-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2012; 2(6): 254-258

doi: 10.5923/j.fph.20120206.10

The Effect of HACCP Based Personal Hygiene on the Products of Galda Prawn (Macrobrachium rosenbergii) at Processing Zone in Khulna, Bangladesh

A. K. Obidul Huq , Shabudden Ahmed , Shifat Md. Arefin , Akteruzzaman

Department of Food Technology and Nutritional Science, Mawlana Bhashani Science and Technology University, Tangail, 1902, Bangladesh

Correspondence to: A. K. Obidul Huq , Department of Food Technology and Nutritional Science, Mawlana Bhashani Science and Technology University, Tangail, 1902, Bangladesh.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

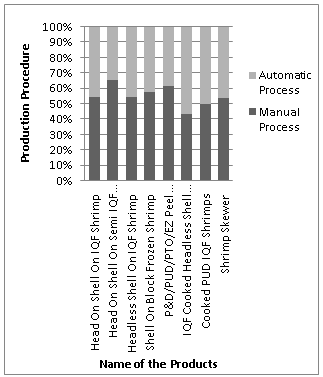

The present study was conducted to compare the quality assurance system for different shrimp products of Galda prawn (Macrobrachium rosenbergii) and identified the possible causes of potential hazards in the processing zone at Khulna, Bangladesh. Physical and microbial investigation was made for observation, interviewing and check the record of quality assurance system according to HACCP establishment from receiving of raw materials to storage at three selected seafood industries. Processing of the entire products are semi automatic and the manual steps done by the daily worker where the major numbers are illiterate women of the regional area and they have not adequate knowledge about hygiene practices according to the HACCP plan. The findings of physical and chemical hazards of those products are same but the biological hazards are verified due to lack of consciousness about personal hygiene as well as food safety abides by the worker. During the processing of Cooked P&D IQF Shrimp 92.29% of hygiene are maintained whereas average personal hygiene maintained only 73% for all products. According to the microbial test of finished products, Cooked P&D IQF Shrimp showed lowest bacterial load 1.87x105 CFUg, MPN count of total coliforms 12/g, MPN count of Faecal coliforms <3/g whereas P&D Block Frozen Shrimp found 5.3x105, 53 and 9 total bacterial count, total coliforms and faecal coliforms count respectively. Cooked item has less chance to keep in contact of worker to microbial contamination and greater chance to retardation during processing.

Keywords: Galda Prawn, Shrimp, HACCP, Food Safety, Quality Control, Personal Hygiene

Cite this paper: A. K. Obidul Huq , Shabudden Ahmed , Shifat Md. Arefin , Akteruzzaman , "The Effect of HACCP Based Personal Hygiene on the Products of Galda Prawn (Macrobrachium rosenbergii) at Processing Zone in Khulna, Bangladesh", Food and Public Health, Vol. 2 No. 6, 2012, pp. 254-258. doi: 10.5923/j.fph.20120206.10.

Article Outline

1. Introduction

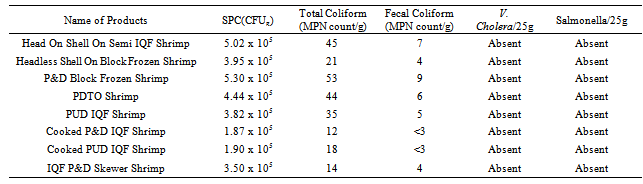

- Shrimp export from Bangladesh have greater acceptance to world market because of naturally better taste and low price, the assurance of food safety and quality is the major concern as highly perishable commodity. About 50% of the seafood products all over the world are being exported from the developing countries and Bangladesh exports 129.81 million lbs in the economic year 2009-10 of shrimp products. Among the sea food products 80% is shrimp product and Raw, Individual Quick Freezing and Cooked shrimp are the most popular product for export among which Cooked IQF shrimps are highly qualified for export purpose and TC, FC and total bacterial count found in Raw Block shrimp were significantly higher than those of Raw IQF shrimp[1]. All the production are semi automatic where the receiving, washing, watering for glazing, weighting, beheading are done manually and Freezing, cooking,chilling, panning are done by automated process and packaging is done by semi automatic process that are maintained and monitored according to the Hazardous Analysis and Critical Control Point system but the personal hygiene are sometime not maintain strictly. Potential hazards as identified at six different phases (prior to processing, hygiene practice, processing, freezing, packaging, storage at factory) of fish/prawn processing plants at Khulna[2]. On the ground that export of shrimp did not meet the provisions of her HACCP, the European Commission (EC) imposed a ban on shrimp from Bangladesh into the EU in July 30, 1997 as they found nitrofurazone and other antibiotics[3]. The physical and chemical parameter are maintain by both the industrial and government initiative but major numbers of the daily worker in the seafood processing units are women of the regional area whose are illiterate and they have not enough knowledge about hygiene practices according to the HACCP plan as the pats of Good Manufacturing Practice and unconscious about food safety. The source of pathogenic bacteria may be come from natural source and hygienic handling of shrimp by the workers[4]. Handling of raw materials influences the bacteriological quality of frozen shrimps[5]. Insufficiently iced and improperly storage of shrimps at higher temperature enhances the growth of microorganisms responsible for microbiological changes[6]. The present study was undertaken to furnished quality assurance system in shrimp processing zone to overcome those adulteration and unexpected problems for the industries that complies with new technique and established critical limits.

2. Material and Methods

2.1. Materials

- Three Seafood industries are selected named Atlas Seafood Ltd., Lockpur Fish Processing Co. Ltd, Organic Shrimp Export Ltd. and New Food Ltd (Khulna, Bangladesh) to observe the quality assurance system and New Food Ltd for practical exicution. Eight shrimp products of 'Galda' (Macrobrachium rosenbergii) are obtained from New Food Ltd among the entire product are Head On Shell On Semi IQF Shrimp, Headless Shell On Block Frozen Shrimp, Peeled & Deveined Block Frozen Shrimp, Peeled Deveined & Tail-on, Peeled & Undeveined IQF Shrimp, Cooked Peeled & Deveined IQF Shrimp, Cooked Peeled & Undeveined IQF Shrimp and IQF Peeled & Deveined Skewer Shrimp as they are most popular and exportable shrimp products.

2.2. Methods

2.2.1. Shrimp Processing Unit

- Physical investigation was made for observation, interviewing and check the record (physical and chemical parameter) of quality assurance system according to HACCP establishment from receiving of raw materials to storage.

2.2.2. Microbial Enumeration

- The sample was collected three time receiving, processing and finished product to microbial analysis. 200gm of sample was taken from each batch of production among which 25gm sample was required for each analysis of standard plate count, total coliform, fecal coliform, salmonella, v. cholerae, shigella.Standard plate count were performed by plating 180 ml of sterile 0.1% peptone water appropriate dilutions onto the plate count agar (Mumbai, India) by surface plating method. Total coliform is conducted by 1 ml of decimal dilution into 3 tubes of Lauryl Tryptose Broth (LTB) and incubated for 48hrs at 37°C. Fecal coliform is tested by the selection of gas production of LTB positive which inoculated into Brilliant Green Lactose Bile Broth (BGLB) is incubated at 44.4℃ for 48hrs[8]. For both total coliform and fecal coliform, the results were computed using MNP chart[9]. To enumerate Salmonella, 25 gm sample taken into 225 ml sterile Buffed Peptone Water at PH 7.5 and incubated for 48 hrs at 37℃. Xylose Lysine Desoxycholate Agar is use as plating media and incubated again. V. Cholera is conducted by using 25 g sample in 225 ml sterile Alkaline Peptone Water aseptically and incubated at 37℃ for 24 hours[7].

2.2.3. Data Analysis

- The data are submitted to Statistical Analysis using the software SPSS 14.0 for windows (SPSS Inc., Chicago, IL) where analyzed by the analysis of variance (ANOVA) and significance difference among means from tripicate analysis at (p < 0.05) were determined by Ducan’s multiple range tests using the statistical analysis system.

3. Results and Discussion

3.1. Processing Steps

| Figure 1. Processing type of shrimps products |

3.2. Hygiene Practice

| Figure 2. Distribution of the products according to hygiene practices |

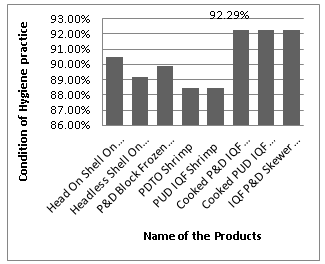

3.3. Risk of Contamination

- Figure 3 shows the potential hazards identified at different

| Figure 3. Potential hazards as identified at different steps of shrimp processing |

|

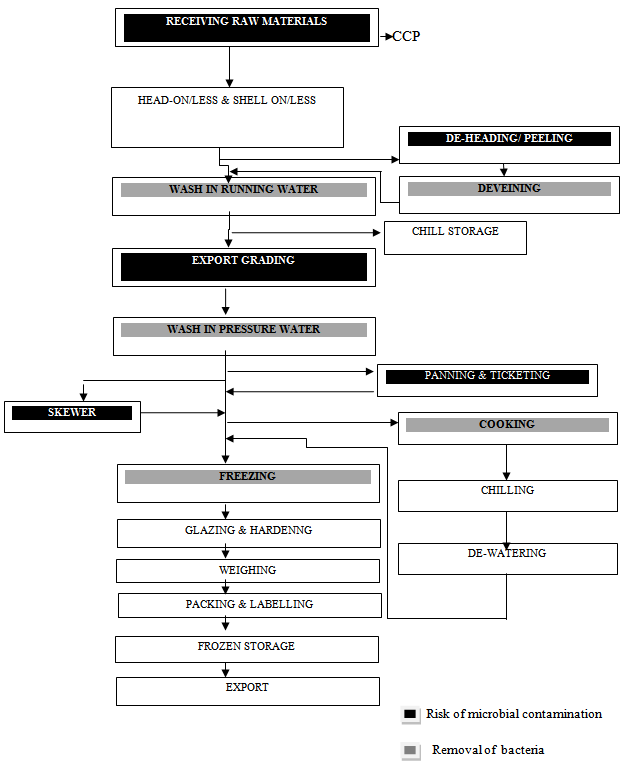

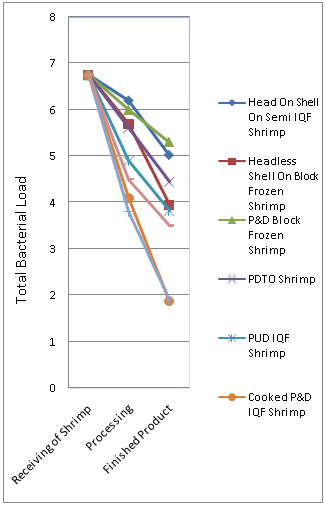

3.4. Hazard Analysis

- The microbial analysis of selected shrimp product showed in table 1 and markedly found P&D Block frozen shrimp has the highest number of total bacteria (5.30 x 105 CFUg) and fecal coloform (9 MPN count/g) and Head On Shell On Semi IQF Shrimp has maximum number of total coliform (45 MPN/g). The table showed the least number of pathogen survives in the Cooked P&D IQF and Cooked PUD IQF shrimp. According to ICMSF[10] the acceptable upper limit of total bacterial load, total coliform and faecal coliform is 10 CFU/g, 100 MPN count/g and <3 MPN count/g, respectably while Salmonella and/or V. cholerae should not present. Thus, all the results of the microbial test of the sample present under the acceptable limit according to ICMSF and FDA guidelines[10],[11]. A study in South-western Nigeria to assess microbial safety of fresh shrimps suggested the consumption of fresh shrimps and shrimp products processed with unhygienic water should be discouraged as the total counts of market sample ranged between 2.7 x 107 CFUml and 7.6 x 107 CFUml[12].Among the selected shrimp products microbial analysis was done in three stages, at the receiving, processing and finished product. Figure 4 shows slop of bacterial load at all these stages. The total bacterial load of the entire products are same but it decreasing at the processing zone whereas the Head On Shell on Semi IQF Shrimp showed the highest bacterial load as 5.40 x 105 CFUg and Cooked PUD IQF Shrimp showed lowest as 1.99 x 105 CFUg. Because of the heating process, the cooked products are safer as they contain fewer amounts of total bacteria .At the finished product Cooked P&D IQF Shrimp showed the lowest bacterial load as (1.87 x 105 CFUg) and the P&D Block Frozen Shrimp showed the highest as 5.30 x 105 CFUg.

| Figure 4. Slop of bacterial load at different finished products |

4. Conclusions

- This study revealed the quality parameter such as health & hygiene practice, physico-chemical and microbial status in selected shrimp products. The results present that cooked product such as IQF Cooked Headless Shell On Shrimp and Cooked PUD IQF Shrimp are more safe to consumer. It is revealed that automatic shrimp processing can be installed and train ups the worker to reduce the risk of contamination in production units. Result revealed that in the study are important to strengthen the monitoring system and take corrective action in marked steps of processing against the hygiene practice abide by the worker especially male worker. Although the result for microbial load of the final shrimp products are acceptable range (by FIQC, Bangladesh), the identification of risk area of contamination and comparative quality status of products are important to producer and consumer continuously.

ACKNOWLEDGMENTS

- The authors express their thankful gratitude to MD, QCM, and other official members of the three renowned companies in Bangladesh (Atlas Sea Food Ltd. and Lockpur Fish Processing Co. Ltd. and New Foods Ltd.) for their kind permission, support and cooperation during the practical execution of this study.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML