-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2018; 8(4): 95-100

doi:10.5923/j.fph.20180804.03

Production and Quality Evaluation of Ikpan Cake Produce from Melon and Plantain Flour Blends

Florence A. Bello1, Aniebiet I. Ukut1, Nkereuwem N. Ekerette2

1Department of Food Science and Technology, University of Uyo, Uyo, Nigeria

2Department of Home Economics, Nutrition and Dietetics, University of Uyo, Uyo, Nigeria

Correspondence to: Florence A. Bello, Department of Food Science and Technology, University of Uyo, Uyo, Nigeria.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The study was conducted to determine the possibility of blending unripe plantain flour with melon to produce ikpan (mushroom-melon cake), a traditional cake served in some parts of Southern Nigeria. The cake was prepared by substituting melon flour with plantain flour and compared with 100% melon flour (sample A) which served as control. Five samples were formulated in ratio 90:10, 80:20, 70:30, 60:40 and 50:50 coded as B, C, D, E and F, respectively. The proximate, mineral and antinutrient contents as well as sensory properties of the cakes were investigated. The moisture, ash and carbohydrate contents of the cakes increased significantly (p<0.05) when compared with control while significant decrease was observed in crude fibre, crude protein, crude lipid and caloric value as the plantain substitution levels increased. Increases in plantain flour substitution caused an increase in all the selected mineral contents (sodium, potassium, magnesium and iron) of the cakes when compared with control except phosphorus content which decrease gradually as the level of substitution increased. Cakes produced from 50% plantain flour substitution (Sample F) had the least hydrogen cyanide, phytate and oxalate content while increase value was observed in tannin. Sensory attributes such as appearance, texture, aroma, taste, aftertaste and overall acceptability indicated that control ikpan cake was more preferred by the panelists. However, cakes made up to 40% plantain flour substitution were accepted by consumers with 10% substitution level (sample B) having the best acceptability. This leads to the conclusion that nutritionally improved with reduced antinutrients and consumer acceptable ikpan cake can be prepared by substituting up to 10% plantain flour with 90% melon flour.

Keywords: Cakes, Fibre, Composite, Level, Acceptability, Substitution, Sensory

Cite this paper: Florence A. Bello, Aniebiet I. Ukut, Nkereuwem N. Ekerette, Production and Quality Evaluation of Ikpan Cake Produce from Melon and Plantain Flour Blends, Food and Public Health, Vol. 8 No. 4, 2018, pp. 95-100. doi: 10.5923/j.fph.20180804.03.

Article Outline

1. Introduction

- Ikpan is a traditional snack locally made from fermented sclerotium of Pleurotus tuber-regium and melon [1]. It is a traditional ceremonial diet served in some parts of Southern Nigeria [2]. Pleurotus tuber-regium is a tropical sclerotial mushroom which produces the edible sclerotium or the tuber as well as a mushroom. The dried sclerotium is called isuo in Ibibio [1]. The cake is known by different names in different ethnic groups. It is known as Mgbam in Ikwerre and ikpan in Ibibio and Annang in South-South Nigeria [2-4].Melon is any of the various plants of the family cucurbitaceae with sweet edible, fleshy fruit and the word is derived from Latin word “melopepo”. Many species of melon are found, but they belong to four genera: Momordica, Benin casa, Citrullus and Cucumis. Melon seeds are very popular as a condiment in Nigerian local soup. The melon plant is grown in all regions of Nigeria and the seeds are consumed within the region in which they are produced [5]. Melon seed, the primary constituent of ikpan, is rich in oil and protein but poor in carbohydrate. The Institute of Medicine suggests a daily carbohydrate consumption of 45-65% which makes a standard of 2,000 calories/day which amounts to 225-325g/day. Below this level, the individual may be deficient in carbohydrate which subsequently results in fatigue, exercise intolerance, possible nausea, headaches and dehydration [6]. Due to this, there is a need to produce a traditional cake fortified with carbohydrate-rich crop with a good balance of nutrients.Plantain (Musa paradisiaca L.) is a staple crop and an important dietary source of carbohydrate in Nigeria and in the humid tropical zones of Africa, Asia and South America [7]. Plantain is a rich source of important minerals like sodium, potassium, calcium, magnesium, phosphorus and iron. Plantain is a fruit similar to the banana but it is traditionally consumed cooked, rather than raw. Therefore, the main objective of the study was to produce and evaluate the nutritional, antinutritional and sensory qualities of ikpan cake prepared from melon and plantain flour blends.

2. Materials and Methods

2.1. Raw Materials and Source of Procurement

- Melon seeds, unripe plantain and seasonings (maggi cubes, salt and pepper) were purchased from a local market (Itam market) in Uyo Local Government Area of Akwa Ibom State while dried sclerotium (isuo) and mfang ikpan leaves (Mallotus spp) were purchased from a retail dealer in Ikot Ekpene Local Government Area of Akwa Ibom State. Reagents used in this study were of analytical grade and were obtained from the Department of Food Science and Technology, University of Uyo, Uyo.

2.2. Samples Preparation

2.2.1. Preparation of Melon Flour

- Three (3) kg of shelled melon seeds were sorted to remove the impurities. They were milled using manual grinder (model Corona) and packaged in air tight containers labeled and stored in refrigerator (model Haier Thermocool) at a temperature of -4°C for subsequent use.

2.2.2. Preparation of Plantain Flour

- Plantains were washed using tap water and blanched at 60°C for 15 min using water bath (model Griffin) to control enzymatic browning. The fruits were immediately cooled and peeled using a sharp knife. The peeled plantains were sliced to a thickness of 1 cm. The sliced plantains were placed in stainless trays covered with aluminium foil to avoid sticking to the tray and dried in a cabinet oven (model NAAFCO BS Oven: OVH-102) at 60°C for 24 h. It was milled using hammer mill (model Corona) and sieved through a mesh of 425 mm pore size sieve to obtain fine flour. The flour was packaged in air tight containers, labeled and stored in refrigerator (model Haier Thermocool) at a temperature of -4°C for subsequent use.

2.2.3. Preparation of Isuo Flour

- Five hundred (500) g of isuo (dried mushroom sclerotium) was washed and soaked in water for 24 h in order to soften it. It was removed, peeled, washed and cut into pieces. It was grated using a traditional metal grater, sieved and packaged in an air tight container labeled and stored in refrigerator (model Haier Thermocool) at a temperature of -4°C for subsequent use.

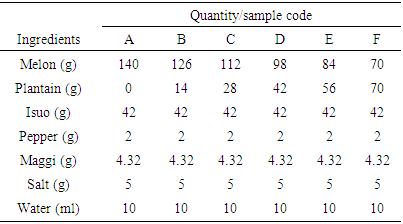

2.2.4. Production of Ikpan Cake

- Ikpan was prepared by substituting melon flour portions with unripe plantain flour in the ratios 100:0, 90:10, 80:20, 70:30, 60:40 and 50:50 designated as samples A, B, C, D, E and F, respectively. The flour blends were thoroughly mixed together. Isuo powder was added to the mixture. The seasonings (maggi cubes, salt and pepper) and hot water were added and mixed together in right proportions as shown in Table 1. The mixtures were moulded into oval shape. Water and mfang ikpan leaves (Mallotus spp) which serve as colour enhancer were placed in a pot and allowed to boil while the moulding was on. The moulded cakes were placed carefully inside the pot and were covered. The cakes were allowed to cook for 4 h during which water was added at intervals to prevent burning. The cooked cakes which were brownish in colour were removed, oven dried at 55°C for 3 h to further loose moisture. Ikpan samples were stored in clean containers prior to analysis.

|

2.3. Determination of Proximate Composition

- The moisture, ash, crude fibre, crude protein and crude lipid contents of ikpan samples were determined using the official method of analysis described by [8].Determination of carbohydrate was determined by difference method on a dry weight basis, as described by [9] and was quantified based on the percentage difference of the other proximate indices as follows: %carbohydrate = 100-(% ash+%crude fibre+%crude protein+%crude lipid). The caloric values of the samples were obtained by multiplying the value of the crude protein, lipid and carbohydrate by 4, 9 and 4 kcal respectively and taking the sum of the product [10].

2.4. Determination of Mineral Composition

- The minerals were determined using the method described by [11]. The samples were ashed at 550°C in a muffle furnace (model SXL) for 2 h. The ash content was dissolved in 10% HCl and made up with distilled water to 100 ml in a standard flask. Sodium and potassium were estimated by corning 405 standard flame emission photometer (model 721D) and about 1.0 g of the sample was digested with 20 ml of acid mixture (650 ml of conc. HNO3, 80 ml PCA and 20 ml conc. H2SO4) and aliquots of the diluted clear digest was taken for photometry using flame analyzer. Magnesium and iron were determined using a 721D Atomic Absorption Spectrophotometer (AAS) while phosphorous was analyzed by adopting vanadomolybdate method using hydroquinone.

2.5. Determination of Antinutrient Composition

- Determination of hydrogen cyanide was done using alkaline filtration method as described by [12]. Phytate content was determined using the method described by [13]. Tannin content was analysed using the method of [14] and oxalate content was determined using the method described by [15].

2.6. Sensory Evaluation of Produced Ikpan Cake

- The organoleptic properties (appearance, texture, aroma, taste, after taste and overall acceptance) of the ikpan was assessed by twenty semi-trained panelist from the Department of Food Science and Technology, Faculty of Agriculture, University of Uyo, Uyo using a nine-point Hedonic scale as described by [9], where 1 = dislike extremely and 9 = like extremely. Samples were prepared in identical sample containers and presented one at a time to each panelist. All panelists were regular consumers of ikpan and they were asked to rate the samples for each organoleptic property.

2.7. Statistical Analysis

- All experiments were carried out in triplicate. The data obtained were subjected to statistical analysis of variance (ANOVA) using the Statistical Package for Social Statistics (SPSS Version 20). Means were separated with the use of Duncan’s New Multiple Range Test (DNMRT) and significance was accepted at 95% confidence interval.

3. Results

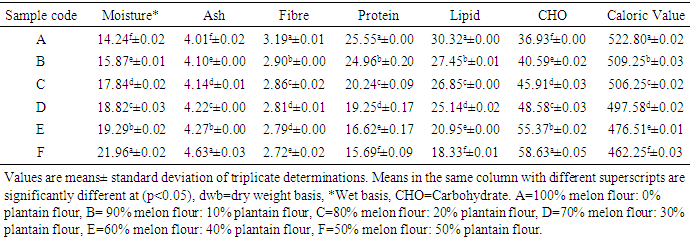

3.1. Proximate Composition and Caloric Value of Melon -Plantain Ikpan Cake

- Proximate composition (%) and caloric value (kcal) of ikpan produced from melon and plantain flour blends are shown in Table 2. Moisture, ash, crude fibre, crude protein, crude lipid and carbohydrate content of sample A were 14.24, 4.01, 3.19, 25.55, 30.32 and 36.93%, respectively. Substitution of melon flour with different levels of unripe plantain flour resulted in significant (p<0.05) increase in moisture, ash and carbohydrate content of ikpan which ranged from 15.87-21.96%, 4.10-4.63% and 40.59-58.63%, respectively, for sample B and C. Conversely, substitution of melon flour with unripe plantain flour resulted in significant (p<0.05) reduction in crude fibre, crude protein and crude lipid content of the cake. Ikpan produced from 100% melon had higher energy value than those produced using melon-plantain flour blends.

|

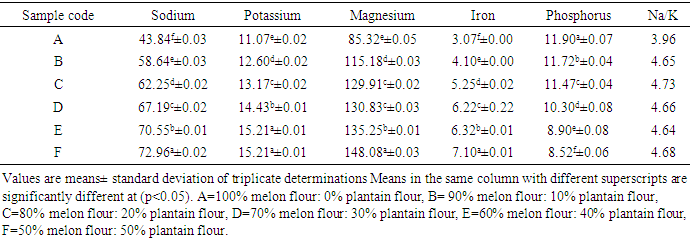

3.2. Mineral Composition of Melon-Plantain Ikpan Cake

- Table 3 shows the selected mineral content of ikpan produced from melon and plantain flour blends. Significant (p<0.05) difference existed in all the samples.

|

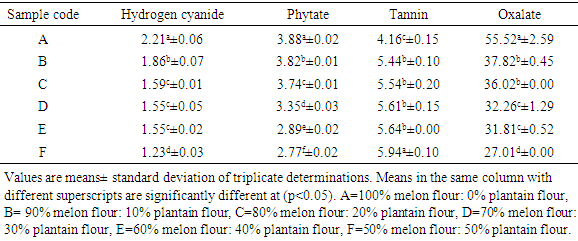

3.3. Antinutrient Content of Melon-Plantain Ikpan Cake

- Table 4 shows the selected anti-nutrient content (mg/100g) of ikpan produced from melon and plantain flour blends. The hydrogen cyanide, phytate and oxalate content of the cakes decreased significantly (p<0.05) from 2.21 mg/100g, 3.88 mg/100g and 55.52 mg/100g in sample A to 1.23 mg/100g, 2.77 mg/100g and 27.01 mg/100g in sample F, respectively. The tannin content of the cakes increased significantly (p<0.05) from 4.16 mg/100g (A) to 5.94 mg/100g (F).

|

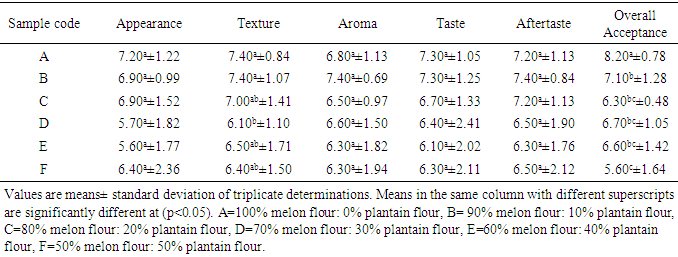

3.4. Sensory Evaluation of Melon-Plantain Ikpan Cake

- There was no significant (p<0.05) difference in the appearance, aroma, taste and aftertaste of control and plantain substituted cakes (Table 5). Cakes produced from 10% plantain flour (B) had the highest overall acceptance (7.10) after the 100% melon cake (A). Significant (p>0.05) difference was observed in the texture and overall acceptance of the cakes which ranged from 7.40 and 8.20 in sample A to 6.40 and 5.60 in sample F, respectively.

|

4. Discussion

4.1. Proximate Composition and Caloric Value of Ikpan Cake

- The moisture content of the produced ikpan is lower than the value (47.20%) reported by [4] for ikpan produced from 100% melon flour and the values (50.01% and 50.56%) reported by [16] for groundnut and melon- soybean snacks, respectively. High moisture content could affect the storability of the products [17]. By implication, ikpan cannot be stored for long time without deteriorating. The increase in ash content of the cakes could be due to the higher ash content of plantain relative to melon. The ash content of the produced ikpan is lower than the value (5.39%) reported by [4] for ikpan but higher than the value (0.9%) reported by [19] for biscuits produced from unripe plantain and chickpea flour blends. Fibre increases stool bulk and decreases the time that the waste materials spend in the gastro intestinal tract [17]. Reduction in crude protein content of the cakes as plantain substitution increased could be attributed to the low protein content (8.83%) of plantain as reported by [19]. The crude protein content of ikpan is higher than the value (9.5%) reported by [20] for bread prepared from 100% wheat flour. The lipid content of ikpan is within the Acceptable Micronutrient Distribution Range (AMDR) of 20-35% of energy as recommended by the [21]. The carbohydrate content, as expected, increased with increase in plantain flour substitution. This is due to the high carbohydrate content of unripe plantain flour. [22] reported a carbohydrate content of 77.58% for plantain which is greater than the value (7.22%) reported by Jacob et al. (2015) for melon. The carbohydrate content of ikpan is lower than the value (75.42%) reported by [24] for cookies prepared from 100% unripe plantain flour. Reduction in caloric value of the cakes as a result of increase in plantain flour substitution could be due to the variations in the crude protein, crude lipid and carbohydrate contents of the cakes.

4.2. Mineral Composition of Ikpan Cake

- The increase in sodium content of the cakes could be attributed to the high sodium content of plantain relative to melon as reported by [19]. Since isuo powder was the most abundant ingredient used in the preparation of ikpan, the high sodium content of the cakes in general, could be attributed to the high sodium content (987 mg/100g) of isuo powder as reported by [25]. Increase in potassium content of the cakes could be due to the high potassium content of plantain as reported by [22]. The sodium/potassium (Na/K) ratio of the cake is greater than one. The high Na/K ratio of the cakes in general is due to the high Na/K ratio of isuo powder (4.68) as reported by [25]. According to [23], the recommended Na/K ratio should be less than one. By implication, ikpan is not recommended for hypertensive patients. Magnesium content of the cakes was of increase as this could play a key role in bone mineralization, building of protein, enzyme action and transmission of nerve impulses. The iron content of the cakes increased with increase in plantain flour substitution and could be attributed to the high iron content of plantain relative to melon as reported by [19] and [26]. Decrease value observed in phosphorous content of the cakes could be due to the low content of phosphorus in plantain compared to melon [26, 27].

4.3. Antinutrient Content of Ikpan Cake

- Reduction in hydrogen cyanide content of the cakes was satisfactorily below the safety level for cyanide poisoning (10 mg/kg) according to [28]. The phytate content of the cakes decreased with increase in plantain substitution and this could be due to the low phytate content of unripe plantain relative to melon. It is a strong chelator of important minerals such as calcium, magnesium, iron and zinc, and could therefore contribute to mineral deficiencies in people whose diet rely on these foods for their mineral intake. Methods like cooking, soaking in an acid medium, lactic acid fermentation and sprouting can reduce phytate level in food [29]. Increase in tannin content of the cakes observed could be due to the high tannin content of unripe plantain relative to melon. Reduction in oxalate content of the cakes was appreciated since high oxalate content in a diet can precipitate calcium and make it unavailable for nutritional purposes. The results revealed that the anti-nutrient composition of the cakes were generally low to cause any health risk in human beings.

4.4. Sensory Evaluation of Ikpan Cake

- Sensory scores for appearance, aroma, taste and after taste of sample A were not different from plantain substituted samples (B-F) while texture and overall acceptance of the cakes decreased with increase in unripe plantain flour substitution. However, cakes containing 10% unripe plantain flour had the highest acceptability.

5. Conclusions

- This study has revealed that ikpan is a good source of protein, fat, carbohydrate and energy. The high carbohydrate content of ikpan can contribute to the daily carbohydrate requirement for a healthy living. The sodium is comparatively more abundant than potassium. Salt-sensitive hypertensive individuals with diet restrictions may have health problems through the high sodium/potassium ratio. Also, it is rich in iron which is needed for blood. The low concentration of anti-nutrients suggests that ikpan is a good snack for humans. The research has also shown that melon and unripe plantain flour substituted at the level of 10% in the preparation of ikpan gives a rich snack that is nutritional balanced and acceptable by the panelists.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML