-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2012; 2(4): 85-91

doi: 10.5923/j.fph.20120204.01

Effect of Different Concentrations of Coconut Milk on the Chemical and Sensory Properties of Soy-coconut Milk Based Yoghurt

Adelodun L. Kolapo , Abiodun O. Olubamiwa

Biology Department, The Polytechnic, Ibadan. Ibadan.Nigeria

Correspondence to: Adelodun L. Kolapo , Biology Department, The Polytechnic, Ibadan. Ibadan.Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

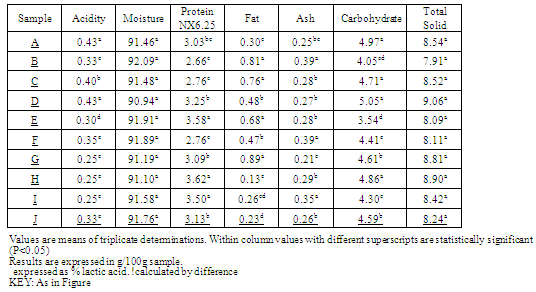

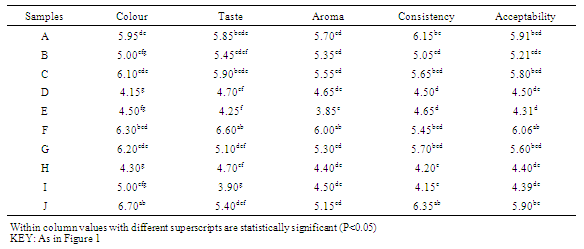

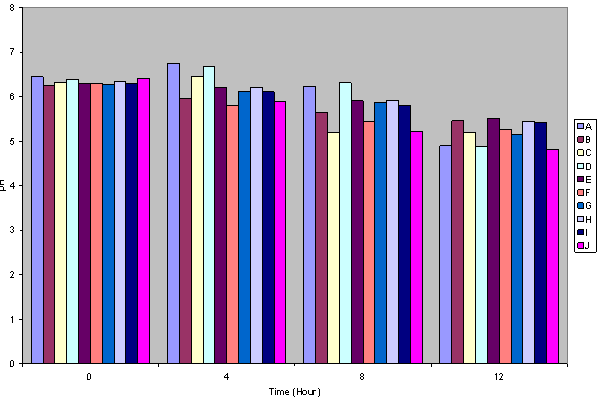

The possibility of enhancing the sensory attributes of soy yoghurt through the use of composite soymilk was investigated. The effect of using starter cultures from different sources on the chemical characteristics and consumer acceptability was also studied. Soy milk containing 0, 10 and 20% coconut milk were used in the production of soy yoghurt using commercially available yoghurt starter and starters isolated from naturally fermenting soy milk and cow milk. Chemical and sensory characteristics of soy yoghurts obtained were evaluated. The pH of the yoghurt premixes at the beginning of fermentation ranged between 6.25 and 6.45; after fermentation the values were between 4.81 and 5.51 with commercially available starter bringing about greatest pH reduction. Chemical compositions of obtained soy yoghurts were as follows: titratable acidity as %lactic acid (0.25-0.43%), crude protein (2.66-3.62%), fat content (0.13-0.89%), total solid content (7.91-9.06%). Variation in premix formulation had no significant (P>0.05) effect on the chemical composition of different soy yoghurts obtained. Addition of coconut milk to soy milk improved the sensory characteristics of soy yoghurts with the premix containing 10% coconut milk fermented with starter obtained from cow milk producing yoghurts with the best taste, aroma, and acceptability. Results from the present study have demonstrated a further way of enhancing soy yoghurt acceptability by the western ‘palate’.

Keywords: Soy Milk, Coconut Milk, Soy Yoghurt, Yoghurt Starter

Article Outline

1. Introduction

- The continuous increase in population and inadequate supply of protein has inadvertently increased the occurrence of malnutrition in developing countries[1]. However, in order to meet the protein demands in developing countries, where animal protein is also grossly inadequate and relatively expensive, research effort is geared towards finding alternative sources of protein from legume seeds[2].While describing the precarious state of food supply in the developing countries, Ene-Obong[3] posited that milk and its products are hardly major items of diet in developing countries. However, it must be stressed that for the selective few that are able to afford animal milk, there is always an increasing concern about its fat and cholesterol contents. This factor has made vegetable milk to become an alternative source of milk. In this regard, soymilk has been recognized as being nutritionally helpful. For instance, Murti et al.[4] stated that soy yoghurt (a product from soymilk) accords advantages in terms of nutrition and health, since it contains no cholesterol or lactose and only small quantities of saturated fatty acids; in addition to its advantage of low cost.Many soy products have limited human use in the Western hemisphere due to undesirable off-flavours[5,6]. Lactic acid fermentation has been reported as a means of reducing beany flavours and anti-nutritional factors in soybean products, and with the addition of sweetners it is possible to obtain products with better acceptance by panelists[6,7]. Report has also indicated that soy yoghurt acceptability could be enhanced by the addition of various flavourants and fruit flavours[8].In the recent past, soy yoghurt has been put in the same class as cow milk based yogurt. Consequently, the regular yoghurt starters are being employed in soy yoghurt production. However, documented information indicates that soy milk has a significant amount of raffinose and stachyose[9] and that lactic acid bacteria (LAB) from different sources are quite different in their efficiencies in soy yoghurt fermentation[10]. This overlooked aspect of soy yoghurt fermentation might have been responsible for the non production of butter milk like aroma in soy yoghurt obtained through conventional yoghurt starters as noted by Nsofor et al.[11].There are hundreds of ways of using both young tender and mature coconuts as food and useful source of raw materials. Malolo et al.[12] reported that the meat of coconut can also be used in preparation of fermented dishes and coconut sauce or seasonings for vegetables and root crops, or cooked with other root crops to enhance flavour.The objective of the present study was to explore the possibility of enhancing the sensory attributes of soy yoghurt obtained from composite milk comprising soymilk and coconut milk. The effect of using different yoghurt starters on its chemical composition and acceptability was also investigated.

2. Materials and Methods

2.1. Materials

- Fresh cow milk was purchased from nomads at Bodija Market, Ibadan .Nigeria. It was transferred in a sterile container to the laboratory for the isolation of LAB. Soybean seeds (variety TGX-923-2E) were obtained from the Institute of Agricultural Research and Training, Moor Plantation, Ibadan. Nigeria. Commercially available yoghurt starters and other ingredients were purchased from local stores.

2.2. Methods

2.2.1. Production of Soy Milk and Coconut Milk

- The method of Mital et al. as reported by Lee et al.[13] was used to produce soy milk. To produce coconut milk, coconut seed was cracked manually and the coconut meat removed with sharp knife. The brown part of the coconut meat was gently scraped off. It was cut into smaller pieces to enhance quicker blending. Two hundred grammes of white coconut meat was blended with 1litre of distilled water. The slurry obtained was further diluted with 1 litre of distilled water. It was then sieved with double layers of cheese cloth. The filterate obtained is coconut milk. It was kept inside refrigerator and used within 45 minutes.

2.2.2. Isolation, Characterization and Identification of Yoghurt Starters

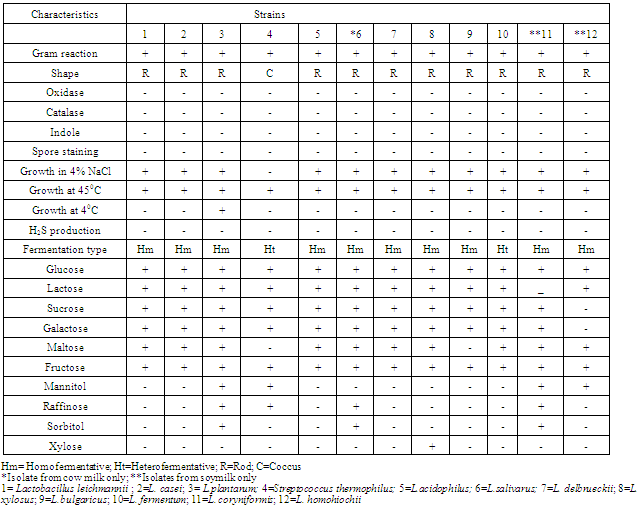

- Both fresh cowmilk and soymilk were covered and left on the laboratory bench at 29±20C overnight. LAB were isolated from the naturally fermenting milk by serial dilution in 0.1% peptone water and poured into De Mann Rogosa Sharpe (MRS) agar. The isolates were purified by streak plating using the same medium. Morphological characteristics such as cell shape and arrangement were noted. Biochemical and physiological studies such as catalase reaction, oxidase reaction, type of fermentation, production of ammonia from arginine, growth in 4% NaCl and sugar fermentation profiles were determined using standard methods[14,15].The results obtained from the tests carried out were used to identify the organisms by reference to Bergey’s Manual of Systematic Bacteriology[16].

2.2.3. Yoghurt Manufacture

- Three soy-based yoghurt premixes were formulated to contain; (a) Soy milk containing 20% coconut milk, (b) Soymilk containing 10% coconut milk and (c) Soymilk only. The premixes also contained 3% sugar and 0.5% gelatin. Mixtures of premixes, sugar and gelatin were prepared, homogenized and pasteurized as previously described by Collins et al.[17]. The mixture was subsequently placed in water bath to cool down to 430C prior to inoculation of starter cultures. The cooled mixtures were inoculated with 1% commercial yoghurt culture (50:50 mixture of Lactobacillus bulgaricus and Streptococcus thermophilus) as described by Lee et al.[13]. The preculture of each of the two isolated LAB from soymilk (Lactobacillus bulgaricus and Streptococcus thermophilus) was prepared; and the mixed culture were inoculated into the second portions of cooled mixture of each of the premixes at 5% final volume as described by Murti et al.[4]. The same procedure was repeated for yoghurt started obtained from cowmilk.. All the inoculated premixes were poured into plastic cups. They were then incubated at 430C and allowed to ferment for 12 hours. After incubation, they were cooled in an ice bath, placed in a cabinet at 6±20C and held for evaluation within 12 hours.

2.2.4. Analyses

- Samples were analyzed for proximate composition using standard methods of analyses of AOAC[18]. The pH of the various samples was determined using a pH meter. Acidity was measured as we have described previously[19]. A half milliliter of a 1% solution of phenolphthalein in 95% alcohol was added to ten milliliters of yoghurt sample. Acidity was measured by titrating the mixture thus obtained with 0.1N NaOH; and it aws expressed as g equivalent lactic acid/100g. All the determinations were carried out in triplicates and mean values were calculated.

2.2.5. Sensory Evaluation

- The yoghurt samples were held at 6±20C until presented for evaluation. A 20-member panel who were regular yoghurt consumers consisted of students and staff of The Polytechnic, Ibadan. Evaluation was done on a nine point hedonic scale. Characteristics evaluated included flavour, colour, taste and overall acceptability.

2.2.6. Statistical Analysis

- Data obtained were expressed as means. The statistical significance of differences was assessed using analysis of variance. A two-tailed P value of less than 0.05 was considered to be statistically significant. Values that were significantly different were separated by Duncan Multiple Range test using SPSS for windows Version 11.0 statistical package.

3. Result

- The characteristics of LAB isolated from naturally fermenting soymilk and cowmilk are tabulated in Table 1. All the isolates were gram positive, catalase negative, indole negative, oxidase negative and produced acid from glucose and galactose. Some of them fermented raffinose and sorbitol. The majority of them grew in 4% NaCl and at 450C while only Lactobacillu. plantarum grew at 40C. Substantial portion of these LAB were homofermentative.

|

|

4. Discussion

- Majority of the LAB isolated from the naturally fermenting cowmilk and soymilk belong to the genus Lactobacillus. This is in close agreement with the report of Adel Moneim et al.[20] who reported that Lactobacillus constituted 74% of the LAB associated with garris (a Sudanese fermented camel’s milk product). This is not surprising as strains of these genera of LAB are known to contaminate raw milk during milking from various sources such as the exterior of the udder, dairy utensils, dust, grass, cattle dung and feedstuffs[21,22]. Some strains of Lactobacillus reported in the present study are similar to those reported in many cultured African dairy products. For instance, Abdel Moneim[23] and Sulma et al.[24] reported on the occurrence of L. fermentum in Sudanese robe and kisra respectively. L. plantarum was found to be associated with fermented milk in Northern Tanzania and Cameroon[25,26].The pH values of the soymilk used in soy yoghurt fermentation in the present study compare favourably with the value of 6.6 reported by Favaro et al.[27] but lower than 7.2 reported by Osundahunsi et al.[8]. Though the pH of all the yoghurt premixes decreased with fermentation time, however, the differences observed in the degree of pH decrease in the fermenting yoghurt premixes might be a reflection of the ability of the yoghurt bacteria to grow in the premixes and ferment the carbohydrates they contained. It is possibly in this background that yoghurt premixes that contained higher quantity of coconut milk underwent least pH change. It has been reported that coconut oil contained some antimicrobial compounds[28]. The addition of coconut milk while the yoghurt fermentation was already in progress may retard acidity development in yoghurt so produced. This might be consequent upon the inhibitory effect of some chemical compounds present in coconut milk on the yoghurt bacteria that were supposedly in the exponential (active) phases of growth.Davis[29] recommended lactic acid of 0.1% in yoghurt. The value reported in this study is considered to be satisfactory. The lactic acid contents obtained in this study compared favourably with values (0.17-1.16%) reported in the earlier studies[19,30] Acidity developed in the different soy yoghurts produced depended on the starter culture used and the formulation of the premix used for fermentation. Results from the present study further corroborate the earlier report of Tuitemwong and Tuitemwong[10] who observed that LAB from different sources were different in their efficiencies to ferment soymilk.The proximate composition of soy yoghurts from the present study is similar to those reported by Favaro et al.[27]. Addition of coconut milk to soymilk did not produce any significant changes (P>0.05) in the proximate compositions of the soy yoghurt. However, data emanating from the present study depicts that soy yoghurt could be helpful in meeting a significant portion of the daily needs of these nutrients. Reports have shown that consumers’ acceptability of soymilk and its fermented product could be enhanced by premix formulation during the production process[8,31]. The result of the sensory evaluation in the present study has shown that soy yoghurt could become acceptable product in the Western hemisphere when appropriate quantity of coconut milk is added to yoghurt premixes.The world in 2000 pledged through Millennium Development Goals (MDGs 1 and 2) to halve hunger and KEY.A,B&C are yoghurt premixes containing 20% coconut milk and fermented with commercial yoghurt starter, starter from soymilk and starter from cow milk respectively.D,E&F are yoghurt premixes containing 10% coconut milk and fermented with commercial yoghurt starter, starter from soymilk and starter from cowmilk respectively.G is a yoghurt premix containing 20% coconut milk and fermented with commercial yoghurt starter with coconut milk added 3hrs after the commencement of fermentation.H,I&J are yoghurt premixes containing 0% coconut milk and fermented with commercial yoghurt starter, starter from soymilk and starter from cowmilk respectively. ensure universal primary education by the year 2015. It has since been recognized that school feeding programs could be a key to achieving these goals because they bring many synergies that support each other. As a response, the Federal Government of Nigeria launched a Home-Grown School Feeding and Health Program (HGSF&HP) in 2005[32]. An Indonesian version of the similar program was described by Minarno[33].Ene-Obong[3], stated that milk and its products hardly feature among the major items of food in developing countries. This is especially critical in the diets of low income families. Soymilk and its fermented products that could serve as alternative milk is not widely acceptable in the Western hemisphere because of its unpleasant flavour and taste. Results from the present study have demonstrated a further way of enhancing soy yoghurt acceptability by the Western ‘palate’. In this regard, adoption of soymilk-coconut milk based yoghurt in the feeding regime of HGSF&HP in Nigeria and other developing countries with similar programs will be helpful in achieving some of the MDGs.

| Figure 1. pH changes in fermenting soy yoghurt premixes |

|

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML