-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2014; 4(5): 214-222

doi:10.5923/j.fph.20140405.02

Evaluation of the Physical and Sensory Characteristics of Bread Produced from Three Varieties of Cassava and Wheat Composite Flours

E. Eriksson1, K. Koch1, C. Tortoe2, P. T. Akonor2, C. Oduro-Yeboah2

1Department of Food Science, Swedish University of Agricultural Sciences, Uppsala, Sweden

2Council for Scientific and Industrial Research, Food Research Institute, Accra, Ghana

Correspondence to: C. Tortoe, Council for Scientific and Industrial Research, Food Research Institute, Accra, Ghana.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

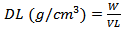

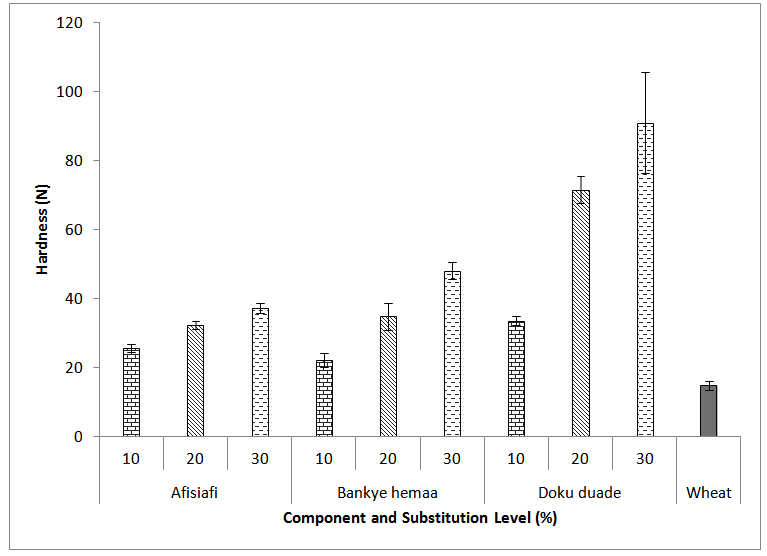

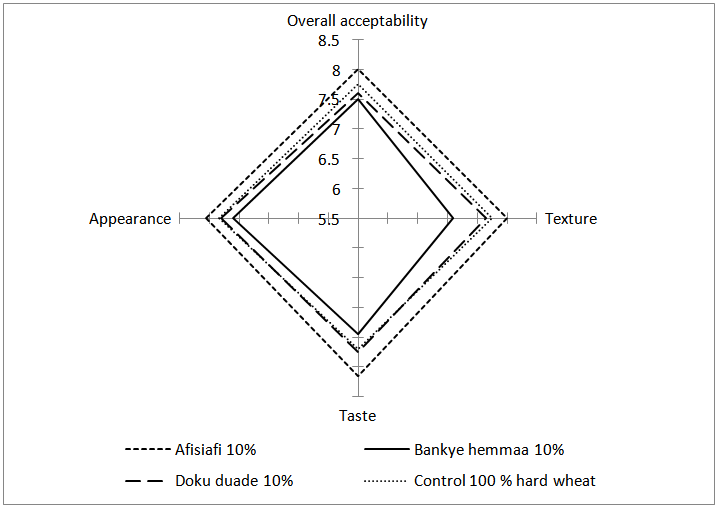

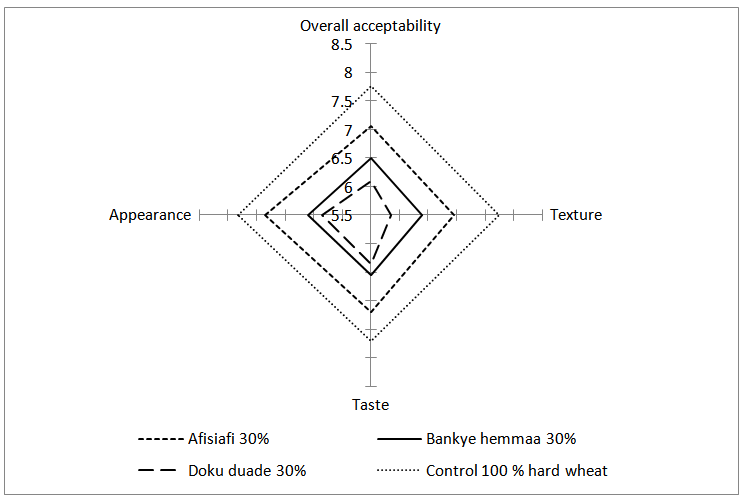

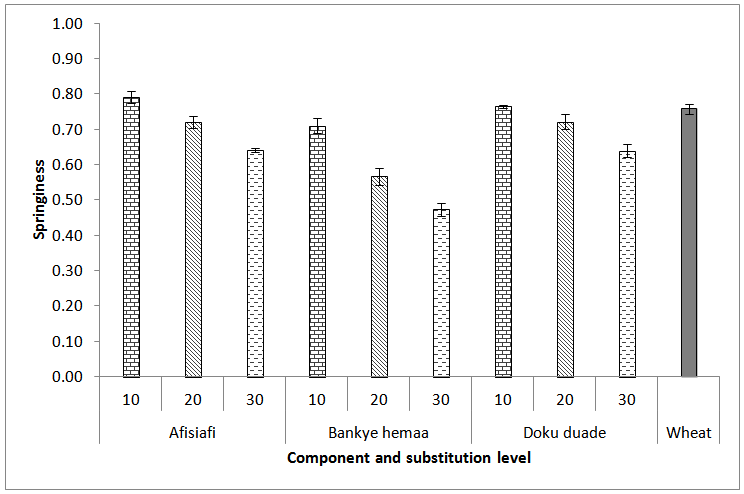

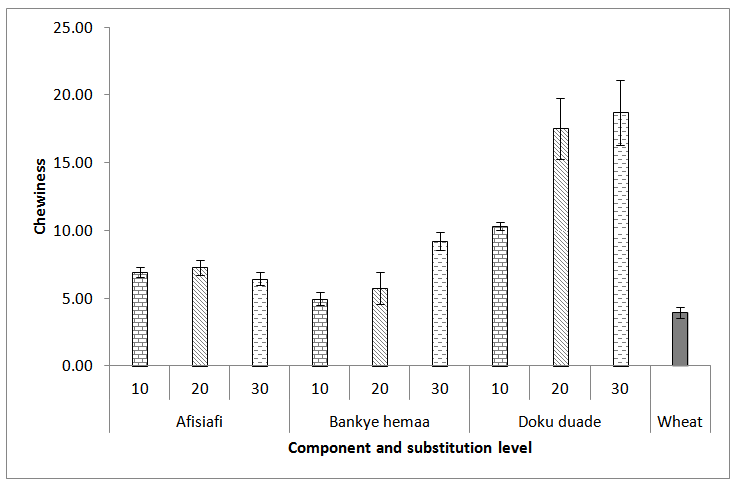

This study determines the most suitable cassava variety and an acceptable maximum substitution level of wheat flour with cassava flour for bread production in terms of baking and organoleptic characteristics using three varieties of cassava. High Quality Cassava Flour produced from three cassava varieties (Afisiafi, Bankye hemmaa and Doku duade) was used together with wheat in composite at 10%, 20% and 30% substitution levels. Bread samples were baked from the resulting composites and examined for its specific volume, density and hardness. The products were also subjected to sensory analysis for appearance, taste, texture and overall acceptability by a semi-trained panel of consumers. Increasing proportion of cassava flour in the composite bread reduced bread specific volume and increased density and hardness. Increasing the content of cassava in the composite resulted in bread that was less springy and difficult to chew. Springiness of bread substituted with 10% and 20% cassava flour compared well with the control, while those with 30% cassava were significantly less springy than the control. A substitution level of 10% Afisiafi and 20 % Bankye hemmaa cassava flour in composite bread on overall acceptable was similar to 100% wheat bread and therefore has the most suitable potential to replace part of wheat flour in bakery products.

Keywords: Physical properties, Sensory analysis, Cassava, Wheat, Composite flours, Bread

Cite this paper: E. Eriksson, K. Koch, C. Tortoe, P. T. Akonor, C. Oduro-Yeboah, Evaluation of the Physical and Sensory Characteristics of Bread Produced from Three Varieties of Cassava and Wheat Composite Flours, Food and Public Health, Vol. 4 No. 5, 2014, pp. 214-222. doi: 10.5923/j.fph.20140405.02.

Article Outline

1. Introduction

- Over the past decades, changing food habits has increased demand for wheat-based convenient foods such as bread and pastries in many developing countries [1-3]. These products are processed with wheat flour as the main raw material because of the superior baking properties of its proteins [4]. The soaring wheat prices on the global market [5] and local concern about huge import of cereal grains, there is an interest to promote the utilization of local sources of flour for partial substitution of wheat flour in these applications. This would reduce the dependency on wheat imports and also increase livelihoods of local farmers who produce crops that may be applied in flour composites. High Quality Cassava Flour has been identified as a local alternative to substitute part of wheat flour in composite flours [1]. In Ghana, cassava is one of the most important crops in terms of production, energy intake, and contribution to Agricultural GDP [6]. Afisiafi, Bankye hemmaa and Doku duade cassava varieties are among the improved varieties most preferred due to their high quality attributes in food forms, pharmaceutical and industrial uses in Ghana. The possibility of using starchy tubers instead of wheat flour in foods depends on their chemical and physical properties. Amylose / amylopectin ratio for example influences the flour’s behavior in food systems; example is the viscosity, gelatinization and setback which affect texture of the end product. The absence of gluten and the acceptability of the end products among consumers in terms of sensory attributes are important issues to be considered in bakery products. The objective of the study was to determine a maximum inclusion level of cassava flour from different cassava varieties in composite flour of wheat and cassava for baking bread without any significant changes in baking capacity and sensory attributes compared to 100% wheat products. Further, we aimed to determine which of the cassava varieties presents the best option in composite flours of wheat and cassava for bread making.

2. Materials and methods

2.1. Cassava

- Three different local cassava varieties, Afisiafi, Bankye hemmaa and Doku duade, were purchased from farm gates at Pokuase, north of Accra, Ghana.

2.2. Processing of Cassava into Flour

- The cassava roots were processed into flour [7]. Afisiafi, Bankye hemmaa and Doku duade cassava varieties were washed in potable water, peeled and secondarily washed and grated with a motorized cassava grater (Cassava Grater, CSIR-FRI, Accra, Ghana). The grated cassava was pressed using a manual screw press (Screw Press, CSIR-FRI, Accra, Ghana). The pressed cassava mash was disintegrated using a cassava grater and dried in a solar dryer of temperature 35 - 48℃ until constant weight. The dried cassava grits were milled into flour using a disc-attrition mill (Mill Machine, CSIR-FRI, Accra, Ghana). Fine flour with a uniform particle size was obtained by employing a motorized flour sifter (Flour Sifter, CSIR-FRI, Accra, Ghana) with a 250 µm screen. The cassava flour was vacuum sealed in air-tight polyethylene bags until subsequent use [8, 9].

2.3. Preparation of Composite Flour

- The three cassava flours were blended with (hard wheat flour at inclusion levels of 10, 20 and 30% and stored in high density polyethylene bags (HDPE) prior to analysis.

2.4. Baking of bread

- Bread was baked with the ingredients composition proportions expressed as the percentage of flour used as 100% flour, 43.6% water, 16.6% margarine, 8.3% Sugar, 2.3% concentrated milk, 0.9 salt, 0.6% dried yeast, 0.4% vanilla flavor and 0.2% nutmeg. The ingredients were purchased from a local market in Accra. Bread baked with 100% wheat flour was used as control. All ten flour samples were baked in duplicate. The dough was kneaded by hand for 20 min, molded into loaves and proofed for 3 hr at room temperature (28°C). The loaves were baked in a gas oven (Ariston, New Zealand) at 180°C for 25 min. Five bread samples per composite flour prepared was allowed to cool to room temperature and stored in HDPE bags for further analysis.

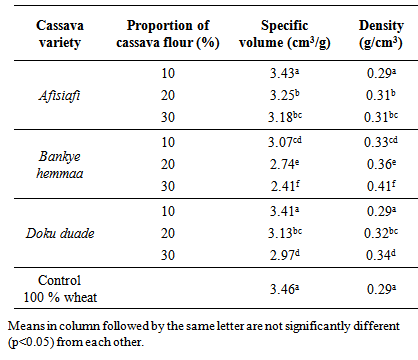

2.5. Specific Volume and Density of Bread

- The weight (W) of the loaves was measured. Loaf volume (VL) was determined by a modification of the rapeseed replacement method according to the AACC [10] using millet instead of rapeseeds. Bread was put in a basin of known volume (VB) and the basin filled to the brim with millet. The bread was removed and the volume of the millet (VM) was measured with a measuring cylinder. Loaf volume (VL) was then determined according to the following formula:

| (1) |

| (2) |

| (3) |

2.6. Texture Analysis of Bread

- Eighteen grams (18 g) of dough from each flour sample was weighed into aluminum molds of 30 mm diameter and baked into bread. The bread samples of 30mm thickness were then used for the Texture Profile Analysis (TPA) using a TA-XT2 Texture Analyser (Stable Micro Systems Surrey, UK), with a 75 mm compression platen probe. A double-bite compression cycle was carried out. The probe was set to compress the samples from a height of 45 mm down to 23 mm (corresponding to 50% of the average bread sample height) at a speed of 7.5 mm/s during each bite. The hardness of the bread samples was determined as the peak force required to compress it through half of its weight. Other parameters derived from the TPA were springiness as the degree to which samples return to their original size after compression and chewiness, which measure the energy required to masticate the bread. Determinations were carried out on all fives loaves per composite flour.

2.7. Sensory Evaluation

- Bread loaves were allowed to cool for 1 h and cut into slices of uniform thickness and transferred onto white coloured plates coded with random 3-digit codes. A sensory panel consisting of 20 semi-trained staff members and graduate students at CSIR-Food Research Institute and familiar with sensory attributes of local bread was employed to evaluate the products. A 9-point Hedonic scale was used to rate the breads for appearance, taste, texture and overall acceptability. A score of 1 represented “dislike extremely” and a score of 9 represented “like extremely” [11]. An atmosphere of complete quietness and privacy was provided for each panelist. The sensory evaluation was conducted between 10:30 am and 11:30 am and a randomized complete block design was used in which the samples were randomly assigned to each panelist [12, 13]. Four bread samples were evaluated at a time and individually to the panelists along with water and neutral cream crackers. The sensory evaluation was performed in a designated sensory analysis facility at CSIR-Food Research Institute with conventional lightning and equipped with individual booths.

2.8. Data Analysis

- The data obtained were analyzed by ANOVA using SPSS 16.0. Duncan multiple range test (level of significance of p = 0.05) was performed to evaluate the level of differences among means of baking properties and sensory attributes of bread samples baked with increasing substitution of cassava flour from the different cassava varieties in the composite flour.

3. Results and Discussion

3.1. Specific Volume and Density of Composite Wheat/ Cassava Bread

- Specific volume of bread made from wheat and cassava composite flour decreased significantly (p<0.05) with increasing proportion of cassava flour (Table 1). Highest bread specific volumes were obtained with 10% Afisiafi flour and 10% Doku duade flour and were similar to the control bread made of 100% hard wheat. Bread made with 20% and 30% Bankye hemmaa flour had lower specific volume than the other bread samples with the same substitution level. Breads made with Afisiafi flour showed the highest specific volume, which was comparable to that of breads baked with 10% Bankye hemmaa and 20% Doku duade flour. This confirms the findings of Almazan [14] who observed a significant genotypic effect on cassava/wheat composite bread quality, especially at high cassava flour concentrations.

|

| Figure 1. Hardness of wheat/cassava composite flour bread measured using a texture analyzer |

| Figure 2. Sensory profile of bread from different varieties of cassava-wheat composite at 10% substitution level |

| Figure 3. Sensory profile of bread from different varieties of cassava-wheat composite at 20% substitution level |

| Figure 4. Sensory profile of bread from different varieties of cassava-wheat composite at 30% substitution level |

| Figure 5. Springiness of wheat/cassava composite flour bread measured using a texture analyzer |

| Figure 6. Chewiness of wheat/cassava composite flour bread measured using a texture analyzer |

4. Conclusions

- An increased proportion of cassava flour in wheat plus cassava composite bread reduced bread specific volume and increased density and hardness due to reduction in wheat proportion and thus of gluten-forming proteins in the composite flours. A substitution level of 10% Afisiafi and 20% Bankye hemmaa cassava flour in composite bread on overall acceptable was similar to 100% wheat bread and therefore has the most suitable potential to replace part of wheat flour in bakery products. The production of cassava flour from the varieties studied is a huge opportunity for commercial production of bread made from composite flour of cassava and wheat. This is very appropriate for cassava growing regions as alternative value addition to reduce the high post-harvest losses associated with cassava.

ACKNOWLEDGMENTS

- The first author wishes to thank the Swedish Development Agency (SIDA) for financial support and CSIR-Food Research Institute, Accra, Ghana for working in the laboratories.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML