Finzer J. R. D.1, 2, Valduga A. T.3, Parckert E. D. T.2, Ferreira M. M. P.2

1School of Chemical Engineering, UNIUBE, Uberaba, 38055.500, Brazil

2Federal University of Uberlândia, UFU, Uberlândia, 38408-100, Brazil

3School of Food Engineering, URI, Erechim, 99700-000, Brazil

Correspondence to: Finzer J. R. D., School of Chemical Engineering, UNIUBE, Uberaba, 38055.500, Brazil.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

This paper reports the development of technology for the processing of a renewable natural resource for the sustenance of small farmers in the south of Brazil. The technology was applied to the processing of maté leaves, neem leaves and coffeeleaves. The processing of maté leaves, lineage “Cambona 4”, was carried out in a laboratory prototype for singeing, where the enzymatic inactivation was accomplished. The initial moisture of the maté leaves was 61.9% (wet basis). At the end of four minutes of singeing, under the action of combustion gases at the average temperature of 181℃, the moisture was reduced to 14.6% (wb). The leaves were then dried in a vibrating bed drier operating at the frequency of 60 Hz and amplitude of 0.5 mm, with air flowing at the temperature of 66℃. The convective coefficients of heat transfer were measured in singeing and drying operations, and the average values were 5.3x10-3 to 10.1x10-3 and 1.62x10-3 kJ/m2.s.℃, respectively.Further information about processing of sheets is included.

Keywords:

MatéProcessing, Neem, Singeing, Drying in Vibrating Bed, Convective Coefficient of Heat Transfer

Cite this paper: Finzer J. R. D., Valduga A. T., Parckert E. D. T., Ferreira M. M. P., Processing Leaves for the Preparation of Beverages, Food and Public Health, Vol. 3 No. 6, 2013, pp. 257-266. doi: 10.5923/j.fph.20130306.01.

1. Introduction

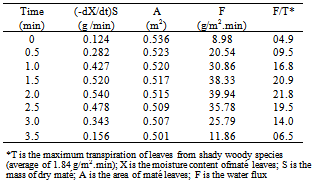

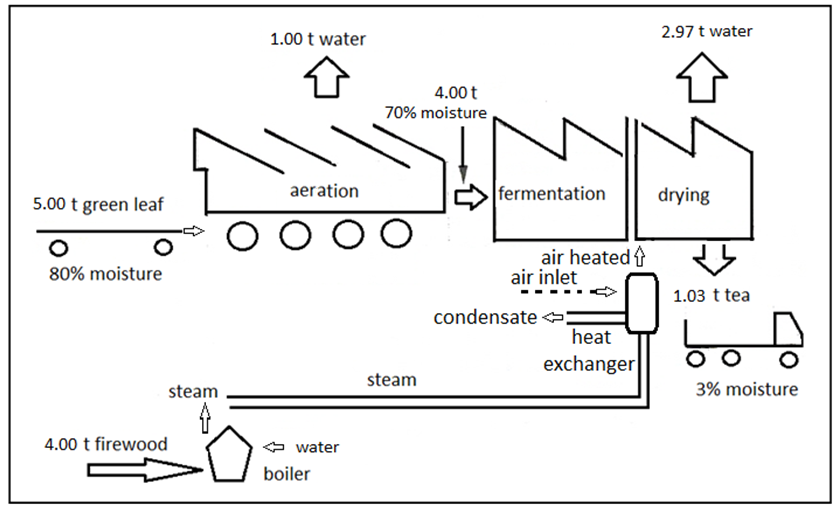

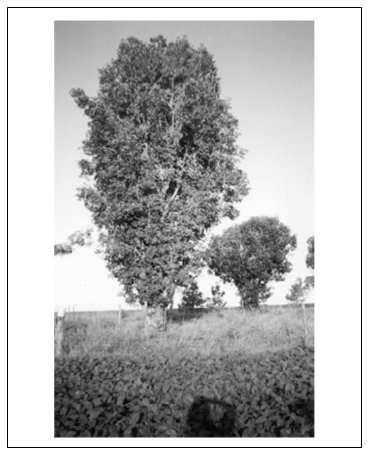

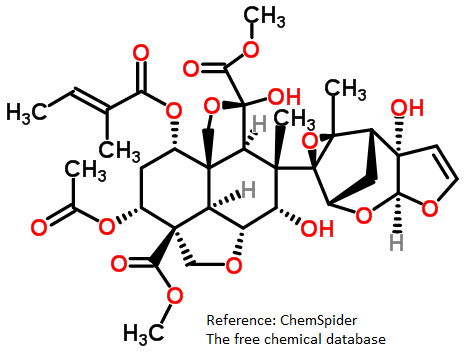

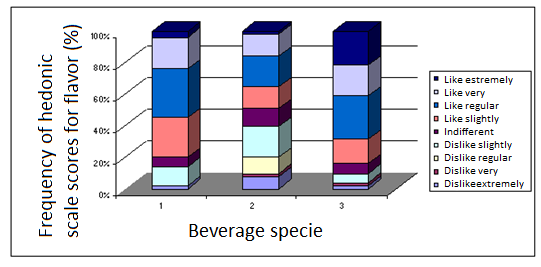

Tea, maté, coffee and neem are important crop in several tropical and sub-tropical regions of the world.Many products from leaves are marketed as "tea," although the term to be closely associated with the beverage from the leaves of Camellia sinensis.Tea and maté can be processed in various ways, see Figure 1[20],[24]. To demonstrate the quantities of water to be removed and wood to be burnt, the Figure 2 illustrates thatfor every ton of tea leaving the factory, approximately 9 ton of material enter the factory[20].On arrival at the tea factory, the shoots are spread out in layers, so the air can be blown through the leaf mass to stop the temperature rising from respiratory heating and to reduce the moisture content[20].

1.1. The Sustainable Use of a Natural Resource

In small rural properties in the south of Brazil, the production system of largest ecological and socio- economicimportance is the one formed by native species, where the maté tree takes part. This activity constitutes a source of employment and continuous annual income for the small rural producers,[4],[8],[9],[14].The city of Machadinho, located in the north of the Rio Grande do Sul State-Brazil, has, according to[15], more than 90% of the rural properties with area smaller than 50 hectares, which represents 0.13% of the area of the Rio Grande do Sul State. In this area, 17.8 thousand t/year of maté leaves are produced, participating with 3.2% of the state’s production. This production represents on the average 23% of the total income of the small producers. | Figure 1. Flow diagram for the manufacture of green or black tea and maté |

The enhancement of this culture on the income and employment in the small agriculture in the south of Brazil depends fundamentally on the increase of the internal and foreign markets for the maté (dried and triturated), and the addition of value to the final product marketed (new products). Especially for the foreign market of foodstuffs, the quality demands and the guarantee of uniformity of composition and flavor of maté products require standardized handling conditions of the culture and genetic material.In this sense, the raw material used in this research was organic and genetically homogeneous, consisting of a variety of the species Ilex paraguariensis St. Hil, which received the denomination lineage “Cambona 4”, by the group of the Agro forestal Systems, Project “Floresta”, of the Brazilian Agricultural and Livestock Research Institute - EMBRAPA (Colombo, Paraná State). Figure 3 is a picture of the tree that originated lineage “Cambona 4”. This original tree, exuberant, got the attention of the maté leaf producers of the city. It was found that the drink coming from aqueous extract of leaves matéhad aroma and flavor smooth. The tree, although having developedin adverse conditions and under thermal stress from solar radiation, showed significant resistance, sparing special cultural treatments, because it developed ratheraway from the group of trees ofwhich Ilexparaguariensis is one of the components. The Environmental Impact Report of the Machadinho Dam in Rio Grande do Sul State showed that 1.5 million trees should be planted to compensate for the amount flooded by the dam. The Environment Secretary of the State, which inspects the re-planting, authorized the planting of the maté tree from the variety lineage “Cambona 4” in an area of 105 hectares[2],[21]. In the bordering lake, 376,000 trees of the 74 native species found in the area had been planted (from which 30 are fruiting trees). The reforestation with 279,930 maté trees in an area adjacent to the above mentioned bordering lake, correspond to 74% of the number of trees in that area, which is quite expressive.Maté tree plantations of organic “Cambona 4” already exist in rural properties close to the lake of the Hydroelectric Power Plant of Machadinho - Rio Grande do Sul State, which were used in the processing tests in this work.

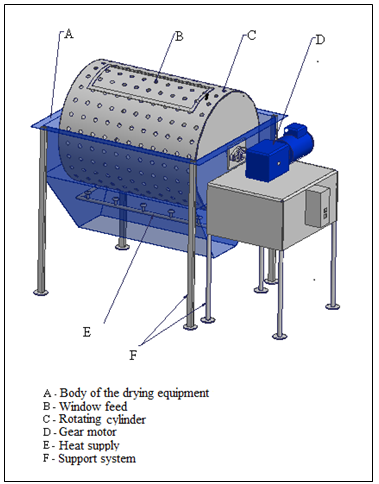

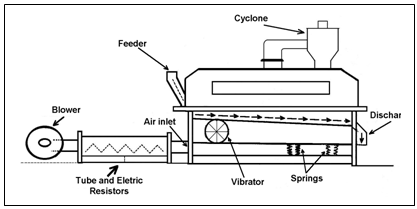

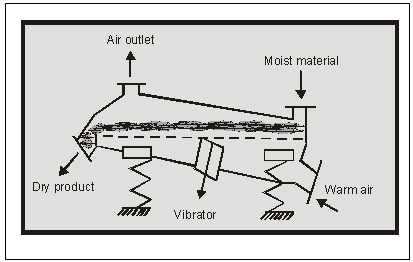

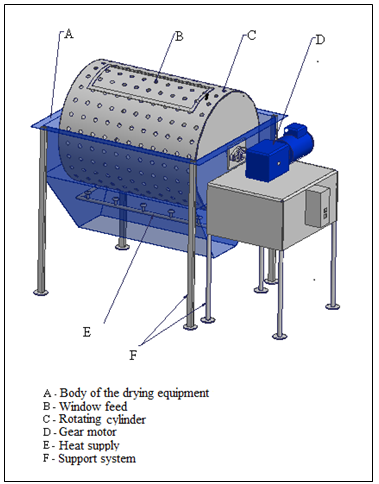

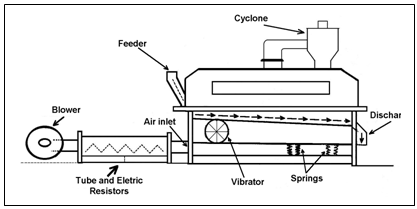

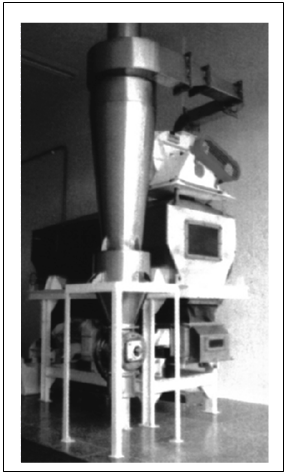

2. Drying Techniques

Several products such as pharmaceutical, biological and food products are submitted to drying by convection with the objective of preserving its properties. The vibrating beds have been widely used for conductive or convective drying of granular products, pastes and powders[7],[17]. In vibrating dryers the forces acting on the particles are weak, making them appropriate for processing friable materials. Figure 4 illustrates the principle of operation of vibrating bed dryers[3],[23].In this work the processing of maté leaves was carried out in a singeing equipment and in a vibrating dryer of perforated tray, which allows the gentle transport of the leaves during the drying process. The device is compact, and doesn't need a return mechanism. In this study, the heat transfer coefficients during the singeing and the drying of maté leaves were measured. The singeing consists of a stage preliminary to the drying in which the enzymatic inactivation of the leaves happens, avoiding their darkening [19].The singeing operation was done using a singeing prototype comprised by a perforated cylinder with diameter of 0.35 m and length of 0.50 m. The maté leaves were placed inside the perforated chamber and the operation carried out in batch. Figure 5 consists of a view of the singeing equipment. | Figure 2. Diagram of mass flow in a tea factory[20] |

| Figure 3. View of the original tree lineage “Cambona 4” |

| Figure 4. Principle of operation ofa vibrating bed dryer |

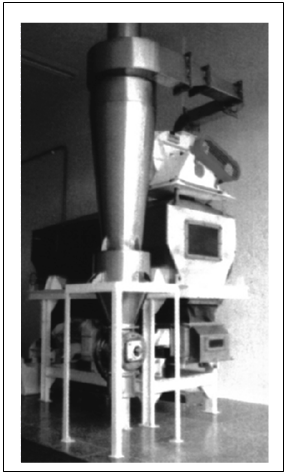

The control parameter to measure the efficiency of the singeing operation was the final color of the leaf, which should be close to the natural one, olive green and presenting brittle aspect, even though with some flexibility. These characteristics, desired for the product of the singeing, are based on observations in the industrial processing of the maté leaves, such as those verified at “ErvateiraBarão” and “ErvateiraCamol”, processing plants respectively in Barão de Cotegipe and Machadinho, both in Rio Grande do Sul State-Brazil. These characteristics should produce the typical aroma indicative of good acceptability of the product. After each singeing operation, samples were placed in a stove at the temperature of 105℃ until the constant mass, which was also done in the drying.The vibrating bed dryer used in this work consists of a horizontal chamber with dimensions of 1.61 m by 0.70 m by 0.987 m, provided with a perforated tray of stainless steel to supply air through the material that moves on the tray (see Figures 6 and 7). This tray has dimensions of 1.6 m by 0.25 m, with holes of 0.0015m of diameter disposed in a triangular arrangement and with distance between two holes of 0.0022 m. It has an inclination of 25° in relation to the horizontal to facilitate the flow of the material. The tray is connected to a structure supported on springs. In the structure two electric vibrators of 0.33 hp of unbalanced masses are connected, arranged symmetrically on the two sides of the structure but inclined 45° in relation to the hor-izontal. The unbalanced condition provides the vibration of the structure. The amplitude and frequency of the vibration operation was of 0.5x10-3 m and 183 rd/s. The dimensionless Aω2/g was of 1.7, which represents the number of times that the vibrational force is greater than the gravitational one, where: A is the vibration amplitude; ω is the velocity angular and g is the gravity acceleration. The drying air is admitted by the blower of 2 hp placed in the left extremity of the drier (see Figure 6). | Figure 5. View of the singeing equipment |

At the top of the cyclone, shown in Figures 6 and 7, an exhauster of 1.5 hp drags small particles and conduct the drying air to the outlet. To the right, in the central part of the body of the dryer, there is an inspection window, which was used to get samples to measure the temperature of the leaves during the drying process. Through the inspection window a calorimeter was inserted and maté leaves were put inside it to measure the temperature.

2.1. Singeing

Preliminary experiments using the singeing equipment showed with during the processing the internal temperature at the top of the singeing equipment was of 120℃, which was measured with a copper-constantan-thermocouple. The temperature at the bottom of the singeing equipment (242℃), in an area oxidized by the heat, was determined with the use of a laser temperature meter (Raytek-Raynger ST). To determine the convective coefficient of heat transfer, the temperature of the gases, 181℃, was evaluated as being the arithmetic average between the indicated temperatures. After about 5 minutes of processing, the singed maté leaves had the desired qualitative characteristics, even though some presented charred borders. | Figure 6. Outline of the vibrating bed dryer |

| Figure 7. View of the vibrating bed dryer |

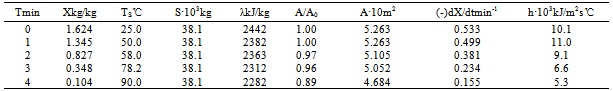

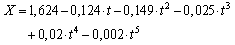

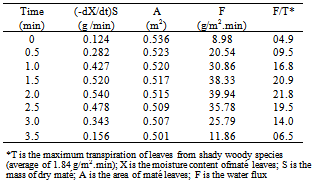

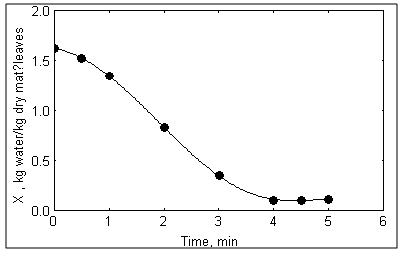

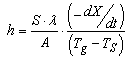

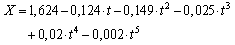

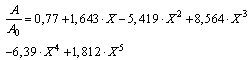

Singeing experiments were made at the rotation of 80 rpm and using around 100 g maté leaves in each test. The average moisture content of the processed maté leaves was 61.9% (wb). From the global mass of 500 leaves (642.83 g), the average mass of a leaf was determined to be 1.29 g. Thus, 77 leaves were added in the singeing equipment for each singeing batch. In each experiment a new sample of maté leaves was used, and the singeing time was varied from 0.5 to 5 minutes. Three maté leaves were removed from each experiment to quantify the loss moisture in the singeing process. The results are shown in Figure 8, and the Equation (1) consists of the result of a polynomial adjustment [21] using the software Statistica 7-StatSoft®with confidence level of 95% (as well as in the other correlations of this work). Technical details about singeing using the indicated methodology can be obtained in[23] and[24].During the singeing the stomata open or the aqueousvessels of the leaves break up by dilation under the action of heat[6], and this process has vital importance on the quality of the product. Concerning Figure 8, it can be seen that during the first minute of processing the singeing rate increases (which is the angular coefficient of the curve). The maximum rate remains constant until near the third minute of singeing. After the third minute of operation the rate gradually decreases.The Equation (1) was derived as a function of time, and the values multiplied by the mass of dry maté leaves (S=38.1g) for specific times, which gave the rates of water evaporation. The surface area of the leaves was determined as a function of their moisture content, using Equation (5) and their initial specific area, was equal to 52.63 cm2/g (to see the section on heat transfer). The water evaporation rates were divided by the area of the leaves, providing the water flux (effective transpiration of the leaves during the singeing). The results are shown in the Table 1. | (1) |

Table 1. Water flow during the singeing

|

| |

|

The maximum transpiration of shady woody species (with stomata totally open), which are part of the mixed rain forest (forest with pine trees), where the Ilex paraguariensis is part of the under forest, varies from 1.30 to 2.38 g/m2.min, with average of 1.84 g /m2.min[10].Several singeing experiments were carried out (triplicate) for 4 minutes, at the same operational conditions, to avoid the charring that happened when operating during 5 minutes. These operational conditions allow the maté leaves to attain color and homogeneity characteristics of high standard, when compared with industrial products[22].The stomata of vegetable leaves, with abundance of water, under moderate action of heat, they open allowing transpiration. In a stress situation had to the heating, for separate leaves of the plant, the stomata of the same ones if close. This consists of a physiological defense. However, under action of the temperature increase, still moderate (with leves in a stove), probably occurs rupture of cellular membranes and enzyme activation, which will go to act on the chemical constituent of the solution, causing irreversible darkening. Sensorial tests with this material evidence the occurrence of disagreeable flavor and aroma. When submitting the leaves to the intense action of heat, in contact with combustion gases, occur tissues rupture (what it can be evidenced by crackling occurrence)[13]. As a consequence, the moisture loss of the tissues is intense. It is probable that enzymes inactivation occurs due to high temperature, associated to the little water availability. | Figure 8. Singeing curve; operation conditions: average gas temperature, 181oC; liquefied petroleum gas rate, 0.24 g/s; cylinder rotation, 80 rpm; deviation from the average lowerthan 5% |

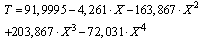

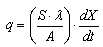

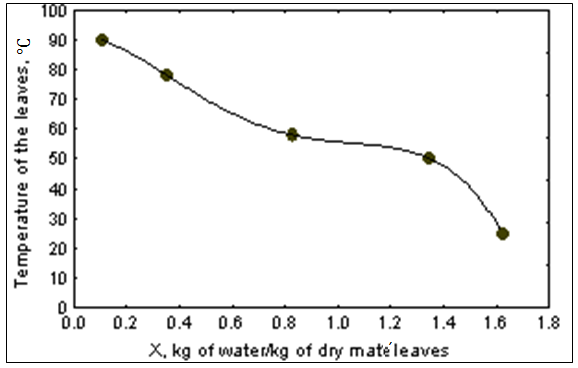

The singed leaves were numbered from 1 to 500 (so that they could be identified in the drying operation) and the individual masses were measured to be used in the drying in the vibrating bed. The residual average moisture of the 500 leaves was calculated after the singeing to be 14.6% (wb). Comparing with the moisture content of the maté leaves after 4 minutes of singeing (see the Figure 8), which is around 10%, one can suggest that the difference is due to the heterogeneity of the raw material. Therefore, carried out experiments at these operational conditions, singed maté leaves will be obtained with moisture content in the range from 10 to 15% (wb). To obtain the moisture content needed for commercialization, smaller than 5%, the maté leaves should undergo drying after the singeing.To measure the temperature of the leaves during the singeing, experimentswere carried out using 100 g of maté leaves in each one, which on average corresponds to 77 leaves. In each batch new maté leaves were used. A total singeing time of 4 minutes was selected, which consisted of the best visual conditions that produced singed maté leaves homogeneous and with green-olive coloration.In each experiment (in triplicate), samples of maté leaves were removed at a pre-established time and placed in a calorimeter made of Styrofoam, of cubic geometry with edge of 0.15 m, with a copper-constantan thermocouple (resolution of 0.1oC) inserted in one side, 0.05 m from the bottom. The results of the temperature measurements of the leaves are shown in Figure 9 and they are represented by Equation (2). The temperature of the leaves varies from 25℃, at the beginning of the process, up to 90℃ for a total singeing time of 4 minutes. | (2) |

2.2. Heat Transfer

During the singeing and the drying, which consist of two sequential thermal treatments, the maté leaves lose moisture. | Figure 9. Temperature of the maté leaves in the singeing, standard deviation lower than 3℃ |

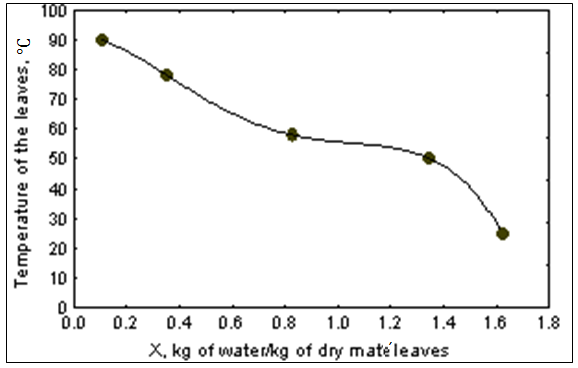

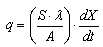

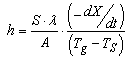

The flow of heat received by the leaves can be quantified by Equation (3). | (3) |

where: S is the mass of dry maté leaves; λ is the water vaporization enthalpy at the temperature of the surface of the leaf; A is the area of the heat exchange surface of the leaves; (dX/dt) is the drying rate.During the process, the heat is supplied in the singeing by the direct flame from burning liquefied petroleum gas and in the drying by the heated air. Equation (4) correlates the heat input with the convective coefficient of heat transfer, h. | (4) |

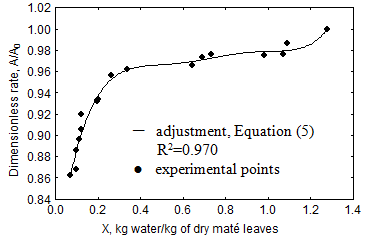

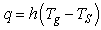

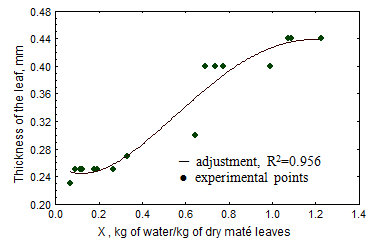

where: Tg is the temperature of the gas and TS the temperature of the surface of the maté leaves.During the process the cellular tissue of the leaves shrink along with the loss of moisture. To measure the shrinking of the leaves, an experiment was made (in triplicate) using twenty leaves removed randomly from the tree, put inside an oven and kept at the temperature of 60℃. The leaves were previously marked, to be identified during the process and its mass was measured.Before putting the leaves in the oven, each one had the contour of its surface drawn on sheets of paper with 624 cm2 of area and mass of 4.8228 g per sheet. The leaves were periodically removed from the interior of the stove and the procedure repeated. Each leaf had, then, two representations on the paper surface. They were then cut out with scissors and their areas were quantified by the proportionality between the individual mass and the paper sheet. The results are shown in Figure 10 and correlated by Equation (5). A is the area of the surface of the leaves and Ao the initial area. The initial average moisture of the leaves was 61,9% (wb) and after the dehydration in the stove the moisture of the last sample was of 6.18% (wb). Analyzing the results of Figure 11, it can be seen that when they reached the moisture content of 6.18%, there had been a 14% surface contraction of the leaves. The initial average area of a maté leaf (two faces) was 83 cm2. The specific average area of the maté leaves was 52.63 cm2/g. | Figure 10. Dimensionless rate of the areas, standard deviation lower than 0,05 |

| (5) |

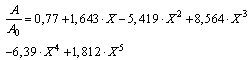

The thicknesses of the leaves were measured at the beginning and during the drying process in stove and the results are shown in Figure 11. | Figure 11. Variation of the thickness of the maté leaves as function of the humidity content, standard deviation lower than 0,02 mm |

Analyzing the curve that shows the variation of the thickness, it can be seen that it varied from 0.44 mm to 0.25 mm, meaning a thickness decrease of 43%. This shows that during the drying process the maté leaves shrink with greater intensity in the normal direction to the faces of the leaf. This happens, biologically, due to the physiology of the leaf, which has small-specialized organs responsible for the breathing metabolism and photosynthesis[10]. Therefore, the moisture loss occurs preferentially on these surfaces, which corresponds to a response from the biological tissue to the thermal stress. The global percent shrink rate between the thickness and the faces was of R=43.18/14.0, or R=3.0, which shows that the percent contraction of the thickness of the leaves is 3.0 times greater than the contraction of the faces.From the equivalence of Equations (3) and (4), Equation (6) is obtained, which determines the convective coefficient of heat transfer. | (6) |

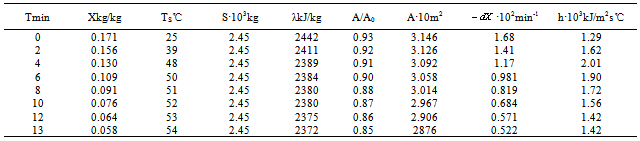

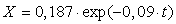

Table 2. Parameters and values of the convective coefficient of heat transfer for the singeing process

|

| |

|

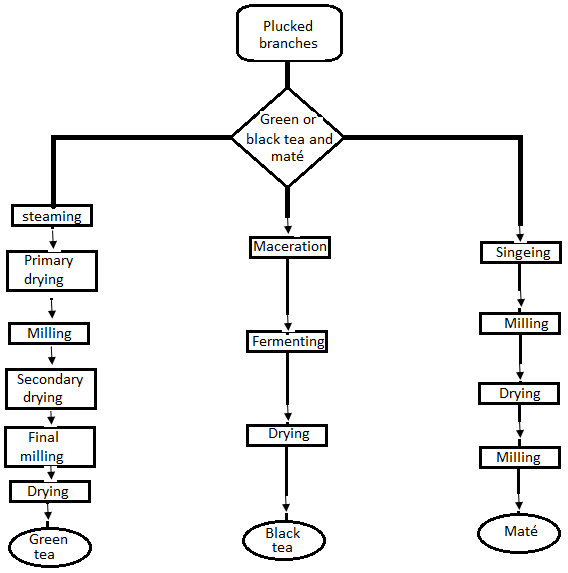

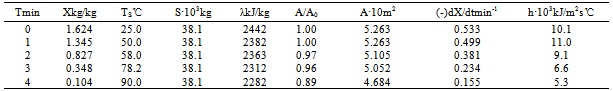

Table 3. Parameters and values of the convective coefficient of heat transfer for drying process

|

| |

|

Where: S is the mass of dry maté leaves; λ is the water vaporization enthalpy at the temperature of the surface of the leaf; (-dX/dt) is the drying rate; A is the surface area of heat transfer; Tg is the temperature of the singeing gases and Ts is the temperature of the surface of the leaf.The data shown in Table 2 were obtained using Equations (1), (2), (5) and (6). The latent heat of vaporization of the water was obtained in[1].The variation of convective coefficients of heat transfer are, 5.3x10-3 to 10.1x10-3 kJ/m2.s.oC for the singeing operation, for the operation conditions used in the experiments. These results show that the convective coefficient of heat transfer it is presents more appreciable variation after the second minute of singeing.

2.3. Drying Operation in Vibrating Bed Dryer

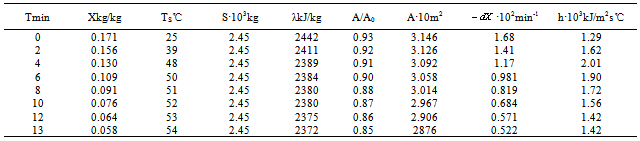

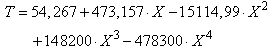

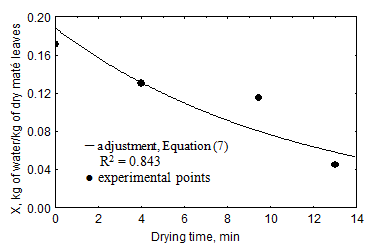

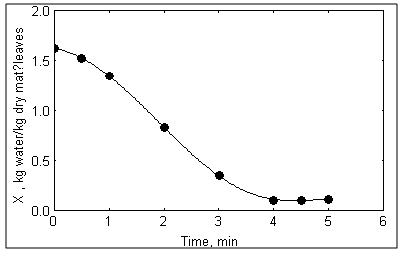

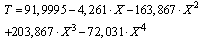

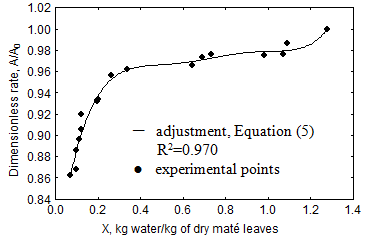

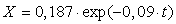

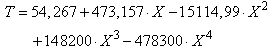

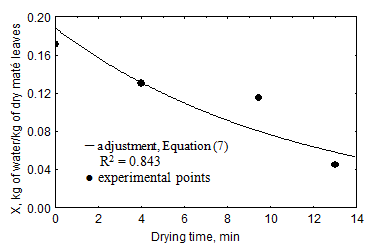

Maté leaves processed in the singeing equipment, coming of several batches of 4 minutes each, according to the operational conditions previously mentioned, were used for processing in the vibrating bed dryer.The singed material, 500 leaves making up a global mass of 286.854 g, was used in the drying. Therefore, the average mass of a leaf is 0.574 g and the average moisture is 14.6% (X = 0.171 kg water/ kg of dry maté leaves). Using Equation (5), the dimensionless A/Ao was determined to be 0.93. The initial area of the surface of the 500 leaves was: 52.63 cm2/g x 642.832g (specific average area multiplied by the initial global mass), giving the area of 33,832 cm2 (3.3832m2). Using this parameter in the above relation, the area of the singed leaves in the beginning of the drying operation is calculated to be 0.93 x 3.3832 = 3.1464 m2.In the drying (in triplicate) of the maté leaves, the previously singed leaves were fed into the distributor of the vibrating bed dryer, (see Figure 6). The leaves were then dried in a vibrating bed drier operating at the frequency of 60 Hz and amplitude of 0.5 mm, with air flowing at the temperature of 66oC and superficial velocity of 0.64 m/s. During the process the maté leaves were recycled (re-fed) to the distributor (see the Figure 6). The recycling criterion was the following: when half of the mass of the leaves had exited the dryer outlet they were fed back. After 1.08 min the first maté leaf left the dryer. After 10.72 min half of the leaves had left. Thus, the average residence time of them in the drying chamber was of (1.08+10.72)/2 = 5.9 min. Before being recycled, the temperature of this material was measured with of the same calorimeter used in the singeing process and the individual masses of the leaves were measured to determine the average moisture content. This was possible because numbers previously identified the leaves and their masses were measured. The elapsed time for the second half of the leaves to exit the dryer was 15 minutes. The average drying time for this second half of leaves was: (10.72 + 15)/2 = 13 min. The average drying time of the leaves for a complete cycle was assumed to be the arithmetic average between the two halves, or: (5.9 + 13)/2 = 9.4 min. The same procedure was used in a second drying cycle. The results are shown in Figures 12 and 13, which refer to the drying curve for maté leaves previously submitted to 4 minutes of singeing. The final moisture of the leaves after 13 minutes of drying in vibrating bed was X = 0.045 (4.3% wb). Equation (7) represents the curve of drying and Equation (8) represents the temperature of the maté leaves. In Figure 13 it can be seen that the temperature of the leaves increased gradually with the decrease of the moisture content of the solids. | (7) |

| (8) |

| Figure 12. Drying curve of maté leaves previously submitted singeing, deviation from the average lowerthan 5% |

The data shown in Table 3 were obtained using Equations (5), (6), (7) and (8).These results show that the convective coefficient of heat transfer, concerning the drying of the leaves in vibrating bed, is about five times smaller than the convective coefficient of heat transfer in the singeing operation. | Figure 13. Temperature of the maté leaves during drying in vibrating bed, standard deviation lower than 3℃ |

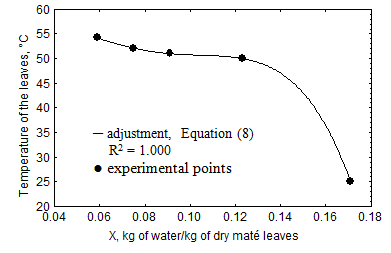

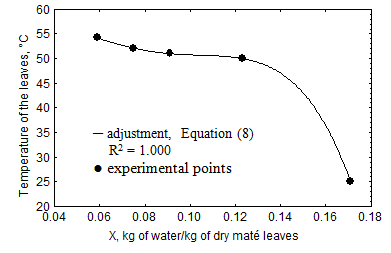

These results show that the convective coefficient of heat transfer, concerning the drying of the leaves in vibrating bed, is about five times smaller than the convective coefficient of heat transfer in the singeing operation.The average convective coefficient of heat transfer is 1.62x10-3 kJ/m2.s.℃ for the drying operation in vibrating bed, for the operation conditions used in the experiments.In the drying of the singed leaves the water flux eliminated for leaves is of 60% of the foliar transpiration of shady woody vegetable species.Considering the drying curve for the leaves previously submitted to singeing (see the Figure 12) the angular coefficient of the curve was calculated for the time zero (0.0143 kg water/kg dry maté.min), what it corresponds to the curve derivative in point zero. The evaporation rate was calculated to be 0.0185 g water/m2.s. Comparing with the previously indicated perspiration of the maté leaves in nature, 1.30 to 2.38 g/m2.min[10], it can be seen that in the drying process the flux is inferior to the one in the natural perspiration, chiefly due to the low moisture content in the processed leaf which was previously singed.There are few records of phenomenological parameters of heat transfer concerning leaves. In Figure 14, for “gmelina” leaves of several sizes in horizontal position, the behavior of the Nusselt number (h.L/k) is shown, where h is the coefficient of heat transfer, L the characteristic size of the leaf and k the thermal conductivity of the air, as a function of the Reynolds number (ρ.v.L/μ), where ρ, μ and v are the density, viscosity and velocity of the air[5]. The results of the beginning of the singeing and drying processes, obtained in the current work (Lleaves av.= 0.086m), are shown in the same figure. The Reynolds number was smaller for the singeing process when compared to the drying in vibrating bed. The behavior of the maté leaves is similar to the one for the “gmelina”, meaning that the Nusselt number increases with the increase of the Reynolds number according to an angular coefficient of the same order. But the two curves are shifted, that is, for a same Reynolds number there are larger values of the Nusselt number for maté leaves.Representations as shown in Figure 14 are useful to estimate the coefficient of convective heat transfer (h) included in the Nusselt number. Knowing the value of h, the heat transfer to the leaves can be measured with Equation (4) Newton's law of cooling. | Figure 14. Relationship of Nu and Re for “gmelina” and maté leaves in horizontal position |

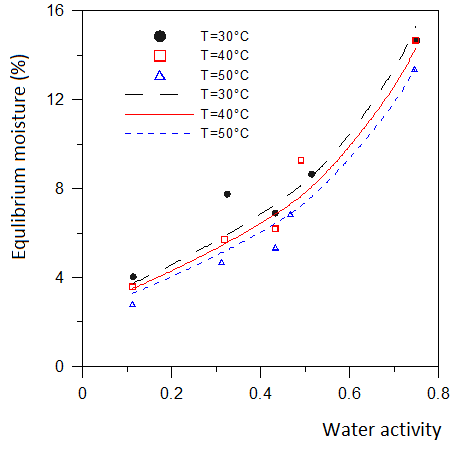

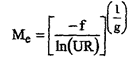

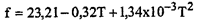

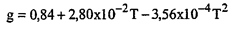

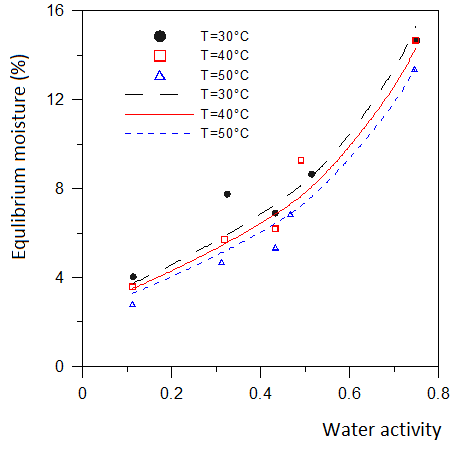

2.4. Equilibrium Isothermals

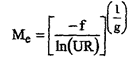

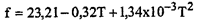

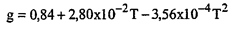

Isotherms of yerba maté are fundamental to relate the equilibrium moisture content of leaves with water activity (RH in Figure 15), the experimental data were correlated by Equation (9),[16]. Equation 9 is the correlation of experimental data. At T = 25℃ and water activities of 0.4 and 0.6, one obtains the equilibrium moisture content: 8.8% (db) and 13.7% (BU), respectively. This shows the need for a barrier transfer of moisture in the packaging of dry maté to keep the quality. | Figure 15. Maté isotherms |

| (9) |

Referring to Figure 2, for the processing of maté, for 5 tons of Ilex paraguariensis processed, the moisture after 4 min of singeing, Equation (1), is 17.8% and after 13 min of drying (Table 3) is 5.5 (wb) or 0.058 kg water / kg dry maté. These data show that after the singeing has 2.3 t of material, after drying has 2.0 t. The production of dry maté is double black tea due to the fact to select young leaves with higher humidity in the processing of Camellia sinensis.

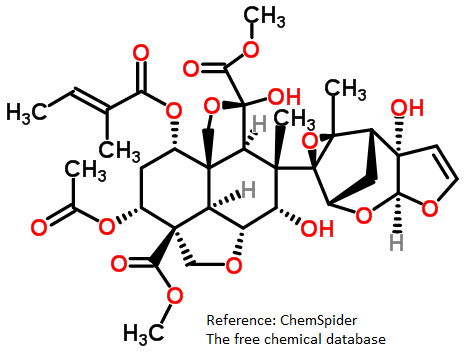

Referring to Figure 2, for the processing of maté, for 5 tons of Ilex paraguariensis processed, the moisture after 4 min of singeing, Equation (1), is 17.8% and after 13 min of drying (Table 3) is 5.5 (wb) or 0.058 kg water / kg dry maté. These data show that after the singeing has 2.3 t of material, after drying has 2.0 t. The production of dry maté is double black tea due to the fact to select young leaves with higher humidity in the processing of Camellia sinensis. | Figura 16. Structure of the azadirachtin molecule[12] |

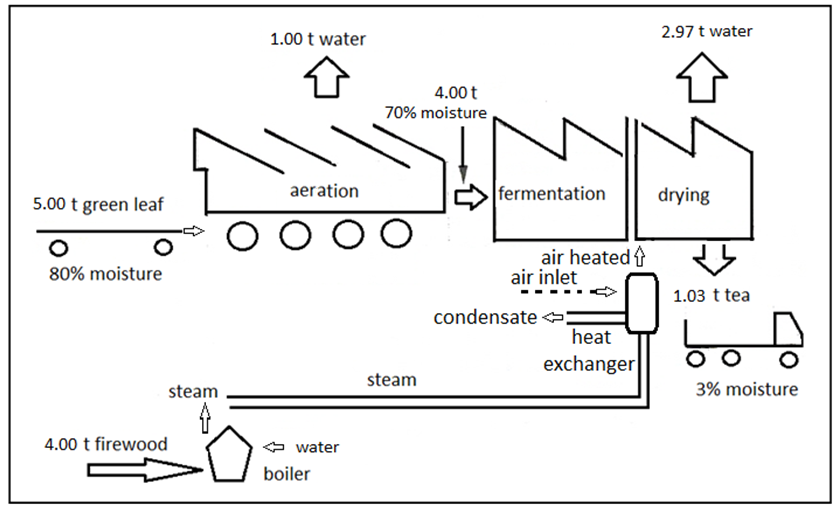

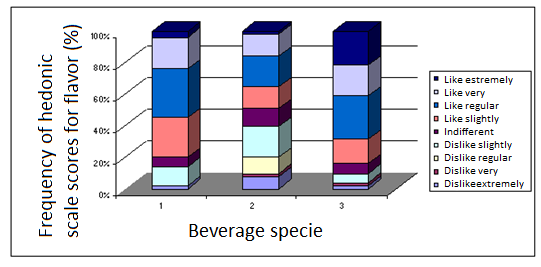

| Figure 17. Histograms of notes percentages of hedonic scale for flavor, in sensory testing for drink prepared with: (1) coffee leaves processed, (2) black tea and (3) of yerba maté tea toast |

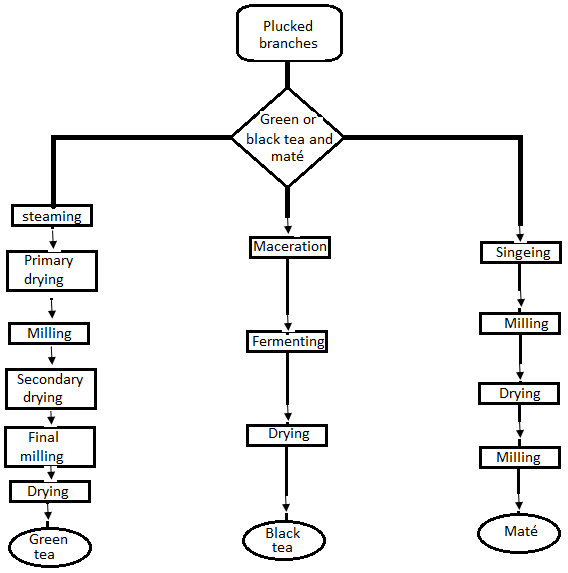

2.5. Processing Leaves Neem

The Neem, Azadirachtaindica A. Jussieu, originates in Burna, India. Neem products have valuable medicinal properties and a multitude of traditional uses as medicine, pesticide, insect repellent, fertilizer, food for diabetics and the production of toothpaste.The Azadirachtin, from the neem, is soluble in water, and important active principle[12].The structure of the molecule Azadirachtin is shown in Figure 16.The purpose of the present section was the report of process development to obtaindry neemleaves using anenzymatic inactivator and a tray dryer with heating air.The best operational condition consisted on singeingfor 5 min running the device in 200.1 rpm. The final product resulted in olive green coloration, brittle aspect and absence of peroxidase enzyme. The initial moisture of leaves was reduced from 88.33% (wet base) to 24.81% (wb). Using a drier with hot air stream (60ºC) at 0.55 m/s; after 120 min of drying process the leaves moisture content, in wet base, was 5% approximately, that is an appropriate value for storage[18].Again, referring to Figure 2, now processing neem to 5 t of sheets processed, the data show that after the singeing has 0.78 t and 0.61 t after drying. The production of dry neem is quite lower than that of black tea and mate, due to higher moisture neem leaves at harvest.

2.6. Enzymatic Browning and Enzymatic Inactivation by Singeing

Certain fruits and vegetables intended for processing, apples,bananas, potatoes, lettuce and other vegetables, when injured, the plant tissues are broken and the enzymes are placed in contact with the phenolic substrates, developing dark areas in food that identify the phenomenon of enzymatic browning. In intact plant tissues, the substrates are not in contact with the oxidizing enzymes and not darkening occurs.Peroxidase, a redox enzyme, participates in numerous physiological processes in plants, including, loss of color, taste, texture and nutrient of fruit[11]. The peroxidase enzyme is considered a more heat resistant so that when inactivated, certainly other enzymes are also inactivated.To perform the test that detects the presence of peroxidase, were homogenized with water using a knife mill type, a portion of the inactivated sample, and then filtering the material.Transferred to 2 mL of the filtrate to a test tube containing 20 mL of water was added 1 mL of 0.5% guaiacol. Then there was added 5 drops of 0.3% hydrogen peroxide. It was observed after three minutes, for changes in color, being defined as (P) positive for brown and reddish (N) as negative if the original colour had been maintained.Whereas as control parameters of the operation characteristics of the leaves after singeing and the test results for peroxidase, it was found that processing of the mass of 200 g of neem leaves shows best results with the inactivator operating at 200.1 rpm for five minutes, allowing green leaf and partially brittle, which facilitates further processing, especially for grinding.

2.7. New Products - Tea of Leaf Coffee

Referring again to Figure 2, now processing coffee leaves similarly to the maté process. The initial moisture content is 69% after 4 min of singeing, the moisture is 30% (wb) followed by drying with air heated up to 8% (wb). These data show that the process 5 t leaves after the singeing has 2.2 t and 1.7 t drying. The yield of dried leaves studied ranged from 1 to 2 t for each 5 t of leaves.The processed leaves and used for sensory analysis to verify the acceptability regarding the aroma and flavor, were obtained in the Two Bridges Farm in the city of Araguari-MG, Brazil. The coffee at this site is produced in small quantities for consumption of selected customers. Are not used pesticides or chemical fertilizers, namely, having no contaminants. The production is considered organic because it meets the requirements for certification of this product.For the flavor, surprisingly, the drink of coffee leaves was very well appreciated (see Figure 17). This shows a potential for expansion of new products using by-product of coffee is the most consumed beverage in the world of which Brazil is a reference in quality and quantity.

3. Conclusions

Singed maté leaves were obtained with moisture content in the range from 10 to 15% (wb). To obtain the moisture content needed for commercialization, smaller than 5%, the mate leaves should undergo drying after the singeing.The temperature of the leaves varies from 25℃, at the beginning of the process, up to 90℃ for a total singeing time of 4 minutes.On maté processing the contraction of the thickness of the leaves is 3.0 times greater than the contraction of the faces.The convective coefficient of heat transfer, concerning the drying of the leaves in vibrated bed, is about five times smaller than the convective coefficient of heat transfer in the singeing operation.

References

| [1] | Ashrae. (1985), Psychrometrics. In: ASHRAE Handbook – 1985-Fundamentals. ASHRAE, Atlanta, pp. 6.1- 6.16. |

| [2] | Bertoletti, J. J. (1997), Environmental impactreportofthe Machadinho Dam in Rio Grande do Sul State.Centrais Elétricas do Sul do Brasil S.A. ed. MCT. UBEA-PUCRS 131pp. (in portuguese). |

| [3] | Borde, I., Dukhovny, M., Elperin, T., Katz, V.(1996), Investigation of drying in a multistage dryer with a vibrofluidized bed. Paper presented at 10o International Drying Symposium (IDS’96). Kraków, Poland, pp. 409-415. |

| [4] | Brandenburg, A. (1999), “Familiar agriculture:ONGs sustainable development”, ed. UFPR, Curitiba-PR, 326pp. (in portuguese). |

| [5] | Córdoba, C. V. & González, M. E. L. (1984), “Environmentphotonphysical”Ediciones Pirámide, Madrid, pp. 106. (in Spaniard). |

| [6] | Embrapa. (1975), Maté, Origin, CultureandIndustrialization Departamento de Industrialização e Comercialização, URPFCS, Curitiba, Brasil, 25pp. (in portuguese). |

| [7] | Hasatani, M., Itaya, Y., Miura, K. (1991), Drying of granular materials in an inclined vibrated fluidized bed by combined radiative and convective heating. Drying Technology, 9(2): 349-366. |

| [8] | Jollivet , M. (1992), Le développment local, mode ou movement social. EconomieRurale, SocietéFrancaise d’ EconomieRurale, Paris, 166: 10-17. |

| [9] | Klein, R. N. (1984), Dynamic aspects of Brazil southvegetation.Sellovia, 36: p 5-54. (in portuguese). |

| [10] | Larcher, W., (2000) Vegetable Ecological physiology. São Carlos, Rima Artes e Textos. 531pp. (in portuguese). |

| [11] | Lima, E. D. P. A.; Pastore, G. M.; Lima, C. A. A. Purification of the enzyme polifeoloxidase (PFO) pulp sugar apple (Annonasquamosa L.) mature. Science and Food Technology. Campinas, Jan-Apr, 2001. |

| [12] | Martinez, S. S. (2002) The Neem - Azadirachtaindica: its nature, multi-use production. Agronomic Institute of Paraná: Londrina: IAPAR. 142 p. (in portuguese). |

| [13] | Mazuchowski, J.Z., 1989. “Maté Handbook”. Curitiba, EMATER-Paraná. 104pp. (in portuguese). |

| [14] | Mazuchowski, J.Z.&; Rucker, N.G.de A (1993). ‘Diagnosis and alternatives for the maté” (Ilex paraguariensis), ed. SEAB/DERAL .Curitiba:.141pp. (in portuguese). |

| [15] | Mosele, S., Rodigheri, H.R., Medrado, M.J.S., Melo, I.B., Grison, A. (1998), Diagnosisofthematéculture in Machadinho city, Estado do Rio Grande do Sul. Perspectiva,22(79): 17-26. (in portuguese). |

| [16] | Menin, J. C.; Pasa, B. C.; Zanoelo, E. F.; Finzer, J. R. D. (2000) Equilibriummoistureisotherms for maté. IV Brazilian Meeting on adsorption. Rio de Janeiro. 283-290. (in portuguese). |

| [17] | Ono, T., Yoshida, T.(1986) Designing of dryer in tobacco manufacturing process. In: Drying 86. Hemisphere Publishing Corporation. vol. 2. Washington pp. 630-636. |

| [18] | Parckert, E. D. T. (2000) Processing sheets nim: enzymatic inactivation and drying. Thesis Uberlandia University. 66 p. |

| [19] | Souza, T.L. (1937) “Matétechnology”. Secretaria de Estado dos Negócios da Agricultura, Indústria e Comércio. Porto Alegre, Brasil, 56. 18pp (in portuguese). |

| [20] | Temple, S. J. (2.000) Control of fluidized bed tea drying. Thesis WageningenUniversiteit. 203 p. |

| [21] | Valduga, A. T. (2003). Sustainable Use and Processing of Ilex paraguariensis St. Hil (Maté). Thesis UFSCar. São Carlos.Brazil. 216 p.(in portuguese). |

| [22] | Valduga, A. T.; Battestin, V.; Krüger, R. L.; Benincá, C,;Finzer, J. R. D.(2001), Techniques and solid-liquid equilibrium in the maté processing.Ciência&Engenharia, 10(2): 69-78. (in portuguese). |

| [23] | Valduga, A. T.; Finzer, J. R. D.( 2008); The Use of the Renewable Natural Resource Ilex Paraguariensis St. Hill “ProgênieCambona 4” - Aspects of Heat Transfer. FAZU emRevista. ), v. 5, p. 58-68, (in portuguese). |

| [24] | Valduga, A. T.; Finzer, J. R. D.; Mosele, S. H. (2003)Processing of maté. EDIFAPES. Erechim. 182 p (in portuguese). |

Referring to Figure 2, for the processing of maté, for 5 tons of Ilex paraguariensis processed, the moisture after 4 min of singeing, Equation (1), is 17.8% and after 13 min of drying (Table 3) is 5.5 (wb) or 0.058 kg water / kg dry maté. These data show that after the singeing has 2.3 t of material, after drying has 2.0 t. The production of dry maté is double black tea due to the fact to select young leaves with higher humidity in the processing of Camellia sinensis.

Referring to Figure 2, for the processing of maté, for 5 tons of Ilex paraguariensis processed, the moisture after 4 min of singeing, Equation (1), is 17.8% and after 13 min of drying (Table 3) is 5.5 (wb) or 0.058 kg water / kg dry maté. These data show that after the singeing has 2.3 t of material, after drying has 2.0 t. The production of dry maté is double black tea due to the fact to select young leaves with higher humidity in the processing of Camellia sinensis.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML