-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2013; 3(6): 323-328

doi:10.5923/j.fph.20130306.09

Physico-Chemical Properties of Complementary Food from Malted Quality Protein Maize(Zea mays L.) and Defatted Fluted Pumpkin Flour (Telfairia occidentalis Hook, F)

Ikujenlola A. Victor1, Oguntuase S. O.2, Omosuli S. Vincent3

1Department of Food Science and Technology, Obafemi Awolowo University, Ile-Ife, Nigeria

2Department of Food Science and Technology, Federal University of Technology, Akure, Nigeria

3Department of Food Science and Technology, Rufus Giwa Polytechnic, Owo, Nigeria

Correspondence to: Ikujenlola A. Victor, Department of Food Science and Technology, Obafemi Awolowo University, Ile-Ife, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The aim of this study was to produce complementary food that will meet the nutritional requirement of infants and children from blends of maize and defatted pumpkin flour. Maize varieties (Common Maize and Quality Protein Maize were processed by cleaning, steeping(8hr), germinating(72hr), drying, milling and packaging. Pumpkin seed was also processed by cleaning, milling, defattening, drying, re-milling, and packaging. The resulting flours were formulated at ratios of 100:0; 70:30%( maize:pumpkin). The resulting products were subjected to proximate composition and functional properties determinations. The results showed that the maize varieties processed using similar method were within the same range in terms of the ash, fat, protein and carbohydrate. However, addition of pumpkin flour increased the level of ash, protein, fat and energy of the products by above 29, 92, 52 and 3% respectively. There were significant differences (p<0.05) in the swelling, and water absorption capacities and viscosity of the unmalted and malted based diets. Malted QPM fortified with defatted pumpkin flour was the best in terms of proximate composition and functional properties; it will be valuable to the fast growing children who require food of low viscosity and high nutrient density.

Keywords: Quality Protein Maize, Germinating, Functional Properties, Protein, Viscosity, Swelling Capacity

Cite this paper: Ikujenlola A. Victor, Oguntuase S. O., Omosuli S. Vincent, Physico-Chemical Properties of Complementary Food from Malted Quality Protein Maize(Zea mays L.) and Defatted Fluted Pumpkin Flour (Telfairia occidentalis Hook, F), Food and Public Health, Vol. 3 No. 6, 2013, pp. 323-328. doi: 10.5923/j.fph.20130306.09.

Article Outline

1. Introduction

- According to World Health Organization's recommendations, the transition from exclusive breastfeeding and/or infant formula feeding to complementary food, referred to as complementary feeding, typically covers the period from 6 to 24 months of age, and is a very vulnerable period[1]. This is because, after 6 months of age, the contribution from human milk becomes progressively insufficient as a unique nutrient source in relation to the optimal requirements for growth and thus, a greater demand is placed on the complementary food - part of the diet. It is the time when malnutrition starts in many infants, contributing significantly to the high prevalence of malnutrition in children under five years of age worldwide and affecting subsequent optimal development.Several factors determine when to introduce it or not, amongst the factors are the age of the child, the health of both the mother and child, existing taboos, the vocation or occupation of the mother or caregiver[1,2]In most developing countries, complementary diets are derived mainly from local staples such as cereals and tubers, with animal proteins used as supplements. However, since animal proteins are expensive, attempts have been made to identify alternative sources of protein, especially from plants[3,4]. In Nigeria, where cereals are staple, mothers usually use rice, maize, sorghum or millet in children’s homemade foods. The protein of cereals revealed that they are deficient in lysine and tryptophan, but provide adequate amounts of methionine and cysteine which are sulphur-containing amino acids[2,5]. The amino acid profile of leguminous seeds is considered a rich source of lysine but it is quite deficient in methionine and cysteine [6,7]. So, combining cereals and leguminous seeds can increase the quality of protein in children’s food[2,8].The use of legume and oil seed in addition to cereal has been identified as a means of solving the problem of malnutrition associated with the consumption of cereal products like ’ogi’, ’akamu’, ’eko’ all from maize[3,7].Quality Protein Maize (QPM) was developed from opaque-2(o2) maize by the efforts of researchers in CIMMTY. QPM essentially has about twice the levels of lysine and tryptophan than common maize and also increased levels of histidine, arginine, aspartic acid and glycine[9,10]. The report of the comprehensive study carried out on Ghanaian children (0-15 months) fed with supplementary food from both quality protein maize and Common maize, showed that children fed with QPM were healthier, suffered fewer fatalities and had better growth rates[11]. Also the report of Ikujenlola[10] showed that diet prepared from quality protein maize fed to experimental animals gave better result in terms of growth and development. Fluted pumpkin (Telfairia occidentalis Hook, F) is known to be of high nutritional value in terms of protein and minerals. The seed of fluted pumpkin, is widely consumed in Nigeria, especially in the south eastern part of Nigeria where it is used as a condiment in soup. The fermented seeds of fluted pumpkin is used in the production of “Ogiri ugu”, a locally made custard. The seeds of fluted pumpkin could also be used in cookie formulations and marmalade manufacturing. The seed is also a good source of edible oil[12]. The combination of QPM and pumpkin has not been explored as complementary food meant for children. This type of combination should offer a good protein base diet that will satisfy the nutritional requirement of growing children thereby maintaining the health and development of children. Also the supplementation with pumpkin flour is desired to enhance the functional properties of the resulting diets. These properties determine to a large extent the acceptability or otherwise of the diets.Consequently, the aim of this study is to produce high quality complementary food from blends of pumpkin flour and quality protein maize (malted and unmalted) and to assess the physico-chemical composition of the diets.

2. Materials and Methods

2.1. Materials

- The maize varieties used for the purpose of this study were common maize and quality protein maize. The quality protein maize (EV99 QPM) was obtained from Obafemi Awolowo University Research farms, Ile- Ife. Common maize and pumpkin seeds were purchased from Central market Owo, Nigeria.

2.2. Methods

2.2.1. Production of Unmalted Maize Flour

- The maize flour was produced by cleaning, sorting, washing, and drying the maize grains. The dried grains were milled using attrition mill, sieved and packaged according to method of Ikujenlola[6].

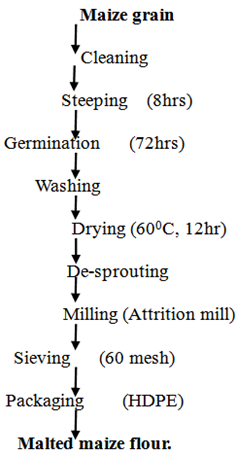

2.2.2. Production of Malted Maize Flour

- The malted maize flour was produced by the method of Ikujenlola and Fashakin[2]. The grains were cleaned and steeped for 8 hours. The Figure 1 showed the various unit operations involved in the production of malted maize flour.

| Figure 1. Flow diagram for the production of malted maize flour |

2.2.3. Production of Defatted Pumpkin Seed

- The pumpkin seeds were washed, dried and milled using attrition mills. The resulting meal was defatted with food grade hexane as solvent. The defatted meal was dried in a cabinet dryer, re-milled, sieved and packaged until needed[12].

2.2.4. Proximate Composition Determination

- The proximate parameters (fat, crude protein, crude fibre, ash, moisture content) were determined using the methods of A.O.A.C[13]. Carbohydrate content was obtained by difference while energy value was calculated using At water factors[14].

2.2.5. Functional Properties

- The method of Okaka and Potter[15] was used to determine the bulk density. The oil and water absorption capacities were determined by the method of Abbey and Abeh[16], foaming capacity and gelation property were determined by the method described by Coffman and Garcia[17]. The viscosity of the diet were determined according to method reported by Ikujenlola and Fashakin[2].

2.2.6. Formulation of Complementary Food

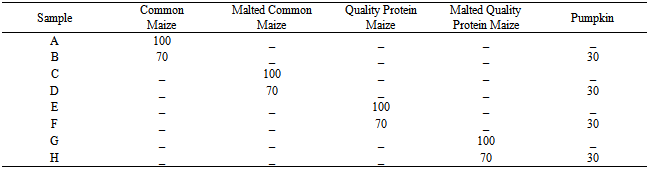

- Complementary foods were formulated to meet the nutrient requirements of children ages 6 months to 1 year[18]. In addition to breast milk, for the first 4 to 6 months, a baby should be provided with 96 kcal/kg of energy per day. The level of protein needed is 14 to 15.5 g protein/day of a quality equivalent to that in milk or eggs[18]. Common maize, quality maize protein, malted common maize, malted quality protein maize and pumpkin flour were blended. The compositions of formulation are shown in Table 1. The blends were prepared in duplicate and the results of all analysis were reported as the means of three replicates.

|

2.2.7. Statistical Analysis

- Data were subjected to analysis of variance (ANOVA) where applicable and a difference was considered to be significant at p < 0.05. Means were separated using Duncan’s multiple comparison tests where applicable.

3. Results and Discussion

3.1. Proximate Composition

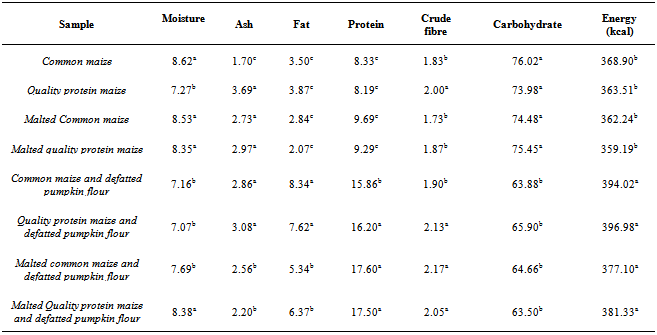

- The proximate composition of the various complementary foods are shown in Table 2. The fat content of the diets varied between 2.07 and 8.34%. The fat content of the diets increased with the addition of 30% pumpkin flour. The fat content of the diets were below 10%. The fat content of complementary diets should not be unnecessary high in order to prolong the shelf life of the diets. Rancidity and off – flavour are the attending effects of high fat in floury products.The common maize flour had a protein content of 8.33% while QPM had 8.19%, the protein content increased with the addition of pumpkin flour. The QPM had almost the same protein content as common maize however according to Prassana et al.,[19], Vassal et al.,[20], Gupta et al.,[21] and Ikujenlola[10] QPM has better protein quality in terms of essential amino acids especially lysine and tryptophan. The inclusion of pumpkin flour which is of high protein quality in terms of essential amino acids further boosted the protein quality of the resulting diet. The malting process improves protein in various cereals and legumes according to the reports of Nnam[22], Ikujenlola and Fashakin[2], Ikujenlola[6]. The increase in protein during malting is attributed to a net synthesis of enzymic protein by germinating seeds as reported by Inyang and Zakari[23]. The reports of Tsai et al. [24] and Inyang and Zakari[23] showed that the increase in protein on germination of corn seed is due to mobilization of storage nitrogen in the grains.The moisture content of the diets ranged between 7.07 and 8.62%. Moisture levels less than 10% is recommended in order to keep the floury product for a reasonable longer time[25]. All the diets had less than the recommended moisture content and are expected to keep for a reasonable long time without remarkable negative change. The 30% substitution of pumpkin flour to some of the diets showed a significant difference (p>0.05) in the value of carbohydrate content of the diets.Total energy calculated from the formulations ranged from 362.24 – 396.33 kcal/100g on dry matter basis. These values are similar to the acceptable and typical energy level of 375 kcal/100g dry weight provided by industrially processed weaning foods and predicted energy level[26].The ash content is an indication of the level of mineral contents present in the diet. The result did not show a significant increase (p<0.05) with the addition of pumpkin flour. The crude fibre of the diets increased with addition of 30% pumpkin flour. The crude fibre of diet meant for infants is expected to be less than 5%[25].

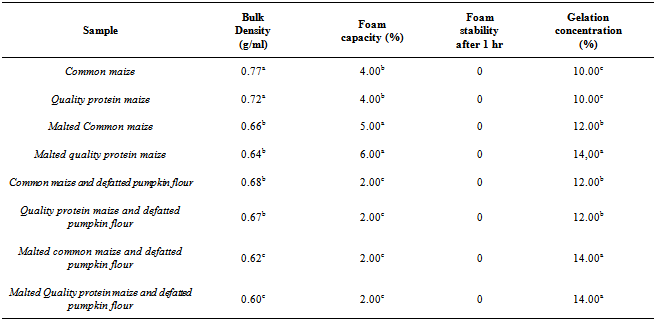

3.2. Functional Properties

- The bulk density (Table 3) of the diets ranged between 0.62 and 0.77g/ml. There was significant difference (p<0.05) between the bulk density of common maize (0.77 g/ml) and QPM (0.72 g/ml). The addition of pumpkin flour reduced the bulk density of the diets. Also the malted diets had lower bulk density. The reduction in the bulk density on malting was a reflection of the activity of alpha - amylase enzyme which was activated during malting process and dextrinifies starch to its constituents sub-units. Germination has been reported to be a useful method for the preparation of low bulk weaning foods[27]. This observation agrees with the reports of Ikujenlola[6] and Inyang and Zakari[23]. Diet of lower density is required for infants to allow them swallow it with ease without choking or suffocation. The foam capacity (Table 3) ranged between 2.00 and 6.00%. Foaming properties refer to the ability of a dispersion of protein to form a stable foam when air is beaten in[28]. The foam formed was not stable more than 30 minutes and after an hour the foam collapsed. The result of the gelation property(Table 3) of the diets showed that the diets gelled at concentration above 10%. The gelation concentration of the malted was significantly lower (p>0.05) than the other formulations. Gelation is an important property which influences the texture of various kinds of foods such as ‘moi-moi’, ‘agidi’ and soup[29].

|

|

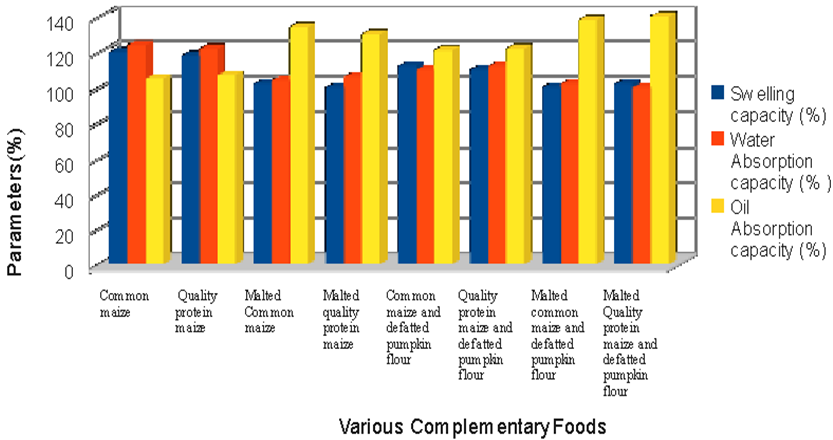

| Figure 2. Swelling, Water Absorption and Oil Absorption Capacities |

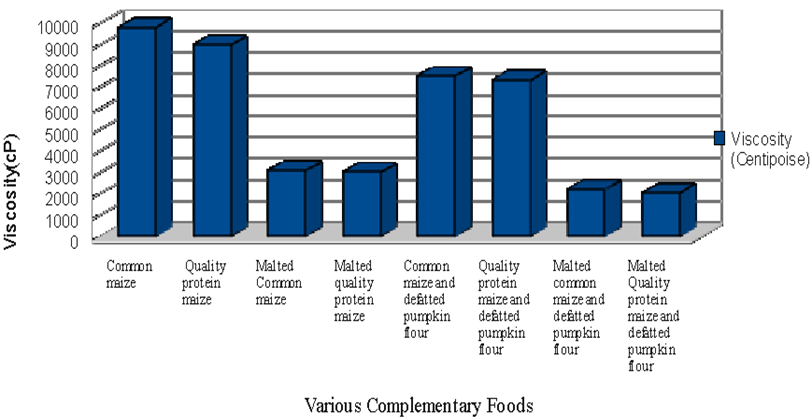

| Figure 3. Viscosity of the various Complementary foods |

4. Conclusions

- The processing parameters and formulations used in this study successfully produced a high protein-energy food with acceptable physico-chemical properties. The substitution of maize varieties with 30% defatted pumpkin flour showed a remarkable improvement in the protein (8.19%-17.2%), fat(2.07%-8.34%) and energy content (359.19 kCal - 396.98 kCal) of formulated diets. Malting process led to the reduction in bulk density(0.77- 0.60g/ml), swelling capacity(120-100%), viscosity (9,800-2,500 cP) and water absorption capacity (124-100%). This study showed that the combination of malted QPM and 30% defatted pumpkin flour was the best among the samples analysed. Therefore, this product will be valuable for growing infant who is transiting from breast milk to semi-solid foods. This combination is capable of reducing malnutrition and mortality among infants in the developing countries.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML