-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2014; 4(6): 293-300

doi:10.5923/j.fph.20140406.06

The Effect of Season, Age and Preservation on Camel Meat Sausage

Abdel Moneim E. Suliman1, Selma A. Fadlalmola2, Al Sir E. Babiker3, Omer A. Arabi3, Safa M. Ibrahim3

1Department of Biology, Faculty of Science, University of Hail, Hail, Kingdom of Saudi Arabia

2Faculty of Veterinary Medicine, University of Butana, Tamboul

3Faculty of Animal Production, University of Gezira, El-Managil

Correspondence to: Abdel Moneim E. Suliman, Department of Biology, Faculty of Science, University of Hail, Hail, Kingdom of Saudi Arabia.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

AbstractThe present study was conducted to investigate the influence of season, age of animal and preservation period on camel meat sausages. A total of 108 camels at different ages and 216kg of camel meat were used. The samples were also stored for 1, 2 and 3 months at (–18℃) during summer, winter and autumn. Sausages were prepared at the end of each storage period. The sausage samples were evaluated chemically and microbiologically and subjected to sensory evaluation at different storage periods. The results revealed significant interaction between the season, age and storage time. Oxidative rancidity of sausages and burger were significantly (p ≤ 0.05) affected by the storage time. Sausages and burger colour lightness (L), redness (a) and yellowness (b) were affected significantly with increasing storage time. Sensory analysis results of sausages showed that the sensory characteristics: color, tenderness, juiciness, flavor and acceptability were not significantly (p 0.05) different in all seasons among the groups during different storage periods. The total viable count of sausages stored at –18℃ for up to day 14 was decreased significantly (P ≤ 0.05) with increasing storage time. E. coli was detected all samples of sausages. It is highly recommended to utilize fresh or frozen camel meat in production of many products such as sausages.

Keywords: Sausage, Oxidative rancidity, Tenderness, Juiciness

Cite this paper: Abdel Moneim E. Suliman, Selma A. Fadlalmola, Al Sir E. Babiker, Omer A. Arabi, Safa M. Ibrahim, The Effect of Season, Age and Preservation on Camel Meat Sausage, Food and Public Health, Vol. 4 No. 6, 2014, pp. 293-300. doi: 10.5923/j.fph.20140406.06.

Article Outline

1. Introduction

- The camels in Sudan are estimated to be 3-3 million and contribute to the country’s, it is exported to neighboring countries as live animals; however there is a need to improve meat productivity to look for possible meat product export. Nevertheless there is no modern camel meat processing industry in the country for domestic or export purposes [1]. The camel meat production represents about 0.7% of the world meat production, i.e. 216,315 tons [2], but information is quite difficult to collect as the main part of the camel meat data comes from the informal market. Traditionally, camel meat consumption is not common in a subsistence system, the size of the carcass needing to share the meat between a wide numbers of people. However, the urbanization has increased the camel meat demand in most of the arid countries.Camel meat was an integral part of Arabian cuisine. The animal was also extensively used by the ancient Greeks and the Persians for desert travel. Both cultures used to roast the animal whole and serve it as a gourmet dish during special state occasions. According to legend, the Roman emperor Heliogabalus used to ask for camel to be prepared as he preferred the camel heel for himself. In Arabia, Somalia, Egypt, Libya and Sudan, the animal was much revered for its multiple uses and it was only prepared as a meat dish for special occasions.Camel meat is not universally eaten. In the pastoral communities camel meat is only eaten on special occasions. These include festive gatherings following the return of the herd from grazing and ritual celebrations. In some cases animals belonging to a certain tribe will not normally be slaughtered as they have been named and are considered to be an integral part of the tribe. This does not prevent people from such tribes from stealing and eating camels from neighboring tribes.Several methods have been used to preserve meat including cooking, fermenting, salting, smoking and drying. Fermentation is an inexpensive method for preservation of meat and meat products. Acid formation (low pH), H2 O2 and bacteriocins produced by starter cultures are responsible for preventing the growth of food poisoning and spoilage bacteria in meat [3]. The shelf-life of meat could be extended by low temperatures combined with a treatment with lactic acid bacterial strain [4].Sausages are meat products in which fresh comminuted meats are modified by various processing methods to yield desirable and keeping properties. Sausages are one of the oldest forms of meat processing and modern sausage technology has its roots deeply embedded in history. The degree of comminution differs among various processed products and is often unique characteristic of particular product ranging from coarse comminuted, to finely comminute to form an emulsion [5].Sausage ingredients frame meat from Beef, veal, fish, lamb and poultry are all suitable for use in sausage High quality sausages can be made only if the starting raw materials are of high quality [6]. The objectives of the present study were to improve the quality of camel meat by processing into sausages and to investigate the effect of different ages of camel, storage period on the quality characteristics of the products.

2. Materials and Methods

2.1. Materials

- A total number of 108 camels (Camelus dromedaries) ranged in live ages 1-9 years from Tamboul slaughter house, central Sudan. The camels were divided into three age groups as follows: - Group A: 1-3 years.- Group B: 4-6 years.- Group C: 7-9 years.Fresh camel meat samples were kept in refrigerator at (4℃) over night after that kept on deep freezer at (-18℃) and stored for 1, 2 and 3 months. At the end of each storage period, meat samples were transported hygienically to Department of Meat Production, Faculty of Animal Production, University of Khartoum. Then the samples labeled wrapped and kept in at refrigerator overnight until used for sausage production.

2.2. Sausage Processing

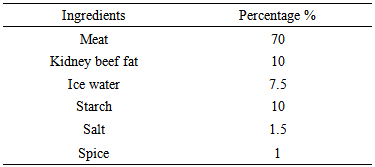

- Fresh camel sausages were prepared from the different groups according to the procedure of FAO [6]. Recipes were given in (Table 1).

|

2.3. Sausages Sample Preparation for Analysis

- Pieces of sausage product (about 50 grams) from every group were taken for microbial evaluation (total count, E .coli, S. aureas, ), also some of the products were used for determination of water holding capacity (WHC), color, pH, cooking loss, rancidity and sensory evaluation.

2.4. pH Determination

- pH values of sausage samples was determined immediately after preparation of the samples. 10 gm of the sample were blended with 100ml distilled water for one minute before measurement of pH values using a pH meter.

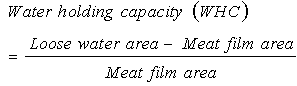

2.5. Water Holding Capacity (WHC)

- For determination of water holding capacity (WHC), duplicate samples (about 1 gram) from the camel meat sausage were used. Each sample was placed on humidified filter paper and pressed between two Plexiglas plates for 1 minute at 25 kg /cm2 load. The meat filter area was traced with a ball pen and the filter paper was allowed to dry. Meat and moisture areas were measured with a compensating Planometer. The resulting area covered by the meat was divided into the moisture area to give a ratio expressed as water holding capacity of meat. A large ratio indicates an increase in the watery condition of the flesh or a decrease in the water holding capacity [7].

2.6. Cooking Loss

- The frozen camel meat sausage samples were thawed to determine cooking loss. The sample was placed in a polythene bag and totally immersed in a water bath at 80ºC for 90 minutes. After cooking each sample was cooled in running tap water for 20 minutes in its exuded fluids and then removed and dried with paper towel [8]. Cooking loss was determined as the difference in weight of sample before and after cooking, and was expressed as a percentage of the weight before cooking.

2.7. Oxidative Rancidity Measurements

- The oxidative rancidity of the (meat, burger and sausage) samples was determined using 2- thiobarbituric acid (TBA) method as described by Hoyland and Taylor [9]. The reading of oxidative rancidity was taken using a spectrophotometer at the wave length of 538 nm as follows:

2.8. Colour Measurements

- The colour of samples of camel meat sausages was determined by using Hunter lab Tri-stimulus colorimeter Model D 25 M.2 optical sensor machine. lightness (l), redness (a) and yellowness (b) measurements .

2.9. Microbiological Analysis

- The microbiological analysis was carried out for sausage produced from various camel meat samples according to Harrigan [10].Appropriate dilutions of the respective sausage samples in 0.1 gm aliquots were spread on pre-poured plates of Plate count agar for the presumptive enumeration of total viable count and Baird-Parker agar for staphylococci. Inoculated plates, were incubated for 24-48 h at 37℃. Characteristic colonies appearing on the respective selective agar media were counted, multiplied by the dilution factor and expressed as colony forming units per ml c.f.u/ml.

2.10. Determination of coliform Bacteria

- It was carried out by using the most probable number (MPN) technique presumptive coliform test.One ml of each of three first dilutions (10-1, 10-2, 10-3) was inoculated aseptically in 9 ml of sterilized macconcy broth using the five –tube technique with Durhan tubes. The tubes were incubated at 37℃ for 48 hours. The production of acid together with sufficient gases to fill the concave of the Durham tube is recorded as positive presumptive test.

2.11. E. Coli Test

- From every tube showing positive results in the presumptive test inoculate a tube of Ec broth containing Durham tube the tubes were incubated at 44.5℃ for 24 hours. Tubes showing any amount of gas were considered positive result. Then the most probable number (MPN) was recorded. For further confirmation of E. coli tubes Ec showing positive results at 44.5℃ for 24 hour were streaked on (E.M.B) agar Eosin Methyle Blue agar plates. The plates were incubated at 37℃ for 48 hour colonies of E. coli are usually small with metallic green sheen on EMB agar.

2.12. Sensory Evaluation

- Samples for sensory evaluation were conducted in the sensory evaluation facilities of meat laboratory, Faculty of Animal Production University of Khartoum. The samples to be used for sensory evaluation were randomly selected and cooked in a pan for 5 minutes and kept warm by using aluminum foil. 20 semi-trained panelists were used to evaluate the sausage samples. The evaluation included; colour, tenderness, flavour, juiciness and overall acceptability using an 8- point scale score (hedonic scale) card as described by Cross et al. (1978), in which the highest score of 8 being extremely desirable and 1being extremely undesirable.

2.13. Statistical Analysis

- Data were analyzed as with a 4x3 factorial arrangement of treatments using analysis of variance, treatments means were compared by Duncan's multiple range tests and ANOVA table by using SPSS version 15 computer programs.

3. Results and Discussion

3.1. Influence of Season and Storage Time in Camel Meat Sausages

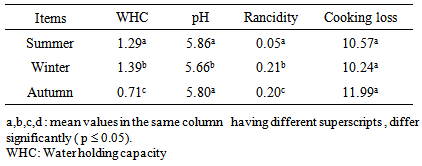

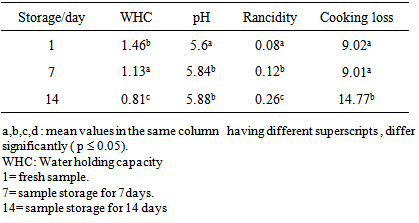

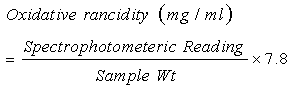

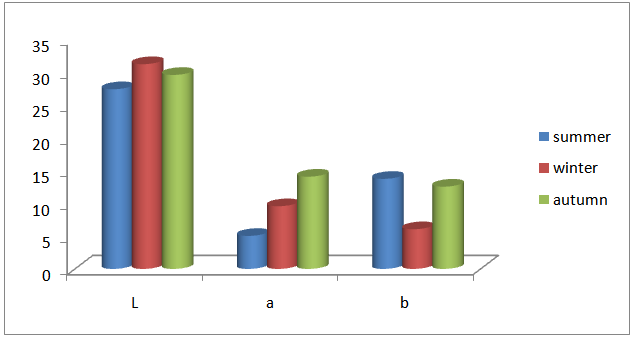

- The effect of different seasons (summer, autumn and winter) and storage time on physical properties and oxidative rancidity of camel meat sausage is presented in Table (1). Results show that WHC of sausages were1.29, 1.39 and 0.71 in summer, winter and autumn, respectively. Increasing the storage period from day 1 to day 14 at -18℃ resulted in an improvement of the WHC values. WHC values increased significantly (P<0.05) with increasing storage time in sausages. However, these values were in close agreement to those of Ibrahim [11] who found sausages WHC had increased with increasing the percentage of camel meat. The increase of WHC throughout the storage period could be attributed to an increase in released water which was presumably caused by denaturation of meat proteins resulted from the accumulation of acid and the decrease in pH [12]. Our results were against the findings of by Jouki and Khazaei [13] who found that WHC of packed camel meat values decreased significantly over storage time (p<0.05), and also disareed with Doherty et al. [14] who found that the liquid extracted from the meat the liquid extracted from the meat into the free space around the meat can appear as a red liquid either on the surface of the packaged meat or within the pack, affecting the appearance and acceptability of the meat.Babiker and Tibin [15] reported that the percentage of losses in cooking were affected by the level and type of fat in emulsion. During heat treatment of sausage, added starch binds part of the free water and swells, thus decreasing cooking loss. Also these findings agreed with Lawrie [16] who reported that higher water holing capacity of meat decreased cooking loss in final products. Jaroslav [17] found that drip losses are influenced by many factors, size of meat cut (higher losses come from sliced meat and steaks), postmortem, storage temperature and the most important factor is the pH value of the meat.Increasing the storage period from day 1 to day 14 at - 18℃ resulted in an increase of the pH values. These results agreed with Van den Beg et. al, [18] who reported that changes in pH during freezing storage might be caused by the increase in concentration of soluble materials, by the subsequent precipitation of salt, and probably by the interaction of protein with ionic substance. Elshrif [19] found that pH values of fresh sausages made with different percentage of camel meat were significantly different (P ≤ 0.05). pH values increased significantly (P ≤ 0.05) with increasing added level of camel meat and storage time. Tissue breakdown may be responsible for this increase in pH values [20]. Our results in agreement with other study by Jouki and Khazaei [13] who found no significant differences in chemical composition such as pH of packed camel meat during low temperature storage..Oxidative rancidity (TBA-value) of fresh sausage made from fresh camel meat and storage at -18℃ in different seasons of camel meat was investigated. Results show that TBA value of sausages was significantly (P ≤ 0.05) affected by storage period up to 14 days and season. The results showed that TBA values increase significantly (P ≤ 0.05) in winter on fresh camel sausages. This could be due to the higher fat content of camel meat. These results confirm the finding of Elshrif [19] who found that TBA values were decreased with increasing the level of camel meat on fresh beef sausages this could be due to the lesser fat content of camel meat. The post-mortem factors can influence lipid oxidation and decreases shelf life of the meat products. Livs medelsrerket [20] reported that meat and meat products vary greatly in their fat content according to the animal species, age of the animal and part of the carcass used. The results indicate show an increase of TBA with increasing storage in sausage. These results are supported by Younthan et. al. [21] who reported that rancidity increased with increasing storage time. Dwood [22], Fathi El-rhman [23] and Elshrif [19] found that unsaturated fatty acid are very prone to oxidation, even in meat in which most of the fat is saturated as the cell membranes contains phospholipids. Figure (1) shows that the objective colour measurements of fresh sausage manufactured from camel meat and kept at -18℃ for up to day 14 were affected significantly (P 0.05) with increasing the storage time.

| Figure (1). The effect of different seasons (summer, autumn and winter) on colour measurement lightness (l), redness (a) and yellowness (b) of camel meat sausage |

|

|

| Figure (2). The effect of different storage time on colour measurement lightness (l), redness (a) and yellowness (b) of camel meat sausage |

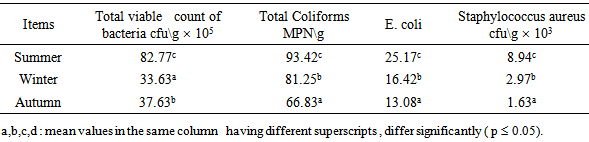

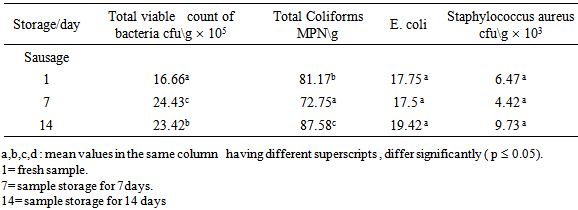

3.2. The Effect of Different Seasons and Storage Time on the Microbiological Characteristics of Sausages

- Table (4) presents the microbiological characteristics of the camel meat sausages in different seasons and storage periods at -18℃. Muscle tissues of healthy animals contain few bacterial cells, but cuts and exposed surfaces are easily contaminated after slaughter and during and after processing. Bacteria can readily multiply on the cut surfaces, although the bacterial count of the interior of the meat usually remains much lower. Multiplication of microorganisms may occur in fresh meat, in such cases there may be no correlation between numbers and the level of initial contamination (Harrigan and MacCance [10].

|

|

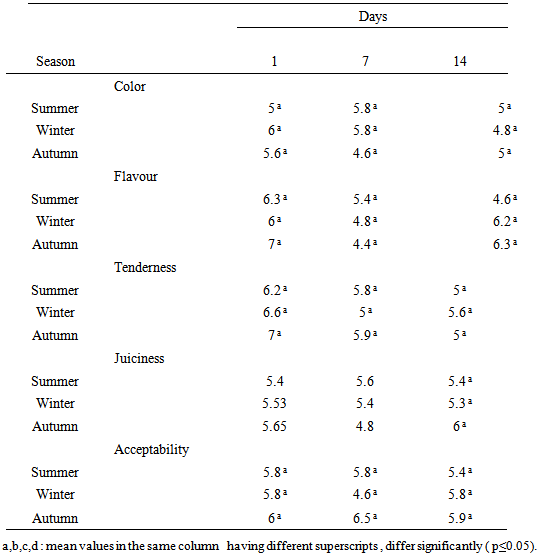

3.3. The Effect of Season on Sensory Evaluation of Camel Sausages

- Table (6) presents the results of sensory evaluation of sausages samples. The colour, tenderness, juiciness, flavor and overall acceptability were non- significantly (p ≤ 0.05) differ among the all groups during the storage period. Moreover, there was no significant changes (p ≤ 0.05) in color, tenderness, juiciness, flavor and overall acceptability as a result of season of production of burger and sausages stored for up to 14 days at -18℃. This indicates that sausages and burger made from camel meat with different ages can be stored for up to 14 days in freezing condition. These results are comparable with those of Elshrif [19] who found that sausage made from camel meat retained their water and fat during cooking better than those made with beef. These results were also supported by Babiker and Tibin [15] who reported that the sensation of tenderness is influenced by the juiciness of meat, the water holding capacity of protein and the amount and distribution of fat. Babiker and Tibin [15] found that flavor of sausage prepared of camel meat and beef with two fat levels (10 and 15%) were accepted by panelists. Many authors suggested inoculation sausage with starter culture as it resulted in higher sensory properties [27-29].

|

4. Conclusions

- Based on the results, it has been found that there are substantial variations in the chemical, microbiological characteristics and sensory parameters of the investigated camel meat sausages. Therefore the production of camel meat sausages, should be standardized. In addition, a good hygienic practice applied during production gives healthy sausages for consumers. There is a clear effect of season and preservation time on meat quality. So, the optimum period for camel meat preservation seems to be during winter and summer months. Meat produced by younger camels has higher quality than old camels. The season had a significant effect on the quality of camel’s meat, due to its effect on pH and water holding capacity. Age of the animals had an effect on water holding capacity and rancidity, but had no effect on pH. The storage period had a significant effect on the oxidative rancidity that affect the shelf life of meat.Camel meats have good processing characteristics and quality. Results of taste panel reveal that camel products such as sausage prepared from stored meat were acceptable. Furthermore camel meat can be frozen for long time.Data of freezing and processing camel meat products is lacking. So we need more studies and research on this field, to be used in take away food in Sudan.

ACKNOWLEDGEMENTS

- The authors express their sincere thanks to the Academic Exchange Service (DAAD), Germany, for financing this work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML