-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2018; 8(2): 47-56

doi:10.5923/j.fph.20180802.03

Evaluation of Microbiological Quality and Safety of Milk and Dairy Products with Reference to European and Gulf Standards

Mohamed G. El-Ziney

Department of Dairy Science and Technology, Faculty of Agriculture, Alexandria University, PO Box 21454, Alexandria, Egypt

Correspondence to: Mohamed G. El-Ziney, Department of Dairy Science and Technology, Faculty of Agriculture, Alexandria University, PO Box 21454, Alexandria, Egypt.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This study investigated the microbiological quality and safety of milk and dairy products including pasteurized milk, pasteurized cream, cultured dairy products (labneh), a wide range of cheese varieties (fresh, soft, semi-hard, hard and processed cheese) and ice cream obtained from Qassim market, Saudi Arabia. The samples were evaluated for microbiological criteria; which included Salmonella sp., and Listeria monocytogenes; served assafety index criteriawhereas, aerobic plate count (APC), Enterobacteriaceae and Escherichia coli were considered as quality guideline criteria. The outcome results were checked in accordance with the European Regulation EC 2073/2005 and Gulf standards GSO /FDS 1016 / 2014. None of the samples tested contained Salmonella sp. or L. monocytogens with 100% compliance with the standards. Regards to APC level, unacceptable levels were only found in pasteurized cream samples (25%) whereas, processed cheese, pasteurized milk, and ice cream graded as satisfactory according to standards. The highest level of Enterobacteriaceae was detected in soft cheese while 42.85% and 23.8 were unacceptable according to Gulf standards and EU regulation respectively. Also, E. coli were existed only in soft cheese with 14.3% rejected samples. It worth noting, that critical processing evaluation and reevaluation of HACCP plan should be considered to improve the quality of soft cheese products.

Keywords: Dairy Products Quality, Microbiological Criteria, Salmonella, Total Viable Count, Enterobacteriaceae, EU Regulations, Gulf Standards

Cite this paper: Mohamed G. El-Ziney, Evaluation of Microbiological Quality and Safety of Milk and Dairy Products with Reference to European and Gulf Standards, Food and Public Health, Vol. 8 No. 2, 2018, pp. 47-56. doi: 10.5923/j.fph.20180802.03.

Article Outline

1. Introduction

- Dairy industry remains the main core of the food sector all over the world. In Saudi Arabia (KSA), milk and dairy products are perceived as a crucial part of routine diet, further consumption is expected to expend as a result of the growing birth rate of 3.2% annually [1]. The milk production elevated in Center Eastern Nations, particularly the KSA, has additionally been recognizable [2]. In 2006, milk consumption was 3.58 million liquid milk equivalent (LME) tons. The quantity of dairy cattle, barring the young stock, has expanded from 81,710 to 135,000 for 2003 and 2008 respectively [3]. The statistical analysis showed that the production of milk and dairy products in Saudi Arabia in 2016 and 2017 were estimated to be 2.41 and 2.44 million metric tons of milk respectively [4]. Total dairy ingredients i.e. whole milk powder (WMP), skim milk powder (SMP), buttermilk powder (BMP), butter, cheese and whey protein (WP) usage in KSA was 253,000 tons in 2015, out of this cheese amounted to 46,476 tons. According to an estimate by the Institute of Middle East Studies (IMES), overall dairy ingredients usage is growing by 6.2% compound annual gross rate (CAGR) to 2020 [5]. The most attractive dairy products in KSA are butter, yogurt, laban and cheese as a result of geographic, demographic, monetary and social reasons. This demands that safety and quality concern of dairy products will be continued to face challenges by the dairy industry [6]. In the last decades, various food-borne illnesses have been demonstrated to be related to milk and dairy products. In France, it has been reported that milk and dairy products were implicated in 1–5% of total foodborne disease outbreaks between 1988 and 1998 [7]. In the USA during the period of 1998–2011, cheese was responsible for 90 outbreaks. Meanwhile, cheese made with unpasteurized milk was responsible for 38 (42%) and 44 (49%) were due to cheese made with pasteurized milk, while the rest (9%) had no information in regard to pasteurization status [8]. In Saudi Arabia, there was a steadily raising of foodborne disease outbreaks for more than a decade as reported by ministry of health [9]. A surveillance study of food-borne outbreak in Qassim region (KSA) in 2006, showed that both male and female suffered from gastroenteritis at the same instance while, the main causative agent was Salmonella sp. followed by Staphylococcus aureus [10]. Salmonellosis is an infection cause by Salmonella sp. in human. In the European Union (EU), it is reported that there are more than 100,000 cases of salmonellosis every year [11]. In the United States, besides an expected one million salmonellosis cases occur in conjunction with 400 salmonellosis-associated deaths [12]. Salmonella species have been regularly isolated from the faeces of healthy dairy cattle, which it might reflects they presence as natural flora of the gastrointestinal microbiome [13]. El-Ziney and Al Turki, [14] reported that 24% of the raw camel milk samples in Qassim region (Saudi Arabia) were contaminated with Salmonella sp. As a ubiquitous pathogen, Listeria monocytogenes have many possible modes to enter dairy processing facilities. It has been pointed out that L. monocytogenes are wide-spread in cheese processing plants [15, 16]. It has been demonstrated that the long term persistence of this bacterium causing a continuous cross-contamination of the dairy products. L. monocytogenes has been shown to cause life-threatening in sensitive immune depressed human groups [17, 18].Evaluation of microbiological criteria in dairy products is indispensable step to ensure efficiency of HACCP plan. The level of Enterobacteriaceae and E. coli (total) are crucial criteria to monitor processing hygienic conditions. Further, the aerobic plate count or the total viable count, also known as standard plate count (SPC) is one of the most common tests applied to indicate the microbiological quality of food. Thus, those quality criteria were the bases for the proposed microbiological standards which were derived from several survives [19, 20]. The current study presents a critical evaluation of microbiological safety and quality of the marketed milk and dairy products in Buraydah, Qassim province, Saud Arabia. The assessment of the compliance of the dairy products was based on the microbiological specifications provided by European Microbiological Regulation, EC 2073/2005 [21] and Gulf standardization organization, microbiological criteria for foodstuffs, GSO /FDS 1016 / 2014 [22].

2. Materials and Methods

2.1. Sampling

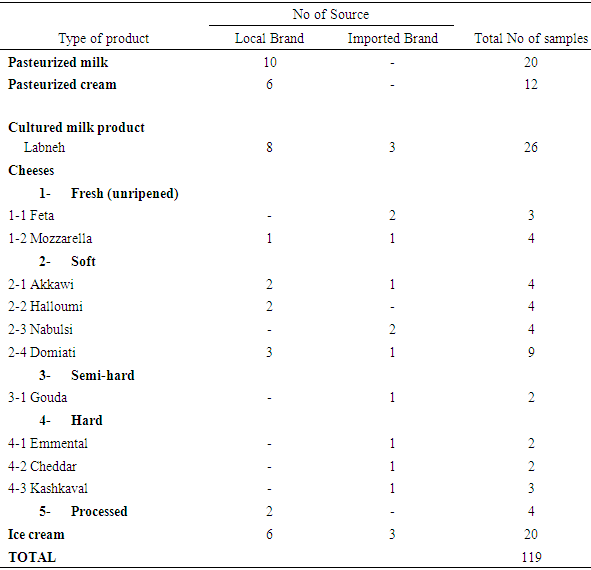

- Samples (n=119) were obtained from retail premises in Buraydah, Qassim region. Random collected samples had a shelf life between the beginning of production and not exceeding the middle of that period. The collected milk and dairy samples included pasteurized milk, pasteurized cream, cultured milk product (Labneh) cheeses, and ice cream as illustrated in Table 1. Five varieties of cheese were analysed including fresh unripened cheese (Feta and Mozzarella), soft brined cheese (Domiati, Akkawi, Halloumi and Nabulsi), semi-hard (Gouda) and hard cheese (Emmental, Cheddar and Kashkaval) and processed cheese. Ice cream samples included wide varieties i.e. vanilla, strawberry, chocolate, peanut and almonds. Most of the products are sold in sealed packages and some are sold in partition by the weight. The samples were collected in insulated cooling box at 4°C and then it brought to the lab to be analyzed in the same day.

|

2.2. Microbiological Analyses

- Samples were analyzed for the microbiological parameters included the aerobic plate count (APC), Enterobacteriaceae, E. coli, Salmonella sp. and L. monocytogenes using reference methods. The determination of APC was done using the pour plate method on plate count agar in accordance to the ISO 4833:2003 standard protocol [23]. The Enterobacteriaceae enumerations were performed using the pour plate method on violet red bile glucose agar (VRBGA) following ISO 21528-2:2004 [24]. Escherichia coli were enumerated on tryptone-bile-glucuronide medium (TBX agar) at 44°C according to ISO 16649-2:2001 [25]. The detection of Salmonella was performed in 25-ml/g samples according to ISO 6579:2002+A1:2007 [26] by enrichment in buffered peptone water (non-selective), and then in Rappaport Vassiliadis broth (selective). Cultivation was carried on xylose lysine desoxycholate agar (XLD), Bismuth sulfate agar (BSA), Hektoen enteric agar (HEA). Finally, typical colonies were confirmed by the triple sugar iron test and polyvalent antisera (Oxoid Salmonella test kit, DR1108). L. monocytogenes was isolated using ISO 11290-1 [26] method in 25 ml/g with a enrichment in Fraser broth (Oxoid), cultivation on Brilliance Listeria agar and confirmation of typical colonies by a catalase test, hemolysis, carbohydrate use, and Camp tests. All the used media throughout the study were purchased from Oxoid (Oxoid, Cambridge, UK).

2.3. Statistical Analyses

- Descriptive statistical analysis of collected data and analysis of variance (ANOVA) and the post hoc the Least Significant Difference (LSD) at significant ≥0.05 and Duncan’s multiple range test (DMRT) were performed using SPSS software version 16.

3. Results and Discussion

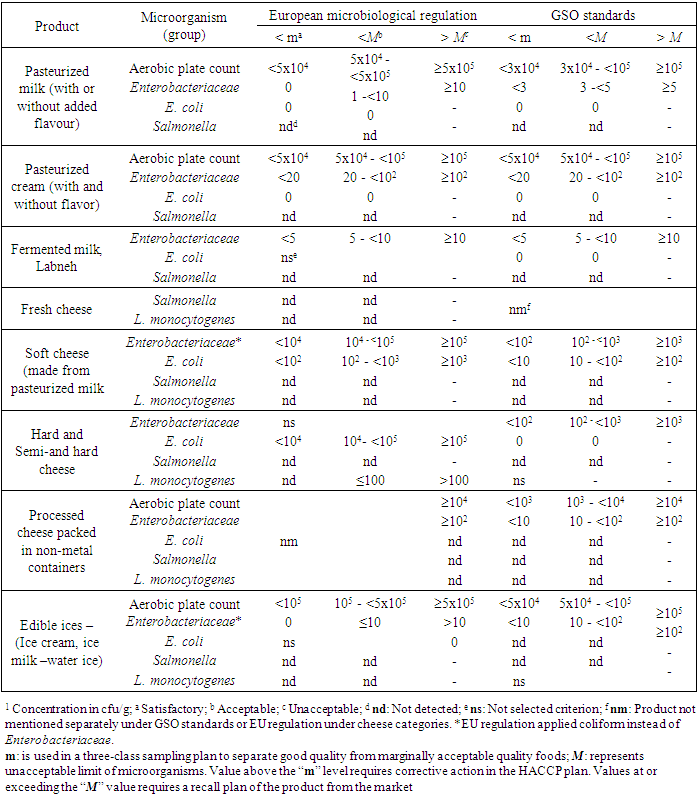

- In the present study, wide range of dairy products (n=119) were analyzed for Salmonella and L. monocytogenes as safety index and total viable count, Enterobacteriaceae and E. coli as food hygienic indicators. The microbiological quality and safety of examined dairy products assessed using criteria limits in the EU regulations [21] and Gulf standards for foodstuffs [22] as shown in Table 2. Both agencies almost use the same microbiological criteria to assess the safety and quality of dairy products however, GSO is applying higher conservative measures. The EU microbiological regulation is considers pasteurized milk is satisfactory at APC of <5x104 cfu/g and Enterobacteriaceae of 0 cfu/g but it is <3x104 cfu/g and <3 cfu/g respectively in GSO standards, further the unsatisfactory limit showed to be more rigid in GSO standards (Table 2). The same category is noticed with Enterobacteriaceae limit in soft cheese. Furthermore, some microbiological criteria were not selected in the EU regulation i.e. E. coli in fermented and cultured milk and Enterobacteriaceae in hard and semi-hard cheese and ice cream. In regards to different types of cheese, some types were not separated in special section such as fresh cheese which is compiled with soft cheese in GSO standards whereas, processed cheese was not split from other cheese types in EU regulations. Also it is noticed the contradiction between both standards concerning the permitted level of E. coli in semi-hard and hard cheeses (Table 2). This reflects the necessity of each food safety agency to evaluate the fate of each microbe in their local or imported foods, the present level of contamination and the hazard risk analysis in order to apply and modify the national or regional standards.

|

3.1. Microbiological Safety INDEX of Milk and Dairy Products

- In the present study, Salmonella and L. monocytogenes were not recovered from any of the pasteurized milk and dairy product tested samples. This results clearly indicating efficiency of applied pasteurization process to kill both organisms, good hygienic practice enable to avoid cross-contamination, and inability of Salmonella and L. monocytogenes to survive dairy processing conditions i.e. heat treatment, in cultured dairy products (i.e. labneh) and at low water activity (i.e. hard cheese). High frequency of Salmonella sp. in bulk-tank raw-milk samples amounted to 10.5% was reported by USDA in 2007 while; 3.8% U.S. dairies tested positive for L. monocytogenes was detected [28]. Milk pasteurization is considered one of the capital critical control points (CCPs) in HACCP plan in the dairy processing plant. Good pasteurization practice should secure products and offer total destruction of vegetative pathogens which may be present in the raw milk i.e. Salmonella sp., Verocytotoxigenic E. coli (VTEC) and L. monocytogenes. In Saudi Arabia, Salmonella was found at a higher rate (24%) in raw camel milk [14]. High destruction rate was reported of most virulence cultures of Salmonella (>log10 6.9 at 61.5°C) and L. monocytogenes (>log10 6.9 at 65.5°C) in tubular turbulent flow pasteurizer for 15s [15]. It is worth noting that most of Saudi local milk plants are processing milk pasteurization at a higher temperature range. In Europe, absence of Salmonella and L. monocytogenes in pasteurized and cultured milk, pasteurized cream, butter, cheese varieties and ice cream were reported [30]. All of the tested hard and semi-hard cheeses were imported from the EU. In agreements with our data, the organisms were not detected in pasteurized milk [31]. In previous study, European cheese was found to be salmonella-free [32, 33] while L. monocytogenes was found in 2% and 1% in soft and pressed cheese respectively [33]. Further, recent report found that ice cream was free from Salmonella with only one sample was contaminated with of L. monocytogenes [34]. In contradiction, a high incidence of Salmonella (5%) and L. monocytogenes (4%) in ice cream was reported by El-Sharef et al., [35].

3.2. Microbiological Quality and Guideline Criteria of Milk and Dairy Products

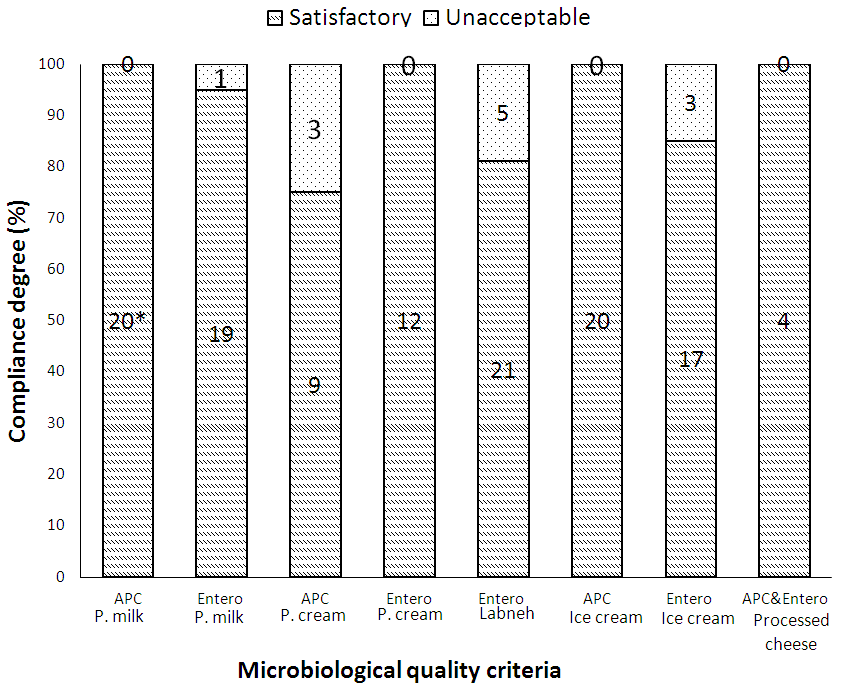

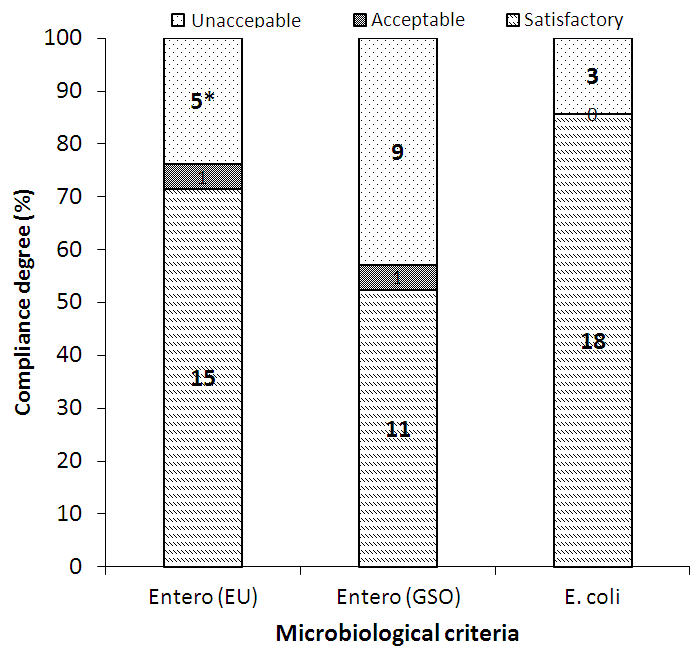

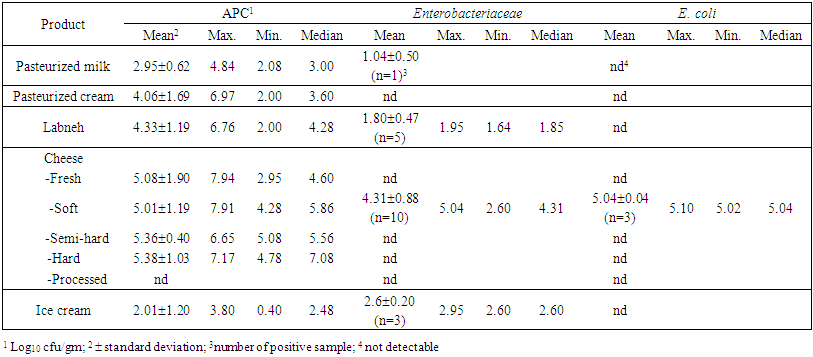

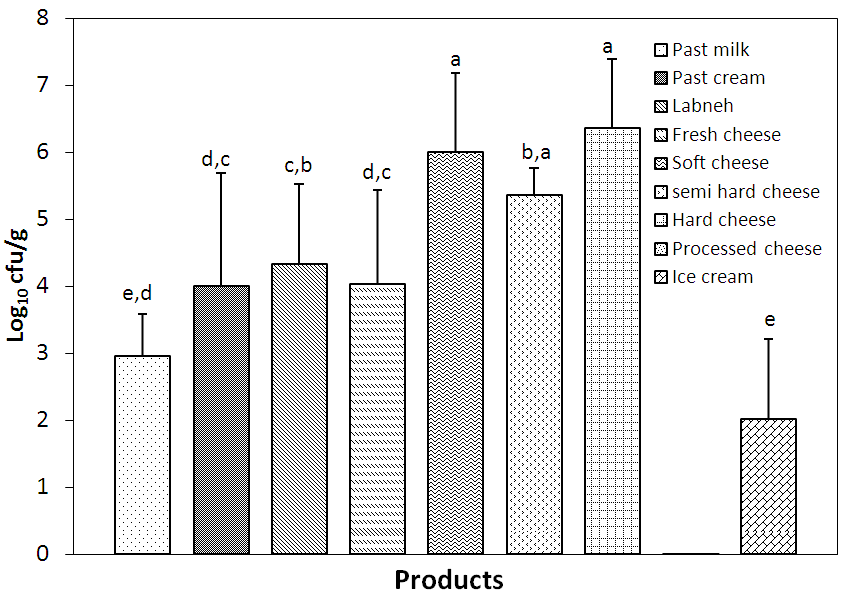

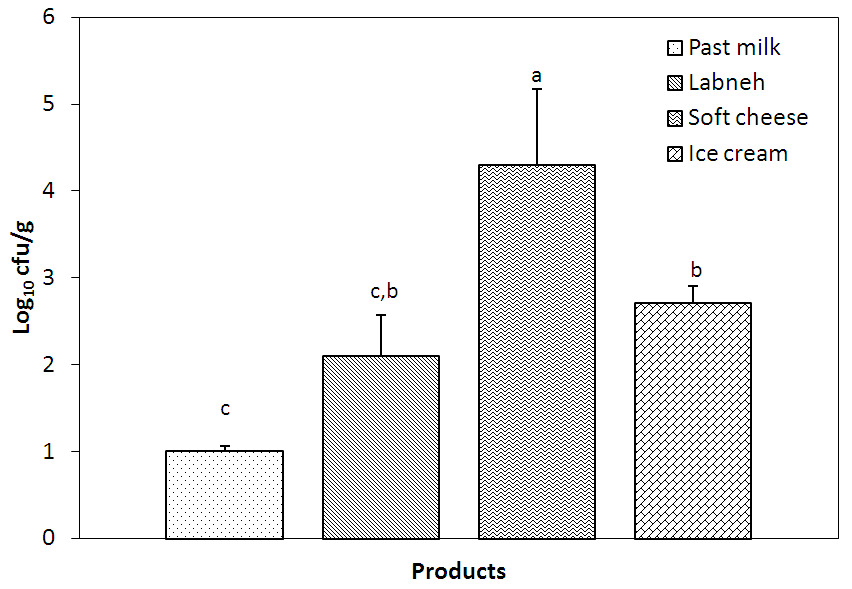

- The means, maximum, minimum and distribution of APC, Enterobacteriaceae and E. coli counts found in the milk and dairy products are given in Table 3. There was a significant difference (p≤0.05) between the dairy products in the aerobic mesophilic count (Fig 1) which was dependent on heat treatment and production process of each product type. The highest microbial load was determined in different cheese varieties (soft and semi-and hard) with estimated at ≥ 5 log10 cfu/g while no detectable growth was found in processed cheese. The viable count in ice cream and pasteurized milk was in range of 2-3 log10 cfu/g. In pasteurized cream the load of APC was 100 doubled that found in pasteurized milk to be 4 log10 cfu/g. The same limit was detected in labneh (Table 3). The Enterobacteriaceae was only found in pasteurized milk, labneh, soft cheese and ice cream with significant difference between products (Fig 2). The presence of Enterobacteriaceae was found to be high in soft cheese at rate of 10 out of 21 samples (47.62%), in compered to other dairy products. This group was absence in pasteurized cream, and fresh, processed, semi and hard cheeses whereas, it were detected at low rate in pasteurized milk (1/20; 5%) rose to 15% (3/20) in ice cream (Fig 2). Enterobacteriaceae was detected in cultured dairy product like labneh with high rate amounted to 19.23% (5/26). It is worth noting that all positive labneh samples (n=5) were only belonged to the retail products sold by weight and not from packed ones. The presence of this microbial group is an indication of cross- contamination, which can occur from poorly personal hygiene, uncleaned equipment, sounded environment, i.e. air, and poor use of product rework [36]. The only presence of E. coli was found in soft cheese, locally produced at rate of 14.30% (3/21). Soft cheese with high moisture content enhances the microbial survival and reproduction. It is usually manually produced which allow a wide range of microorganisms to enter the product during processing and successive handling [37].

| Table 3. Descriptive analysis of microbiological quality criteria of milk and dairy products analyzed throughout the study |

| Figure 1. Aerobic plate count (APC) in different milk and dairy products. Error bars represent standard deviations. Bars with different letters are significantly different (p≤0.5) |

| Figure 2. Count of Enterobacteriaceae in different milk and dairy products. Error bars represent standard deviations. Bars with different letters are significantly different (p≤0.5) |

3.3. Evaluation of Dairy Products Quality in Accordance with European and Gulf Standards

- In reference to safety index criteria, all dairy samples were complied with European microbiological regulation and Gulf microbiological criteria for foodstuff and rated satisfactory as none of pathogens were detected. In regards to the microbiological quality criteria included in the present study there were different assessment results according to each agency standard. The APC criterion is only used to evaluate pasteurized milk, pasteurized cream and ice cream in according to European microbiological regulation and Gulf microbiological criteria for foodstuff while it is only applied by Gulf standards for processed cheese, as EU regulation is not determined special microbial criteria other than safety index (Salmonella sp and L. monocytogenes) for this type of cheese (Table 2). All pasteurized milk, ice cream and processed cheese sample were satisfactory with microbial level <m values settled by European and gulf standards (Table 2 and Fig 3). Unacceptable samples according to APC were only determined in pasteurized cream (25%) produced by two local dairy plants which indicates the demand for reevaluation of the used HACCP plan. In except of soft cheese samples, all other cheese varieties and cream samples were complied with standards (satisfactory grad). The aerobic plate count is normally used to evaluate the sanitary conditions of processing and food products. The high APC level is often indicated contamination of raw materials, unacceptable sanitation and inappropriate storage temperature [38].

4. Conclusions

- While the findings of this study are encouraging in terms of the microbiological quality and safety of milk and dairy products in Saudi market, there is opportunity to get better and it is basic that industry does not wind up self-satisfied. All the analysed pasteurized milk and dairy products were found free from safety Index criteria whereas, the viable counts, Enterobacteriaceae and E. coli were existed at different rates. In regard to soft cheese, the information provided herein may help the authorities and manufacturers to re-evaluate the present production process, legislation, and may suggest more appropriate novel manufacturing processes that may be helpful when designating or strategic management plans to improve the quality and safety. Implementation and verification of HACCP plan in retail market should be consider as powerful tool unable to control post-contamination during handling and selling.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML