| [1] | BBCRESEARCH, 2013, "Starches/Glucose: Global Markets.", [Online]. Available: http://www.bccresearch.com/market-research/food-and-beverage/starch-glucose-fod037b.html |

| [2] | World News Network, 2014, "Starch Derivatives Market to Grow at a CAGR of 6.2% to 2019 in New Research...", [Online]. Available: http://article.wn.com. |

| [3] | Falade, K. O., Okafor, C. A., 2013, "Physicochemical properties of five cocoyam (Colocasia esculenta and Xanthosoma sagittifolium) starches", Food Hydrocolloids, 30, (1), 173-181. |

| [4] | Pascoal, A. M., Di-Medeiros, M. C. B., Batista, K. A., Leles, M. I. G., Lião, L. M., Fernandes, K. F., 2013, "Extraction and chemical characterization of starch from S. lycocarpum fruits", Carbohydrate Polymers, 98, (2), 1304-1310. |

| [5] | Lawal, O. S., 2011, "Hydroxypropylation of pigeon pea (Cajanus cajan) starch: Preparation, functional characterizations and enzymatic digestibility", LWT - Food Science and Technology, 44, (3), 771-778. |

| [6] | Daudt, R. M., Külkamp-Guerreiro, I. C., Cladera-Olivera, F., Thys, R. C. S., Marczak, L. D. F., 2014, "Determination of properties of pinhão starch: Analysis of its applicability as pharmaceutical excipient", Industrial Crops and Products, 52, 420-429. |

| [7] | Pérez-Pacheco, E., Moo-Huchin, V. M., Estrada-León, R. J., Ortiz-Fernández, A., May-Hernández, L. H., Ríos-Soberanis, C. R., Betancur-Ancona, D., 2014, "Isolation and characterization of starch obtained from Brosimum alicastrum Swarts Seeds", Carbohydrate Polymers, 101, 920-927. |

| [8] | Zhu, F., Wang, Y.-J., 2013, "Characterization of modified high-amylose maize starch-α-naphthol complexes and their influence on rheological properties of wheat starch", Food Chemistry, 138, (1), 256-262. |

| [9] | Albano, K. M., Franco, C. M. L., Telis, V. R. N., 2014, "Rheological behavior of Peruvian carrot starch gels as affected by temperature and concentration", Food Hydrocolloids, 40, 30-43. |

| [10] | Yuan, Y., Zhang, L., Dai, Y., Yu, J., 2007, "Physicochemical properties of starch obtained from Dioscorea nipponica Makino comparison with other tuber starches", Journal of Food Engineering, 82, (4), 436-442. |

| [11] | Chung, H. J., Donner, E., Liu, Q., 4.43 - Resistant Starches in Foods, pp.527-534, in: Comprehensive Biotechnology (Second Edition), M. Moo-Young (Ed.), Academic Press, Burlington, 2011. |

| [12] | Klein, B., Pinto, V. Z., Vanier, N. L., Zavareze, E. d. R., Colussi, R., Evangelho, J. A. d., Gutkoski, L. C., Dias, A. R. G., 2013, "Effect of single and dual heat–moisture treatments on properties of rice, cassava, and pinhao starches", Carbohydrate Polymers, 98, (2), 1578-1584. |

| [13] | Wani, I. A., Jabeen, M., Geelani, H., Masoodi, F. A., Saba, I., Muzaffar, S., 2014, "Effect of gamma irradiation on physicochemical properties of Indian Horse Chestnut (Aesculus indica Colebr.) starch", Food Hydrocolloids, 35, 253-263. |

| [14] | Sofi, B. A., Wani, I. A., Masoodi, F. A., Saba, I., Muzaffar, S., 2013, "Effect of gamma irradiation on physicochemical properties of broad bean (Vicia faba L.) starch", LWT - Food Science and Technology, 54, (1), 63-72. |

| [15] | Santelia, D., Zeeman, S. C., 2011, "Progress in Arabidopsis starch research and potential biotechnological applications", Current Opinion in Biotechnology, 22, (2), 271-280. |

| [16] | Almeida, A. P., Rodríguez-Rojo, S., Serra, A. T., Vila-Real, H., Simplicio, A. L., Delgadilho, I., Beirão da Costa, S., Beirão da Costa, L., Nogueira, I. D., Duarte, C. M. M., 2013, "Microencapsulation of oregano essential oil in starch-based materials using supercritical fluid technology", Innovative Food Science & Emerging Technologies, 20, 140-145. |

| [17] | "The difference among Flour, Cornstarch, Potato Starch, and Arrowroot", 2014, [Online]. Available:http://www.hxcorp.com.vn/news/952-the-difference-among-flour-cornstarch-potato-starch-and-arrowroot.html. |

| [18] | "Starch", 2014, [Online]. Available: http://www.bakeinfo.co.nz/Facts/Bread-making/Bread-ingredients/Starch. |

| [19] | Copeland, L., Blazek, J., Salman, H., Tang, M. C., 2009, "Form and functionality of starch", Food Hydrocolloids, 23, (6), 1527-1534. |

| [20] | BioFlora, 2014, "The Dirty Work – Yellow Field Corn Case Study", [Online]. Available:http://www.bioflora.com/case-study-corn/. |

| [21] | Carlstedt, J., Wojtasz, J., Fyhr, P., Kocherbitov, V., 2014, "Hydration and the phase diagram of acid hydrolyzed potato starch", Carbohydrate Polymers, 112, 569-577. |

| [22] | Homer, S., Kelly, M., Day, L., 2014, "Determination of the thermo-mechanical properties in starch and starch/gluten systems at low moisture content – A comparison of DSC and TMA", Carbohydrate Polymers, 108, (0), 1-9. |

| [23] | Bertolini, A. C., Trends in starch applications, in: Starches: Characterization, Properties and Applications, C. Press (Ed.), 2010. |

| [24] | Lawal, O. S., Adebowale, K. O., 2005, "Physicochemical characteristics and thermal properties of chemically modified jack bean (Canavalia ensiformis) starch", Carbohydrate Polymers, 60, (3), 331-341. |

| [25] | Li, J. Z., Chapter 18 - The Use of Starch-Based Materials for Microencapsulation, pp.195-210, in: Microencapsulation in the Food Industry, A. G. Gaonkar, N. Vasisht, A. R. Khare, R. Sobel (Ed.), Academic Press, San Diego, 2014. |

| [26] | Aila-Suárez, S., Palma-Rodríguez, H. M., Rodríguez- Hernández, A. I., Hernández-Uribe, J. P., Bello-Pérez, L. A., Vargas-Torres, A., 2013, "Characterization of films made with chayote tuber and potato starches blending with cellulose nanoparticles", Carbohydrate Polymers, 98, (1), 102-107. |

| [27] | Gregorová, E., Pabst, W., Bohačenko, I., 2006, "Characterization of different starch types for their application in ceramic processing", Journal of the European Ceramic Society, 26, (8), 1301-1309. |

| [28] | Cyprych, K., Sznitko, L., Mysliwiec, J., 2014, "Starch: Application of biopolymer in random lasing", Organic Electronics, 15, (10), 2218-2222. |

| [29] | Li, M., Liu, P., Zou, W., Yu, L., Xie, F., Pu, H., Liu, H., Chen, L., 2011, "Extrusion processing and characterization of edible starch films with different amylose contents", Journal of Food Engineering, 106, (1), 95-101. |

| [30] | Waterschoot, J., Gomand, S. V., Willebrords, J. K., Fierens, E., Delcour, J. A., 2014, "Pasting properties of blends of potato, rice and maize starches", Food Hydrocolloids, 41, 298-308. |

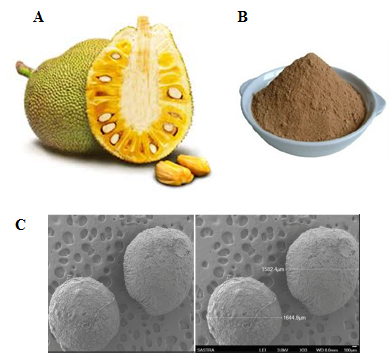

| [31] | "Jackfruit", 2014, [Online]. Available:http://madscientistskitchen.blogspot.com.br/2014/06/neerphanas-aa-chi-bhaji-green-or-raw.html. |

| [32] | "Jackfruit Seeds", 2014, [Online]. Available:http://hxcorp.com.vn/product/508-jackfruit-seeds.html. |

| [33] | Vedha Hari, B. N., Praneetha, T., Prathyusha, T., Mounika, K., Ramya Devi, D., 2014, "Development of Starch-Gelatin Complex Microspheres as Sustained Release Delivery System", J. Adv. Pharm. Tech. Res., 3, (3), 182-187. |

| [34] | Shahid ul, I., Shahid, M., Mohammad, F., 2013, "Perspectives for natural product based agents derived from industrial plants in textile applications – a review", Journal of Cleaner Production, 57, 2-18. |

| [35] | Herrero, A. M., Carmona, P., Jiménez-Colmenero, F., Ruiz-Capillas, C., 2014, "Polysaccharide gels as oil bulking agents: Technological and structural properties", Food Hydrocolloids, 36, 374-381. |

| [36] | Homayouni, A., Azizi, A., Ehsani, M. R., Yarmand, M. S., Razavi, S. H., 2008, "Effect of microencapsulation and resistant starch on the probiotic survival and sensory properties of synbiotic ice cream", Food Chemistry, 111, (1), 50-55. |

| [37] | Liu, Y., Bhandari, B., Zhou, W., 2007, "Study of glass transition and enthalpy relaxation of mixtures of amorphous sucrose and amorphous tapioca starch syrup solid by differential scanning calorimetry (DSC)", Journal of Food Engineering, 81, (3), 599-610. |

| [38] | Rosicka-Kaczmarek, J., Kwaśniewska-Karolak, I., Nebesny, E., Miśkiewicz, K., 2013, "Influence of variety and year of wheat cultivation on the chemical composition of starch and properties of glucose hydrolysates", Journal of Cereal Science, 57, (1), 98-106. |

| [39] | Lu, Z., He, F., Shi, Y., Lu, M., Yu, L., 2010, "Fermentative production of L(+)-lactic acid using hydrolyzed acorn starch, persimmon juice and wheat bran hydrolysate as nutrients", Bioresource Technology, 101, (10), 3642-3648. |

| [40] | Poomipuk, N., Reungsang, A., Plangklang, P., 2014, "Poly-β-hydroxyalkanoates production from cassava starch hydrolysate by Cupriavidus sp. KKU38", International Journal of Biological Macromolecules, 65, 51-64. |

| [41] | Becerra, V., Odermatt, J., 2014, "Direct determination of cationic starches in paper samples using analytical pyrolysis", Journal of Analytical and Applied Pyrolysis, 105, (0), 348-354. |

| [42] | Letelier-Gordo, C. O., Holdt, S. L., De Francisci, D., Karakashev, D. B., Angelidaki, I., 2014, "Effective harvesting of the microalgae Chlorella protothecoides via bioflocculation with cationic starch", Bioresource Technology, 167, 214-218. |

| [43] | Li, M., Liu, G.-L., Chi, Z., Chi, Z.-M., 2010, "Single cell oil production from hydrolysate of cassava starch by marine-derived yeast Rhodotorula mucilaginosa TJY15a", Biomass and Bioenergy, 34, (1), 101-107. |

| [44] | Setty, C. M., Deshmukh, A. S., Badiger, A. M., 2014, "Hydrolyzed polyacrylamide grafted maize starch based microbeads: Application in pH responsive drug delivery", International Journal of Biological Macromolecules, 70, 1-9. |

| [45] | Yang, Z., Yuan, B., Li, H., Yang, Y., Yang, H., Li, A., Cheng, R., 2014, "Amphoteric starch-based flocculants can flocculate different contaminants with even opposite surface charges from water through molecular structure control", Colloids and Surfaces A: Physicochemical and Engineering Aspects, 455, 28-35. |

| [46] | Çatal, H., İbanoğlu, Ş., 2014, "Effect of aqueous ozonation on the pasting, flow and gelatinization properties of wheat starch", LWT - Food Science and Technology, 59, (1), 577-582. |

| [47] | Gonçalves, P. M., Noreña, C. P. Z., da Silveira, N. P., Brandelli, A., 2014, "Characterization of starch nanoparticles obtained from Araucaria angustifolia seeds by acid hydrolysis and ultrasound", LWT - Food Science and Technology, 58, (1), 21-27. |

| [48] | van der Maarel, M. J. E. C., Leemhuis, H., 2013, "Starch modification with microbial alpha-glucanotransferase enzymes", Carbohydrate Polymers, 93, (1), 116-121. |

| [49] | Gamonpilas, C., Pongjaruvat, W., Methacanon, P., Seetapan, N., Fuongfuchat, A., Klaikherd, A., 2013, "Effects of cross-linked tapioca starches on batter viscosity and oil absorption in deep-fried breaded chicken strips", Journal of Food Engineering, 114, (2), 262-268. |

| [50] | Lay, C.-H., Kuo, S.-Y., Sen, B., Chen, C.-C., Chang, J.-S., Lin, C.-Y., 2012, "Fermentative biohydrogen production from starch-containing textile wastewater", International Journal of Hydrogen Energy, 37, (2), 2050-2057. |

| [51] | Czech, Z., Wilpiszewska, K., Tyliszczak, B., Jiang, X., Bai, Y., Shao, L., 2013, "Biodegradable self-adhesive tapes with starch carrier", International Journal of Adhesion and Adhesives, 44, 195-199. |

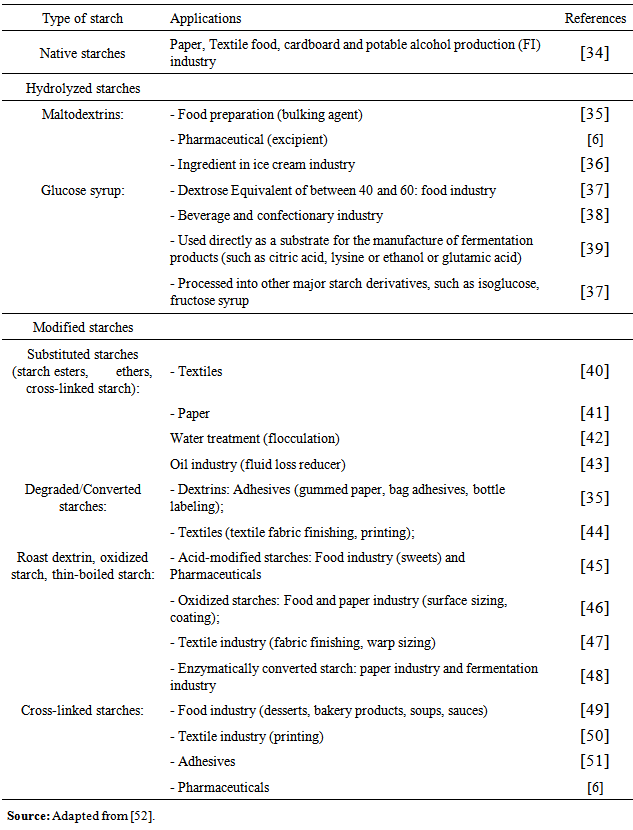

| [52] | Agrosynergie, Description of the sector, pp.17-80, in: Evaluation of Common Agricultural Policy measures applied to the starch sector E. Commission (Ed.), 2010. |

| [53] | de la Torre-Gutiérrez, L., Chel-Guerrero, L. A., Betancur-Ancona, D., 2008, "Functional properties of square banana (Musa balbisiana) starch", Food Chemistry, 106, (3), 1138-1144. |

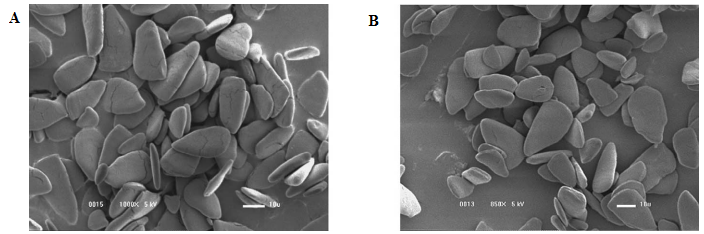

| [54] | Kuttigounder, D., Lingamallu, J. R., Bhattacharya, S., 2011, "Turmeric Powder and Starch: Selected Physical, Physicochemical, and Microstructural Properties", Journal of Food Science, 76, (9), 1284-1291. |

| [55] | Leonel, M., Sarmento, S. B. S., Cereda, M. P., 2003, "New starches for the food industry: Curcuma longa and Curcuma zedoaria", Carbohydrate Polymers, 54, (3), 385-388. |

| [56] | Nwokocha, L. M., Williams, P. A., 2009, "New starches: Physicochemical properties of sweetsop (Annona squamosa) and soursop (Anonna muricata) starches", Carbohydrate Polymers, 78, (3), 462-468. |

| [57] | Madruga, M. S., de Albuquerque, F. S. M., Silva, I. R. A., do Amaral, D. S., Magnani, M., Queiroga Neto, V., 2014, "Chemical, morphological and functional properties of Brazilian jackfruit (Artocarpus heterophyllus L.) seeds starch", Food Chemistry, 143, 440-445. |

| [58] | Van Hung, P., Morita, N., 2007, "Chemical compositions, fine structure and physicochemical properties of kudzu (Pueraria lobata) starches from different regions", Food Chemistry, 105, (2), 749-755. |

| [59] | Braga, M. E. M., Moreschi, S. R. M., Meireles, M. A. A., 2006, "Effects of supercritical fluid extraction on Curcuma longa L. and Zingiber officinale R. starches. ", Carbohydrate Polymers, 63, 340-346. |

| [60] | Goñi, O., Escribano, M. I., Merodio, C., 2008, "Gelatinization and retrogradation of native starch from cherimoya fruit during ripening, using differential scanning calorimetry", LWT - Food Science and Technology, 41, (2), 303-310. |

| [61] | Tovar, J., Bjoerck, I. M., Asp, N. G., 1990, "Starch content and .alpha.-amylolysis rate in precooked legume flours", Journal of Agricultural and Food Chemistry, 38, (9), 1818-1823. |

| [62] | Villarreal, M. E., Ribotta, P. D., Iturriaga, L. B., 2013, "Comparing methods for extracting amaranthus starch and the properties of the isolated starches", LWT - Food Science and Technology, 51, (2), 441-447. |

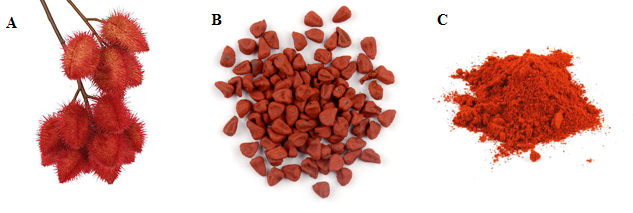

| [63] | Nabard, 2014, "Annatto", [Online]. Available:https://www.nabard.org/english/medical_annato2.aspx. |

| [64] | Kasemsuwan, T., Jane, J., Schnable, P., Stinar, P., Robertson, D., 1995, "Characterization of the dominant mutant amyl-ose-extender (Ae1-5180) maize starch", Cereal Chem., 72, (5), 457-464. |

| [65] | Stevenson, D. G., Domoto, P. A., Jane, J.-l., 2006, "Structures and functional properties of apple (Malus domestica Borkh) fruit starch", Carbohydrate Polymers, 63, (3), 432-441. |

| [66] | Métodos Químicos e Físicos para Análise de Alimentos, Instituto Adolfo Lutz, São Paulo, 2005. |

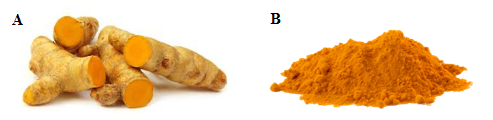

| [67] | Cinelli, B. A., López, J. A., Castilho, L. R., Freire, D. M. G., Castro, A. M., 2014, "Granular starch hydrolysis of babassu agroindustrial residue: A bioprocess within the context of biorefinery", Fuel, 124, (0), 41-48. |

| [68] | Betancur-Ancona, D., López-Luna, J., Chel-Guerrero, L., 2003, "Comparison of the chemical composition and functional properties of Phaseolus lunatus prime and tailing starches", Food Chemistry, 82, (2), 217-225. |

| [69] | Chrastil, J., 1987, "Improved Calorimetric Determination of Amylose in Starches and Flours", Carbohydrate Research, 158, 154–158. |

| [70] | Barminas, J. T., Onen, A. I., Williams, E. T., Zaruwa, M. Z., Mamuru, S. A., Haggai, D., 2008, "Studies on functional properties of borassus starch from fresh germinating nuts of giginya (Borassus aethiopum) palm", Food Hydrocolloids, 22, (2), 298-304. |

| [71] | Nwokocha, L. M., Williams, P. A., 2011, "Comparative study of physicochemical properties of breadfruit (Artocarpus altilis) and white yam starches", Carbohydrate Polymers, 85, (2), 294-302. |

| [72] | AOAC, Official Methods of Analysis of AOAC International, Vol. 2, 16nd ed., Arlington, 1995. |

| [73] | Morrison, W. R., Laignelet, B., 1983, " An improved colorimetric procedure for determining apparent and total amyl-ose in cereal and other starches", Journal of Cereal Science, 1, (1), 9-20. |

| [74] | Flores-Gorosquera, E., García-Suárez, F. J., Flores-Huicochea, E., Núñez-Santiago, M. C., González-Soto, R. A., Bello-Pérez, L. A., 2004, "Rendimiento del proceso de extracción de almidón a partir de frutos de plátano (Musa paradisiaca), Estudio en planta piloto", Acta Científica Venezolana, 55, 86-90. |

| [75] | Aparicio-Saguilán, A., Méndez-Montealvo, G., Solorza-Feria, J., Bello-Pérez, L. A., 2006, "Thermal and viscoelastic properties of starch gels from maize varieties", Journal of the Science of Food and Agriculture, 86, (7), 1078-1086. |

| [76] | Cruz, B. R., Abraão, A. S., Lemos, A. M., Nunes, F. M., 2013, "Chemical composition and functional properties of native chestnut starch (Castanea sativa Mill)", Carbohydrate Polymers, 94, (1), 594-602. |

| [77] | Hoover, R., Ratnayake, W. S., 2002, " Starch characteristics of black bean, chick pea, lentil, navy bean and pinto bean cultivars grown in Canada. ", Food Chemistry, 78, 489–498. |

| [78] | Hughes, T., Hoover, R., Liu, Q., Donner, E., Chibbar, R., Jaiswal, S., 2009, "Composition, morphology, molecular structure, and physicochemical properties of starches from newly released chickpea (Cicer arietinum L.) cultivars grown in Canada", Food Research International, 42, (5–6), 627-635. |

| [79] | Vriesmann, L. C., Silveira, J. L. M., Petkowicz, C. L. d. O., 2009, "Chemical and rheological properties of a starch-rich fraction from the pulp of the fruit cupuassu (Theobroma grandiflorum)", Materials Science and Engineering: C, 29, (2), 651-656. |

| [80] | AACC, Approved methods of the American Association of Cereal Chemists, Vol. 1-2, 9nd ed., St. Paul, Minnesota, 1995. |

| [81] | Huang, Y., Jin, Y., Fang, Y., Li, Y., Zhao, H., 2013, "Simultaneous utilization of non-starch polysaccharides and starch and viscosity reduction for bioethanol fermentation from fresh Canna edulis Ker. tubers", Bioresource Technology, 128, 560-564. |

| [82] | Braga, M. E. M., Moreschi, S. R. M., Meireles, M. A. A., 2006, "Effects of supercritical fluid extraction on Curcuma longa L. and Zingiber officinale R. starches", Carbohydrate Polymers, 63, (3), 340-346. |

| [83] | Miao, M., Zhang, T., Jiang, B., 2009, "Characterizations of Kabuli and Desi chickpea starches cultivated in China", Food Chemistry, 113, 1025–1032. |

| [84] | Miao, M., Jiang, H., Jiang, B., Cui, S. W., Jin, Z., Zhang, T., 2012, "Structure and functional properties of starches from Chinese ginkgo (Ginkgo biloba L.) nuts", Food Research International, 49, (1), 303-310. |

| [85] | Jayakody, L., Lan, H., Hoover, R., Chang, P., Liu, Q., Donner, E., 2007, "Composition, molecular structure, and physicochemical properties of starches from two grass pea (Lathyrus sativus L.) cultivars grown in Canada", Food Chemistry, 105, (1), 116-125. |

| [86] | Bobbio, F. O., EI-Dash, A. A., Bobbio, P. A., Rodrigues, L. R., 1978, "Isolation and characterization of the physico-chemiscal properties of the starch of jackfruit seeds (Artocarpus heterophyllus)", Cereal Chemistry, 55, 505-511. |

| [87] | Rengsutthi, K., Charoenrein, S., 2011, "Physico-chemical properties of jackfruit seed starch (Artocarpus heterophyllus) and its application as a thickener and stabilizer in chilli sauce", LWT - Food Science and Technology, 44, (5), 1309-1313. |

| [88] | Singh, J., McCarthy, O. J., Singh, H., Moughan, P. J., Kaur, L., 2007, "Morphological, thermal and rheological characterization of starch isolated from New Zealand Kamo Kamo (Cucurbita pepo) fruit – A novel source", Carbohydrate Polymers, 67, (2), 233-244. |

| [89] | Klucinec, J. D., Thompson, D. B., 1998, "Fractionation of High-Amylose Maize Starches by Differential Alcohol Precipitation and Chromatography of the Fractions ", Cereal Chemistry, 75, 887–896. |

| [90] | Maaran, S., Hoover, R., Donner, E., Liu, Q., 2014, "Composition, structure, morphology and physicochemical properties of lablab bean, navy bean, rice bean, tepary bean and velvet bean starches", Food Chemistry, 152, 491-499. |

| [91] | Li, B. W., Schuhmann, P. J., Wolf, W. R., 1985, "Chromatographic Determinations of Sugars and Starch in a Diet Composite Reference Material.", J. Agric. Food Chem. , 33, (33 ), 531-536. |

| [92] | Sotomayor, C., Frias, J., Fornal, J., Sadowska, D., Urbano, G., Vidal-Verde, C., 1999, "Lentil Starch Content and its Microscopical Structure as Influenced by Natural Fermentation", Starch/Stärke, 51, (5). |

| [93] | I., G., García-Díaz, L., Saura-Calixto, F., 1997, "A starch hydrolysis procedure to estimate glycemic index", Nutr Res., 17, 427–437. |

| [94] | Bello-Pérez, L. A., Sayágo-Ayerdi, S. G., Cháves-Murillo, C. E., Agama-Acevedo, E., Tovar, J., 2007, "Proximal composition and in vitro digestibility of starch in lima bean (Phaseolus lunatus) varieties", Journal of the Science of Food and Agriculture, 87, 2570-2575. |

| [95] | Areas, J. A. G., Lajolo, F. M., 1981, ".Starch transfor-mation during banana ripening: I-The phosphorylase and phosphatase behavior in Musa acuminate", Journal of Food Biochemistry, 5, 19-37. |

| [96] | Rondán-Sanabria, G. G., Finardi-Filho, F., 2009, "Physical–chemical and functional properties of maca root starch (Lepidium meyenii Walpers)", Food Chemistry, 114, (2), 492-498. |

| [97] | Policegoudra, R. S., Aradhya, S. M., 2008, "Structure and biochemical properties of starch from an unconventional source—Mango ginger (Curcuma amada Roxb.) rhizome", Food Hydrocolloids, 22, (4), 513-519. |

| [98] | Annor, G. A., Marcone, M., Bertoft, E., Seetharaman, K., 2013, "In Vitro Starch Digestibility and Expected Glycemic Index of Kodo Millet (Paspalum scrobiculatum) as Affected by Starch–Protein–Lipid Interactions", Cereal Chemistry Journal, 90, (3), 211-217. |

| [99] | Zhu, F., 2014, "Structure, physicochemical properties, and uses of millet starch", Food Research International, 64, 200-211. |

| [100] | Naguleswaran, S., Vasanthan, T., Hoover, R., Bressler, D., 2014, "Amylolysis of amylopectin and amylose isolated from wheat, triticale, corn and barley starches", Food Hydrocolloids, 35, 686-693. |

| [101] | Shi, M., Zhang, Z., Yu, S., Wang, K., Gilbert, R. G., Gao, Q., 2014, "Pea starch (Pisum sativum L.) with slow digestion property produced using β-amylase and transglucosidase", Food Chemistry, 164, 317-323. |

| [102] | Castaño, J., Bouza, R., Rodríguez-Llamazares, S., Carrasco, C., Vinicius, R. V. B., 2012, "Processing and characterization of starch-based materials from pehuen seeds (Araucaria araucana (Mol) K. Koch)", Carbohydrate Polymers, 88, (1), 299-307. |

| [103] | Selected laboratory methods for maize quality evaluation, International Institute of Tropical Agriculture (IITA), Ibadan, Nigeria, 1995. |

| [104] | Alves, F. V., Polesi, L. F., Aguiar, C. L., Sarmento, S. B. S., 2014, "Structural and physicochemical characteristics of starch from sugar cane and sweet sorghum stalks", Carbohydrate Polymers, 111, 592-597. |

| [105] | Fraser, T. R., Brendon-Bravo, M., Holmes, D. C., 1956, "Proximate analysis of wheat flour carbohydrates. 1. Methods and scheme of analysis", J. Sci. Food Agric., 7, 577-589. |

| [106] | Abebe, W., Ronda, F., 2014, "Rheological and textural properties of tef [Eragrostis tef (Zucc.) Trotter] grain flour gels", Journal of Cereal Science, 60, (1), 122-130. |

| [107] | Rickard, J. E., Behn, K. R., 1987, "Evaluation of acid and enzyme hydrolitic methods for determination of cassava starch", Journal of the Science of Food and Agriculture, 41, 373-379. |

| [108] | Falade, K. O., Ayetigbo, O. E., 2014, "Effects of annealing, acid hydrolysis and citric acid modifications on physical and functional properties of starches from four yam (Dioscorea spp.) cultivars", Food Hydrocolloids, 1-11. |

| [109] | Ambigaipalan, P., Hoover, R., Donner, E., Liu, Q., Jaiswal, S., Chibbar, R., Nantanga, K. K. M., Seetharaman, K., 2011, "Structure of faba bean, black bean and pinto bean starches at different levels of granule organization and their physicochemical properties", Food Research International, 44, (9), 2962-2974. |

| [110] | Williams, P. C., Kuzina, F. D., Hlynka, I., 1970, "A rapid calorimetric procedure for estimating the amylose content of starches and flours", Cereal Chem., 47, 411-420. |

| [111] | Carrillo-Navas, H., Hernández-Jaimes, C., Utrilla-Coello, R. G., Meraz, M., Vernon-Carter, E. J., Alvarez-Ramirez, J., 2014, "Viscoelastic relaxation spectra of some native starch gels", Food Hydrocolloids, 37, (0), 25-33. |

| [112] | Holtekjølen, A. K., Uhlen, A. K., Bråthen, E., Sahlstrøm, S., Knutsen, S. H., 2006, "Contents of starch and non-starch polysaccharides in barley varieties of different origin", Food Chemistry, 94, (3), 348-358. |

| [113] | Osunsami, A. T., Akingbala, J. O., Oguntimein, G. B., 1989, "Effect of Storage on Starch Content and Modification of Cassava Starch ", Starch/Starke, 41, 54-57. |

| [114] | Kim, J.-Y., Choi, Y.-G., Byul Kim, S. R., Lim, S.-T., 2014, "Humidity stability of tapioca starch–pullulan composite films", Food Hydrocolloids, 41, 140-145. |

| [115] | Piyachomkwan, K., Chotineeranat, S., Kijkhunasatian, C., Tonwitowat, R., Prammanee, S., Oates, C. G., Sriroth, K., 2002, "Edible canna (Canna edulis) as a complementary starch source to cassava for the starch industry", Industrial Crops and Products, 16, (1), 11-21. |

| [116] | Joshi, M., Aldred, P., Panozzo, J. F., Kasapis, S., Adhikari, B., 2014, "Rheological and microstructural characteristics of lentil starch–lentil protein composite pastes and gels", Food Hydrocolloids, 35, (0), 226-237. |

| [117] | Mukprasirt, A., Sajjaanantakul, K., 2004, "Physico-chemical properties of flour and starch from jackfruit seeds (Artocarpus heterophyllus Lam.) compared with modified starches", International Journal of Food Science & Technology, 39, (3), 271-276. |

| [118] | Campechano-Carrera, E., Corona-Cruz, A., Chel-Guerrero, L., Betancur-Ancona, D., 2007, "Effect of pyrodextrinization on available starch content of Lima bean (Phaseolus lunatus) and Cowpea (Vigna unguiculata) starches", Food Hydrocolloids, 21, (3), 472-479. |

| [119] | Ahmed, J., Auras, R., 2011, "Effect of acid hydrolysis on rheological and thermal characteristics of lentil starch slurry", LWT - Food Science and Technology, 44, (4), 976-983. |

| [120] | Nguyen, C.-N., Le, T.-M., Chu-Ky, S., 2014, "Pilot scale simultaneous saccharification and fermentation at very high gravity of cassava flour for ethanol production", Industrial Crops and Products, 56, 160-165. |

| [121] | Considine, T., Noisuwan, A., Hemar, Y., Wilkinson, B., Bronlund, J., Kasapis, S., 2011, "Rheological investigations of the interactions between starch and milk proteins in model dairy systems: A review", Food Hydrocolloids, 25, (8), 2008-2017. |

| [122] | Olivato, J. B., Müller, C. M. O., Carvalho, G. M., Yamashita, F., Grossmann, M. V. E., 2014, "Physical and structural characterisation of starch/polyester blends with tartaric acid", Materials Science and Engineering: C, 39, 35-39. |

| [123] | Santos, L. F., Dias, V. M., Pilla, V., Andrade, A. A., Alves, L. P., Munin, E., Monteiro, V. S., Zilio, S. C., 2014, "Spectroscopic and photothermal characterization of annatto: Applications in functional foods", Dyes and Pigments, 110, (0), 72-79. |

| [124] | OrgenFamily, 2014, "Organic Annatto (Bixa orellana)", [Online]. Available:http://www.orgenfamily.com/orgen-bt.html. |

| [125] | "Annatto Powder", 2014, [Online]. Available: http://www.souschef.co.uk/annatto-powder.html. |

| [126] | GourmetStore, 2014, "Annatto Seed", [Online]. Available: http://www.gourmetstore.com/node/718. |

| [127] | "Curcuma longa", 2014, [Online]. Available:http://www.ndhealthfacts.org/wiki/Curcuma_longa. |

| [128] | "Turmeric: an ancient spice that can benefit you today", 2014, [Online]. Available:http://functionalformularies.com/2014/03/28/turmeric/#sthash.pLOFJ8o4.dpbs. |

| [129] | Amaral, L. I. V., Pereira, M. F. D. A., Cortelazzo, A. L., 2001, "Formação das Substâncias de Reserva Durante o Desenvolvimento de Sementes de Urucum (Bixa orellana L. - Bixaceae)", Acta Bot. Bras., 15, (1), 125-132. |

| [130] | Paramera, E. I., Konteles, S. J., Karathanos, V. T., 2011, "Stability and release properties of curcumin encapsulated in Saccharomyces cerevisiae, β-cyclodextrin and modified starch", Food Chemistry, 125, (3), 913-922. |

| [131] | Osório-Tobón, J. F., Meireles, M. A. A., 2013, "Recent Applications of Pressurized Fluid Extraction: Curcuminoids Extraction with Pressurized Liquids", Food and Public Health, 3, (6), 289-303. |

| [132] | Carvalho, P. I. N., Osório-Tobón, J. F., Rostagno, M. A., Petenate, A. J., Meireles, M. A. A., "Optimization of the Ar-Turmerone Extraction from Turmeric (Curcuma longa L.) Using Supercritical Carbon Dioxide", in 14th European Meeting on Supercritical Fluids, 2014. |

| [133] | Albuquerque, C. L. C., Meireles, M. A. A., 2012, "Defatting of annatto seeds using supercritical carbon dioxide as a pretreatment for the production of bixin: Experimental, modeling and economic evaluation of the process", The Journal of Supercritical Fluids, 66, (0), 86-95. |

| [134] | Rodrigues, L. M., Alcázar-Alay, S. C., Petenate, A. J., Meireles, M. A. A., 2014, "Bixin extraction from defatted annatto seeds", Comptes Rendus Chimie, 17, (3), 268-283. |

| [135] | Boschetto, D. L., Aranha, E. M., de Souza, A. A. U., Souza, S. M. A. G. U., Ferreira, S. R. S., Priamo, W. L., Oliveira, J. V., 2014, "Encapsulation of bixin in PHBV using SEDS technique and in vitro release evaluation", Industrial Crops and Products, 60, 22-29. |

| [136] | Martins, R. M., Pereira, S. V., Siqueira, S., Salomão, W. F., Freitas, L. A. P., 2013, "Curcuminoid content and antioxidant activity in spray dried microparticles containing turmeric extract", Food Research International, 50, (2), 657-663. |

| [137] | Li, M., Ngadi, M. O., Ma, Y., 2014, "Optimisation of pulsed ultrasonic and microwave-assisted extraction for curcuminoids by response surface methodology and kinetic study", Food Chemistry, 165, 29-34. |

| [138] | Yolmeh, M., Habibi Najafi, M. B., Farhoosh, R., 2014, "Optimisation of ultrasound-assisted extraction of natural pigment from annatto seeds by response surface methodology (RSM)", Food Chemistry, 155, 319-324. |

| [139] | Abbas, S., Bashari, M., Akhtar, W., Li, W. W., Zhang, X., 2014, "Process optimization of ultrasound-assisted curcumin nanoemulsions stabilized by OSA-modified starch", Ultrasonics Sonochemistry, 21, (4), 1265-1274. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML