-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2017; 7(1): 23-28

doi:10.5923/j.fph.20170701.03

Chicken (Gallus gallus domesticus L.) Cuts Yield Specifics of Cobb 500 Slow and Hubbard Flex Hybrids

Soares C. E.1, Dahlke F.2, Netto D. P.2, Scussel V. M.1

1Food Science and Technology Department, Center for Agricultural Sciences, Federal University of Santa Catarina, Florianopolis, Brazil

2Rural Development and Zootechny Department, Center for Agricultural Sciences, Federal University of Santa Catarina, Florianopolis, Brazil

Correspondence to: Soares C. E., Food Science and Technology Department, Center for Agricultural Sciences, Federal University of Santa Catarina, Florianopolis, Brazil.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Chicken (Gallusgallusdomesticus L.) cuts yield of wing (drummette / middle joint / tip), breast (fillet / tenderloin) and leg (drumstick / thigh / feet) of two specific hybrids (Cobb 500 Slow - CB-Slow and Hubbard Flex - HB-Flex) were evaluated. A total of 150 birds of each hybrid (grown in separate sheds under same management) were utilized for the study. The trials were carried out under randomly design with 24 replicated for each lineage. From the data obtained it was observed that the cuts yield of CB-Slow birds was higher for breast when compared to HB-Flex. On the other hand, the HB-Flex birds had higher cut yields for leg (drumstick - meat & bone) and wing(drummette / middle joint / tip). Yields for tenderloin, breastbone and upperdrumstick (meat) both hybrids did not show significant differences. The knowledge of specific chicken hybrid cuts differences, enables more accurate choices that best fits the consumer’s market needs.

Keywords: Chicken, Carcass, Cuts,Gallusgallusdomesticus, Yield

Cite this paper: Soares C. E., Dahlke F., Netto D. P., Scussel V. M., Chicken (Gallus gallus domesticus L.) Cuts Yield Specifics of Cobb 500 Slow and Hubbard Flex Hybrids, Food and Public Health, Vol. 7 No. 1, 2017, pp. 23-28. doi: 10.5923/j.fph.20170701.03.

1. Introduction

- Chicken meat (Gallus gallus domesticus L.) is considered an excellent source of protein and a low caloric food, providing only 10% of the daily need. A breast fillet portion (100 g) provides 30 g of protein, on the other hand, thigh and drumstick 20 g. It is also a source of minerals (selenium, phosphorus, zinc, iron, potassium and magnesium) and vitamins of B complex (B1, B2, B6, B12 and pantothenic acid), as well as of A, C and K (present in edible viscera – liver/gizzard/heart) [1-3]. The growth speed of birds, has a directly influence on the carcass yield and cuts, which makes chicken an important piece for economic return [4]. The first Brazilian chicken cuts export ocurred in the early 80’s, which led the industries to expand their slaughtering capacities and implement the automated production lines. That period marked also a change on chicken meat consumption habit in the country. These changes in the habit of consuming poultry meat also happen in other continents. Prior that, industries only produced and sold whole chicken [3, 5]. To reach consumers market needs, it is essential to keep updating the birds production characteristics (birth weight / mother age / slaughtering age & weight / average batch weight/ yield & each cuts weight). Therefore, to evaluate the differences between cuttings among chicken, knowledge on hybrids specifics is essential. They provide information on production features to meet the consumer market demand [6, 7]. The animal's carcass quality is determined primarily by its yield of meat / bone / fat.It is worth emphasizing that chicken cuts specifics have been the consumers increasing demand, mainly by their food habit changes on, either of (a) special cuts and/or (b) boneless products consumption. The increasing habits of easy cuts for fast preparations [1, 8, 9].As the birds become heavier due to their genetic enhancement and nutrition, it is expected also their yields improvement. Thus, meat companies that commercialize carcasses (whole or cuts) can better choose the exact hybrid to reach their needs.Several hybrids (Cobb, Hubbard, Ross, Paraíso Pedres, Isa Label, Arbor Acres and Avian Farms), are already in the market and their yield in different cuts have been compared and reported in the literature with different characteristics registered specifically among wings, breast and legs. However, there is a lack of information on specific characteristics among each lineage [10, 11, 3, 12, 9, 13-15].Considering the need for more accurate and specific ratings of the commercial lineages (Cobb and Hubbard), this study investigated the hybrids Cobb500 Slow (CB-Slow) and Hubbard Flex (HB-Flex) utilized in the Southern Brazil chicken production chains for different cuts (wing/breast/leg and yield) from hot carcasses (i.e., prior passing through chillers).

2. Materials and Methods

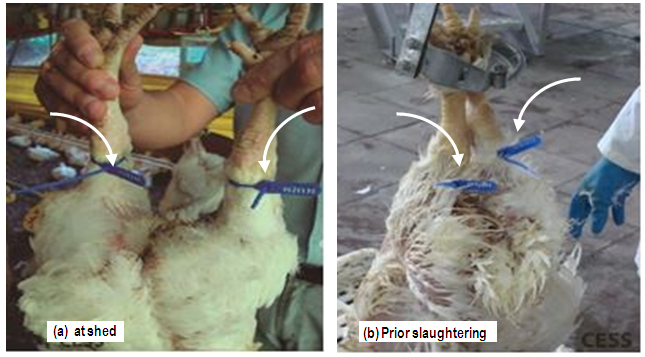

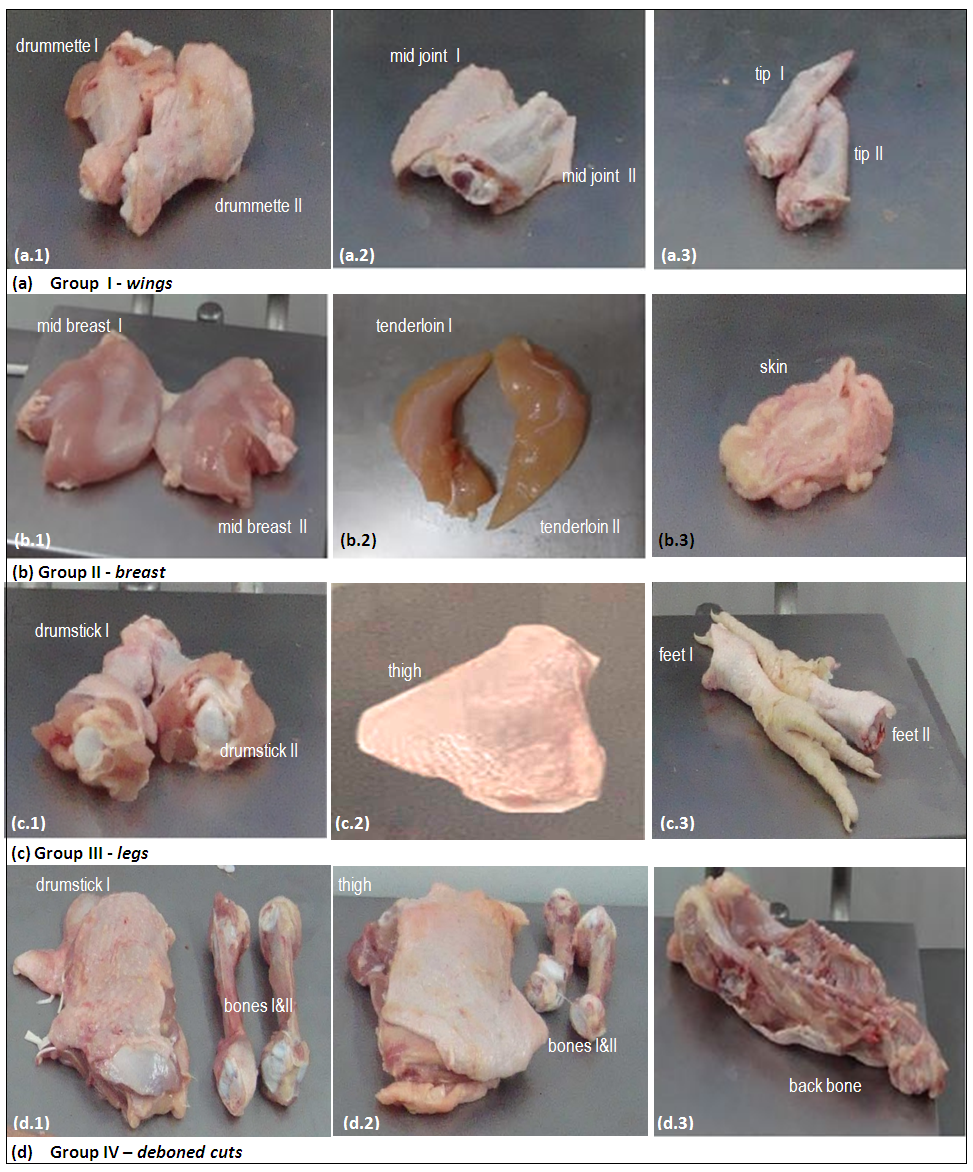

- 1. Animals: 300 chicken (males), 42 days old, from two hybrid specific lineages (Slow-CB and HB-Flex). They were grown in 2 different sheds, separated by lineage (150 birds each). All the birds handling was performed by a single producer under same conditions according to technical material of the cooperative.2. Chicken capture and preparation: when fully grown and ready for slaughtering, chickens were captured randomly, separated by their respective hybrids, weighted (hanging scale, Veit Electronics), identified by a numbered seal on both legs (Figure 1.a) and sent to the slaughtering house (after 8 h fasting) according to the National Ministry of Agriculture regulation procedure [16]. 3. Slaughtering: chicken were previously (a) weighed – by means of a hanging scale, then sent for (b) slaughtering – through stunning, bleeding and evisceration (birds with injuries/missing parts were discarded); followed by (c) carcasses sample collection – 24 units of each lineage were separated (prior passing through chiller) and their seals checked (Figure 1.b) for further cuts identification.4. Cuts preparation and deboning:(a) cuts preparation - the carcass parts were separated according to the different cuts Types as follows. group I: wings (drummette/middle joint/tip) group II: breast (filet / tenderloin *) group III: legs (drumstick / thigh / feet)(b) deboning – drumstick and thighs had their bones separated, including skin and fatgroup IV: drumstick & bones/ thigh & bones/back bone - deboning (Figure 2)All procedure was carried out by the same operator using stainless steel knives. Cuts and seals (from each bird) were kept together in the same tray (expanded polystyrene) for the next step - weight. [* inside breast fillet](c) weighing - each item (cuts, sub-cuts and deboning) obtained in (a) and (b) was weighed (scale, model 2090, Toledo) for yield calculation.5. Cuts weight and yield versus whole carcass: from birds data obtained at the (a) slaughtering house (before conveyor hanging and after slaughtering - whole, clean carcass) and the (b) cuts obtained; the weight and yield Tests were applied (for the cuts groups: I, II, III and IV) as follows. Weight test: with all cuts weighed, the 2 hybrids, had calculated their proportions (meat / bone / skin) versus each carcass, following features of their proper Groups I, II, III and IV. Those data were applied next, to calculate the yield percentage. Yield test: was carry out for the 2 chicken cuts hybrids main Groups, as well as carcass, i.e, (a) per unity (cut) and (b) total (carcass) - weight prior slaughtering (live and after fasting). The following equations were applied:[a] individual yield (%) = slaughter weight x 100 / cutting weight[b] total yield (%) = sum of cuts x 100 / slaughter weight.Note: it is important to emphasize that it was not possible to establish the age of the broiler breeders (eggs) and chicken weight (chicks), also, for the age of the mothers (eggs) and birth weight (chicks).6. Statistical analysis: it was applied ANOVA (SAS, version 9.1) and the averages compared by Tukey test (P <0.05) to evaluate the significant differences.

| Figure 1. Chicken (Gallus gallus domesticus L.) seal identification for tracking individual custs at (a) shed and (b) prior slaughtering |

| Figure 2. Chicken (Gallus gallus domesticus L.) cuts from Groups (a) I –wing; (b) II –breast; (c) III – leg and (d) IV – deboned cuts |

3. Results and Discussion

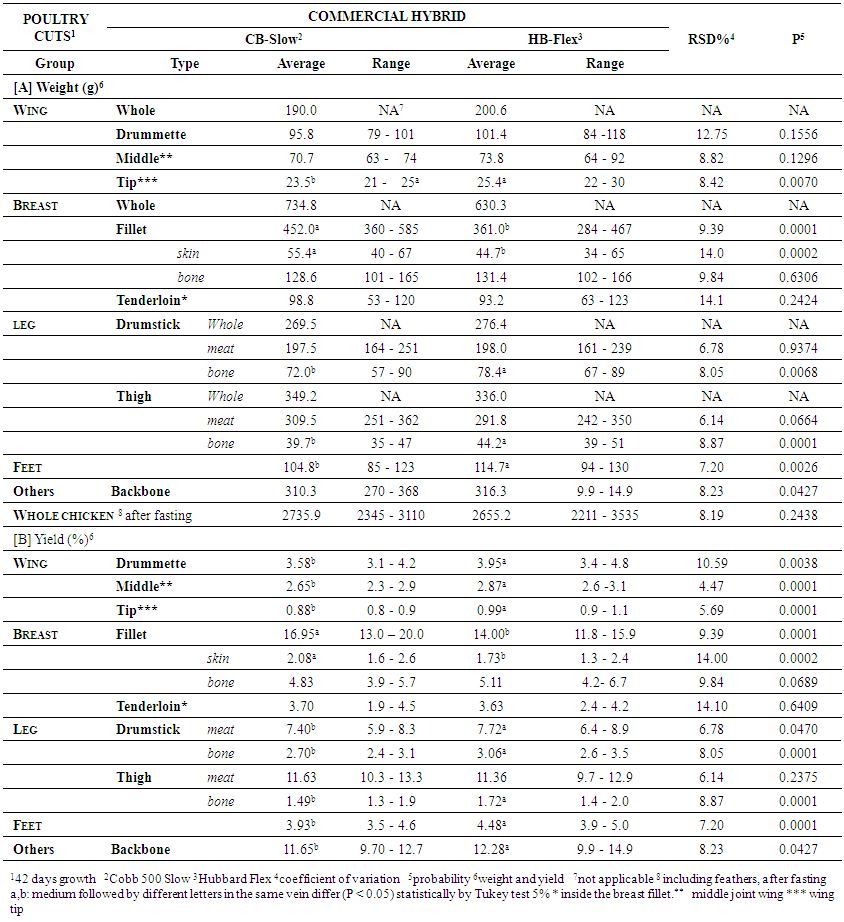

- From the data obtained, some differences were observed for both, weight and yield of chicken cuts of the two specific hybrids (CB-Slow and HB-Flex) evaluated in the study. The main cuts that stood in yield were breast (fillet & skin) and drumstick / thighs / wings, for the CB-Slow and HB-Flex lineages, respectively. Table below shows the weight and yield data of the chicken cuts Groups I, II, III and IV.

| Chicken cuts from Cobb 500 Slow and Hubbard Flex hybrids – weight and yield |

4. Conclusions

- The results obtained allow to infer that there was a significant difference between the two hybrids (CB-Slow and HB-Flex) tested characteristics, both for cuts weight and yield. The CB-Slow showed to be better on weight and yield of breast meat. The HB-Flex offers best results for wing and thigh. Important to emphasize the need for more detailed information about the hybrids (CB, CB-Fast and specific CB-Slow) when reported in the literature, as nuances of each lineage can make a difference in the final cuts data obtained in a study.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML