-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Food and Public Health

p-ISSN: 2162-9412 e-ISSN: 2162-8440

2012; 2(2): 40-49

doi: 10.5923/j.fph.20120202.08

Improving the Microbial Safety of Ice Cream by Gamma Irradiation

Hesham M Badr

Atomic Energy Authority, Nuclear Research Center, Abou Zaabal, P.O. Box 13759 Cairo, Egypt

Correspondence to: Hesham M Badr , Atomic Energy Authority, Nuclear Research Center, Abou Zaabal, P.O. Box 13759 Cairo, Egypt.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

In this study, a survey for the microbiological status of 120 ice cream samples revealed the presence of high microbial counts and different pathogenic bacteria in different samples. Therefore, the possibility of improving the microbial safety of different ice cream samples through irradiation treatment was studied. Ice cream samples were gamma irradiated in the frozen state at doses of 0, 1, 2, 3 and 4 kGy and examined for their microbiological and sensory properties during frozen storage. The results showed that irradiation treatments significantly reduced the counts of microbial populations, while Enterobacteriaceae were completely inactivated in samples irradiated at 2 kGy dose. Furthermore, irradiation dose of 3 kGy completely inactivated the inoculated Staphylococcus aureus, Listeria monocytogenes and Salmonella typhimurium, while significantly reduced the counts of Bacillus cereus spores in samples. Meanwhile, frozen storage had no significant effect on inoculated pathogens. Ice cream samples that irradiated at 3 kGy dose were acceptable for their sensory attributes during storage. Therefore, gamma irradiation can be applied at dose of 3 kGy to improve the microbial safety of frozen ice cream products without adverse effects on their sensory acceptability.

Keywords: Ice cream, Staphylococcus aureus, Listeria monocytogenes, Bacillus cereus, Salmonella typhimurium, safety

Article Outline

1. Introduction

- Ice cream is a major dairy product of dominant interest for large segments of the population. It is sold both in package (cups, cones and cartons) and in open containers at the retail outlets or ice cream parlours, which is distributed manually in scoops, cones or sundaes across the counter[1,2]. Due to its nutrient content, neutral pH, and long storage even though it is stored in a frozen state, the product can be a good source for a microbial growth[1].During processing of ice cream, there is a potential hazard by an addition of contaminated ingredients after the pasteurization step. Furthermore, the microbiological quality of ice cream during retail marketing mainly depends upon the post production handling of the product as well as efficiency and sanitary conditions during frozen storage. The lack of efficient frozen storage under warm tropical climatic conditions causes a chance of temperature abuse during transport and distribution of ice cream. Under such conditions, psychrotrophs can proliferate leading to occasional food poisoning events[1-4].There have been a number of instances of foodborne diseases associated with commercially produced ice cream and several large recalls of the product were reported[5-7]. The occurrence of foodborne pathogens including Salmonellaenteritdis[8], Bacillus cereus[9], Staphylococcus aureus [10,11], Yersinia enterocolitica and Listeria monocytognes [2] in ice cream was documented. Thus, commercial ice cream products were not safe enough especially for infants, children and immunosuppressed patients that are, in particularly, very likely to acquire foodborne disease since their natural defences are below what is considered as ‘‘normal limits’’ and therefore, an efficient quality assurance is increasingly important to control the bacteriological content of ice cream products.Radiation processing has positive effects in reducing numbers of microorganisms and improving the safety and shelf-stability of food products without compromising their nutritional or sensory quality. The food irradiation technologies that have been and continue to be developed and validated can play an important role in ensuring safe, wholesome and high quality foods which at the same time facilitating international trade[12]. The benefits of irradiation also include the fact that products can be processed in the final package and can inactivate organisms in foods that are in the frozen state without thawing them. Ice cream was included in the list of foods that could benefit from irradiation treatment not only for its nutritional value but also to serve a psychological purpose, as a "tit- bit", to raise spirits and enhance appetite, especially when immunocompromised patients are children or the elderly[13].Therefore, the present work was carried out to investigate the microbiological status of samples of the commercially marketed ice cream and the possibility of improving the microbial safety of ice cream by gamma irradiation.

2. Materials and Methods

2.1. Evaluation of the Microbiological Status of Commercially Sold Ice Cream

- A total of one hundred and twenty samples (30 samples each) of freshly manufactured ice cream with vanilla, chocolate, strawberry, and mango flavors (sold in commercial packages of 250 g) were collected from three different ice cream shops (Zagazig, Egypt) in ten separate experiments. In each experiment, the collected ice cream samples were immediately transferred to the laboratory in a cool box and examined for their microbiological status through the determination of total aerobic bacteria, total psychrotrophic bacteria, total molds and yeasts, Enterobacteriaceae, S. aureus, L. monocytogenes, B. cereus and presence of Salmonella spp.

2.2. Studies with Irradiation Treatments

- Studies with irradiation treatments were carried out in three experiments, in which samples of freshly manufactured vanilla, chocolate, strawberry, and mango flavored ice cream were obtained from an ice cream shop (Zagazig, Egypt) and prepared as follows:

2.2.1. Experiments with the Un-inoculated Samples

- In the first experiment, effects of irradiation on the natural microbiota (including total aerobic bacteria, total psychrotrophic bacteria, total molds and yeasts, and Enterobacteriaceae) in the un-inoculated ice cream samples were examined. The obtained ice cream samples with the different flavors were aseptically divided into appropriate samples of about 30 ml in sterilized polypropylene vials with screw cap. The observed vials of samples were subdivided into five groups and frozen stored at – 18℃ for 24 h before irradiation treatment.

2.2.2. Experiments with Artificially Inoculated Samples

- The second experiment dealt with the effect of irradiation on four bacterial pathogens (S. aureus, L .monocytogenes, B. cereus, and Salmonella typhimurium) artificially inoculated into the different flavored ice cream samples. Confirmed cultures of S. aureus, L. monocytogenes and B. cereus, isolated from ice cream samples during the examination of their microbiological status in the first part of the present study, were used as inocula. Whereas, cultures of S. typhimurium (ATCC 98031) was obtained from the Egyptian Microbial culture Collection, Faculty of Agriculture, Ain Shams University, Cairo, Egypt. For preparation of inocula, isolate of each pathogen culture (which was cloned on tryptic soy agar with incubation at 35℃) was cultured in 100 ml of tryptic soy broth at 35℃ with agitation for 18 h. Cultured cells of each pathogen were harvested by centrifugation and resuspended in sterile maximum recovery diluent, which was diluted for obtaining the appropriate counts (~ 107 cells/ml) for S. aureus, L. monocytogenes and S. typhimurium. For B. cereus, a spore suspension was prepared as described by Thayer and Boyed[14] and diluted as the other pathogens.For inoculation of ice cream samples, frozen samples were kept in the refrigerator for 15 min for melting, then samples were inoculated by adding 10 ml of the pathogen suspension (individually) into 500 g of the molten ice cream. The inoculated sample was kneaded to obtain a uniform distribution of inoculum in the ice cream, aseptically divided in sterilized polypropylene vials, subdivided into five groups of samples and frozen stored at – 18℃ for 24 h before irradiation treatments.

2.2.3. Experiment with Un-inoculated Samples for Sensory Evaluation

- Un-inoculated samples of the different flavored ice cream under study were divided in cups of 50 ml capacity with cap without head space. Then the observed cups were subdivided into five groups of samples and frozen stored at – 18℃ for 24 h before irradiation treatments.

2.3. Preparation of Packages for Irradiation

- In each of the performed experiments with irradiation treatments, the observed vials or cups of the frozen ice cream samples were stuffed in a polyethylene pouch. The pouch was sealed and cantered in a cylindrical polypropylene container with polyethylene screw cap while being surrounded by a dry ice pellets in the container. The containers were closed and transported in a cool box for irradiation treatments.

2.4. Irradiation Treatments and Storage of Samples

- Frozen ice cream samples were exposed to gamma irradiation at doses of 0, 1, 2, 3 and 4 kGy. Irradiation of samples was carried out using an experimental Co-60 source providing a dose rate of 3.846 kGy /h at the National Centre for Radiation Research and Technology, Nasr City, Cairo, Egypt. Irradiated and non-irradiated samples were frozen stored at – 18℃ for six weeks and subjected to the periodical analysis at one week intervals.

2.5. Microbiological Determinations

- In all microbiological determinations, the original ice cream packages or vials of samples were disinfected with ethanol (70% w/w), aseptically opened, and sub-samples of 25 ml of the molten ice cream were taken for preparation of the required decimal dilutions using sterilized maximum recovery diluent. Colony forming units for total aerobic bacteria and total psychrotrophic bacteria were determined by plating on plate count agar medium and incubation at 30℃ for 3 days and 7℃for 10 days, respectively, while total molds and yeasts were enumerated on malt agar medium after incubation at 22℃ for 3-5 days[15]. Enterobacteriaceae were counted on violet red bile glucose agar medium after incubation for 20-24 h at 37℃[16]. S. aureus was counted using Baird-Parker RPF medium after incubation at 35℃ for 24-48 h[17], and confirmed by the coagulase test according to Collins et al.[18]. L. monocytogenes was counted after enrichment in Listeria enrichment broth base with Listeria selective supplement followed by plating on Listeria selective medium and incubation at 35℃ for 24-48[17]. Colonies presumptively identified as L. monocytogenes were confirmed by biochemical testing according to Roberts and Greenwood[16]. The enumeration of B. cereus was performed using manitol- egg- polymyxin agar after incubation at 37℃ for 16-24 h and confirmed as described by Roberts and Greenwood[16]. For the detection of Salmonella spp., samples were inoculated into buffer peptone water and incubated at 35℃ for 18 h for pre-enrichment followed by enrichment at 35℃ for 18 h in selenite broth. Then cultures were streaked on Briliant green agar and incubated at 35℃ for 24 h[17].The confirmation of Salmonella spp. was performed through biochemical examination in triple sugar iron agar and lysine decarboxylase broth.

2.6. Sensory Evaluation

- Irradiated and non-irradiated ice cream samples were subjected to sensory evaluation for their appearance, color, odor, taste and texture on day zero only for safety precautions. Moreover, irradiated samples that have acceptable microbiological and sensory quality were evaluated for their sensory properties at the end of the experimental frozen storage. In all sensory evaluation tests, the panelists consisted of ten non-expert members and scores were obtained by rating the examined quality attributes using the following scale: 9=excellent, 8=very good, 7=good, 6=below good/ above fair, 5=fair, 4=below fair/ above poor, 3=poor, 2=very poor and 1=extremely poor. Ratings of 5 and above indicated acceptable samples, while rating of 4 indicated that the samples were of marginal quality, whereas rating of 3 and below indicated unacceptable samples[19].

2.7. Statistical Analysis

- Three different replicate trials were conducted in this study and analysis were performed using duplicate samples per each replicate trail. Data were then statistically analyzed by using the generalized linear model procedure of the SAS software[20], and the differences among means (at p<0.05) were compared using Duncan's multiple range test.

3. Results and Discussion

3.1. Microbiological Status of Commercially Marketed Ice Cream Samples

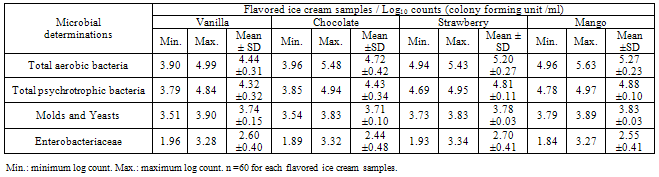

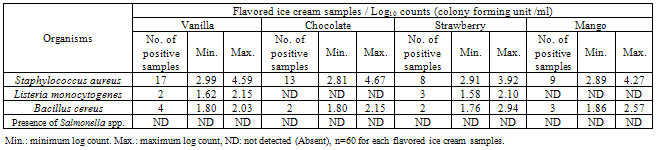

- The microbiological status of the examined commercially marketed ice cream samples with different flavors is presented in Tables 1 &2. As shown in Table 1, some of the examined ice cream samples with different flavors had relatively high microbial counts reaching 9.86x104, 3.02x105, 2.73x105 and 4.27x105; 6.92x104, 8.77x104, 9.03x104 and 9.41x104; 8.01x103, 6.8x103, 6.78x103 and 7.78x103; and 1.91x103, 2.1x103, 2.2x103 and 1.86x103cfu/ml for total aerobic bacteria, total psychrotrophic bacteria, total molds and yeasts and Enterobacteriaceae in some vanilla, chocolate, strawberry and mango flavored ice cream samples, respectively. Furthermore, some of examined samples contained S. aureus, L. monocytogenes and B. cereus at different levels reaching 3.9x104, 4.7x104, 8.4x103 and 1.86x104; and 1.07x102, 1.4x102, 8.7x102 and 3.7x102cfu/ml for S. aureus and B. cereus in vanilla, chocolate, strawberry and mango flavored ice cream samples, respectively, while the counts of L. monocytogenes reached 1.42x102 and 1.26x102cfu/ml in some of the examined vanilla and strawberry flavored ice cream samples. However, none of the examined ice cream samples was found to be positive for the presence of Salmonella spp. (Table 2). Although the observed counts of S. aureus and B. cereus may not be sufficient to cause illness, these counts may reach high levels under temperature abuse conditions. In addition, the presence of even small counts of L. monocytogenes in ice cream constitutes a potential risk, particularly to children, pregnant women and immunocompromised adults and elderly. Ice cream can be contaminated from different sources. In addition to the possible contamination of ice cream products during handling and distribution, there is a potential for flavorings and other ingredients such as sugar, nuts, fruits and chocolate to introduce a wide range of organisms not usually found in dairy products being a potential source of pathogenic organisms. Also dried milk may sometimes be contaminated by B. cereus and may serve as a source of L. monocytogenes[7,5,21]. The obtained results agree with different other studies that showed the contamination of ice cream products with high levels of microorganisms including pathogens in different countries[2,4, 9-11,22]. The results also illustrate the importance of controlling the microbiological contents in ice cream through an efficient quality assurance treatment.

3.2. Effect of Irradiation and Frozen Storage (-18℃) on the Counts of Microbial Populations in the Un-inoclated Ice Cream Samples

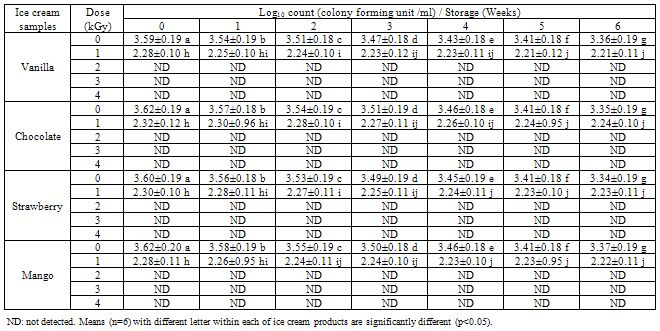

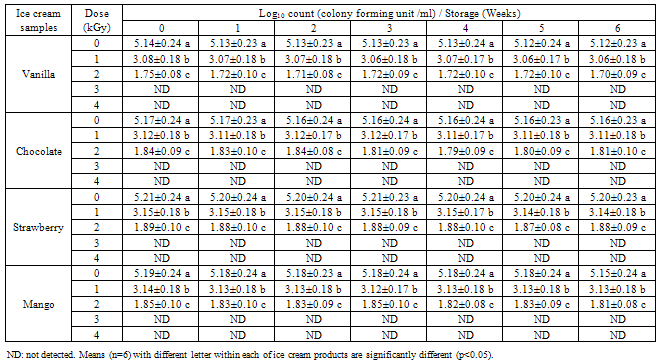

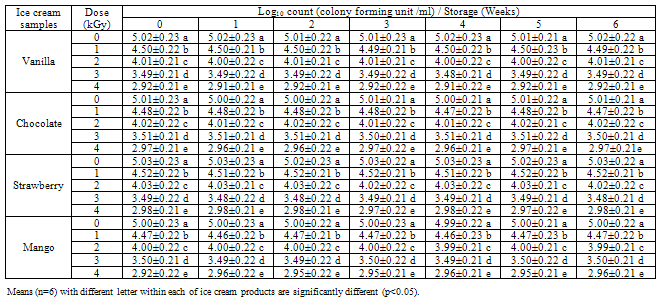

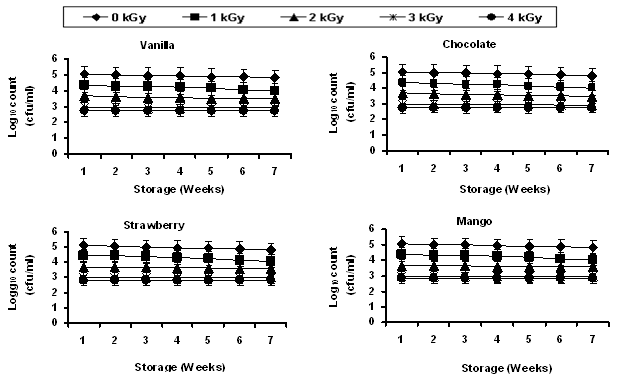

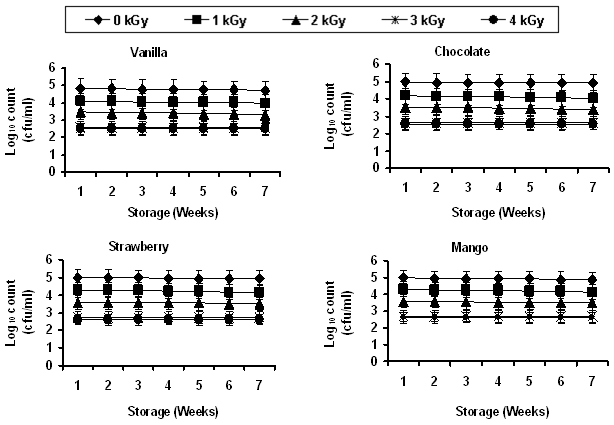

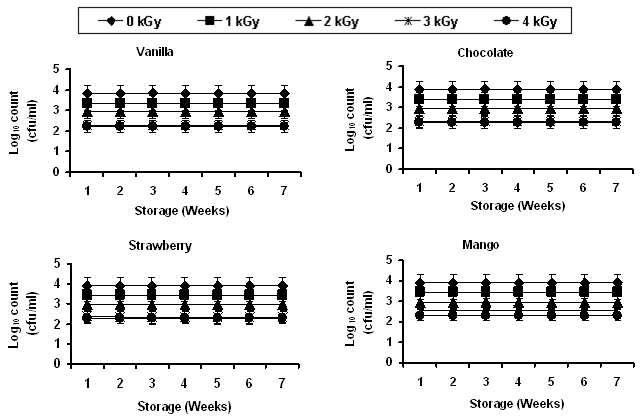

- The effect of irradiation and frozen storage on the counts of microbial populations in the different flavored un-inoculated ice cream samples are presented in Figs 1-3 and Table 3. As shown, the initial mean log counts for total aerobic bacteria, total psychrotrophic bacteria, and molds and yeasts were found to be 4.99, 4.84 and 3.82; 5.02, 4.95 and 3.87; 5.08, 4.97 and 3.90; and 5.13, 4.99 and 3.91 cfu/ml in the non-irradiated un-inoculated ice cream samples with vanilla, chocolate, strawberry and mango flavors, respectively (Figs 1-3), while the initial log counts for the Enterobacteriaceae were 3.59, 3.62, 3.62, and 3.60 cfu/ml in the above mentioned ice cream samples, respectively (Table 3). Irradiation of the different flavored ice cream samples significantly (p< 0.05) decreased their initial counts for total aerobic bacteria, total psychrotrophic bacteria and molds and yeasts in a dose-dependent manner (Figs 1-3).Further significant decreases (p< 0.05) were observed in the counts of total aerobic and psychrotrophic bacteria during frozen storage of control samples and those irradiated at doses of 1 and 2 kGy, but frozen storage had no significant effect (p> 0.05) on the counts of these bacteria in samples irradiated at the higher doses, which may be mainly consisted of the survival bacterial sporeformers. Also frozen storage (-18℃) had no significant effects (p> 0.05) on the counts of molds and yeasts in both irradiated and non-irradiated ice cream samples (Figs 1-3). Furthermore, irradiation of the different flavored ice cream samples at the lowest dose (1 kGy) significantly (p< 0.05) decreased the counts of Enterobacteriaceae in samples, while frozen storage induced significant decreases in the counts of Enterobacteriaceae in these irradiated samples as well as in the controls. Enterobacteriaceae, however, were not detected in samples irradiated at dose of 2 kGy or higher neither post irradiation treatments nor during storage of samples (Table 3).

|

|

| Figure 1. Counts (mean ± SD, n=6) of total aerobic bacteria in the different flavoured ice cream samples as affected by gamma irradiation and frozen storage at-18℃ |

| Figure 2. Counts (mean ± SD, n=6) of total psychrotrophic bacteria in the different flavored ice cream samples as affected by gamma irradiation and frozen storage at -18℃ |

| Figure 3. Counts (mean ± SD, n=6) of total moulds and yeasts in the different flavored ice cream samples as affected by gamma irradiation and frozen storage at -18℃ |

|

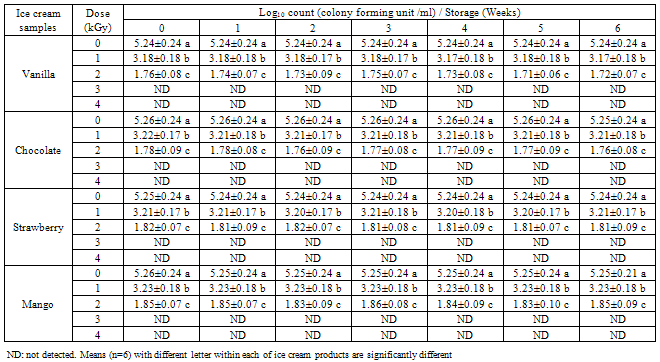

3.3. Effect of Irradiation and Frozen Storage (-18℃) on Inactivation of Pathogens in the Inoculated Ice Cream Samples

- Samples of ice creams with the different flavors were separately inoculated with S. aureus, L. monocytogenes, B. cereus spores and S. typhimurium and the effects of irradiation and frozen storage (-18℃) on these inoculated pathogens are presented in Tables 4 -7. Irradiation treatments at doses of 1 and 2 kGy significantly (p< 0.05) decreased the counts of the inoculated S. aureus and L. monocytogenes in ice cream samples, but frozen storage (-18℃) showed no significant (p> 0.05) effect on the counts of these bacteria neither in these irradiated samples nor in the control ones. However, no colony forming units were detected for S. aureus and L. monocytogenes during frozen storage of ice cream samples irradiated at dose of 3 or 4 kGy (Tables 4&5). In addition, irradiation of ice cream samples at the different applied doses significantly reduced the counts of the inoculated B. cereus spores, in a dose-dependent manner, but their complete inactivation was not achieved even at the highest applied dose (4 kGy). While frozen storage (-18℃) had no significant effects on the counts of B. cereus spores in both irradiated and non-irradiated samples (Table 6). Irradiation at dose of 2 kGy appeared to be sufficient for inactivation of Salmonella spp. which was not detected in any of the ice cream samples that irradiated at this dose or higher, while Salmonella spp. was detectable in samples irradiated at the lowest dose (1 kGy) and the control non-irradiated samples of the inoculated frozen stored ice cream (Table 7).The observed inactivation of pathogens in the irradiated ice cream samples agree with the results reported by Kamat et al.[25] and Adeil and Pietranera[22]. It has been shown that a dose of 3 kGy was the approximate radiation dose needed to reduce viable number a million fold for S. aureus and Salmonella irradiated in frozen media[26]. Meanwhile, Monk et al.[27] revised D10 values for B. cereus spores finding values between 1.25 and 4 kGy when irradiated in different media. On the other hand, the ability of pathogens to survive in the frozen ice cream agrees with the findings of other workers. The viable cell count of L. monocytogenes remained constant during frozen storage of ice cream at -18℃ for 3 months[28], while S. enteritidis and S. typhimurium could survive in ice cream for 7 years at -23℃[29]. Moreover, S. aureus could survive freezing well and even increased in counts in the frozen milk[30] and bacterial spores are extremely resistant to freezing[31]. The composition of the food medium has a direct influence on the survival and injury level of the frozen bacterial population. In ice cream, lactose and sucrose acted as cryoprotectants by depressing the freezing point of the suspension media, in addition to the protection by other milk components and the viscous nature of ice cream[28,32]. Considering the results of microbiological analyses for all irradiated ice cream samples in the present study, it is of interest to note that irradiation at dose of 3 kGy significantly reduced the counts of microbial populations with complete inactivation of Enterobacteriaceae in the un-inoculated ice cream samples and completely inactivated the inoculated S. aureus, L. monocytogenes and S. typhimurium in addition to significant reduction of the counts of B. cereus spores in the inoculated ice cream samples, without differences between the different flavored ice creams. Also considering that the initial counts of B. cereus spores in naturally contaminated ice cream may be much lower than the initial inoculated spore counts (~105cfu/ml), in addition to the high radio-sensitivity of vegetative cells than spores of B. cereus, it is apparent that a dose of 3 kGy was sufficient for attaining an improved microbiological quality and safety for the different flavored ice cream samples in the present study.

|

|

|

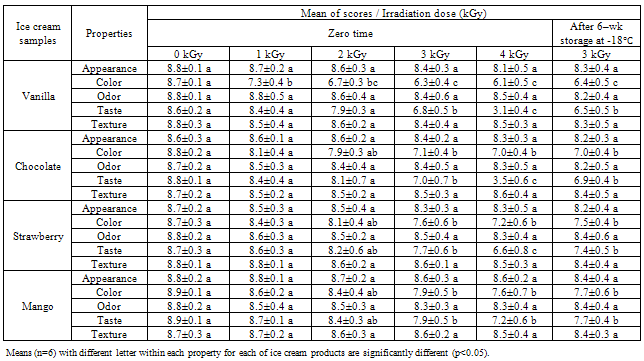

3.4. Sensory Properties

- Table 8 presents the results of sensory evaluation which was carried out for irradiated and non-irradiated un-inoculated ice cream samples on day zero, for safety precautions, and after 6 weeks of frozen storage for samples irradiated at 3 kGy dose (which showed an improved microbial safety with acceptable sensory properties). As shown, irradiation of the different flavored ice cream samples at the different applied doses of gamma rays had no significant (p>0.05) adverse effects on the acceptability of samples for their appearance, odor and texture. All irradiated samples as well as the control non-irradiated ones were highly acceptable for these sensory attributes. The same results also show that significantly lower scores were recorded for the color of the irradiated ice cream samples with increasing the applied dose of irradiation. Irradiated vanilla ice cream showed a slight creamy color, while the color of irradiated chocolate, strawberry and mango ice cream samples was slightly lighter than the color of the control ones. However, all samples were acceptable and the difference in color was evidenced only when comparing irradiated samples with the control ones. Irradiated ice cream samples also had an acceptable taste except vanilla and chocolate ice cream samples that irradiated at the highest dose (4 kGy) which showed unpleasant taste due to the detection of a slight rancidity (Table 8). Similar results were observed by Adel Pitranera et al.[22]. The results in Table 8 further show that the different flavored ice cream samples that irradiated at 3 kGy dose and showed an improved microbial safety were still acceptable for their sensory attributes when evaluated after6 weeks of frozen storage at -18℃.

|

4. Conclusions

- From the results in the present study, it could be concluded that gamma irradiation can be applied at dose of 3 kGy to improve the microbial safety of frozen ice cream products without adverse effects on their sensory acceptability.

References

| [1] | Lee, J.W., Kim, H.J., Yoon, Y., Kim, J.H, Ham, J.S., Byun, M.W, Baek, M., Jo, C. and Shin, M.G., 2009, Manufacture of ice cream with improved microbiological safety by using gamma irradiation. Radiation Physics and Chemistry, 78: 593-595. http://dx.doi.org/10.1016/j.radphyschem.2009.03.016 |

| [2] | Warke, R., Kamat, A., Kamat, M. and Thomas,P., 2000,Incidence of pathogenic psychrotrophs in ice creams sold in some retail outlets in Mumbai, India. Food Control, 11: 77-83. http://dx.doi.org/10.1016/S09567135(99)00027-4 |

| [3] | Champagne, C.P., Laing, R.R., Roy, D. and Mafu, A.A., 1994, Psychrotrophs in dairy products: their effects and their Control. Critical Review in Food Science and Nutrition, 34: 1-30. http://dx.doi.org/10.1080/10408399409527648 |

| [4] | Kanbakna, J., Con, A.N. and Ayor, A., 2004, Determination of microbiological contamination sources during ice cream production in Denizli, Turkey. Food Control, 15: 463-470. http://dx.doi.org/10.1016/S09567135(03)00131-2 |

| [5] | P. Papademas and T. Bintsis, Microbiology of ice cream and related products,1st ed., R. Robinson Ed., Dairy Microbiology Handbook , New York: John Wiley and Sons. Inc., 2002. |

| [6] | E.T. Ryser, Incidence and behavior of Listeria monocytogenes in unfermented dairy products, L.T.Ryser and E.H. Marth, Eds. Listeria, Listeriosis and Food Safety, New York: CRC Press, 2007. |

| [7] | R.Fernandes, Ed., Microbiology handbook: Dairy products, UK: Leatherhead Food International Ltd., 2009. |

| [8] | Vought, K.J. and Tatini, S.R., 1998, Salmonella enteritidis contamination of ice cream associated with a 1994 multistate outbreak. Journal of Food Protection, 61: 1493-1496. |

| [9] | Zhou, G., Zheng, D., Dou, L., Cai, Q. and Yuan, Z., 2010, Occurrence of psychrotolerant Bacillus cereus group strains in ice creams. International Journal of Food Microbiology, 137:143-146. http://dx.doi.org/10.1016/j.ijfoodmicro.2009.12.005 |

| [10] | Gündoğan, N., Citak, S. and Turan, E.,2006, Slime production, DNase activity and antibiotic resistance of Staphylococcus aureus isolated from raw milk, pasteurized milk and ice cream samples. Food Control, 17: 389-392. http://dx.doi.org/10.1016/j.foodcont.2005.01.006 |

| [11] | Fadel, H.M. and Ismail, J., 2009, Prevalence and significance of Staphylococcus aureus and Enterobacteriaceae species in selected dairy products and handlers. International Journal of Dairy Science, 4: 100-108. http://dx.doi.org/10.3923ijds.2009.100.108. |

| [12] | IAEA, 2011, Food & Environmental Protection Newsletter, 14 (2). IAEA, Austria. |

| [13] | Anon, 2003, "Radiation Processing for safe, shelf-stable and ready-to-eat food". Proceedings of a Final Research Co-ordination Meeting held in Montreal, Canada, TECDOC-13372000, IAEA-, IAEA, Summary, p7. |

| [14] | Thayer, D.W. and Boyd, G., 1994, Control of enterotoxicBacillus cereus on poultry or red meats and in beef gravy by gamma irradiation. Journal of Food Protection, 57: 758-764. |

| [15] | APHA, 1992, Compendium of methods for the microbiological examination of foods, Washington, DC.: American Public Health Association, |

| [16] | D. Roberts and M., Greenwood, Eds., Practical Food Microbiology: Methods for the examination of food for micro-organisms of public health significance. USA: Blackwell Publishing LTD., 2003. |

| [17] | Oxoid, The Oxoid Manual, Budapest: Oxoid Ltd., 2006. |

| [18] | C. H Collins., P. M. Lyne and J. M Grange, Eds., Collins and Lyne's microbiological methods. London: Butterworths, 1989. |

| [19] | Wierbicki, E., 1985, Technological and irradiation conditions for radappertization of chicken products used in the United States Army Raltech Toxicology Study. Food Irradiation Processing, Vienna: IAEA, pp. 79-99. |

| [20] | SAS Institute, SAS/STAT user's guide. USA: Cary, NC, Statistical Analysis Institute, 1989. |

| [21] | Palumbo, S.A. and Williams, A.C., 1991, Resistance of Listeria monocytogenes to freezing in foods. Food Microbiology, 8:63-68. http://dx.doi.org/10.1016/07400020(91)90017-V |

| [22] | Adeil Pietranera, M. S., Narvaiz, P., Horak, C. and Eairiyama, E., 2003, Irradiated ice creams for immunosuppressed patients. Radiation Physics and Chemistry, 66: 357–365. http://dx.doi.org/10.1016/S0969806X(02)00389-4 |

| [23] | Jo, C., Kim, H.-J., Kim, D.-H., Lee, W.-K., Ham, J.-S. andByun, M.-W., 2007, Radiation sensitivity of selected pathogens in ice cream. Food Control, 18, 859-865. http://dx.doi.org/10.1016/j.foodcont.2006.04.011 |

| [24] | Stekelenburg, F. K., 1990, Irradiation of pre-packaged sliced cooked meat products with low and normal sodium content. International Journal of Food Microbiology, 10, 23-32. http://dx.doi.org/10.1016/0168-1605(90)90004-O |

| [25] | Kamat, A., Warke, R., Kamat, M. and Thomas, P., 2000, Low-dose irradiation as a measure to improve microbial quality of ice cream. International Journal of Food Microbioogy,62,27-35. http://dx.doi.org/10.1016/S01681605(00)00251-8 |

| [26] | ICMSF, Microbial ecology of foods: factors affecting life and death of microorganisms.UK: Academic Press, INC, 1980, Vol. 1. |

| [27] | Monk, J.D., Beuchat, L.R. and Doyle, M.P., 1995, Irradiation inactivation of food-borne microorganisms. Journal of Food Protection, 58: 197-208. |

| [28] | Dean, J.P. and Zottola, E.A.C., 1996, Use of nisin in ice cream and effect on the survival of Listeria monocytogenes., Journal of Food Protection, 59: 476-480. |

| [29] | J.Y.C. D'Aoust, Salmonella, ed., M. P. Doyle, Ed., Foodborne Bacterial Pathogens. New York: Marcel Dekker, Inc., 1989. |

| [30] | Hubáčkorá, M. and Ryšánek, D., 2007, Effects of freezing milk samples on the recovery of alimentary pathogens and indicator microorganisms. Acta Veterinaria Brno, 76: 301-307. http://dx.doi.org/10.2754/avb200776020301 |

| [31] | B.M. Lund, Freezing, ed., B.M. Lund, T.C. Baird Parker, G.W. Gould, Eds., The Microbiological Safety and Quality of Food. Gaithersburg: MD Aspen Publishers, 2000, Vol.1. |

| [32] | J. Farkas, Physical methods of Food Preservation, ed., M.P.Doyle, L.R.Beuchat and T.J.Montville, Eds, Food Microbiology: Fundamentals and Frontiers. Washington, D.C.: ASM Press, 1997. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML