-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2012; 2(5): 127-130

doi: 10.5923/j.fph.20120205.02

Investigation into the Coagulating Properties of Acid and Enzyme Coagulated Soy Protein Precipitate

P. A. Adepoju 1, A. O. Longe 1, O. B. Odeinde 1, G. N. Elemo 2, O. L. Erukainure 2

1Food Technology Department, Lagos State Polytechnic, Ikorodu, Nigeria

2Department of Food and Analytical Services, Federal Institute of Industrial Research, Oshodi, Nigeria

Correspondence to: P. A. Adepoju , Food Technology Department, Lagos State Polytechnic, Ikorodu, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

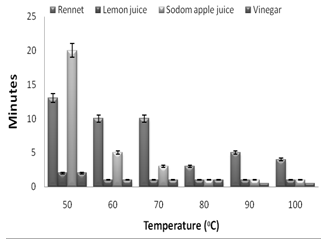

Precipitation is widely used in processing of biological products, such as proteins. The coagulating properties of Sodom apple juice, vinegar, lemon juice and rennet as coagulants of soy protein precipitate from soymilk at different temperature were investigated. Soymilk was produced using the hot grind method. The studied coagulants were used to precipitate soy protein from the produced milk at different temperature respectively. The coagulation time was observed to decrease with increasing temperature, with 100℃ giving the best time. The pH of the coagulated proteins was observed to decrease with increasing temperature with the optimal pH observed at 70℃ for all the coagulants. No significant difference was observed on the effect of coagulating temperatures on the yield of coagulated soy protein precipitate. Results from this study indicate that optimum coagulating activities can be achieved between 70- 80℃. However, the yields by the studied coagulants are not affected by temperature. Thus, implying that temperature modulate the coagulating activities, pH and not yields of the coagulants. Therefore, production at 70 – 80℃ will give the best soy protein quality.

Keywords: Soybeans, Soymilk, Coagulation, Soy Protein

1. Introduction

- Protein deficiency and malnutrition is a well documented cause of ill health and death in developing countries, and plays a major role in the disease, kwashiorkor[1]. Its deficiency can also lead to several ailments including mental retardation. Food-based strategies favouring local multi-nutrient food materials have been reported to be the best suitable and sustainable approach for combating protein malnutrition[2]. Amongst such food is the soybean which contains high quality protein and readily available in most developing countries. Over the years, they have been processed and used to fortify cereal flours and other food products. The use of high-protein soy products to combat malnutrition in developing countries is now being employed by several hunger-fighting organizations[3].Soy protein is a popular food ingredient used throughout the world for its nutritional and functional properties[4]. It has gained considerable attention due to its potential role in improving risk factors for cardiovascular disease (CVD) especially after approval by FDA[5]. Their approval was based on clinical studies showing that at least 25 g of soy protein per day lowered total and LDL cholesterol[6]. Some clinical studies suggest that soy protein and its isoflavones protect bone density, but this has not been firmly established. Soybean protein is regarded as complete protein since it provides all of the essential amino acids for human nutrition[7]. However, some scientific sources disagree on this as the best measure of complete protein[8]. Soybean protein is essentially identical to that of other legume pulses and is one of the least expensive sources of dietary protein[9]. These claims have led to the development of new soy foods and new technologies as well as improvement/modification of old methods of their preparation.Among such methods of preparation is the coagulation of soy protein precipitate employed in the production of tofu from soy milk. Tofu is one of the most important traditional soy foods in the eastern world, with a limited shelf life[4]. Tofu is low in calories, contains a relatively large amount of iron, and contains little fat[10]. Depending on the coagulant used in manufacturing, the tofu may also be high in calcium and/or magnesium. Coagulation of the protein and oil (emulsion) suspended in the boiled soy milk is the most important step in the production of tofu. This process is accomplished with the aid of coagulants. Coagulation could be achieved by increase in the acidity, extended heating or enzyme activity. Rennet extract from the abomasums of calves has been the traditional coagulant, but it is now substituted with rennet extracted from some bacteria and mould[11]. Acidic coagulation is often achieved by the addition of vinegar or vegetable extracts.This paper aims at investigating the coagulating properties of Sodom apple juice, vinegar, lemon juice and rennet as coagulants of soy protein precipitate from soymilk at different temperature.

2. Materials and Methods

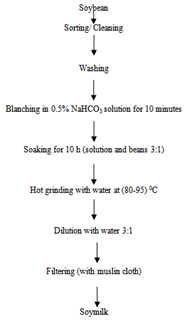

- Plant materialSoybeans (Glycine max) of yellow variety tax 306-036C were obtained from the International Institute of Tropical Agriculture (IITA), Ibadan, Nigeria. Lemon fruits and leaves of Sodom apple (Calotropis procera) were obtained from Ketu fruit market, Lagos, Nigeria. Rennet and vinegar were obtained from a food grade chemical store and supermarket respectively at Lagos, Nigeria.Extraction of lemon juiceThe lemon fruits were washed and cut into halves. The juice was extracted using juice extractor after which it was filtered through a sieve to remove the seeds, packed in air tight containers and refrigerated until further analysis.Extraction of Sodom apple juice45 g of the leaves of Sodom apple juice was homogenized with 300ml distilled water and then sieved to remove solid particles. It was centrifuged at 10,000 rpm for 20 minutes in an ultracentrifuge at a temperature of < 2℃. The supernatant was decanted and stored at < 4℃ for subsequent analysis.Production of soy milkThis was carried out to according to the Illinois method as described by Nelson et al.[12].

| Figure 1. Flow chart of soymilk production |

3. Results and Discussion

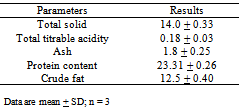

- Precipitation is widely used in downstream processing of biological products, such as proteins[14]. This serves to concentrate and fractionate the target product from various contaminants. This paper reports the coagulating properties of different natural coagulants in soy protein precipitation from soymilk at different temperatures.Physicochemical properties of soymilkThe physicochemical properties of soymilk are presented on table 1. A very high content of crude protein was observed. This is far higher than results observed by Salim-ur-Rehman et al.[15] on soymilk and cow milk. The observed high protein content is very encouraging as protein deficiency is a serious cause of ill health and death in developing countries and plays a part in the disease kwashiorkor[16]. Thus, correlating with previous reports on the choice of soybean in combating protein malnutrition[2]. The fat and ash contents were observed to be much higher than those of previous studies[15, 17]. This may be as result of the method of preparation.

|

| Figure 2. Time of coagulation at different temperature. Values = mean + SD; n = 3 |

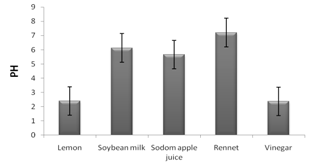

| Figure 3. pH of soybean milk and coagulants. Values = mean + SD; n = 3 |

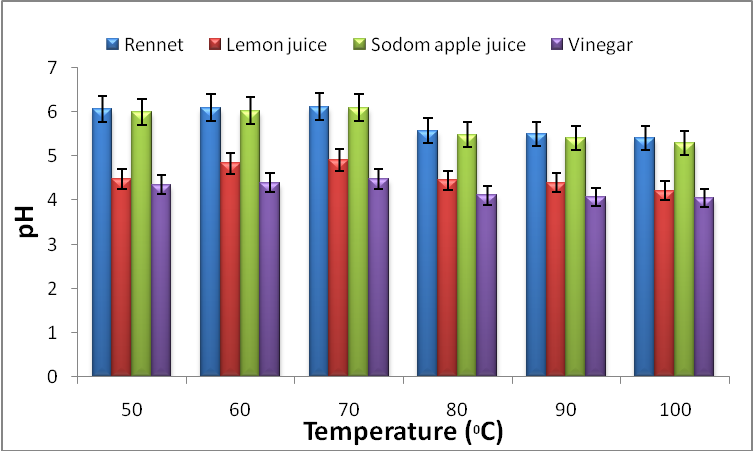

| Figure 4. pH of different samples fortified with coagulants at different temeperatures. Values = mean + SD; n = 3 |

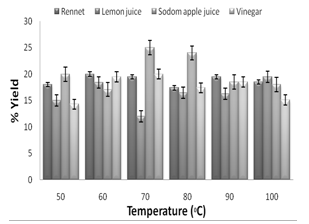

| Figure 5. Percentage yield of soy protein precipitate with different coagulants at different temperatures. Values = mean + SD; n = 3 |

4. Conclusions

- Results from this study indicate that optimum coagulating activities can be achieved between 70- 80℃. However, the yields by the studied coagulants are not affected by temperature. Thus, implying that temperature modulate the coagulating activities, pH and not yields of the coagulants. Therefore, production at 70 – 80℃ will give the best soy protein quality.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML