-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2012; 2(6): 259-264

doi: 10.5923/j.fph.20120206.11

Chemical and Microbiological Characteristics of White Cheese (Jibna-beida) Produced in Sudan

Zakaria A. Salih 1, Abdel Moneim E. Sulieman 2, Elamin A. Elkhalifa 1, Ali O Ali 1

1Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Wad-Medani, Sudan

2Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

Correspondence to: Abdel Moneim E. Sulieman , Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This study aimed to investigate the chemical and microbiological characteristics of Jibna–beida collected from some Sudanese local markets (Kenana, Eldueim, Elobeid, ELgezira and New Halfa ). The average chemical composition was 50.31%, total solids, 49.49% moisture, 20.12 % protein, 22.27 fat, 4.76 salt, 5.57 % ash, 1.64 lactose, 4.85 pH, 1.85 titratable acidity, 1.70 (0.1N ml NaOH /100g cheese ), volatile fatty acids, 10.02 mg/100g acetaldehyde , 30.89 mg/100g diacetyl content. Most of the chemical components of collected cheeses were in close agreements to those of literature values with slight variations. The microbiological analysis revealed the presence of some pathogenic bacteria like Staphylcoccus aureus, Salmonella spp. and coliform bacteria in most of the collected cheeses, which contained high counts of total bacteria (TBC), lactic acid bacteria (LAB) and yeasts and moulds which averaged 9.02x 106cfu/ml for TBC, 6.5x105 cfu/ml for LAB, 5.5x101 cfu/ml for coliform, 3.5× 101 cfu/ml for Salmonella, 3.7x103 cfu/ml for Staphylococcus aureus, 1.86x105 cfu/ml for yeast and moulds.

Keywords: Chemical Composition, Acetaldehyde , Diacetyl, Microbiological Analysis

Cite this paper: Zakaria A. Salih , Abdel Moneim E. Sulieman , Elamin A. Elkhalifa , Ali O Ali , "Chemical and Microbiological Characteristics of White Cheese (Jibna-beida) Produced in Sudan", Food and Public Health, Vol. 2 No. 6, 2012, pp. 259-264. doi: 10.5923/j.fph.20120206.11.

Article Outline

1. Introduction

- Cheese is a vital fermented dairy product which had a major role in human nutrition for centuries. Cheese is perhaps the oldest processed food known to mankind and one of the most ubiquitous food stuffs in the world (Chemical and Engineering News, 2000. It is an excellent tasty, 99% digestible energy food, which is suitable for all age groups and contains high quality proteins[1]Cheese is made in almost every country of the world and there exist more than 2000 varieties of cheese while may be classified into different groups, i.e. ripened and unripened cheese, cheese with low or high fat content and cheese with soft or hard consistency[2]. The global sale value of cheese represents about 30% of total dairy products sales with a forecast of 9.8% growth in cheese sales between 2003 and 2007[3]. Cheese making is a major milk preservation method in Sudan[4]. There are two main types of cheeses in Sudan white cheese (Jibna beida) and braided semi hard cheese (Mudaffarra). Jibna-beida is practically the only kind of cheese on the market available to the public at large in the Sudan. There is little doubt that the technology of making Jiban-beida has been introduced into the Sudan from Egypt or, through Egypt, from the Mediterranean countries, such as Greece. It is not known exactly when jibna-beida was first introduced into the country but it is most likely that Sudan has known this cheese for nearly a century[5]. The processing of Jibna-beida is done traditionally, begins by receiving cow's raw milk which is strained and mixed with salt in a clean petrol drum. Then 4 or 5 rennet tablets (8–10g) are crushed, suspended in a little water and added to each drum, with constant stirring. The milk is next covered with cheese cloth and left to coagulate within 4–6 hours. The curd is transferred to wooden moulds lined with cheese cloth and left to drain overnight. The cheese obtained is cut into cubes and placed into petrol cans. The whey is added to the cheese to immerse it completely and the cans hermetically sealed by soldering. Cheese is then stored for ripening[4]. The objective of the present study was: Determination of the chemical and microbiological characteristics of Jiban – beida found in Sudanese local markets.

2. Materials and Methods

2.1. Sampling

- Cheese samples were collected in clean dry and sterilized plastic containers from local markets in Kenana, Eldueim, Elobeid, ELgezira and New Halfa, during September (2007). All collected samples were then placed in an insolated box containing ice crystals to suppress microbial growth during transportation to laboratory. The samples were kept at 4o and transported to the department of Food Science and Technology, University of Gezira, while some of the sample were transported to the of Food Technology Research Institute– Egypt.

2.2. Methods

2.2.1. Chemical Analysis

- Chemical analysis were conducted for the collected cheese samples, the analysis included the following parameters. The moisture content, total solids, protein content, lactose content, ash content, pH and titratable acidity (TA) of the different samples were determined according to AOAC[6]. Fat content was determined according to Foley and Murphy[7]. The salt in cheese samples was determined according to the method described by Ling (1963). The total volatile fatty acids (TVFA) content in cheese was determined by the direct distillation method of Koiskowski [8].

2.2.2. Acetaldehyde Content

- The acetaldehyde content was estimated as described by Less and Jago[9] using the Conway microdifusion semicarbozide methods. Acetaldehyde reacts with the semi-carbazide to form semi-carbazon with absorption peak at 224nm. The procedure follows: one ml of 1 micromole semi-carbazide solution was pipetted in inner wall of Conway microdifusion cell. Three mls of sample were rapidly pipetted in the other compartment and the cell was converted, confirmed by plaster and incubated at 37℃ for 90 min. The solution in the inner wall was transferred to 10 ml. volumetric flask and made up to volume with distilled water. The absorption was measured at 224 nm.

2.2.3. Diacetyl Content

- The previous procedure for determination of the acetaldehyde content was used also to determine diacetyl content with the exception of measuring the absorption at 270 nm. Using same spectrophotometer as described by Less and Jago[9].

2.2.4. Microbiological Analysis

- Ten gram samples of cheese type were homogenized with 90 ml of distilled water by shaking for several minutes, from this suspension; 1 ml was taken from the dilution and transferred to another tube to make serial dilution up to 10-6. Plate Count Agar (Oxoid) was used for enumeration of total viable count according to APHA[10]. Lactic acid bacteria count was determined according to the method described by Kiss[11], using MRS media. Coliform bacteria count was determined according to Marshall[12] using MacConkey broth. Mannitol Salt Agar was used for enumeration of Staphylococcus aureus count. accoding to Rayman et al.,[13]. Deoxycholate Citrate Agar was used for detection of Salmonella according to Thatcher and Clark[14].Yeasts and moulds were enumerated according to Marshall[12] using Potato Dextrose Agar (PDA).

2.2.5. Statistical Analysis

- Statistical analysis was done using Statistical Package for Social Studies Software SPSS. Complete Randomized Design was used to estimate chemical, microbiological and sensory characteristics of the jibna beida.

3. Results and Discussion

3.1. Chemical Characteristics

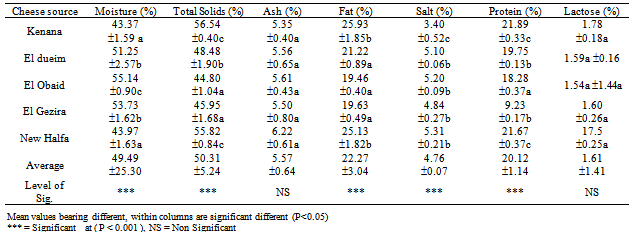

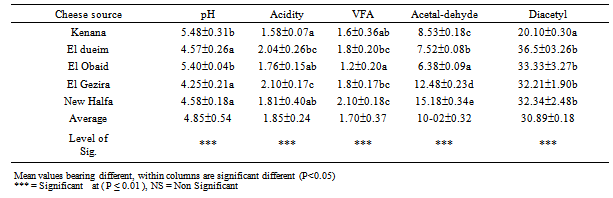

- The chemical characteristics of the collected cheese samples are presented in Table (1). The total solids content ranged between 44.80 and 56.54% with an average value of 50.31%. Statistical analysis showed highly significant differences (P ≤ 0.01) between the different cheeses. Relatively similar values were reported by Babiker[15], while Abdel Razig[16] and Elowni and Hamid[17] reported lower values who found that the total solid contents were 44.00% and 42.38%, respectively. The moisture content ranged between 43.37 % and 55.14 % with an average value of 49.49%. This range is close to the usual value for semi hard cheese (45 – 55%) and also in close agreement with that found by Ali[18] for cheese samples (56%). However, the results were lower than those reported by Alla Gabo[19] and Elshibily et al,[20], who reported moisture content of 61.2% and a range of 54.6–56.4%, respectively. The study showed significant variation (P ≤ 0.01) between collected cheese samples in moisture content. The protein content of cheeses ranged from 18.28 ± 0.37% to 21.89 ± 0.33% with an average value of 20.12 ± 1.14%. These results agreed with those of Ceylan et al.,[21] who reported a range of 16.00 to 22.71% in orgu cheese, higher than those reported by Ali[18] who found a value of 13.8%, and lower than those reported by Elowni and Hamid[17], Nuser[22] and Sulieman et al.,[23] who reported protein content of 22.5%, 23.26% and 33.0% for white cheese, respectively. Statistically, highly significant differences (P ≤ 0.001) in protein content of different cheese samples were found. The fat content of cheese samples ranged between 19.46% and 25.93 % with an average value of 22.27. These values were in close agreement to that reported by Elowni and Hamid[17] who reported a range of 19.17% to 23.83% in jibna-beida samples collected from Zalengei area, On the other hand, fat contents determined in the present study were higher than those reported by Aly and Galal[24], Khalid and Elowni[25], and Elowni and Hamid[26] for cheese samples, who reported fat contents of 12.80%, 11.70%, and 18.9 ± 0.18, respectively. Statistical analysis showed highly significant differences (P ≤ 0.001) in fat content of collected cheese samples. The variation in fat content in this study could be attributed to several factors like breed, individuality of animal, type of feed, health and age of the animal when the milk was taken. The salt concentration in cheese mass is an important parameter affecting acceptability and quality of the product. The salt content of cheese samples ranged between 3.40 % and 5.3 %, with an average of 4.76. The variation in salt content was highly significant at (P ≤ 0. 01). Similar values were reported by Ibrahim (1971) and All Gabo[19] for Sudanese white cheese, who reported salt contents of 4.3% and 4.2%, respectively. The results are not far from those reported by Elowni and Hamid[17] who reported an average of 5.72%.. The ash content of cheese samples raged from 5.35 % to 6.22 % with an average of 5.57 %. The variation in ash contents could be due to the different salt levels used by different producers. Statistically no significant difference (P > 0.05) was found in the ash content of the various cheese samples. The obtained results were higher than those reported by Abdel-Razig[16] and Elowni and Hamid[17] for Sudanese white cheese, who reported a value of 2.2% and 4.8%, respectively. Lactose content of cheese samples varied from 1.54 % to 1.78 % with an average of 1.64. No significant (P>0.05) variations were found in lactose content of the cheese from different areas. The results in this study were higher if compared with that reported by Sulieman et al.,[27] who reported a lactose content of (1.3%) in Sudanese white cheese, However, the value was lower than that reported by Kosikowski[1] who reported a range of 1.80 and 2.0%. pH values of cheese samples (Table 2) varied between 4.25 and 5.48 with an average of 4.85. Significant (P ≤ 0.01) differences were found in pH values of cheese in different areas. The variation of pH values of various cheese samples from different areas might be due to variation in composition and properties of milk[21]. The findings are in close agreement to those obtained by Ibrahim[[4], Ali[18]) and Alla Gobo[19], who reported 4.6%, 4.9% and 4.9% values, respectively for Sudanese white cheese. Titratable acidity of collected cheese samples in different area was 1.58 % to 2.10 % with an average of 1.85. The present study showed significant (P ≤ 0.001) differences between the collected cheese samples from different areas in titratable acidity values. The results were higher than those reported by Elowni and Hamid[17] and Ceylen et al.,[21], who found an average titratable acidity of 1.08% and 1.11%, respectively in Sudanese white cheese. The high acidity of the cheese samples could be due to high lactic acid bacteria counts in raw milk used for cheese making, or might be due to long period of storage of cheese. The range of volatile fatty acids contents of collected cheese samples from different areas (Table 2) was 1.2 and 2.10 (0.1N ml NaOH /100g cheese) with an average of 1.70 (0.1N ml NaOH /100g cheese. The result indicated that significant (P ≤ 0.01) differences were observed in volatile fatty acid content between the cheese samples. The variation of volatile fatty acids content of the different cheese samples was possibly due to the variation in manufacturing conditions. The findings in this study were lower than those obtained by Elowni and Hamid[17] and Elowni and Hamid[26]), who found that the average of volatile fatty acids content of Sudanese white cheese were 9.7 and 14.12 ± 3.09 (0.1N ml NaOH /100g cheese), respectively.

|

|

|

3.2. Microbiological Characteristics

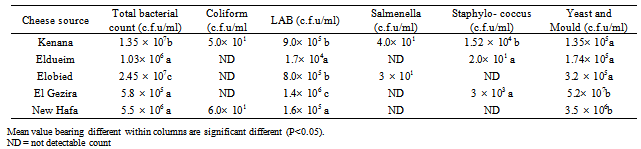

- The results obtained from the microbiological analysis of cheese samples are shown in Table (3). The total bacterial count (TBC) of cheese samples varied between 5.8x105 and 2.45x107 cfu/ml with an average of 9.02x 106cfu/ml). Statistical analysis showed that there were significant differences (P<0.05) found in total bacterial count of the different cheese samples. The high total bacterial count in this study could be due to low quality of the milk used in cheese making or could be due to unsanitary conditions during processing and handling of the cheese[29]. These findings were consistent with the results of Hamid and Elowni[17], Warsama et al.,[30].The average lactic acid bacterial count (LAB) of cheese samples was cfu/ml 6.5x105. The lowest LAB count was 1.7x104 cfu/ml found in El dueim samples, while the highest was 1.4 x106 cfu/ml for ElGezira sample. Significant (P<0.01) differences were found in different cheese samples. The high LAB count in cheese samples could be due to higher initial microbial load of fresh milk. The average lactic acid bacteria counts in this study was lower than those reported by Hamid and Elowni[17] for white Sudanese cheese collected in Zanlngie area, also lower than those reported by Ahmed[31]. Colifrom bacteria were not detected in three cheese samples (Eldaiem, ElObied and ElGezira), whereas, colifrom bacteria were found in two cheese samples( from Kenana and New Halfa) which were 5x101 and 6x101 cfu /ml, respectively. The coliform count in some cheese samples were probably due to production of milk and cheese under poor conditions (Ceylan et al., 2003; Warsama et al., 2006). According to the International Standards, white cheese should not contain more than 100 cfu/ml coliform bacteria (Law.1999). These results were lower than those reported by Elowni and Hamid, (2007) and Hayaloglu. Et al, (2005), however, these findings were in agreement with that reported by Ahmed, (1997).No Salmanella cells were detected in Eldoem, El Gezira and New Halfa cheese samples, while Kenana and El Obeid samples contained 4.0x101 and 3.0x101 cfu/ml, respectively. The high count of Salmonella found in some cheese samples could be attributed to the poor hygienic conditions prevailing during cheese production. On the other hand Salmonella were not found in other cheese samples examined probably due to high levels of salt and titratable acidity. The result agreed with Hamid and Elowni,[17], who did find Salmonella in all collected cheese samples in Zalingi area. However, the Salmonella results disagreed with Warsama et al.,[30].The average Staplylococcus aureus count which was 3.7x103 cfu/ml. However, cheese samples from (Elobeid and New Halfa) showed no growth. The high content of Staphylococcus aureus found in Kenana, ElGezira and Elduiem samples, might be attributed to the high initial numbers of Staphylococcus aureus in milk contaminated during processing[32]os and Genigeorgis 1981). These findings were not in line with those reported by Hamid and Elowni[17]) and Ahmed[31].Yeast and moulds cells were detected in all cheese samples. The average count was 1.86x105 cfu/ml, while the lowest yeasts and moulds count was 1.36x105 cfu/ml found in Kenana samples, whereas the highest count was 5.2 x 107 cfu/ml. Statistical analysis showed that there were highly significant differences at (P<0.01) in yeasts and moulds count of different cheese samples. The high count of yeasts and moulds in the cheese samples indicates poor hygienic conditions. The results were higher than those reported by Hamid and Elowni[17], who stated that the yeasts and moulds count in white cheese samples collected in Zalingi area, was 4.46 log cfu/ml. Also these are higher than those reported by Girgis et al.,[33] for Ras cheese in the Egyption market, who found a range between 0.15x104 and 8x105 cfu/g.Generally, the presence of different microbial groups especially the pathogens in jibna-beida could be attributed to the use of raw milk in its preparation. It is known that the microbiology of raw milk is crucial for the production of any high quality dairy food. Most soft, unripened cheeses are microbiologically unstable due to metabolic activity of bacteria, yeast or mould contaminants[34][35].

4. Conclusions

- The chemical analysis indicated that most of the chemical components in cheese samples from different areas were in close agreements to that of literature values with slight variations. The microbiological analysis revealed the presence of some pathogenic in some cheese samples, and also high total bacterial count, lactic acid bacteria and yeasts and mouldsIt is highly recommended to utilize the surplus milk in rural areas in production of jibna-beida and other dairy products under controlled conditions. In addition to pasteurize milk before preparation of jibna-beida as this heat treatment is suitable to eliminate the pathogenic bacteria and at the same time production of cheese with high quality.

ACKNOWLEDGEMENTS

- The paper is derived from the PhD thesis of the first author. The authors express their thanks for Ministry of Higher Education of Sudan which funded this research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML