-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2018; 8(5): 119-126

doi:10.5923/j.food.20180805.02

Assessment of Chemical Compositions, Physical and Sensory Properties of Biscuits Produced from Yellow Yam, Unripe Plantain and Pumpkin Seed Flour Blends

Florence A. Bello1, Ofonime J. Ntukidem1, Babatunde S. Oladeji2

1Department of Food Science and Technology, University of Uyo, Uyo, Nigeria

2Department of Food Science and Technology, University of Calabar, Calabar, Nigeria

Correspondence to: Florence A. Bello, Department of Food Science and Technology, University of Uyo, Uyo, Nigeria.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Yellow yam, unripe plantain and pumpkin seed flour blends were produced and their potentials for biscuits production were investigated. The blends of yellow yam, unripe plantain and pumpkin seed flour were formulated and compared with 100% wheat flour (control, sample A). The formulated flour blends were in the ratios (w/w) 100:0:0, 80:10:10, 70:15:15, 60:20:20 and 50:25:25 coded as sample B, C, D, E, and F, respectively. The flours were evaluated for their functional properties while chemical compositions, physical and sensory properties of the biscuits produced were evaluated. The result showed that the bulk density of flour blends was not significantly (p>0.05) different from the control. Sample B had the highest water absorption capacity and swelling index but the least wettability compared to sample C to F. Crude protein, crude lipid, crude fibre and energy values of flour blends biscuits were significantly (p<0.05) higher than the values obtained from sample A and B. Ash contents of samples C and D were significantly close to the control while reduction in carbohydrate content was observed as the levels of substitution increased. Appreciable increase was noticed in selected mineral concentrations of flour blends biscuits. Oxalate and phytate values were significantly (p<0.05) higher while saponin, tannin and hydrogen cyanide values were lower than the control. Significant (p<0.05) reduction in weight and spread ratio of biscuits produced from flour blends were observed when compared with the control. However, sample D had the highest diameter while significant (p>0.05) difference was not observed in thickness of flour blends biscuits and the control. The sensory scores showed that sample D compared favourably with sample A as this would enhance the utilization of these underutilized crops.

Keywords: Functional, Underutilized, Quality characteristics, Blends, Formulation, Crispiness

Cite this paper: Florence A. Bello, Ofonime J. Ntukidem, Babatunde S. Oladeji, Assessment of Chemical Compositions, Physical and Sensory Properties of Biscuits Produced from Yellow Yam, Unripe Plantain and Pumpkin Seed Flour Blends, International Journal of Food Science and Nutrition Engineering, Vol. 8 No. 5, 2018, pp. 119-126. doi: 10.5923/j.food.20180805.02.

Article Outline

1. Introduction

- The rising need for production of food product with adequate diet has increased research and product development throughout times. Flour blends are produced not only to improve the desired functional properties of baked foods but also have higher nutritional advantage over individual flours and subsequent products [1]. Biscuit is a term used for a diverse variety of baked products, commonly flour based food products. It is one of the ready-to-eat, cheap and convenience food product that is consumed among all age groups in many countries of the world [2]. Biscuits possess several attractive features including a wider consumption base, relatively long shelf life, greater convenience and good eating quality [3]. The growing interest in this type of bakery product is due to their better nutritional properties and the possibilities. Currently, the production of baked product has being centred on wheat as a major raw material and it is considered nutritionally poor, as cereal proteins are deficient in essential amino acids such as lysine and threonine [4]. Many efforts have been carried out to promote the use of flour blends, in which a portion of wheat flour is replaced by locally grown crops thereby decreasing the cost associated with imported wheat in Nigeria [5-8]. Plantain (Musa paradisiaca) and yellow yam (Dioscorea cayenensis) are among the crops that are locally grown in South region of Nigeria. Plantain is highly nutritious and easily digestible than many other fruits. Plantains are among the green vegetables with the richest iron nutrient contents. The fruit contain vitamins A, B, C, D, E and K. It is also rich in potassium, calcium, and phosphorus [9]. However, they are highly perishable and subjected to fast deteriorations, as their moisture contents and high metabolic activity persist after harvest. Plantain flour is made from both ripe and unripe plantain and is often used as a gluten free replacement to wheat flour [10]. Yellow yam (Dioscorea cayenensis) is a good root crop with high energy, acceptable protein and iron content but low in calcium and zinc [11].One of the locally available, under-exploited but potentially high protein food sources in Nigeria is fluted pumpkin (Telfaira occidentalis Hook) seed. In addition to its importance as an oil seed (54% fat), it is valuable source of protein (27%) with a fairly well-balanced amino acid composition [12]. However, the usefulness of fluted pumpkin seed as a protein source for human food is limited by the presence of antinutrients, particularly phytic acid [13], which have been shown to lower the bioavailability of minerals in humans and inhibit the digestibility of plant proteins [14]. The antinutrient component can be reduced or inactivated through the application of a variety of processing techniques such as boiling, dehulling and drying. The utilization of yellow yam, unripe plantain and pumpkin seed flour blends in the production of baked product such as biscuits can serve as an alternative means of diversifying the use of non-wheat flour. These flour blends have the potential to increase the nutritional value of biscuits, enhance food security and reduce wheat importation thereby increase the farmers’ income. Therefore, the objective of this study was to assess the chemical compositions, physical and sensory properties of biscuits from yellow yam, unripe plantain and pumpkin seed flour blends.

2. Materials and Methods

2.1. Raw Materials and Source of Procurement

- Wheat, yellow yam, unripe plantain and pumpkin seed used for the study were purchased from Etuk market in Uyo metropolis, Akwa Ibom State, Nigeria. Ingredients used for biscuits production (butter, sugar, baking powder, vanilla and eggs) were also purchased from Etuk market in Uyo metropolis. All chemicals used for the analysis were of Analar grade purchased by Food Science and Technology Department, University of Uyo, Nigeria.

2.2. Samples Preparation

2.2.1. Preparation of Unripe Plantain Flour

- The plantain fruits were removed from bunches, washed with clean water and steamed at 60°C for 10 min using water bath (model Griffin) to control enzymatic browning. The fruits were immediately cooled and peeled using a sharp knife. The peeled plantains were sliced at average thickness of 1 cm. The sliced plantain were placed on the tray covered with aluminium foil to avoid sticking to the tray and dried in a cabinet oven (model NAAFCO BS Oven: OVH-102) at 60°C for 24 h. It was milled using hammer mill (model Corona) and sieved through a mesh of 425 mm pore size sieve to obtain the fine flour. The flour was packaged in air tight plastic container, labelled and store in a Haier Thermocool refrigerator (model ED 735, HPZ Nigeria LTD) at a temperature of -4°C for subsequent use.

2.2.2. Preparation of Yellow Yam Flour

- The fresh matured yellow yam tubers were washed in potable water, peeled using knife, sliced at the average thickness of 1 cm and soaked in ordinary water to prevent browning. The water was later drained off and the soaked yam slices were blanched in hot water at 70°C for 10 min using water bath (model Griffin) and immediately cooled with ordinary water. The blanched pieces were dried in a cabinet oven (model NAAFCO BS Oven: OVH-102) at 60°C for 24 h, milled using hammer mill (model Corona) and sieved through a mesh of 425 mm pore size screen to obtain the fine flour. The flour was packaged in an air tight plastic container, labelled and stored in a refrigerator at a temperature of -4°C for subsequent use.

2.2.3. Preparation of Pumpkin Seed Flour

- The fruit was divided into two equal halve and the seeds were removed and washed, followed by boiling using a water bath (model Griffin) at 100°C for 1 h. The seed were drained out, cooled, dehulled, sliced using knife at average thickness of 1 cm and oven dried (model NAAFCO BS Oven: OVH-102) at a temperature of 60°C for 24 h. The dried seed were milled using hammer mill (model Corona) and sieved through a mesh of 425 mm pore size screen to obtain the fine flour. The flour was packaged in an air tight plastic container, labeled and stored in a refrigerator at a temperature of -4°C for subsequent use.

2.2.4. Formulation of Yellow Yam, Unripe Plantain and Pumpkin Seed Flour Blends

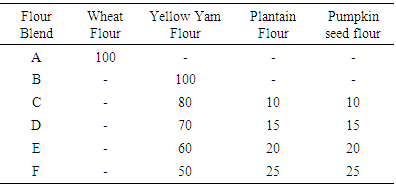

- Table 1 shows the formulation of the flour blends for the production of biscuits.

|

2.2.5. Formulation for Biscuits Production

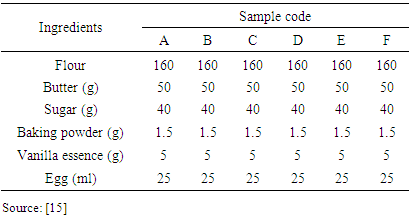

- The formulation used for the preparation of the biscuits is as shown in Table 2 with modification in ingredients weight.

|

2.2.6. Production of Biscuits Samples

- The biscuits were produced following the creamy method described by [15]. The butter and sugar were creamed together until light and fluffy. The measured flour, baking powder and vanilla essence were added and mixed in a bowel mixer to form elastic dough. The dough was then rolled to a uniform thickness and cut to a uniform diameter. The cut dough was left in the freezer for 30 min to rest and baked in blast air oven (KX 350A, Kenxin, Int’l Co Ltd, China) at 18°C for 15 min. The baked products were cooled at ambient temperature for 30 min, packaged in high density polyethylene, labelled and stored at room temperature for various determinations.

2.3. Determination of Functional Properties of the Flours

- Bulk density, gelatinization temperature, water absorption capacity and wettability of the flour samples were determined using the method described by [16]. Swelling index was determined using the method of [17].

2.4. Determination of Proximate Composition and Caloric Value

- Crude protein, crude lipid, ash and crude fibre contents of biscuit samples were determined using the method described by [18]. Total carbohydrate content on a dry weight basis was determined by difference using the method of [19]. The calorific values were estimated by multiplying the values of crude protein, fat and carbohydrate by their respective physiological fuel value of 4, 9 and 4, respectively.

2.5. Determination of Mineral Composition

- The minerals were determined using the method described by [20]. The samples were ashed at 550°C in a muffle furnace for 2 h. The ash content was dissolved in 10% HCl and made up with distilled water to 100 ml in a standard flask. Sodium and potassium were estimated by standard flame emission photometer (model 405, Corning, UK) and about 1.0 g of the sample was digested with 20 ml of acid mixture (650 ml of conc. HNO3; 80 ml PCA; 20 ml conc. H2SO4) and aliquots of the diluted clear digest was taken for photometry using flame Analyzer. Calcium, magnesium, zinc and iron were determined using Atomic Absorption Spectrophotometer (AAS Model SP9, Pye Unicam Ltd, Cambridge, UK).

2.6. Determination of Antinutritional Factors

- Saponin and oxalate and were carried out according to the method described by [16]. The method of [21] was used to determine tannins while hydrogen cyanide was determined using alkaline filtration method as described by [22]. Phytate was determined according to the method described by [23].

2.7. Determination of Physical Properties

- Cookies diameter and thickness were determined using vernier calipers, while cookies weight was determined using an electronic weighing balance. Spread ratio was expressed as diameter/thickness [24].

2.8. Sensory Evaluation

- Sensory characteristics of biscuits were evaluated for different sensory attributes by twenty (20) semi trained panelists drawn from the Department of Food Science and Technology, University of Uyo, Nigeria. All the panelists were briefed before the commencement of the evaluation process. Sensory attributes evaluated were appearance, taste, texture, crispiness, flavour and overall acceptability. The rating were on a nine- point hedonic scale ranging from 9 (like extremely) to 1 (dislike extremely) according to [19]. All panelists were regular consumers of biscuits, water at room temperature was provided to rinse the mouth between evaluations.

2.9. Statistical Analysis

- All the data were subjected to statistical analysis using Analysis of Variance (ANOVA). The means were then separated with the use of Duncan New Multiple Range Test (DNMRT) using the Statistical Package for the Social Sciences (SPSS) 20.0 software.

3. Results and Discussion

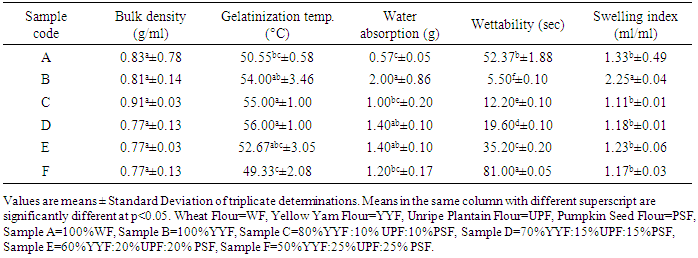

3.1. Functional Properties of Wheat Flour, Yellow Yam Flour and Blends of Yellow Yam, Plantain and Pumpkin Seed Flours

- The functional properties of wheat flour, yellow yam flour and flour blends are presented in Table 3. The bulk density of the 100% wheat flour (control) was not significant (p<0.05) different from the flour blends. It ranged from 0.77-0.91 g/ml. Sample C had the highest value while the least value was observed in sample D, E and F. Reduction in bulk density of flour blends means that all the flours can be packaged the same way and this is advantageous. The result agreed perfectly with [25] whose value ranged from 0.62-0.83 g/ml for trifoliate yam enriched with pumpkin seed flour. Sample C was not significantly (p<0.05) different from sample D and had the highest gelatinization temperatures of 55.00 and 56.00°C, respectively. The result agreed with [26] whose value ranged from 50.93-57.90°C for composite of rice, African yam and brown cowpea composite flour. This property of starch granules to form a gel when subjected to heat is important in the formulation of baked goods. Sample A exhibited the least water absorption capacity of 0.57 g while sample B had the highest value of 2.00 g. The baking quality of flour has been associated with water absorption of such flour [27]. High water absorption capacity of the flour suggested that the flours could be used in the formulation of bakery products [28]. The higher level of water absorption capacity of sample B relative to flour blends could be attributed to its high carbohydrate content. However, there was significant (p<0.05) increased in the wettability of the flour blends from 12.20 sec in sample C to 81.00 sec in sample F. Sample B was found to have the least wettability of 5.50 sec. Wettability of flour helps to determine the time it will take for it to dissolve completely in water. The wettability of the flour increase significantly with the addition of unripe plantain and pumpkin seed flour, this could be as a result of increase crude protein and lipid content in pumpkin seed flour, since it is oil based seed. This simply implied that, sample F which had the highest wettability value required much longer time to wet and to also initiate reconstitution than the other flour samples. The swelling index of the flour blends were not significantly (p<0.05) different from sample A, but lower than sample B with the highest value of 2.25 ml/ml. It ranged between 1.11-1.23 ml/ml for sample C and E, respectively. The swelling index in the flour blends was affected by the substitution of pumpkin seed flour which has considerable amount of protein and fat. The result is in agreement with [29] for watermelon seed, cassava and wheat composite flour.

|

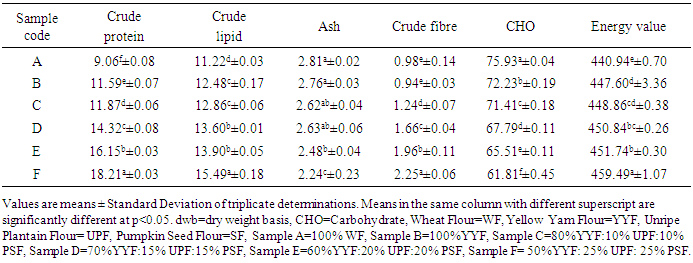

3.2. Proximate Composition of Biscuits

- Biscuits produced from flour blends resulted in significant (p<0.05) increased in crude protein content and it ranged from 11.87% (sample C) to 18.21% (sample F) as shown in Table 4. The least value (9.06%) was found in Sample A while flour blends biscuits (sample F) had the highest value of 18.21%. The higher protein content in pumpkin seed flour relative to unripe plantain and yellow yam could have been responsible for the observed higher protein content in flour blends biscuits. Adelekan et al. [25] had earlier reported an increase in protein content of trifoliate yam when fortified with pumpkin seed flour. Similar results have been reported by [6] and [30]. The result showed that flour blends biscuits could be used to address the protein-energy malnutrition prevalence in most of our communities. Crude lipid content of the biscuits produced from flour blends increased significantly (p<0.05) from 12.86% (sample C) to 15.49% (sample F). The biscuits from flour blends had higher value than sample A (11.22%). Increase levels of crude lipid as a result of increasing level of pumpkin seed flour addition indicates that the pumpkin seed flours had higher fat content compared to 100% yellow yam and wheat flour. Sample A exhibited the highest ash content (2.81%) when compared with the biscuits from flour blends whose value ranged from 2.24% (sample F) to 2.63% (sample D).

|

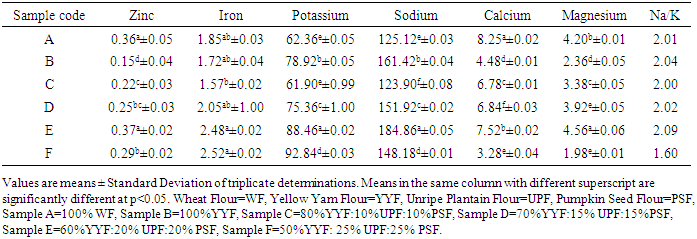

3.3. Mineral Composition of Biscuits

- The result of the mineral composition of biscuits produced from wheat flour, yellow yam and flour blends of yellow yam, plantain and pumpkin seed flour is shown in Table 5. Highest zinc value (0.37 mg/100g) was found in sample E and not significantly (p>0.05) different from sample A (0.36 mg/100g). Substitution of yellow yam with unripe plantain and pumpkin seed flour led to significant (p<0.05) increased in the iron content of the biscuits whose value ranged from 1.57 mg/100g in sample C to 2.52 mg/100g in sample F. Sample A had the least value of 1.85 mg/100g. Similar result was reported for iron by [5] whose value ranged from 0.67-4.78 mg/100g for cookies produced from unripe plantain and sesame flour blends. The values are lower than the findings of [32] who reported higher zinc content whose value ranged from 6.02-9.94 mg/100g for composite of unripe plantain with wheat flour. Magnesium is a constituent of bone and teeth and is closely associated with calcium and phosphorus. Potassium content of the samples ranged from 61.90 (sample C) to 92.84 mg/100g (sample F). Significant (p<0.05) increase was observed in sodium content of flour blends biscuits (sample C to E) when compared with sample A. It ranged from 123.90 (sample C) to 184.86 mg/100g (sample E). Potassium content in the samples is relatively high but lower than the finding reported by [33] whose value ranged from 2037.00-2310.00 mg/100g. Sodium content was considerable high which agrees with the report of [33]. Na/K ratio ranged from 1.60-2.09 for sample F and E, respectively. The Na/K ratio of the biscuit is greater than one. According to [34], the recommended Na/K ratio should be less than one. Na/K ratio plays a very important role in the control of high blood pressure. The result is in agreement with [35] whose Na/K ratio was 2.20 for biscuits produced from wheat and wheat germ. The same trend was observed in calcium and magnesium contents of the flour blends biscuits which significantly (p<0.05) increase as observed in sample C to E. It ranged from 3.28-7.52 mg/100g for calcium and 1.98-4.56 mg/100g for magnesium, where sample A had the highest calcium content of 8.25 mg/100g. Calcium stimulates muscles while magnesium relaxes the muscles [36].

|

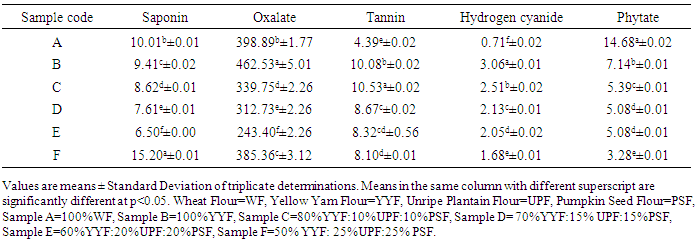

3.4. Antinutrient Contents of Biscuits

- Significant (p<0.05) reduction was observed in all the selected antinutrient contents of biscuits from flour blends (Table 6). Saponin content ranged from 6.50-10.01 mg/100g where sample A had the highest while least value was found in sample E. The saponin value in the samples was highly significant as a result of increased in pumpkin seed flour. The values for oxalate content was high in all the samples, sample B had the highest value (462.53 mg/100g) while sample E had the least value (243.40 mg/100g). The reduction in the oxalate value is due to the substitution of unripe plantain and pumpkin seed flour to yellow yam. High oxalate diet can increase the risk of renal calcium absorption and has been implicated as a source of kidney stones [37]. Tannins content ranged from 4.39-10.53 mg/100g in sample A and C, respectively. The tannins value in the product is considerably high. The biscuits from flour blends had highest hydrogen cyanide content when compared with the sample A. Sample A exhibited the least value (0.71 mg/100g) while the highest value (3.06 mg/100g) was found in sample B. the concentration of hydrogen cyanide in the product is higher than the value reported by [33]. Plants with more than 200 mg of hydrocyanic acid equivalent per 100 mg fresh weight are considered dangerous [38]. Highest phytate value (14.69 mg/100g) was found in sample A when compared with the flour blends biscuits while sample F had the least value of 3.28 mg/100g. The phytate content in the biscuit samples is low compared to the result presented by [38] whose phytate content is 35.06 mg/100 in pumpkin seed.

|

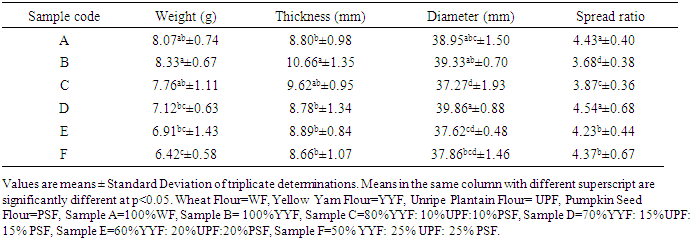

3.5. Physical Properties of Biscuits

- The result of the physical properties of biscuit samples is shown in Table 7. The weight of biscuits produced from flour blends was considerably low compared to the sample A. It ranged from 6.42 g (sample F) to 7.76 g (sample C) while the weight of the control sample was 8.07 g. The difference in weight could be attributed to different water holding capacities of the flour. The slight decrease in the weight of biscuits made from flour blends could be as a result of lower bulk density of unripe plantain and pumpkin seed flours. Biscuits from flour blends had the highest thickness when compared with the sample A and its value ranged from 8.66 mm in sample F to 9.62 mm in sample C. Sample A exhibited 8.80 mm thickness while sample B had the highest value of 10.66 mm. The slight increase in thickness of sample C compared with the sample A could be attributed to the hydrophilic nature of substituted flours which causes reduction in spread ratio. Diameter of all the biscuit samples ranged between 37.27 mm (sample C) and 39.86 mm (sample D). The low diameter value of biscuits made from 100% wheat flour may be due to its high gluten content. The spread ratio of all the biscuit samples ranged from 3.68-4.54. The least value was found in sample B while the highest values (4.43 and 4.54) were found in sample A and D, respectively, and not differ significantly. Spread ratio reduces with a reduction in plantain and pumpkin seed flour in the biscuits. Similar observations were reported by [6, 39, 40] while contrary findings were observed by [41] who worked on wheat and sorghum composite biscuit and [30] who reported higher spread ratios for wheat, cocoyam and African yam beans composite flours biscuits.

|

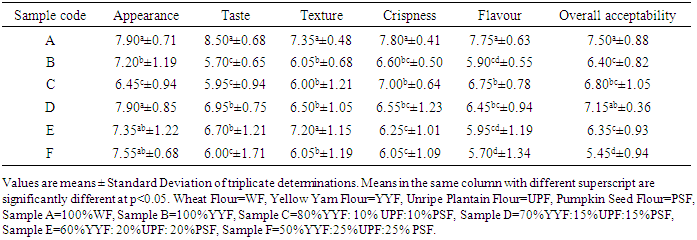

3.6. Sensory Scores of Biscuits

- The mean sensory score of biscuits produced is shown in Table 8. The result showed that sample A had the highest ratings for all the parameters tested. The scores for biscuits produced from flour blends ranged from 6.45 (sample C) to 7.55 (sample F), 5.95 (sample C) to 6.95 (sample D), 6.00 (sample C) to 7.20 (sample E), 6.05 (sample F) to 7.00 (sample C), 5.70 (sample F) to 6.75 (sample C), and 5.45 (sample F) to 7.15 in sample D for appearance, taste, texture, crispiness, flavour and overall acceptability, respectively. Sample D were rated to be significantly (p<0.05) better in terms of appearance, taste, texture, and overall acceptability than the remaining flour blends biscuits.

|

4. Conclusions

- This study has shown that acceptable biscuits of increased protein, fibre, energy, mineral and low antinutrient contents could be produced from yellow yam, unripe plantain and pumpkin seed flour blends. Biscuits produced from 70% yellow yam, 15% plantain flour and 15% pumpkin seed flour blends compared favourably in physical characteristic with 100% wheat flour and were preferred in term of appearance, taste, texture, and overall acceptability. The use of these locally grown crops will go a long way in reducing dependence on wheat flour for biscuits production in Nigeria, thereby reducing foreign exchange used in importing wheat.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML