-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2018; 8(3): 72-78

doi:10.5923/j.food.20180803.03

Effect of Drying Techniques, Harvest Season and Their Interaction on the Functional Properties of Instant Yam Flour

Alabi Opeyemi Esther

Department of Food Science and Technology, Federal University of Technology, Akure, Ondo State, Nigeria

Correspondence to: Alabi Opeyemi Esther, Department of Food Science and Technology, Federal University of Technology, Akure, Ondo State, Nigeria.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The knowledge of the effect of drying technique and harvest season is necessary in determining the most suitable conditions for the production of instant yam flour to imitate closely the traditionally produced pounded yam. This research work examined the effects of drying technique (sun, oven, vacuum and freeze drying), harvest season (old and new) and the interaction of these factors on the functional properties of instant yam flour. Yams of the same specie (Dioscorea rotundata) obtained at two separate harvest seasons were purchased from Oba Market, Akure, Nigeria. Sample was processed into instant yam flour using standard method. The samples were prepared using general factorial design [2 factors: harvest (2 levels) and drying (4 levels)]. Functional characteristics were assessed. From the results obtained, it was observed that drying technique had no significant influence on the bulk density, swelling capacity, water absorption capacity, oil absorption capacity and dispersibility. However, it had influence on wettability. Sun dried instant yam flour exhibited the highest wettability while freeze drying had the least value, the difference reaching 41%. Harvest season had a significant effect on swelling capacity and water absorption capacity but no differences were observed in the bulk density, oil absorption capacity, dispersibility and wettability of the instant yam flour samples. New yam exhibited slightly higher swelling capacity translating to about 27% upturn when compared to old yam. Both old and new yam possibly will result in instant yam flour with similar instant characteristics and reconstitution ability. However, considering yield, old yam may be preferred over new yam. The interaction of drying techniques and harvest season was significant for all the parameters.

Keywords: Dioscorea rotundata, Drying, Harvest season, Functional, Instant flour

Cite this paper: Alabi Opeyemi Esther, Effect of Drying Techniques, Harvest Season and Their Interaction on the Functional Properties of Instant Yam Flour, International Journal of Food Science and Nutrition Engineering, Vol. 8 No. 3, 2018, pp. 72-78. doi: 10.5923/j.food.20180803.03.

Article Outline

1. Introduction

- Yam (Dioscorea spp) is a root crop and very important source of carbohydrate for people in sub-Saharan Africa; Nigeria been one [4]. However, [28] indicated that other nutrients such as caloric proteins, minerals and vitamins are also present in yam. In terms of production, [11] reported that yam is the second most important root crop in the world while [13] reported that Nigeria cultivates annually more than 2.8 million hectares of land for yam production, thus, making her the largest producer of yam with Dioscorea rotundata and Dioscorea alata identified as popularly cultivated species. [26] itemized certain importance of yam in diet diversification, employment, household food security, income generation and poverty alleviation. In Nigeria, yam is a common staple food and has been consumed in different ways such as boiling, frying, roasting or as pounded dough meal at household levels [12]; [33]; [36]. Aside household usage, industrially, yam has been used in starch, livestock feeds, yam flour or instant-pounded yam flour production [35]. In Nigeria, there exist two marked harvest seasons for yam; “old”, also referred as “dry” (i.e., November–February) and “New”, also referred to as “wet” (i.e., March–October) yam [23]. Pounded yam happens to be a key native food in Western Nigeria and traditionally, it is prepared by cooking peeled yam pieces and then pounding using a wooden mortar and pestle until a sticky dough is obtained [7]. However, the process of yam pounding is very stressful and time-consuming; therefore, it has become less popular among the elites. The need to reduce the labour associated with the preparation of pounded yam brought about instant yam flour which can be reconstituted into dough similar to the pounded yam [7]; [3]. The instant yam flour is mixed with a stipulated proportion of hot water until a thick paste is formed. The alternative, instant yam flour, which mimics closely the properties of traditionally pounded yam, is sought after by a large number. FIIRO [10] and Aworh [7] elucidated different methods of the production of instant yam flour. Consumer perspectives on the quality properties of instant yam flour when reconstituted have been linked to how different the product is when compared to traditionally pounded yam. However, these differences may be somewhat due to technological variables i.e. production parameters (drying methods, time) and/or agronomical conditions (yam cultivar, genetic, harvest time). Therefore, study on the influence of two or more of these variables, for example, drying techniques and harvest season on the functional characteristics of the instant yam flour become necessary. Drying is a critical factor in the process technology for instant yam flour as physical or chemical changes may occur thus resulting in extreme changes in product quality [21]; [29]. Research have been carried out in diverse ways on Instant yam flour but there remains little or no information regarding the effect of harvest season, drying technique and the interaction of these variables on the functional properties of instant yam flour. The aim of this research is to evaluate the impact of harvest season and various drying methods on the functional properties of instant yam flour.

2. Materials and Methods

2.1. Source of Materials

- Yams of the same specie (Dioscorea rotundata) obtained at two separate harvest seasons (old and new) were obtained from Oba Market, Akure, Ondo state, Nigeria. All the chemicals used were of analytical grade.

2.2. Preparation of Instant Yam Flour Samples

- A modified version of the production of instant yam flour as described by [10] was carried out using vacuum drying, oven drying, freeze drying and sun-drying methods of drying. The yam tuber was peeled, washed and sliced, sodium metabisulphate was added, cooked (100°C for 15 minutes), dried (70°C for 10 hours), milled, packaged and stored at room temperature until further analysis.

2.3. Instrumental Analyses

2.3.1. Determination of Functional Properties

- The Bulk density was determined as described by [1]. The swelling capacity of the samples was determined by the method described by [16] as reported by [25]. Water absorption capacity was determined according to the method described by [22]. Oil absorption capacity was determined as described by [1]. Wettability was determined according to the method of [27] was adopted as described by [22]. Dispersibility was determined as described by [14].

2.4. Statistical Analysis

- Data was reported as mean ± standard error of triplicate readings and analyzed using one-way analysis of variance (ANOVA) with significant differences between means determined at p< 0.05 and measured with Duncan’s multiple range tests using the Statistical Package for Social Science Research version 17 (SPSS).

3. Results and Discussion

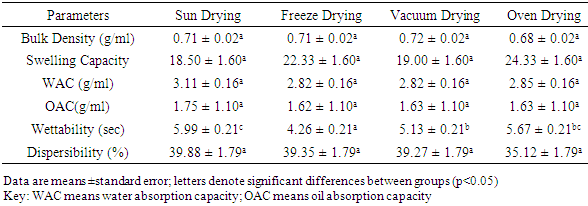

3.1. Influence of Drying Technique

- The result obtained for the effect of drying technique on the functional properties of instant yam flour is presented in Table 1. As shown in table 1, there were no significant differences (p≥0.05) among the drying techniques considering the bulk density, swelling capacity, oil absorption capacity and dispersibility of the instant yam flour samples. The bulk density of the samples ranged from 0.68 g/ml of oven drying to 0.72 g/ml of vacuum drying. Bulk density is a function of ease of dispersibility [34]. The result obtained for instant yam flour dried using the aforementioned drying techniques are comparable to values (0.65- 0.78 g/ml, 0.68-1.07 g/cm3) reported by [50] and [39] for cabinet dried yam flours and oven dried yellow trifoliate yam flour respectively. Also, current results are higher than values (0.55 g/ml, 0.57 g/cm3) reported by [46] and [40] for cabinet dried water yam flour and cabinet oven dried white aerial yam flour respectively. Comparing data obtained for instant yam flour with other carbohydrate-based instant flours, current bulk density is lower but close to values (0.86-0.88 g/ml) reported by [6] for unripe plantain flour while obtained data is comparable to values reported by [5] for cocoyam flour samples. All instant yam flours studied show comparable bulk density which suggests that their starch polymers showed same stable structure considering the different drying methods. This is important in determining package requirement, material handling, transportation and storability [15]; [2], therefore, a high bulk density is desirable [9]. The bulk density of flour, affected by particle size, also plays important roles during mixing, amidst other parameters, of particulate foods [38].

|

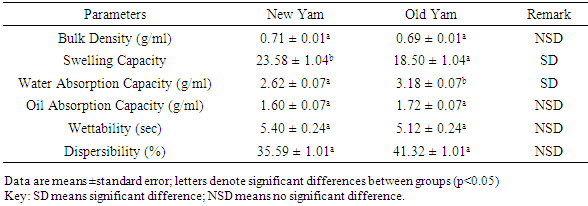

3.2. Influence of Harvest Season

- Table 2 shows the result obtained for the effect of harvest season on the functional properties of instant yam flour. From result obtained, the bulk density of new yam (0.71 g/ml) was slightly higher than old yam (0.69 g/ml), however, since their values were quite close, there was no significant different. Harvest season may possibly not affect bulk density of instant yam flour. In contrast, harvest season (rainy and dry season) had significant influence on bulk density of cassava gari [49]. Since observed bulk density are higher than that reported by [46] and [40], instant flour from the old and new yam (D. rotundata) under study are expected to offer greater packaging, handling and storage advantage.

|

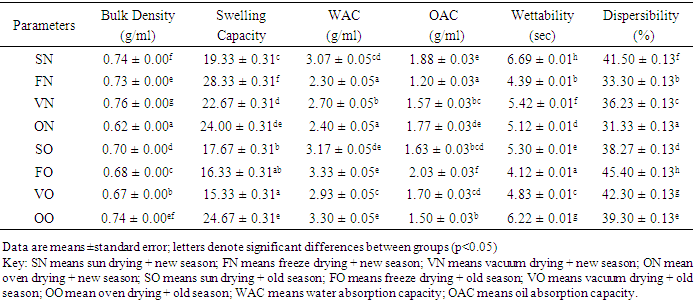

3.3. Influence of the Interaction of Drying Technique and Harvest Season

- The result of the effect of the interaction of drying technique and harvest season on the functional properties of instant yam flour is presented in table 3. It can be observed that samples showed observable differences regarding drying and seasonal differences. The bulk density of instant flour made from new yam and was vacuum dried had the highest value (0.76 g/ml) while instant flour made from new yam and oven dried had the least value (0.62 g/ml). From literature, higher bulk density has been attributed to low moisture content which is dependent on drying techniques [42]. It is expected that when new yam is used and vacuum dried, there will be packaging advantage and better ease of dispersibility.

|

4. Conclusions

- The drying technique and harvest season were identified as factors that will possibly affect the functional properties in the production of instant yam flour from white yam (Dioscorea rotundata). Consequently, to produce instant yam flour with high and acceptable functional properties from white yam (Dioscorea rotundata), old yam with freeze drying is recommended. Instant yam flour when reconstituted should have properties comparable to the traditionally prepared pounded yam as desired and savoured by consumers in Western part of Nigeria.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML