,38]. Maximum firmness was observed in the YPP1, YPP2 and YPP3 samples, and the plain (-) and plain (+) samples had the lowest firmness, (Table 3). All the parameters increased significantly as the percentage of pumpkin powder increased. The firmness of yogurt depends on the total solid content of the milk mixture [39] In this case, pumpkin powder addition increased the total solids of yogurt by 1, 3 and 5% (w/w), resulting in higher firmness compared to the control. These results are agreement with Sodini, Remeuf [40] who reported that long periods of storage affect some textural properties like firmness and mention that it may result from an increase in acidity and casein hydration. Cohesiveness evaluates the extent of deformability of material before it is ruptured and is directly related to internal strength of the material structure [41]. The values of cohesiveness increase in the yogurts containing pumpkin powder compared with control, this may be ascribed to the high viscosity contributed pumpkin powder. No significant differences were obtained for springiness values of yoghurt containing different concentration of pumpkin powder and the plain (-) and plain (+) samples. Increase in gumminess was also reported for yoghurt samples with increase in the amounts of pumpkin powder. Increase in gumminess and chewiness were observed, which might be due to increased hardness of the yoghurt samples [42]. Resilience as a parameter of texture profile analysis, increased in yoghurt containing different concentration of pumpkin powder compared with the plain (-) and plain (+) samples. The reasons for these changes may be due to the interaction between presence of a mixed gel of inulin and casein [42], and the presence of several protein-pound polysaccharides in the pumpkin [28], as in case of yoghurt. On an average, results of textural profile tests showed yoghurt samples containing pumpkin powder YPP1, YPP2 and YPP3 with 1% inulin giving firm and creamy texture that improved the mouth feel characteristics thereby enhanced sensory appeal for the product in which incorporated.

|

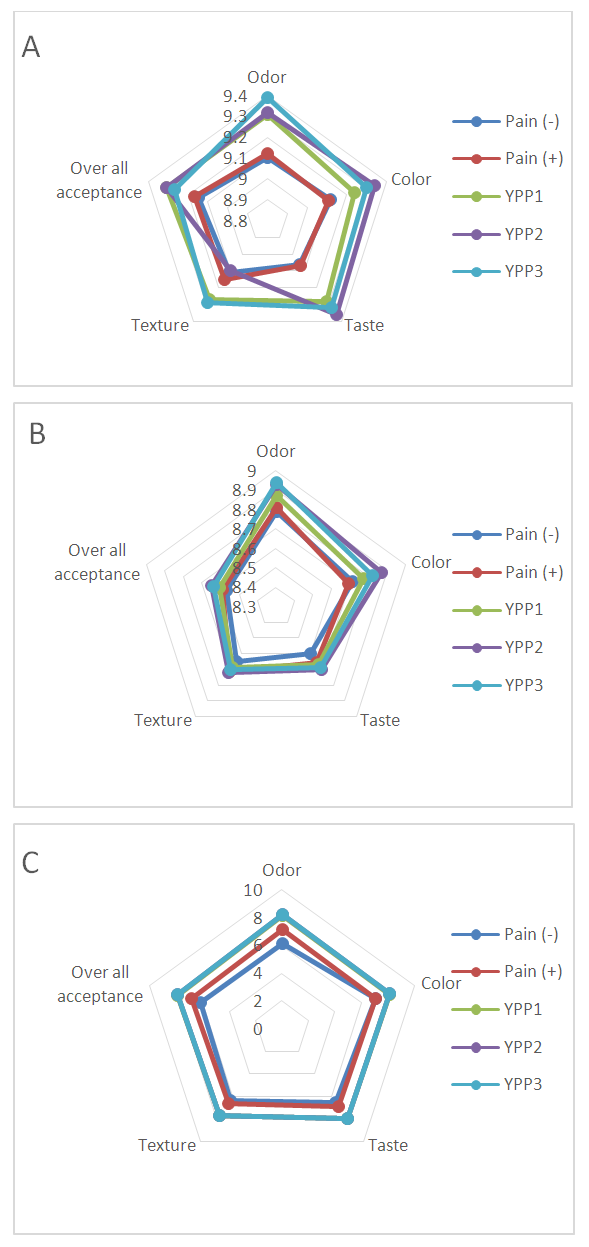

3.2. Sensory Evaluation

- Fig.3 presents the results of sensory evaluation of plain (-), plain (+) YPP1, YPP2 and YPP3 samples of yogurts after 14 days of cold storage. Generally, there were significant differences (p ≤ 0.05) among treatments for odor, color, taste, texture and overall acceptability of sensory evaluation during storage. The present data showed that the addition of inulin 1% improved the taste and texture of low-fat probiotic yoghurt. Inulin has been used as a fat replacer in low-fat yoghurt where it was found to considerably improve mouthfeel, smoothness and creaminess [43]. The textural parameters of the low-fat synbiotic yoghurt containing 1% inulin were similar to those of the full-fat probiotic yoghurt [44,45]. Also, addition of powder pumpkin powder improved the odor, color, taste, texture and overall acceptability of low-fat probiotic yoghurt. At day one Treatments YPP2 and YPP3 of low-fat probiotic yoghurt had the highest odor, color, taste, texture and overall acceptability than other treatments. The odor, color, taste, texture and overall acceptability of all samples decreased significantly (P ≤ 0.05) after 7 days of storage. While, after 14 days of storage there is no significantly (P ≥ 0.05) differences among YPP1, YPP2 and YPP3 samples of low-fat probiotic yoghurt. As the pumpkin powder rates increased the sensory properties scores of the low-fat probiotic yoghurt. Moreover, added powder pumpkin and inulin to low-fat probiotic yoghurt improved a lot of water binding and presence of several protein-pound polysaccharides, respectively. The addition of powder pumpkin and inulin improved the body and texture and resulted in increased the shelf life of low-fat probiotic yoghurt.

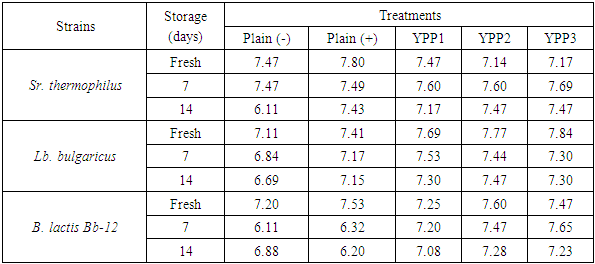

3.3. Microbiological Analyses

- The changes in microbial count of Sr. thermophilus, Lb. bulgaricus and B. lactis Bb-12 for different treatments of probiotic yoghurt during storage are shown in Table 4. The count of Sr. thermophilus, Lb. bulgaricus and B. lactis Bb-12 decreased slightly during the storage period for all probiotic yoghurt treatments. However, the counts remained at sufficient levels to have beneficial effects as a probiotic by standards (> 6 log cfu g−1) for up to 14 days. The viable counts of Sr. thermophilus, Lb. bulgaricus and B. lactis Bb-12 decreased during the storage period. The highest Sr. thermophilus, Lb. bulgaricus and B. lactis Bb-12 counts were found in probiotic yoghurt containing 1% inulin (plain(+)) compared with control. Reason for this increase in probiotic counts of yoghurt is that inulin acts as a prebiotic substance [45,47,48]. Also, It was observed that a higher addition of powder pumpkin with inulin to probiotic yoghurt leads to an enhanced in viable counts of Sr. thermophilus, Lb. bulgaricus and B. lactis Bb-12. Furthermore, the chicory-based inulin was a preferred carbon source for probiotic bacteria, thereby increasing growth performance and sustaining viability during storage [49]. One of the most important factors affecting the viability of S Sr. thermophilus, Lb. bulgaricus and B. lactis Bb-12, is acidity [22].

|

4. Conclusions

- The propose of current study is improving texture, taste and flavor to fortify of low-fat probiotic yoghurt by using inulin and powder pumpkin as an alternative adding artificial texture and fat alternatives. The results support the conclusion that the incorporation of inulin1% and pumpkin powder (1%, 3% and 5%) in low -fat probiotic yogurt formulation improved fermentation process, as the growth of the yoghurt starters culture and B. lactis Bb-12. Enriching low-fat probiotic yoghurt with inulin and pumpkin powder offered a strengthened the yoghurt's structure and increases viscosity during cold storage period. Also, pumpkin powder improved the color and texture profile analysis during the storage period and increased the probiotic yoghurt shelf life. According to our results, the addition of inulin and pumpkin powder in yogurt making process could be a promising strategy to incorporate inulin pumpkin powder instead of fat and texture enhancers to dairy foods, and thus increase the healthy properties low-fat probiotic yoghurt. Inulin and powder pumpkin important ingredient for providing new avenues for dairy product production in the development of novel dairy products.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML