-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2013; 3(6): 336-340

doi:10.5923/j.fph.20130306.11

Nutritional Assessment of Wheat Biscuits and Fortified Wheat Biscuits with Carob Pod Powder (Ceratonia Siliqua L.)

M. Kamal E. Youssef1, Hend M. Ali2, Moshera M. El-Manfaloty2

1Food Science & Technology Department, Faculty of Agric., Assiut University, Assiut, A. R. Egypt

2Home Economic Department, Nutrition and Food Science, Faculty of Specific Education, Assiut University, Assiut, A. R. Egypt

Correspondence to: Hend M. Ali, Home Economic Department, Nutrition and Food Science, Faculty of Specific Education, Assiut University, Assiut, A. R. Egypt.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The current study aimed to utilize the carob pod powder (due to its nutritional and healthful functional values) in wheat biscuits fortification. Study included determination of gross chemical composition, caloric value, minerals (Mn, Zn, Fe, Cu, Se, Ca, Na, K, P and S) and phenolic compounds content of studied biscuits. Likewise physical and sensory characteristics of studied biscuits were assessed. The data revealed that incorporation of both 10% and 20% of carob pod powder in wheat biscuits increased crude fat, ash, crude fiber and caloric value to 16.66%, 17.33%; 1.0%, 2.0%; 0.44%, 40.0% and 477.54, 478.49; respectively. However it decreased protein and carbohydrate contents. The supplementation of control biscuits with 10% carob pod powder recorded the highest Cu, Ca, K and Se contents 0.0175, 6.32, 1452.08 and 0.7931; respectively. Meanwhile, both 10% and 20% carob pod powder fortified biscuits (CPFB) recorded the highest phenolic compounds, namely: gallic, pyrogallol and vanillic. The data revealed that both 10% and 20% (CPFB) improved all studied sensory and physical characteristics of all studied biscuits, therefore could be recommended for children and adolescent persons. Consequently, it recommended to utilize the carob pod powder in order to enhance the nutritional values of biscuits.

Keywords: Chemical composition, Caloric value, Minerals, Phenolics, Physical, Sensory characteristics, Fortified biscuits, Carob

Cite this paper: M. Kamal E. Youssef, Hend M. Ali, Moshera M. El-Manfaloty, Nutritional Assessment of Wheat Biscuits and Fortified Wheat Biscuits with Carob Pod Powder (Ceratonia Siliqua L.), Food and Public Health, Vol. 3 No. 6, 2013, pp. 336-340. doi: 10.5923/j.fph.20130306.11.

Article Outline

1. Introduction

- The carob (Ceratonia Siliqua) is a perennial leguminous tree, native to the Mediterranean basin and southwest Asia. It had been cultivated throughout the Mediterranean region for approximately 4000 years[1].Carob is drought resistant, requires little maintenance and produces a range of products from the seed and the pod. The pod is useful for high-energy stock feed and the human food industry as a coca substitute and in syrups carob pod is also an anti-diarrheic product because of its high tannin content. [2].Carob pod characterized by a high content of carbohydrate (45%, sucrose at more than 30%), appreciable amount of protein (3%), low levels of fat (0.6%)[3].Carob is used in many Arab Countries to make a popular drink which is consumed mainly in Ramadan month. Carob is also used in preparation of special traditional types of Arabic Confectionery[4].Carob is a natural sweetener with a flavor and appearance similar to chocolate. Carob is often used as a chocolate or coca substitute[5].The literature data on chemical composition of carob seed germ showed that its nutritive value is high, due to the protein content (> 50%). The germ oil (some 5 – 8%) is highly unsaturated (iodine value > 100) and more than 50% of the protein is water soluble[6, 7].Carob pod is the fruit of the carob tree (Ceratonia Siliqua L.) and is mostly used in food industry for carob been gum, which are poly saccharides (galactomannans) contained in the endosperm of the seeds[8, 9]. However, carob pod mainly consists of pulp (90%), which is rich in sugar (48 – 56%), but it also contains a large amount of condensed tannins (16 – 20%) (1.3 – 5), although lower tannin values have been reported[10].In recent years interest in carobs as a cheap source of various products had been increasing. Some investigations explored carob pods as a readily available and inexpensive material for the production of bioethanol[11, 12] and as a substrate for citric acid production[13]. However, carob pod antioxidant properties related to its polyphenolic composition are very limited[14].This investigation was designed to produce fortified wheat biscuits with carob pod powder, which has better nutritional value, available and relatively cheap and does not require any preparation efforts before using. The objectives of this investigation was to study the gross chemical composition, caloric value, the mineral composition, the polyphenolic compounds composition as well as physical characteristics and sensory quality attributes of wheat biscuits and wheat biscuits fortified with carob pod powder.

2. Materials and Methods

2.1. Materials

- 5 kg wheat flour 72% extraction hard red winter were obtained from El-Haram Milling Company, Faesal, Giza. Sugar powder, margarine, and baking powder were purchased from Assiut local market. Sodium chloride, ammonium bicarbonate, were purchased from El-Jomhouria Company of Drugs in Assiut. 1 kg. of carob pod powder were procured from Aswan Governorate in November 2012, where carob is cultivated. The seeds were removed and the carob was ground to particles of 1≤ mm. Samples were stored in glass containers at 4°C in the refrigerator till the analysis.

2.2. Technological Process

2.2.1. Biscuit Formula and Ingredients

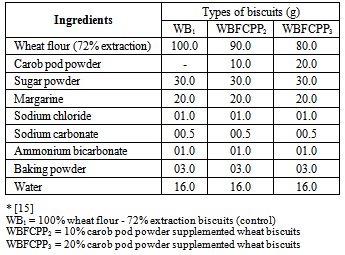

- Control biscuit dough was prepared according to the formula presented in Table (1),[15]. The supplemented biscuits with carob pod powder were prepared using the same formula except for replacing the wheat flour with 10% and 20% of studied carob pod powder.

2.2.2. Dough Preparation

- Powdered sugar and margarine were creamed in Braun Mixer with a flat beater for 2 minutes at 6 rpm. Water containing sodium chloride, sodium carbonate, ammonium bicarbonate and were added to the cream and mixed for 5 minutes at 125 rpm to obtain a homogenous cream. Baking powder was added slowly to the flour and was mixed for 2 minutes at 60 rpm to obtain biscuit dough[15].

|

2.2.3. Preparation of Biscuit

- The dough was sheeted to a thickness of about 3 mm using Atlas Brand rolling machine. The sheeted dough was cut into round shape using a 45 mm diameter cutter and baked on an aluminium tray in an electric oven at 180°C for 6 minutes. The biscuit was cooled for 30 minutes, packed in polyethylene bags stored under desiccation[16, 17].

2.2.4. Preparation of Different Blends of Biscuits

- Blends of biscuits were prepared using wheat flour 72% extraction rate as control and that substituted with 10% and 20% of carob pod powder,

3. Methods

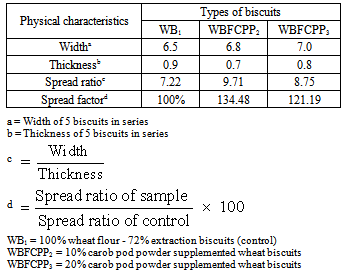

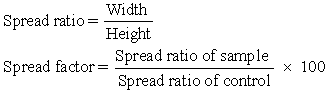

3.1. Physical Evaluation of Biscuits

- Biscuits were evaluated for height (cm), width (cm), spread ratio and spread factor. Three biscuits were used for the evaluations from each of the three studied biscuits and averages were recorded. The spread ratio and spread factor were calculated according to[16] using the following equations:

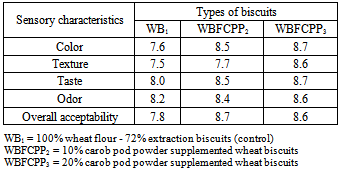

3.2. Sensory Evaluation of Biscuits

- Sensory evaluation for the color, texture, taste, odor and overall acceptability were done in order to determine consumer acceptability. A numerical hedonic scale ranging from 1 to 10 (1 is very bad and 10 for excellent) was used for sensory evaluation[18]. Ten experienced judges participated in the test.

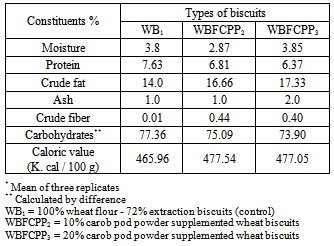

3.3. Determination of Gross Chemical Composition

- Moisture, crude protein, crude oil, crude fibers and ash contents were determined according to the procedures described in the[19]. The total carbohydrates were calculated by difference according to[20]. The Caloric value was calculated using values of 4 k. cal / g. of protein, 4 k. cal / g. of carbohydrate and 9 k. cal / g. of fat according to[21, 22].

3.4. Determination of Minerals Content

- The samples were wet acid-digested using a nitric acid and perchloric acid mixture (HNO3; HCSO4; 2: 1 v / v). The amounts of iron, zinc, copper and manganese in the digested sample were determined using a GBC Atomic Absorption 906 A, as described in[23]. Sodium and potassium were determined by a flame photometer 410, calcium was determined by titration with version 0.0156 N according to[24]. Phosphorus, sulphur and selenium were determined according to the methods described by[23].

3.5. HPLC-separation and Identification of Phenolic Compounds

- Phenolic compounds were determined by HPLC according to the method of[25]. As follows: 5 g of sample were mixed with methanol and centrifuged at 10,000 rpm for 10 min and the supernatant was filtered through a 0.2 µm. Millipore membrane filter then 1 – 3 ml was collected in a vial for injection into HPLC Hewllet Packared (series 1050) equipped with auto sampling injection, solvent degasser, ultraviolet (UV) detector set at 280 nm and quarter HP pump (series 1050). The column temperature was maintained at 35℃. Gradient separation was carried out with methanol and acetonitrile as a mobile phase at flow rate of 1 ml / min. phenolic acid standard from Sigma Co. were dissolved in a mobile phase and injected into HPLC. Retention time and peak area were used to calculation of phenolic compounds concentration by the data analysis of Hewllet Pakared software.

4. Results and Discussion

4.1. Physical Characteristics of Biscuits

|

| Figure (1). 100% wheat flour - 72% extraction biscuits |

| Figure (2). 10% carob pod powder supplemented biscuits |

| Figure (3). 20% carob pod powder supplemented biscuits |

4.2. Sensory Characteristics of Biscuits

- The sensory characteristics of the studied wheat biscuits as influenced by the incorporation of 10% and 20% carob pod powder are outlined in Table (3). The data revealed that both fortified biscuits improved all studied sensory characteristics. However, the best scores of all studied sensory characteristics were recorded for 20% fortified biscuits with carob pod powder. Therefore, it could be recommended to be produced as biscuits with good quality acceptable sensory quality attributes. Such data are in good accord with[26] findings.

|

4.3. Gross Chemical Composition of Biscuits

- The mean value of gross chemical composition of wheat biscuits and fortified wheat biscuits with carob pod powder are given in Table (4). The data revealed that incorporation of 10% and 20% of carob pod powder in wheat flour biscuits increased crude fat, ash, crude fiber contents as well as the caloric value. However, such supplementation decreased moisture, crude protein and carbohydrate contents. Such data are in good agreement with that previously reported by[27, 28, 10].

|

4.4. Minerals Composition of Biscuits

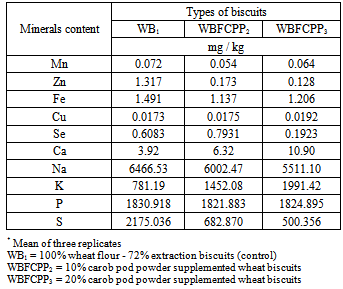

- The mean values of minerals composition of wheat biscuits and fortified wheat biscuits with carob pod powder are outlined in Table (5). The data revealed that both 10% and 20% incorporation of carob pod powder to wheat flour biscuits increased Ca, Cu, Se and K. However, such supplementation decreased Mn, Zn, Fe, Na, P and S. Such data coincide with[29 and 30] findings.

|

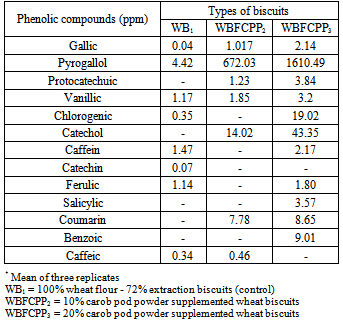

4.5. Phenolic Compound of Biscuits

- The mean values of phenolic compounds of wheat biscuits and fortified wheat biscuits with carob pod powder are given in Table (6). The data revealed that gallic, pyrogallol and vanillic phenols increased in wheat biscuits fortified with both 10% and 20% of carob pod powder. On the other hand 10% fortification of wheat biscuits with carob pod powder resulted in an increment in caffeic. Likewise, 20% fortification of wheat biscuits with carob pod powder increased chlorogenic and caffien. Such data are in good agreement with[31] findings.

|

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML