Abdel Moneim E. Sulieman, Heba M. Siddeg, Zakaria A. Salih

Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Wad-Medani, Sudan

Correspondence to: Abdel Moneim E. Sulieman, Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Wad-Medani, Sudan.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

HACCP (Hazard Analysis Critical Control Point) is a preventive system concerned with food safety. This system has become a prerequisite for transactions involving food products.The purpose was to set up specific HACCP plan for Sudanese biscuit processing plant in an existing biscuit processing plant in Wad Medani, central Sudan. A specific generic HACCP model was developed to improvesafety and quality of biscuit produced in this plant. This was based on actual conditions in the biscuit manufacturing plant, the seven principles of HACCP and several existing generic models of HACCP using qualitative approach. Six-member HACCP team was constituted and HACCP chart, verification procedures and record-keeping were initiated. Four CCPs were identified in the production of biscuit in the manufacturing plant. The most important identified CCPs were raw material receipt and storage, blending, packaging and product storage. However, the HACCP plan in this study has not been implemented in the biscuit making process. Based on the findings of this study, the authors recommend implementation of HACCP system in all food facilities.

Keywords:

Biscuit, Critical Control Point, Control Chart, Verification

Cite this paper: Abdel Moneim E. Sulieman, Heba M. Siddeg, Zakaria A. Salih, The Design of Hazard Analysis Critical Control Point (HACCP) Plan for Biscuit Plant, Food and Public Health, Vol. 3 No. 5, 2013, pp. 240-246. doi: 10.5923/j.fph.20130305.02.

1. Introduction with Food Safety

Biscuit is a nutritious, easy-to-store, easy-to-carry, and long-lasting food product. It is hard and dry, survives rough handling and high temperature. It can be kept without spoiling for years as long as it is kept dry[1]. Biscuits are made from flour with the addition of other ingredients such as salt, fat, sugar and flavoring agents. Protein-fortified biscuits contain nutrients in concentrated forms for feeding programmes as emergency rations. However, the acceptance of protein-fortified biscuits depends on: However, the acceptance of protein-fortified biscuits depends on their nutritional and organoleptic qualities and cost of production.HACCP has been recognized as an effective and rational means of assuring food safety from primary production through final consumption, usinga “farm to table “methodology. HACCP was developed by Pilsbury Companyalong with NASA in the 1960s. It was originally developed as a microbiological safety system to ensure food safety for astronauts. At that time most food safety and quality control systems were based on end product testing, which is an inefficient method due to product waste. Therefore, a preventive system was needed to give a high level of food safety[3],[4],[5]. HACCP is an acronym for the Hazard Analysis critical control point[3]. It is useful to think of HACCP as a preventative food safety system, and not traditional quality control inspection system. HACCP is not "zero risk" and does not eliminate the possibility of a hazard getting into the food product. HACCP attempts to decrease that possibility to an acceptable level. The most effective way to active food safety is to focus on prevention of possible hazards and to improve the process[6].Hazard Analysis Critical Control Points (HACCP) is a systematic method that serves as the foundation for assuring food safety in the modern world. The HACCP system is designed to be used to prevent the occurrence of food-borne hazards from production through manufacturing, storage and distribution of a food product.The assurance of safe production and the supply of adequately safe and healthy food products appear to be the main aims of the food industry. These aims can be achieved by adopting a systematic and organizational structure, controlling activities, procedures and resources according to the standards which constitute the basis for total quality systems, including ISO 9000 series and the Hazards Analysis Critical Control Points(HACCP)[7].HACCP system demands a high initial quality of financial resources. The initial input of this system requires additional resources for staff training, equipment and extra supplies, purchase as well as technical support[8].

2. Materials and Methods

2.1. Study Area

This study was performed in a biscuit plant in Wad Medani, Gezira State, Sudan. The plant supplies the local markets in Gezira State and other Sudan States. The plant has about 500 employees working in three shift to produce different biscuit products. The plant has a capacity to produce around 40,000 boxes of biscuits and wafer biscuits per day.The researchers spent six weeks in the biscuit plant in order to observe all the to final product, the employees and operators and monitor quality controlin order to design a brief HACCP plan based on the setting and processing in this plant to improve the quality of biscuit products. Data were collected during monitoring of the various stages of the process, raw materials, storage and until dispatch of finished products, including all current procedures. Further information was obtained from laboratory analyses records and also from data provided by factory management and staff.

2.2. Research Method

The purpose of this study was to design a HACCP model for possible implementation in an actual situation. The study matched a qualitative approach because it provides depth and careful scrutiny of the program situation. The study observed behavior were also recorded.Events, employee interaction and observed behavior. It gives the interacted details of phenomena that are difficult to convey with quantitative methods. Qualitative research is exploratory andopen-minded which is applicable to this study[9].

2.3. Study Approach

The researchers designed a brief HACCP plan based on the setting and processing in this plant in order to improve the quality of biscuit product. Based on the principle and several existing generic model of HACCP, the recordkeeping forms of the model in this study were designed in the following manner. They included; prerequisite program, product description, list of product ingredients and incoming materials, process flow diagram, hazard identification, critical control points determination and HACCP control chart .

3. Results

3.1. Prerequisite Programs

The first step in the study was bringing in all existing prerequisite programs under the umbrella of HACCP and giving them a common direction of attaining zero defects with the final product so as to ensure that there are no health concerns in the final product. Several programs have been used in the plant based in good manufacturing practices (GMP)

3.2. Design and Layout of Plant

It was observed that the grounds of the grounds of building of the plant or store are not slopedand drained to prevent stagnant water and not free of waste and debris. This floor design could expose the products to dust and sources of contamination or pest infestation. The corners and joints in all structure lead to accumulation of contaminants, making cleaning difficult. Additional shortcomings were presence of cracks and openings, the surface of floors not being of appropriate slope for drainage of waste water and other liquids and some internal walls being rough.The plant has good lighting and ventilation. Large windows opening with wire mesh allow air into building. It also provides good natural lighting. Hand washing stations are at inappropriate locations, but without soap or other sanitizing materials.Toilet room is not separated from the plant building (near the food store, handling and process areas), and this create a big source of contamination. Toilet room is not separated from the plant building. It was in fact near the food store, handling and process areas. This creates a big source of contamination.Only one quality control laboratory is available in the plant. In this laboratory only few experiments are carried out such as inspection test ofthe raw materials. The tests included gelation of flour and moisture of flour, oil moisture and peroxide value.

3.3. Personal Hygiene

Personal hygiene was improper because they do not follow the personal hygiene instructions in a proper way, and although employees wear the uniform, employee do not use gloves and do not cover their hair. So these constitute a source of contamination of the products.The proper personal hygiene involves that the employees must refrain from placing fingers in mouth, nose, ears, and from eating, chewing, spitting and smoking during food handling operation. The employees must wash hand before start of work and when re-entering their work area after visiting thetoilet(www.k12.wa.us/.../pubdocs/standardoperatingprocedures-haccp.doc).

3.4. Water Supply

A good quality potable water is supplied at the desired temperature for use in processing operations and cleaning.

3.5. Equipment

All the equipment were being checked routinely to ensure a smooth running system. The equipment has been operating properly and were found to be free of cracks, rust and dents..

3.6. Storage And Transportation

The storage room does not ensure appropriate temperature and humidity for the raw materials and the final product. Also proper transportation of equipment is needed.

3.7. Sanitation Program

The goal of the sanitation program is to maintain a sanitary environment, necessary for the warehousing and distribution of safe and legal products(https://www.aibonline.org/newsletter/.../Mar.../6DistributionCenters.pdf). There are several components of a Sanitation Program that must be in place to meet the goa. The sanitation program in the biscuit plant has not been practiced properly, clean in place for equipments and tools is done but not properly, so these equipments can be a source of contamination .

3.8. Pest Control Program

The pest control program was to eliminate from rodent, insects and birds.Pest management programs need more than traditional spraying techniques to eliminate pests. Modern pest management programs are designed to allow pest prevention as well as control(http://www.gov.mb.ca/agriculture/foodsafety/processor/cfs02s17.html).This is practised in the plant every month.

3.9. Application of HACCP

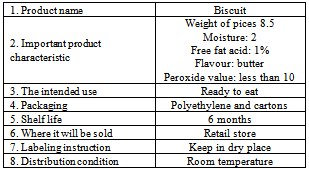

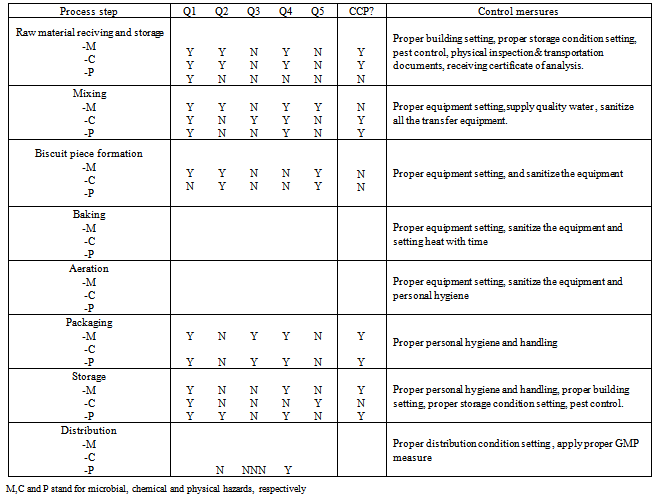

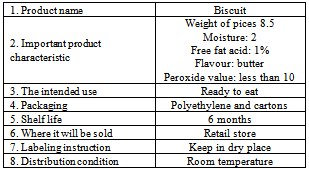

Table 1. Biscuit product description

|

| |

|

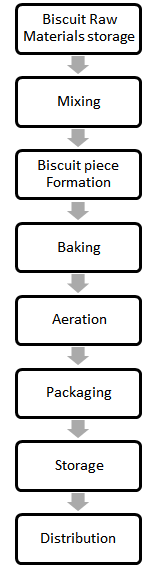

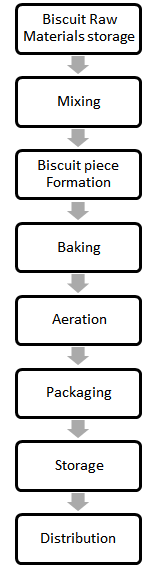

A team consisting of six members was constituted, with one of them acting as a team leader. The team consisted of senior quality control person/QA manager, food technologist / line supervisor, microbiologist, purchasing agent, stores supervisor and maintenance manager.The flow diagram is specific for the biscuit production in this plant. The details of the flow diagram are shown in Figure 1. The process flow diagram was verifiedto establish that the diagram accurately represents the actual activities and operations used in the manufacture of the product. This was done by observing each step of the manufacturing process.The description of product (Table 1) was used to alert the consumer of potential hazards in the final product. | Figure 1. Biscuit flow diagram |

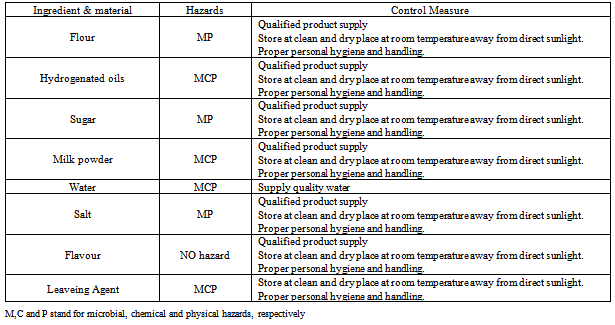

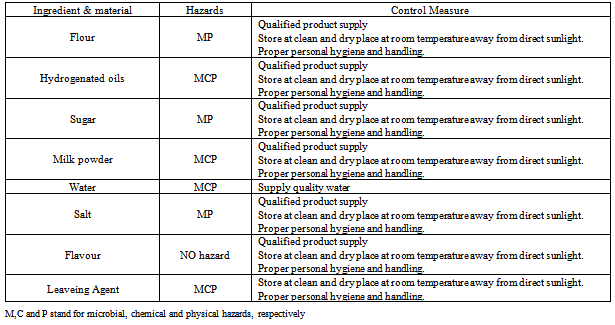

Table 2. The hazards identified in biscuit ingredients and their control measures

|

| |

|

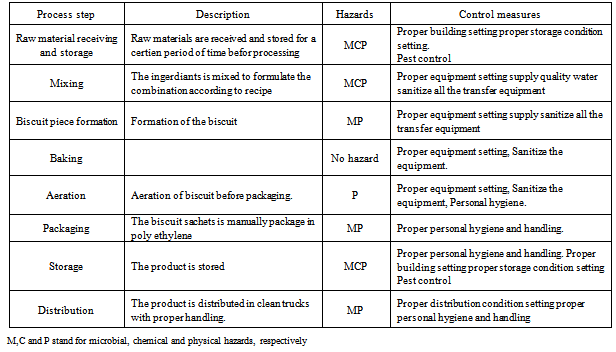

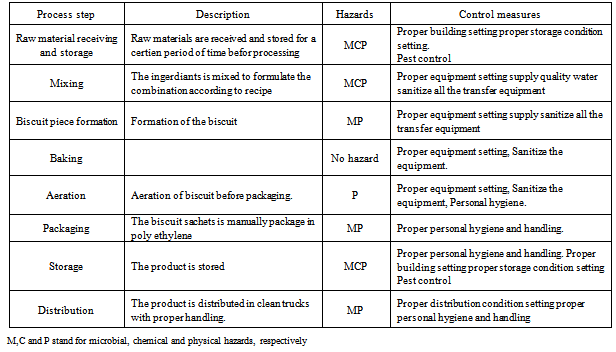

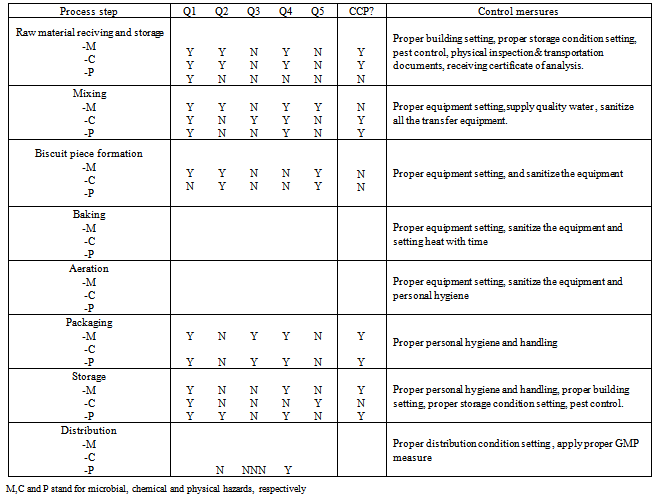

Table 3. The hazards identified in biscuit processing steps and their control measures

|

| |

|

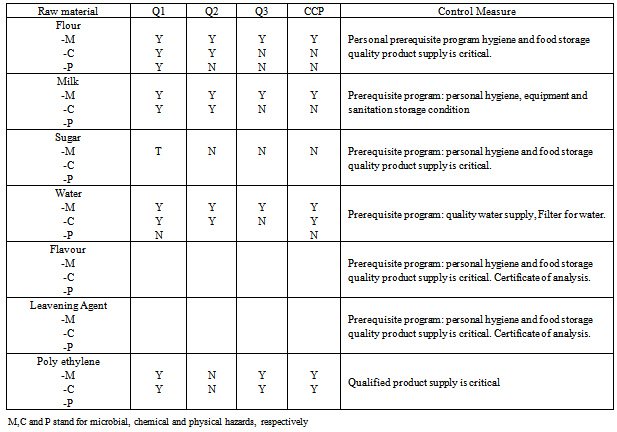

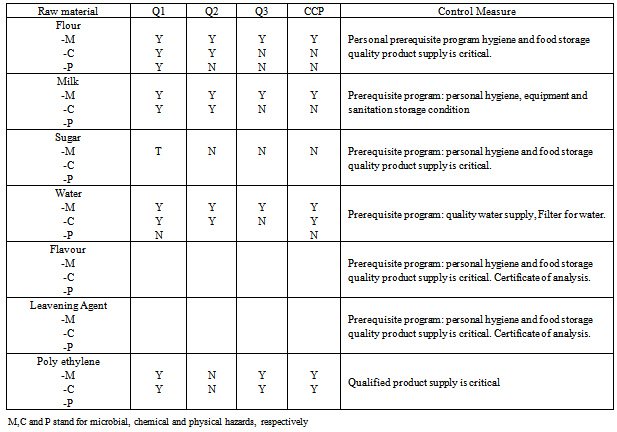

Table (2) shows the microbiological, chemical and physical hazards in the raw material for biscuit products. The table also includes the preventive measures for the hazards in each raw material.In Table (3) the preventive measures are provided for the hazards in each processing step. All the natural situations were set up under the requirements in this plant to make safe and quality product.Table 4. Biscuit ingredients decision matrix

|

| |

|

Table 5. Biscuit process decision matrix

|

| |

|

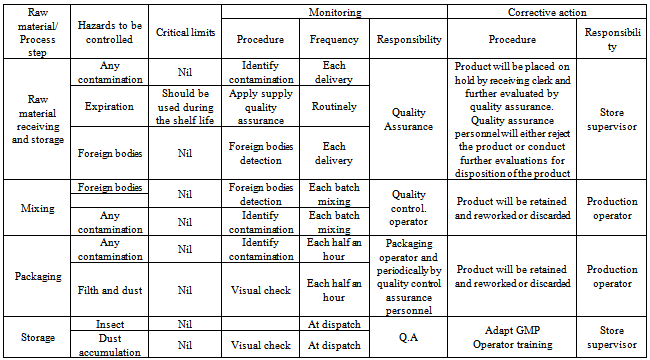

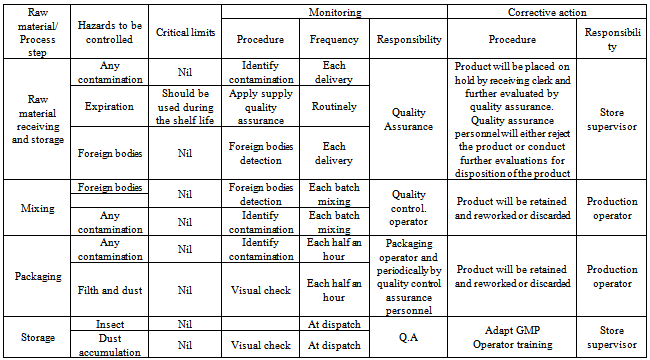

Table 6. Biscuit HACCP control chart

|

| |

|

The decision matrix was then filled out based on the answers given to the question from the decision tree. Other hazards were control points that could be controlled in a prerequisite program or other process. Tables 4 and 5 represent the decision matrix for biscuit product.The potential control points of the hazards appeared in the process along with the prevention measures is indicated in Table (6). The HACCP control chart was developed to include components of several HACCP principles which are critical limits, monitoring and corrective actionFor biscuit product, the most essential part of the whole HACCP plan, is the organization analysis and documentation of the CCPs. The column of the control chart will be filled out by the operator or the supervisor who is responsible for the control. The steps that contain CCPs will be emphasized during production. The documentation of the HACCP plant which is suitable for the conditions in this plant will help to prevent and eliminate those critical hazards in its production. Therefore, safe and quality products could be produced in this plant. The document also can be used for improvement of a HACCP plant in the future.By answering the questions in the decision trees, the critical control points were determined.

4. Discussion

The raw material is received after….. Then raw materials are stored at ……supervisor follows…..product spoilage. Bad storage…….Based on the process decision tree, four CCPs were identified in the present study. All those four CCPs were determined based on the prerequisite programs requirement in the plant. These programs were crucial to determine the critical control points. Without the programs, the researchers need to consider more hazards that are possible to the product from outside the process. These CCPs include:1- Raw material receiving and storage: The raw material is received afterthe quality assurance personnel inspect certificate of analysis and confirm it. Then raw materials are stored at appropriate conditions in clean and dry place away from direct sun light in wooden or steel pallets (skids) to keep the material off the ground. Store supervisor followsthe distribution manner (first-in first-out). Bad quality raw material can result in product spoilage. Bad storagecondition results in material deterioration and will decrease the shelf life of the material. Raw material receiving and storage has been critical for the final product quality which can add hazards to the materials and decrease the quality.2- Mixing: Mixing step takes place when the ingredients are mixed in the biscuit mixture after weighing them on defined recipe bases. The mixture operator opens the sachets and adds the ingredients manually to the blender, the mixing process accompanied by exchange of water between the mixing tank and the blender. This step could add hazards and contamination to the process which will affect the quality of the final product.3- Packaging: The finished product is manually packed in cartons as secondary packaging by workers. The workers hygiene is very critical to consumer health.4- Product storage: The finished product is stored at appropriate conditions in clean and dry place away from direct sunlight in wooden or steel pallets (skids) to keep the product off the ground to follow and test the product quality. The quality assurance personnel conduct quality tests to permit product release. Then the product is distributed during its shelf life. Storage condition is critical for developing spoilage and deterioration of the product. Quality of the product should be monitored and the stock must be managed carefully.

5. Conclusions

As a result of development and improvements in food industry and international trade, customers are demanding safe and wholesome food products. As a result, food processing companies are implementing food safety management systems to ensure the production and distribution of safe foods. The present study designed a HACCP plan for a biscuit plant to improve the safety and quality of products. The model is developed step-by-step based on the seven principles of HACCP system.The reduction of identified CCPs number is necessary since it will lead to a decrease of the overall cost hence increase the net outcome of the company. Further research is needed to design HACCP plans for other bakery industries in Sudan.

References

| [1] | Divya, M. (2012). Biscuit industry in india – an overview . www.slideshare.net/.../biscuit-industry-in-india-an-overview |

| [2] | Manley ,D. J. ( 2000).Technology of Biscuits, Crackers, and Cookies. Woodhead Publishing Series in Food Science, Technology and NutritionSerieshttp://books.google.com.sa/books?id=tKbu1icH5oYC&dq=Biscuits+wheat+flour&source=gbs_navlinks_s |

| [3] | Bardic A., 2001. HACCP ready. Dairy Field 184, 6. |

| [4] | Bennet L., Steed L., 1999. An integrated approach to food safety. Qual. Progr. 32, 37-42. |

| [5] | Mortimore S., Wallace C., 1997. HACCP. Chapman and Hall New York. |

| [6] | Swanson, K.M.J. and Anderson J. E. (2000). Industry Perspective on the use of microbial data for HACCP validation and verification. Journal of food protection 63(6), 815-818 |

| [7] | Banat, A. R.; Shaker, R.R. and Ibrahim, S.A. (2004). Implementation of HACCP System to Large Scale Processing Line of Plain Set Yogurt. Italian Food and Beverage Technology. 35: 12-17. |

| [8] | Morjajemi, Y. and Kaferstein, F. (1999). Food safety hazard analysis critical control points and the increase in foodborne diseases: A Paradox? Food Control, 10( 4-5), 325-333. |

| [9] | Patton, M. 1987. How to use qualitative methods in evaluation. Beverly Hills, CA: SAGE Publication, Inc. |

| [10] | www.k12.wa.us/.../pubdocs/standardoperatingprocedures-haccp.doc.https://www.aibonline.org/newsletter/.../Mar.../6DistributionCenters.pdf |

| [11] | http://www.gov.mb.ca/agriculture/foodsafety/processor/cfs02s17.html |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML