-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2019; 9(2): 31-36

doi:10.5923/j.food.20190902.01

Effect of Physical and Microbiological Parameters on Ready –Made Pickles: A Review

Misha Anishkumar Patel

Ramdev Food Products, Pvt. Lmt., Changodar, Ahmedabad, India

Correspondence to: Misha Anishkumar Patel, Ramdev Food Products, Pvt. Lmt., Changodar, Ahmedabad, India.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Pickles or other Ready-to-Eat types of food items are becoming very common now-a-days. India has become a hub for producing a variety of pickled food items. This review paper describes the methods for the production and characterization of pickled food items. Pickling of food items allows the formation of lactic acid bacteria which are very important for the process of fermentation. Thus, physical conditions like temperature, humidity, acidity and pH should be maintained to keep the pickles safe. The variation in environmental condition leads to microbial growth. Different types of pathogenic bacteria grow at different levels of pH and acidity. They not only damage pickles but also increase the level of biogenic amines which can cause severe health problems. PCR and HPLC techniques are usually used to investigate the presence of a number of histamines producing bacteria and quantify the level of histamine before and after pickle production. The studies show that the level of histamine content should not exceed 1000 mg in a particular pickle sample.

Keywords: Acidity, Biogenic amines, Fermentation, Histamine, HPLC, Lactic acid bacteria, Pathogenic bacteria, PCR, pH, Pickle, Temperature

Cite this paper: Misha Anishkumar Patel, Effect of Physical and Microbiological Parameters on Ready –Made Pickles: A Review, International Journal of Food Science and Nutrition Engineering, Vol. 9 No. 2, 2019, pp. 31-36. doi: 10.5923/j.food.20190902.01.

Article Outline

1. Introduction

- Processing and storage of fruits, vegetables and other types of eatables is known as Pickling. Fruits and vegetables like mangoes, tomatoes, olives, chillies, okras and other various types of eatables can be stored or preserved with the help of pickling. Fruits and vegetables that are very juicy with short shelf life are particularly used as pickling agent as they decay very easily and quickly. Pickles are found in various types of shapes and sizes: squared pieces, slices, whole or quartered and are found in sweet and sour flavours. In order to store such types of fruits and vegetables, preservatives are added to increase their shelf life. Such processes that involves the long - term storage of particular food item when it is unavailable or is not produced during particular season or period is termed as Pickling. India is a country which experiences climatic change every year and therefore requires storage of food items periodically. In some area there is maximum rainfall at a particular season and thus no food crops can be cultivated; while some regions are very dry where there is minimum or no rainfall. This includes the regions of Rajasthan and northern Gujarat. Northern India due to hilly regions experiences a wide climatic change from hot and humid and cold to alpine. Snowfalls are major concern in such areas causing maximum damage to cultivated foods and grains. India also experiences drought and famine types of disaster where people rarely find any food to eat and survive [1]. Not only fruits and vegetables are used for preservation but eggs, fish and grain items like wheat berries, rye berries, spelt, kamut and coconut seeds are used for preservation or pickling. India has become a hub of producing pickles. India produces 65,000 tons of pickles every year with an estimated value of Rs. 5 Billion [2]. Pickles are produced by two types of processes: Fermentation and without fermentation. Both the process involves the use of brine solution (mixture of high quantity of salt in water). The high quantity of salt used is responsible for providing characteristic flavour to the pickled food items.Fermentation: Food item that has to be pickled contains nutrients in the form of sugar. Salt present in the brine solution withdraw the nutrients and lactic acid bacteria that are naturally present on the food items feed on these sugars to get nutrients. They give end products like lactic acid, carbon dioxide and other compounds which provides flavour, texture and aroma to a particular type of pickles.Without Fermentation: Food materials that has to be pickled are placed in a brine solution for many hours and are then transferred to boiling solution of vinegar and pickling herbs. Spices and herbs like cinnamon, cardamom, mustard seeds are used for the production of pickles. The undesirable substances and microorganisms are killed in the boiling solution. Boiling solution helps vinegar and herbs to penetrate into a particular fruit or vegetable item to give pickling flavour, texture and aroma [3]. In India pickling of food items is usually done using anaerobic fermentation process. Variety of agents like acetic acid (vinegar), citric acid, brine solution (solution having high salt content) and vegetable oils are used for the process of fermentation. The application of quality and quantity of these agents may vary depending upon the item that has to be pickled. Different type of food products contains varying amount of moisture content in them. If the food items contain sufficient or high moisture content than dry salt is added to the pickling mixture. Sometimes sugar is also added as a preservative to increase the rate of fermentation and add sweet flavour to the pickled food. Lactobacillus Bacilli a type of Lactic Acid Bacteria (LAB) is used for the natural process of fermentation [1].Apart from the advantages, pickles also have other types of disadvantages. It is become mandatory to maintain proper temperature, acidity and pH for the prevention of undesirable bacteria other than LAB. Best quality of water and vegetable oils should be used to maintain the purity of pickles. The traditional method includes the use of sugar, salt, lemon juice and mustard oil as a pickling agent. Salt is commonly used for the pickling of meat and fish; and sugar is used to give sweet flavour to pickles. Such natural process is time consuming but allows the natural fermentation of LAB and is least hazardous. Now-a-days new and modernized methods of pickling are getting introduced in the market. Such methods include the use of synthetic materials for preservation and storage of food items. These synthetic materials include citric acid, acetic acid and other types of hydrocarbons like nitrates, benzoates, sorbates and formaldehyde. Though, such synthetic compound is least time consuming but can be carcinogenic and can create high risk damage to public health. Food borne diseases is a major concern now-a-days which damages public health to greater extent. Indian based vegetable pickles are found as a source of increasing rate of cancer (especially oesophageal cancer) [4]. This review paper compares and characterizes the process of production and tests physical and microbiological characteristics of pickles. Salt content, acidity, pH, temperature and undesirable microbial growth other than LAB is responsible for maintenance of quality and purity of pickled food items. If these all physical and chemical conditions are not maintained at proper rate then it affects the fermentation process of pickles.

2. Method

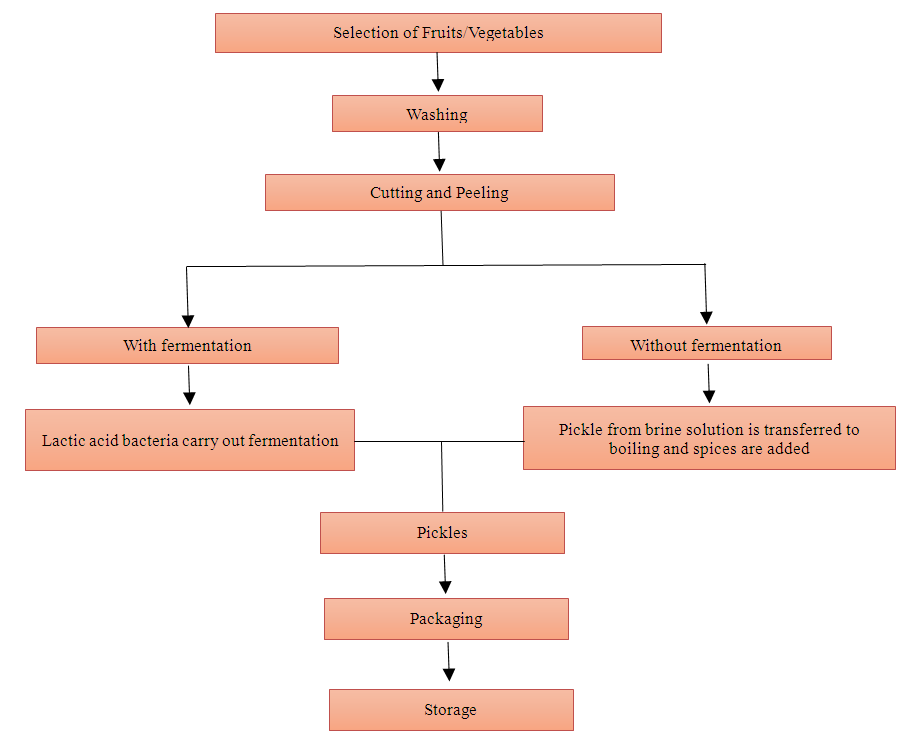

- The table describes about the process for the production of pickles. Pickles are usually manufactured by small scale industrialists. Physical environmental conditions like pH, temperature and acidity should be controlled and monitored periodically. Fruits/vegetables are taken, washed and skins are peeled off using stainless steel knives. They are usually cut into desired one fixed shape and size in such a way that it gets submerged into the brine solution. The ratio of brine solution and that of fruit/vegetable taken must be 1:1. The concentration of brine solution is maintained at 15-20% by adding salt in water. Temperature of 15-25°C is maintained to prevent contamination. Fermentation lasts for four weeks. Bubbles are produced when bacteria give out carbon dioxide during the process. Figure 1 shows the flow chart of the process of pickle production.

| Figure 1. Process of manufacturing and packaging of pickles |

3. Effect of Acidity and pH on Microbial Growth

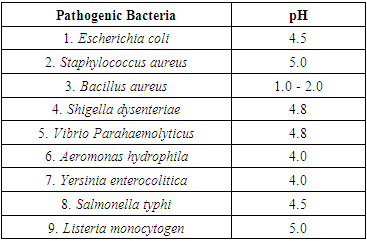

- Acidity determines the ability of microorganisms to grow on a fermented pickled item. To prevent the growth of microorganisms o particular food item acidity should be increased. Acidity should be maintained in such a way that it prevents the growth of bacteria and at same time it is safe for human consumption. Therefore, a mild change in acid content disrupts the growth of bacteria as they are much more sensitive to acidic condition as compared to humans. The acidity in pickled food items is determined mainly by three parameters listed below:1. Effect of pH2. Dissociation of the acid present in the pickle3. Effect of organic acid (acetic acid) in the pickle fermentationThe main concept of acidity relays on the dissociation of acid present in the pickle. HCl is a strong acid and therefore dissociates completely in water to give H+ and Cl- ions. Weaker acids like citric acid or acetic acid does not dissociate completely. Use of stronger acid like HCl helps to prevent microbial growth but it makes food unsafe for consumption. Thus, to maintain acidic condition weaker acids like citric acid and acetic acid are used which prevents microorganisms to grow on the pickle and makes it safer for the human consumption. This is because bacteria are much more sensitive towards acid then human. On the other hand, the bacteria that undergoes fermentation during the process of pickling, i.e., Lactobacillus and other type of LAB can withstand such acidic condition. The bacteria other than LAB cannot withstand such condition leading to decay. Organic acids like citric acid and acetic acid is harmful for some of the bacteria like E. coli, Salmonella and C. botulinum [5–7]. Acidity measures the total amount of acid that is present in the pickle product. Titration method is used to measure the acid content [3]. Acidity determines the value of pH of pickles. Measuring acidity means measuring the amount of particular acid present in the pickle, while measuring pH means measuring strength of that acid. The value of pH ranges from 0 to 14. pH value 7 is considered to be neutral. If the value decreases from 7 then the substance is said to be acidic in nature and if the value increases from 7 then it is considered to be basic in nature. There are two types of foods available for human consumption: (i) Food with lesser acid content and (ii) Food with higher acid content. Pickles usually have pH ranged in between 4.5 to 10 in which bacteria except LABs are unable to survive. This make the pickle bacteria free and safe for consumption. A study was done using Chinese pickles where it was found that pH decreases during first 24 hours of the storage period and then decreases gradually at 60 hours of storage period [5]. The number of food borne pathogenic microorganisms increased with decreasing pH value of fermented pickle. Table 1 shows the list of food-borne pathogenic bacteria that can cause adverse effect to human population [6–12]. According to the analysis of growth of various types of pathogenic bacteria at different level of pH, it was found that most of pathogenic microorganisms grow at pH less than 5.0. This implies that the pH should be maintained between 5 and 10. pH value below 5.0 or above 10 makes the pickles unsafe for consumption due to higher level of acidity and bacterial growth [13]. Such type of changes in pH also affects aroma and flavour of pickled vegetable or fruit. Linoleic acid and Linolenic acid are type of natural fatty acid found in plant oil. They are responsible for maintaining natural aroma of fresh cucumbers. Some artificial flavouring agents are used to preserve the smell in cucumber pickle (E, Z)-2,6-nonadienal and (E)-2-nonenal [14]. These agents are affected by the changes in pH. Acidity increases when pickles are kept for fermentation in refrigerator. This is because of fermentation allows the action of LABs that increases the acidity of the pickles. Thus, pH decreases and level of compound producing aroma also decreases. There was no effect of added spices in the pickles [15].

|

4. Microbiological Analysis

- Pickles are usually meant to be eaten during off season or when there is no availability of particular vegetable, fruit or meat during particular season. Pickles are type of Ready-to-Eat type of food products. These instant mix products require microbiological testing for estimation of its quality and purity [16]. The fermentation process requires the use of various microbial species that includes L. plantarum, Leuconostoc mesenteriodes, Lactobacillus brevis, Lactobacillus planarum and various others. L. plantarum is one of the most important species for the fermentation of pickles [17–18]. LAB count depends upon the storage period. It decreases significantly on 30th day of storage period. The addition of L. plantarum into the pickled the sample not only increased the count of LAB but also improved the taste, flavour and odour of the mixed vegetable pickle (Turşu). Moreover, they also found that on 60th day of storage period there was presence of thick layer of yeast and moulds on the surface of Turşu pickle. They are meant to cause spoilage in the pickled food items [19].LABs not only help in preserving food items for longer period of time but also improve our health and digestive system. Thus, preservation of any food item in a form of pickle requires proper fermentation in anaerobic condition. The improper fermentation may lead to the growth of food-borne pathogens that can generate various types of health issues like neurotoxicity, stomach infection, skin damage and various others in human population. Addition of proper quantity of preservatives like salt, acid and sugar can reduce the growth of unwanted microorganism. Along with preservatives, physical conditions like temperature, acidity and time is required for proper fermentation to occur. Temperature should be maintained between 15 to 25°C and pH at about or less than 4.5 to allow proper fermentation to occur. Temperature more than 25°C can lead to spoilage. As fermentation requires such a low pH, there are bacteria that grow during such condition. For example, Listeria monocytogen. Such food borne pathogen grows when proper anaerobic conditions are not provided or when the lid of pickle container remains slight open when fermentation is going on. Such anaerobic condition may affect the functioning of LABs present in the pickles which leads to the production of lesser amount of acid than required. Such circumstances may also result in the production of Clostridium botulinum which may cause neurotoxicity and other type of diseases in human beings. Thus, to help proper fermentation, starter cultures came into picture. Starter culture refers to the bacterial cultures that are being used for initiating the process of fermentation. Using starter culture increases the speed and efficiency of fermentation. They also help in enhancement and improvement in pickle preservation, maintain its nutritional value, aroma and taste [21]. The microorganisms used for the preparation of starter culture must have characteristics mentioned below:(1) It must adapt itself to the raw materials used in the pickle production and contain proper nutritional value.(2) It should enhance the fermentation process with less time consumption.(3) It should increase the shelf-life of pickles.(4) Reduce the risk of toxicity and growth of pathogens in the pickles.(5) Culture strains should detoxify and degrade mycotoxins and various other toxic compounds to reduce health risk [22].The technique of using LABs in the form of starter culture is very interesting but care is to be taken during the preparation of starter cultures to get benefits of above all mentioned characteristics.

5. Histamine Analysis

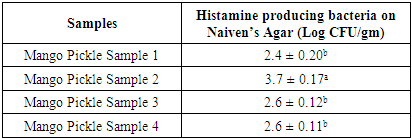

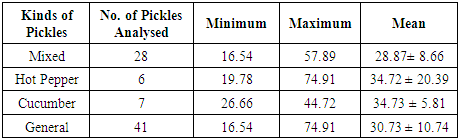

- Histamine is a type of biogenic amines found in various types of food items produced with the help of enzymes and bacteria. It is mostly found in fermented food items. It is required by human immune system and is generally produced from mast cells. It is a mediator for allergen and inflammation process. Histidine and other type of biogenic amines are required by our body in a moderate amount: about 70-1000 mg in one meal to fight against pathogen encountering human body [23]. The variation in the histamine levels in human body may cause dangerous effects. Histamine is usually consumed by humans in the form of fermented food items, meat and fish. Scombroid fish is major example of histamine toxicity. The species from suborder Scombridae includes mackerel, tuna, sword fish and various other fishes that are responsible for histamine poisoning [24]. Fermented food items like pickles are also major source of histamine. Fruits/vegetables that are used for storage in the form of pickles already contain some amount of histidine in it. The level of histidine varies in different fruits and vegetable items. Thus, it becomes necessary to check the variation of histamine level before and after fermentation of food items. A recent research was done to investigate the process of production of histamine in pickles. The presence of histamine producing bacteria using Niven’s agar in mango pickle [25]. Twelve isolates of bacteria were found on Niven’s agar media. Table 2 shows the microbial population from 4 different types of mango pickles on Niven’s agar. Enterobacteriaceae and Bacillus group of bacteria are potential histamine producers in fermented pickle items [26]. Further confirmation of histidine producing bacteria was done through PCR technique using HDC primers.

|

|

6. Conclusions

- The study describes the effect of various environmental factors like acidity, pH, microbial growth and histamine level in the ready – to – eat pickled food items. Proper control on the physical and microbial factors can lead to the production of good quality of pickles. Thus, physical conditions like temperature, humidity, acidity and pH should be maintained to keep the pickles safe. Different types of bacteria grow at different level of pH and acidity. Therefore, depending upon the fruit/vegetable taken, the level of pH, acidity and temperature should be maintained to produce best quality of pickles. Different types of pathogenic bacteria grow at different levels of pH and acidity. PCR and HPLC techniques were done to investigate the presence of number of histamines producing bacteria and quantify the level of histamine before and after the pickle production. The analysis shows that Enterobacteriaceae and Bacillus group of bacteria are major producers of histamine. The studies also show the maintenance of the level of histamine was below 1000 mg in each and every pickle sample. This makes pickles safe for consumption.

ACKNOWLEDGEMENTS

- I am obliged to Mr. Gaurang N. Patel, director at RAMDEV for giving me an opportunity to work in RAMDEV as intern. I would like to express my gratitude towards Laboratory Incharge Ms. Vanita Vanza and Mrs. Monica Gajera who guided me at each and every stage for helping me to write a research-based review paper. They made numerous valuable suggestion and correction, which greatly improved the quality of my paper. The practical and theoretical knowledge that I have gained from them will help me in enhancing my career and managing things in a better way. I also thank my parents, family members, colleagues and friends who helped indirectly throughout the project duration always have been a constant source of encouragement.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML