-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2014; 4(5): 223-228

doi:10.5923/j.fph.20140405.03

Impact of Halal and Non-halal Slaughtering on the Microbiological Characteristics of Broiler Chicken Meat and Sausages

Safa Mustafa. Ibrahim1, Mutaman Ali Abdelgadir1, Abdel Moneim Elhadi Sulieman2

1Centre for Biosciences and Biotechnology, Faculty of Engineering and and Technology, University of Gezira

2Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

Correspondence to: Abdel Moneim Elhadi Sulieman, Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The halal (permissible) rules of slaughter are based on Islamic law. The animal has to be alive and healthy, a Muslim has to perform the slaughter in the appropriate ritual manner, and the animal's throat must be cut by a sharp knife severing the carotid artery, jugular vein and windpipe in a single swipe. Blood must be drained out of the carcass. The main objectives of this study were to compare between the quality characteristics of chicken slaughtered according to Islamic rules (halal) and those slaughtered according to non-Islamic rules (non-halal). Twenty hydroid strains of broiler chickens were used and their weights ranging between 1.5-1.75 kg, these chickens were divided into two groups; the first group were slaughtered according to Islamic rule, while according to non-Islamic rule. Sausage was prepared from both types of meat. Microbiological methods were used to analyze chicken meat as well as sausage. The results showed that coliforms were not detected in halal chicken meat, while the non-halal meat contained 3.0 x 103 c.f.u./g. Moreover, the E. coli were found in relatively large number in non-halal meat (4.0 x 104 c.f.u./g) in contrast to halal meat which did not contain any E.coli cells. The halal meat sausage samples were not contaminated with either Coliforms, E. coli or Salmonella, while the non-halal meat sausage contained 15.0 x 105, 23.3 x 104 and 15.0 x 104 c.f.u./g of Coliforms, E. coli and Salmonella, respectively. It is highly recommended to follow the Islamic rule in slaughtering poultry and to apply hazard analysis and food hygiene to reduce the risk of cross contamination with foodborne pathogens in poultry farms.

Keywords: Halal slaughtering, Chicken, Meat, Sausage

Cite this paper: Safa Mustafa. Ibrahim, Mutaman Ali Abdelgadir, Abdel Moneim Elhadi Sulieman, Impact of Halal and Non-halal Slaughtering on the Microbiological Characteristics of Broiler Chicken Meat and Sausages, Food and Public Health, Vol. 4 No. 5, 2014, pp. 223-228. doi: 10.5923/j.fph.20140405.03.

Article Outline

1. Introduction

- Sudan has a very good potential to be world major player in poultry products exports, a lot of local and international investors are starting new poultry business in Sudan. This development in poultry sector is a part of Sudan huge economic development (http://news.sudanvisiondaily.com/details.html?rsnpid=206028) [1].An efficacious way of preventing food-borne human diseases is to monitor the microbiological quality of poultry meat and meat products during production, storage and distribution. According to Fries [2], the microflora of poultry is transferred from the primary production sites to production lines, and further, by subsequent contamination. Microflora of crude chicken meat is heterogeneous and originates from slaughtering premises, operators’ hands, equipment and outfit, and water and air [3]. Processed raw poultry meat naturally harbors bacteria. Most of thebacteria are responsible for the spoilage of poultry meat. However, poultry products can harbor food borne pathogens, from which salmonella stereotypes, Clostridium jejun, Listeria monocytogen, Clostridium perfringens and Staphylococcus aureus [4]. Therefore, poultry and poultry products ranks first or second in foods associated.Halal meat essentially is meat that Muslim is allowed to eat according to Islamic law. The laws require that only certain types of meat can be eaten and that meat must be prepared in a certain way, it is also essential that halal foods is not prepared with non-halal food as there is a risk of cross contamination if a chef accidentally uses the same knife to cut the different types of meat with for example. According to Qur'an and Islamic law some substances are wrong for people to eat, whether by their nature in the way in which they have been treated or butchered, so all halal meat is prepared according to strict guidelines [5]. Allah's name should be pronounced over the meat as thanks during the slaughter process, any animal slaughtered in another idol's name can be never being halal.Processing of poultry meat involves conversion of raw poultry carcasses into value added products e.g. reconstructed products, cold cuts or breaded products. Further processing of poultry meat are improving juiciness and flavor, shelf life and water holding capacity [6].Sausages are a category of processed meat. They are minced processed meat and/or comminuted meat, which may be combined with other foods, and are encased or formed into discrete units. They do not include meat formed or joined into the semblance of cuts of meat. They often used as substitutes for meat flesh. They have a maximum of 50% fat-free meat flesh [7]. Natural and artificial casings are used as forms and containers for sausages. The casings bind and protect the sausage mixture as well as the expansion of the sausage.The objective of the present study was to compare between the microbiological qualities of broiler chicken slaughtered according to Islamic and non-Islamic rules as well as to produce sausage from the two types of chicken meat and evaluation of its microbiological quality.

2. Materials and Methods

2.1. Collection of Samples

- Twenty broilers chicken were collected from Wad Almajzoob farm (cenral Sudan). These chickens are hydroid strains and their weights ranging between 1.5 - 1.75 kg. Each sample was taken immediately after slaughtering in a sterilized container, and transported under aseptic conditions to the Meat Technology Laboratory at the Department of Food Science and Technology of the University of Gezira.

2.2. Methods of Slaughtering

2.2.1. Halal Slaughtering

- The chickens were divided into two groups; each group contained ten broilers chicken. The first group was slaughtered according to Islamic rule (Halal slaughtering). The Halal slaughtering method started with holding the right foot, the feet of the broiler chicken was held. With the left foot, the wings were held down. The boiler chicken was given a drink water so that it relaxed as by this time it was under a lot of stress. The feathers were picked off from the front of the neck so that the knife did not have to cut through the feathers and takes too long. The process started at the beginning by reciting Allah's name and Tasmiyah (Bismillah Allahu Akbar). Then with a very sharp knife, the neck of the chicken was cut till reaching the bone, to ensure that the neck was properly cut for bleed out. The jugular veins and windpipe were cut. To ensure the quality of proper cutting as required by Halal processing, if the knife missed the chicken, cut the chicken neck would be cut by hand.

2.2.2. Non-Halal Slaughtering

- For non-Halal slaughtering, all steps followed in Halal slaughtering were followed with exception to beginning by reciting Allah's name and Tasmiyah (Bismillah Allahu Akbar).

2.3. Preparation of Meat Samples

- Poultry meat samples were prepared for analysis, these samples included: Halal and Non-halal chicken meat samples. The meat samples were transported immediately to the Department of Food Science and Technology laboratory pending.

2.4. Manufacture of Sausage

- Chicken sausage products from halal chicken meat (HCS) and non-halal chicken meat (NHCS) were prepared at the laboratory using standard method adopted by the sausage manufacturer in the Sudan. In this method: Three kg of minced chicken meat were mixed with the ingredients which included: 150 gm wheat flour, 150 gm of vegetable protein (chickpea), 4gm of coriander, 4 gm of shamar, 2gm of chili powder, 2gm of pepper, 2gm of cinnamon, 2gm canella, 2gm of nutmeg, 3 gm of garlic and 10 gm of salt. All these spices had been ground before addition to the recipe. The minced meat and ingredients were mixed in an electric mincing machine, then the mixture was transported to the sausage casing machine, in which the minced meat was enforced into previously prepared cleaned sheep intestine casings, the product was formed into finger-like forms of about 5-7 cm in length.

2.5. Preparation of Serial Dilution

- For preparation of serial dilution, 10 grams meat sample was shaken thoroughly with 90 ml sterile distilled water to give 10-1 dilution. Asset of 6 tubes containing 9ml sterile distilled water was prepared and 1ml of the suspension was transferred to the first tube of the dilution series. This was repeated up to the dilution 10-7 and 1 ml of the suspension was transferred to the first tube of the dilution series. This was repeated up to the dilution 10-7.

2.6. Microbial Analysis

- The different microbiological characteristics of chicken meat product (sausages) were carried out according to Harrigan and McCane [9] methods. These methods included:

2.6.1. Total Viable Count

- One ml aliquots from suitable dilution were transferred aseptically into sterile Petri dishes. To each dilution, 10–15 ml of melted and cooled (42℃) plate count agar were added. Inoculums was mixed well with the medium and allowed to solidify. The plates were then incubated at 37℃ for 24 hours. The total viable count was calculated by the standard formula

2.6.2. Yeast and Mould Count

- From suitable dilution 0.1 ml samples was aseptically surface plated on to Potato Dextrose Agar medium (PDA ) with 40 ppm Chlor amphenicol added to inhabit bacterial growth .The plates were incubated at 25℃ - 28℃ for 48 hour as described by Harrigan and Mac Can [9]. The counts were presented as colony forming units per gram (cfu /g).

2.6.3. Coliform Test

- One ml of sample was plated onto (MacConky Agar) media. The plates were incubated at 37ºC for 48 hours and the counts were presented as colony forming unites per gram (cfu/g).

2.6.4. E.coli Test

- Plates showing positive coliforms were subjected to the confirmed test using Brilliant green bile lactose broth in test tubes with Durham tubes. The test tubes were then incubated at 44ºC for 48 hours. Each confirmed positive tube was sub cultured into E.C. broth medium and then incubated at 44.5ºC for 24 hours. Tubes showing any amount of gas production were considered to be positive.

2.6.5. Salmonella Detection

- Ten grams of sample were weighted aseptically and mixed well with 100 ml sterile nutrient broth. This was incubated at 37ºC for 24 hours. Then 10 ml were drawn aseptically and added to 100 ml selenite broth. The broth was incubated at 37ºC for 24 hours. Then with a loopful streaking was done on dried Bismuth sulphite agar plates. The plates were then incubated at 37ºC for 72 hours.Black metallic sheen discrete colonies indicated the presence of salmonella. A confirmatory test was carried out by taking a discrete black sheen colony and sub culturing it in a Triple sugar iron agar tubes.Production of black colour at the bottom of the tube confirms the presence of salmonella.

3. Results and Discussion

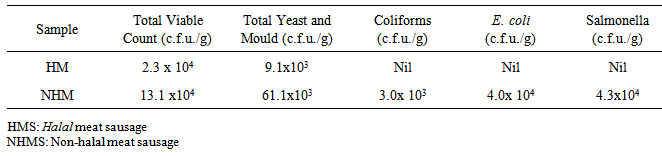

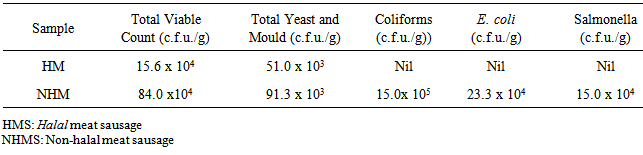

- The study has taken into consideration all the samples of poultry meat and sausage made from poultry meat that arrived at the laboratory during the period from 01/8/2013 to 10/30/2013. The microbiological safety and quality of poultry meat are equally important to producers, retailers and consumers, and both involve microbial contaminants on the processed product. Two quite different groups of microorganisms are relevant: on the one hand certain foodborne pathogens, and, on the other, organisms that are generally harmless to human health, but, being psychrotrophic, are able to multiply on the product during chill storage. Spoilage results mainly from 'off'-odour development, and product shelf-life is determined both by the number of spoilage organisms present initially and the temperature history of the product at all stages of production and subsequent storage and handling [10]. For chill-stored poultry, Viehweg et al. [11] demonstrated that virtually all the odorous substances found at spoilage could be attributed to microbial growth and metabolism.Friedhoff et al. [12] have described the use of simple microbiological criteria, including aerobic mesophilic colony counts, Enterobacteriaceae counts and in some instances, enumeration of yeast, performed on samples taken during processing in small businesses to verify good manufacturing practices. This verification through monitoring was found to be an attractive alternative to the examination of end products. Contamination of poultry meat with foodborne pathogens remains an important public health issue, because it can lead to illness if there are malpractices in handling, cooking or post-cooking storage of the product. In developed countries, foodborne illness causes human suffering and loss of productivity, and adds significantly to the costs of food production and healthcare. It is also a possible cause of mortality, which is even more of a problem in developing regions, where the health status of many individuals is already compromised. The microbiological characteristics of halal and non halal poultry meat and sausage prepared from that meat are indicated in Tables (1 and 2).

|

|

3.1. Microbiological Characteristics of halal and Non Halal Poultry Meat

- The Microbiological characteristics of halal and non halal poultry meat is shown in Table (1). Almost half of the tested samples of poultry show a low contamination and only a few samples had high microbe contamination. The total viable count of halal poultry meat (2.3 x 104 c.f.u./g) was less than that of non-halal poultry meat which was 13.1 x 104 c.f.u./g. Also the yeast and mould count of non-halal poultry meat (61.1x104 c.f.u./g) exceeded that of halal poultry meat which was 9.1x103 c.f.u./g. On the other hand, coliforms were not detected in halal poultry meat, while the non-halal meat contained 3.0 x 103 c.f.u./g of coliforms. Moreover, the E. coli were found in relatively large number in non-halal meat (4.0 x 104 c.f.u./g) in contrast to halal meat which did not contain any E.coli cells. Salmonella spp. were not detected in halal meat while it was found in large numbers in non-halal meat (4.3x104 c.f.u./g). Little et. al., [13] detected Salmonella spp. and E.coli in 7% and 0.6%) of the 183 raw meat products he tested, respectively. Generally, the microbial analysis indicated that halal slaughtering method resulted in lowering the various microbial loads of poultry meat. These data, however, coincide with that reported in the literature[14] [15] whereas they are shown to be much higher with respect to that recently found by Teldeschi [16] in samples of meat from chicken and products derived from chicken.The levels of viable bacteria recovered from non-halal meat samples in this study are similar to those found in a Canadian baseline study of poultry carcasses slaughtered in federally inspected abattoirs in 1997 to 1998 and in the USDA baseline study conducted in 1994 to 1995). The majority of samples had coliform bacteria and generic E. coli at levels of 11 to 100 CFU/cm2, which is also the range for coliforms found in the USDA baseline study for the majority of the samples. The level of E. coli isolated from non-halal meat, however, was higher than the levels reported in the previous Canadian and USDA baseline studies in which most samples had E. coli in the range of 1 to 10 CFU/cm2.Coliform bacteria are one of most important indicator organisms that are most commonly used to ensure food safety. Coliform bacteria include a large group of many types of bacteria that occur throughout the environment. They are common in soil and surface water and may even occur on your skin. Large numbers of certain kinds of coliform bacteria can also be found in waste from humans and animals. Most types of coliform bacteria are harmless to humans, but some can cause mild illnesses and a few can lead to serious waterborne diseases.Specific types of coliform bacteria may be tested for, especially after a total coliform bacteria test is positive. These subgroups of coliform bacteria include fecal coliform and Escherichia coli or E. coli. Fecal coliform bacteria are specific to the intestinal tracts of warm-blooded animals, including humans, and thus require a more specific test for sewage or animal waste contamination. E. coli is a type of fecal coliform bacteria commonly found in the intestines of animals and humans. A positive E. coli result is much more serious than coliform bacteria alone because it indicates that human or animal waste is entering the water supply. There are hundreds of strains of E. coli. Although most strains are harmless and live in the intestines of healthy humans and animals, a few strains can produce a powerful toxin and can cause severe illness and death.Contamination of poultry carcasses and parts with salmonella is well documented and data are available for many parts of the world [4] [17], although inter-country comparisons are not usually possible, because of differences in sampling and methods of testing. Most salmonellas found on poultry meat are non-host-specific and are considered capable of causing human food poisoning. Salmonellas survive well in the environment. Also, growth only occurs under conditions of high moisture, reduced oxygen and an environmental temperature above 30ºC. The organisms are particularly sensitive to drying and the effects of freezing and thawing, which can cause a 1 - 2 log reduction in the level of contamination on poultry meat.It has been reported that E. coli O157 and Salmonella pathogens are known to colonise the intestines of farm animals and may contaminate meat of cattle, sheep, and poultry at the time of slaughter. Pathogenic microorganisms are therefore inherent constituents of raw meat and its products. Subsequent handling and processing of raw meat products such as comminution may spread [18][19].

3.2. Microbiological Characteristics of Sausages Prepared from halal and Non Halal Poultry Meat

- Meat products may be contaminated with microorganisms from meat handlers, who carry pathogenic microorganism during the processes of manufacturing, packing and marketing. Improper cooking, refrigeration or storage may lead to meat borne illness [20]. Foodborne pathogens are the leading causes of illness and death in developing countries costing billions of dollars in medical care medical and social costs.The microbiological characteristics of sausages prepared from halal and non halal poultry meat is shown in Table (2). The total viable count of halal meat sausage (HMS) and non-halal meat sausage (NHMS) was 15.6 x 104 c.f.u./g and 84.0 x104 c.f.u./g, respectively. On the other hand, the total yeast and mould count of HMS and NHMS was 51.0x103 and 91.3x103 (c.f.u./g), respectively. The results in Table (4.2) indicted that the HMS samples were not contaminated with either Coliforms, E. coli or Salmonella, while NHMS samples contained 15.0x 105 c.f.u./g 23.3 x 104 c.f.u./g and 15.0 x 104 c.f.u./g of Coliforms, E. coli and Salmonella, respectively. This indicates that halal slaughtering method resulted in lowering microbial viable counts of halal meat sausage samples. The large counts of different microbial groups in these raw prepared sausages could reflect contaminated supply, cross contamination, and/or poor hygiene practices. However, the microbial contamination may be added or reduced at different stages of processing of hot sausage. Dowdell and Board [21] carried out a microbiological survey of British Fresh Sausage and reported the presence of coliform bacteria. Also, Sachindra et al. [22] who isolated coliforms from raw and cooked sausage concluded that cooking process reduce the microbial counts substantially in the sausage.Some studies showed that the augment of the additives, onion, garlic meal, pepper and E vitamin can decrease the microbial agents in cooked sausage products [23][24][25].

4. Conclusions

- Generally, the microbial analysis indicated that halal slaughtering method resulted in lowering the various microbial loads of poultry meat although the raw meat as well as its product sausage were contaminated with various microbial groups which could reflect contaminated supply, cross contamination, and/or poor hygiene practices. However, the contamination data obtained in the present study are in line with or even less than those reported in the cited literature and fall within within the limits set by national legislation.It is highly recommended to apply the basic rules of hygiene to prevent raw poultry meat from contaminating other foods.

ACKNOWLEDGEMENTS

- The authors express their gratitude and thanks to the staff of the Department of Food Science and Technology of Gezira University for presenting technical assistance.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML