-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2017; 7(6): 125-131

doi:10.5923/j.food.20170706.01

Formulation of Flat Bread (Kitta) from Maize (Zea Mays Linaeus.) and Amaranth (Amaranthus Caudatus L.): Evaluation of Physico-Chemical Properties, Nutritional, Sensory and Keeping Quality

Dereje Getahun Bassore, Beruk Berhanu Desalegn

School of Nutrition, Food Science and Technology, Hawassa University, Southern Ethiopia

Correspondence to: Beruk Berhanu Desalegn, School of Nutrition, Food Science and Technology, Hawassa University, Southern Ethiopia.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Global food demand has resulted in increased attention towards underutilized crops with the potential to improve global food security and ability to mitigate adverse effects of climate changes. Changing consumer demands in favor of more nutritionally balanced and organically grown crops have added to the interest in species such as amaranth. The objective of this research was to develop unleavened bread (flat bread) from maize and amaranth at different proportions and processing, and analyze its proximate, minerals and anti-nutrients (tannin and phytate), microbial load (bacteria, yeast and mold), physico-chemical property (texture) and consumer acceptability. Standard methods were used to evaluate the proximate composition, minerals’ and anti-nutrients’, microbial load, texture and consumer acceptability of the flat breads. Consumer acceptability test was carried out using five-point hedonic scales with 50 consumer oriented panelists in triplicates. Data from the experiments were analyzed using SAS version 9.0 software. Completely randomized design was used to see the effect of different proportion and pretreatment methods on proximate composition, minerals, anti-nutrients and texture. Likewise, the factorial (CRD and RCBD) experimental design was employed for microbial load and sensory analysis, respectively. The results showed that significant differences (p < 0.05) were observed in protein and carbohydrate mean score values. Fe and Ca mean score values also exhibited significant differences. As the proportion of amaranth increased, the mean score values of Fe and Ca increased. No significant differences were observed in phytate and tannin mean score values. The acceptability test revealed that all the flat breads were acceptable for all sensory attributes. The microbial load mean scores showed that there was no significant difference due to the treatments effect on the microbial loads. The mean score values of the texture did not show any significant differences. It is concluded that addition of amaranth flour up to 20% during preparation of flat bread from amaranth and maize flour has no acceptability problem. In addition, addition of amaranth flour significantly increased the nutritional values. Pretreatment methods have no significant effect on the microbial load of the flat breads. The flat breads were safe for consumption for 48 hrs after preparation. Incorporation of amaranth flour up to 20% is recommended since it was accepted by consumers and also increased the nutritional values. Further researches with wide range of blending ratio as well as treatment methods (time-temperature combinations) are recommended to see their effect on sensorial, microbial, nutritional and texture (hardness) of flat bread from maize and amaranth.

Keywords: Amaranth, Maize, Nutritional value, Microbial load, Sensory acceptability, Texture

Cite this paper: Dereje Getahun Bassore, Beruk Berhanu Desalegn, Formulation of Flat Bread (Kitta) from Maize (Zea Mays Linaeus.) and Amaranth (Amaranthus Caudatus L.): Evaluation of Physico-Chemical Properties, Nutritional, Sensory and Keeping Quality, International Journal of Food Science and Nutrition Engineering, Vol. 7 No. 6, 2017, pp. 125-131. doi: 10.5923/j.food.20170706.01.

Article Outline

1. Introduction

- Amaranth was one of the staple plants and considered as it had supernatural power and it was used in religious ceremonies in South and Central America. The grain amaranth has been grown since 8,000 years back [1]. About 60 Amaranth species is categorized under family Amaranthaceae, a number of the species are cultivated as leaf vegetables, grains or ornamental plants, while others are weeds [11]. Amaranthus. tricolor, A. dubius, A. lividus, A. creuntu, A. palmeri and A. hybridus are mainly grown as vegetables whereas A. hypochondriacus, A. cruentus and A. caudatus are the main grain species [16].Amaranth has adapted to marginal land and potential crop for further activities and improvement considering its high genetic diversity and range of phenotypic plasticity [3, 6, 20]. In addition to these, amaranth has naturally tolerable to high temperature, combining these characteristics with its inherent tolerance to high temperatures, water stress, deprived soil conditions and less prone to classical disease problems, cultivated in extremely diverse lands from tropical lowlands up to 3500m altitude makes amaranth ideal and highly fascinating crop for existing capital and labor intensive farming system, climate change problem and possible mitigation strategy and food security [7, 8, 20]. Nutritionally, it is rich in carbohydrate (48–69%), protein (12–18%) and fat (5–8%) [3, 6, 16, 20]. It also contains a high concentration of limiting amino acids like lysine (0.747g) and tryptophan (0.181g) [16]. In addition, it is also relatively rich in the sulfur-containing amino acids which are limiting in the pulse crops at the normal circumstance [4]. On previous studies, the potential of higher protein content of amaranth grain was observed by blending with different cereals like wheat, sorghum and maize [9]. Among the studies previously mentioned, toasted amaranth blended with ordinary maize at 12.7% (w/w) flour showed higher amount of protein content and can satisfy the young children protein requirements and provide also about 70% of required diet energy [9, 10]. Beside these, another scholar showed amaranth has high amount of iron (13.79g per 100g) and zinc (4.23g per 100g) and potential for fulfilling recommended daily allowance of children aged between 1-3 years (7 mg for Fe and 3 mg for Zn) [12, 20]. A number of formulations of nutritious foods have been done and nutritional qualities of raw and processed amaranth have been reported in eastern African countries like Kenya and Ethiopia [9, 15, 20, 29]. In some parts of south and south west Ethiopia, amaranth is used to prepare local beverage known as ‘Chaqa’, porridge, and ground seeds are mixed with tef to prepare pancake-like bread (injera), borde, kitta (unleavened bread) and atmit [20]. Maize (Zea mays L.) has been the prime source of nutrition for one-third of the global population mainly for developing and developed countries of Sub-Saharan Africa and South-east Asia including Ethiopia. Of the major cereals, maize, wheat and rice covers about 85% of total cereals production globally which is about 200 million tons annually and contributing an average of 10% protein content, out of which a significant portion goes into human consumption [13]. In Africa, maize is an important cereal crop, serving as a staple food for majority of population and has been used for industrial purpose as raw material for brewery, confectionary, livestock and flour feed mills. It is also primarily provider of calories supplying 20% of the world’s food calories and 15% of all food crop protein even though it has low contents of lysine and tryptophan from the protein components, except the quality protein maize (QPM) variety which is known to have double lysine and tryptophan than the classical maize variety [14]. In Ethiopia, maize has been used alone and/or blending with other cereals, root crops, legumes, fruits and vegetables for preparing different food and beverage products like kitta (unleavened flat bread), porridge, local alcoholic drinks (tella, areke, cheka), injera and others. Of this food products and beverages, Kitta (unleavened flat bread) is one of the major which is prepared and consumed daily as a family food including young children in southern Ethiopia. Global food demand has resulted in increased attention towards underutilized crops with the potential to improve global food security and ability to mitigate adverse effects of climate changes. Changing consumer demands in favor of more nutritionally balanced and organically grown crops have added to the interest in species such as amaranth. Promoting the consumption and cultivation of amaranth could be valuable due to its unique nutrient composition and inherent tolerance of drought and other stress factors. Due to current and predicted effects of climate changes, these attributes are becoming increasingly important. Amaranth is a source of high quality protein, as well as dietary fibre and lipids rich in unsaturated fatty acids. The seeds contain desirable levels of minerals, vitamins for human diets, in addition to other bioactive components such as phytosterols, squalene, fagopyritols, saponins and polyphenols. Amaranth is currently in demand by specific consumer groups, such as high-performance athletes, malnourished children, and people suffering from diabetes and coeliac disease and potential crop for family food. The potential effects of climate change on global agricultural production, such as poor crop yields, desertification, deforestation, erosion, degradation of water quality and depletion of water resources, have widely been projected to hamper future crop productivity levels, thus further complicating the challenge of maintaining food security in agriculturally vulnerable areas [17-19]. The combination of global population growth and the above factors, together with increasing energy prices and subsequent increases in costs of agricultural inputs, will add to the challenge of maintaining global food security. Some of the strategies recommended for climate change mitigation and adaptation include the establishment of more diverse cropping systems with the inclusion of crops that are drought and heat stress tolerant, in order to better adapt to climate variability and new pest and disease pressure [18, 30]. Therefore, in this study unleavened bread (kitta) was tried to be developed from the conventional crop (maize) and underutilized crop (amaranth) and the study focused on assessing the effect of different processing and blending proportion on proximate composition, physico-chemical properties (Texture), minerals, anti-nutrients, keeping quality, and sensory acceptability at community level.

2. Materials and Methods

2.1. Study Area

- The study was conducted in Hawassa city Administration, Hawella-tulla sub-city, which is located 275 km from Addis Ababa. According to Hawassa city Administration report in 2014, the population of the sub-city is 102,016. From the total populations 102,016 are male 57250 and 44766 and are female. The sub-city consists of 23 kebeles comprising of 30, 820 residential houses with an average household family size of 4.9. The altitude of the sub-city ranges from 1501 to 2500 above sea levels and that of the average annual rainfall record varies from 801 to 1000 mm. The total area of the sub-city is 100 sq km. The average temperature of the sub-city is between 17.6-22.5°C. The sub-city is known in growing maize, potato, haricot bean and enset [5].

2.2. Sample Materials Collection and Preparation

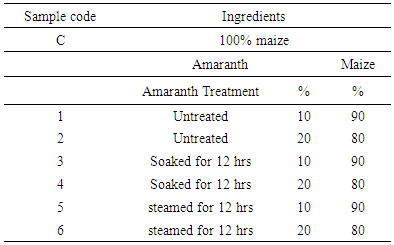

- The grains of Amaranthus caudatus with pale-white color was purchased from capital of Konso woreda Karate local market, Segene people’s Zone in southern Ethiopia. The maize grain was purchased from Hawella-tulla sub-city local market. All the grains were cleaned to remove stones, dust, light materials, and broken, undersized and immature grains. The maize grain was then soaked for one day in clean tap water, drained and sundried until we get constant weight. After getting the dried maize grain, it was milled using a cyclone mill (Tecator AB, Haganas, Sweden) to pass a 0.5 mm mesh screen so as to get the flour. The milled samples were then packed in polyethylene bags [20, 28]. The cleaned amaranth grain was divided in to three as control and was not be exposed to any treatment, the second one was exposed to 12hrs soaking in tap water at 1:3w/v concentration with changing soaking water at six hrs, interval and the third one was exposed to 12hrs soaking in steaming tap water (initial temperature around 70°C). Then, all the three amaranth grains (control and treated) were sundried and milled using cyclone mill (Tecator AB, Haganas, Sweden) to pass a 0.5mm mesh and filled in polyethylene bags. After getting the flours of amaranth and maize, they were mixed according to the formulation (Table 1).

|

2.3. Preparation of Flat Bread

- Preparation of dough for flat bread production was done by mixing 1% iodized salt, the composite flour and water. After that, the dough was kneaded until it becomes oft, smooth and non-sticky. Pre-heated local clay griddle (Mitad) was used for baking and the leaf of enset (Ensete ventircosum) for wrapping the dough to be baked. The baking was continued until a brown color developed (which took about 10 minutes at about 140°C). The bread which was prepared in the above way was cooled down to room temperature and wrapped in polyethylene bags [27].

2.4. Laboratory Analysis

2.4.1. Chemical Analysis

- Proximate chemical composition analysis of the flour and bread like moisture, total ash, crude protein (N x 6.25), crude fiber and crude fat content were performed according to [2]. The carbohydrate content was determined by differences. Gross energies of were also calculated by using the Atwater’s conversion factor, 16.7 KJ/g for protein and carbohydrate and 37.4 KJ/g for fat. The mineral contents were analyzed by the procedure of [23] using an Atomic Absorption Spectrophotometer. Condensed Tannin and phytate contents were determined by the method used by [24, 25]. The mole of phytic acid was calculated as measured value of phytic acid divided by molecular weight of phytic acid (240) whereas the mole of mineral (Fe or Zn) was calculated as measured value of the mineral divided by individual mineral molecular weight (Fe: 56, Zn: 65) [26].

2.4.2. Physical Analysis

- The texture (hardness) of the flat bread was measured by using TA Plus texture analyzer. The force required breaking the flat bread at a specific velocity and probe type were measured.

2.4.3. Microbial Analysis of the Flatbread

- The total mold, yeast and bacteria count was carried out on the flat-bread samples during 2 days’room temperature storage using the procedure of [22]. Flat-bread samples were taken aseptically and homogenized in 99ml sterile peptone water 0.1% in a blender for about 2 minutes and serial dilutions were made. One milliliter of each dilution was pour plated in sterile Petri dishes, the stomacher dilution represents the 10-1 dilution, 10-2, 10-3, 10-4 and 10-5 dilution prepared by using 9ml peptone water tubes and plate count agar (PCA) with chloramphenicol addition and incubated at 25°C for 5 days for mold and yeast count and molten plate count agar (PCA) was used and incubated for 48 hours at 35°C for total bacterial count. Counts of visible colonies by using colony counter was made and expressed as log CFU/g of the original sample.

2.5. Sensory Evaluation of Flat-Breads at Community Level

- The prepared flat-bread samples were coded with three digit numbers randomly and were presented to the panelists (mothers) in random order. The sensory evaluation was carried out using a five-point hedonic scale (1= dislike very much, 2= dislike, 3= neither like nor dislike, 4=like, 5= like very much) in terms of color, appearance, flavor, taste, texture and overall acceptability with 50 panelists. In addition, preference test was carried out at the same time. The sensory evaluation was carried out in three consecutive days so as to produce valid result.

2.6. Experimental Design

- Factorial experimental design was applied for nutrient contents, minerals, anti-nutrients and microbial analysis. The treatments were processing (untreated amaranth, amaranth soaked in tap water for 12 hrs and amaranth soaked in steamed water for 12 hrs) and blending at different proportions maize and amaranth (90:10, 80:20) where as 100% maize was used as control for blending. Randomized complete block design (RCBD) was used for sensory analysis.

2.7. Data Analysis

- Two-way analysis of variance using SAS software version 9 for windows was applied. The means separation was done using the Fischer’s least significant differences (LSD) at p<0.05.

3. Results and Discussion

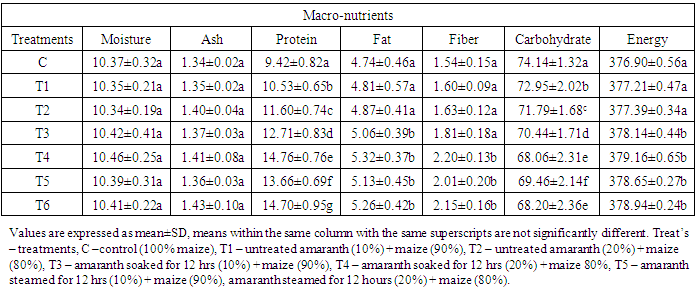

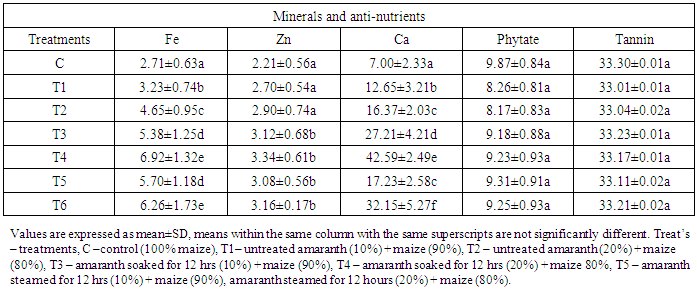

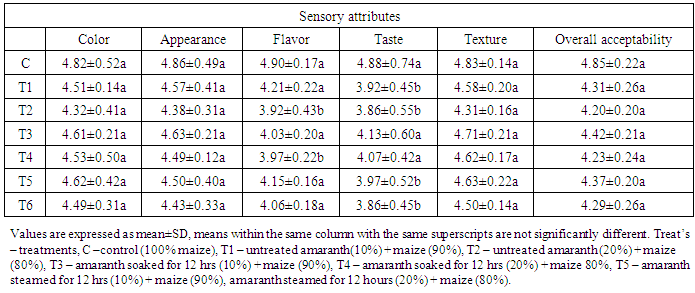

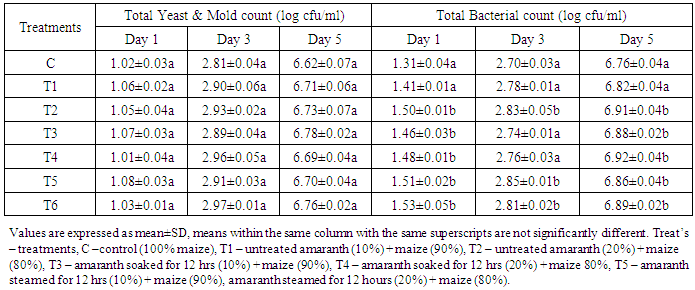

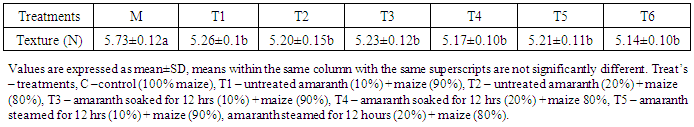

- As indicated in the table 2, the mean scores of moisture contents of the flat breads were not significantly different (p<0.05). The slight increment in the mean scores of moisture contents of T3, T4, T5 and T6 might be due to the soaking and steaming effects of the amaranth grain. The mean scores of the ash contents were not significantly different (p<0.05). The ash contents of the treatments were slightly increased as the proportion of amaranth was increased. This might be due to amaranth has higher minerals content than maize. The mean scores of the protein contents were significantly increased (P<0.05) from C to T6. This might be due to the higher protein content of amaranth than maize. In addition, the pretreatments (soaking and steaming) might contribute for the increment. There was no significant difference (p<0.05) between C, T1and T2 for fat mean scores. Similarly, there was no significant difference between T3, T4, T5 and T6. Significant difference was exhibited between (C, T1, T2) and (T3, T4, T5, T6). The mean scores for fiber exhibited significant difference for samples (C, T1, T2, T3), (T4, T5, T6). The treatments within the same bracket are not significantly different but the treatments in one bracket are significantly different from those in the other bracket. Except T4 and T6, the mean scores of carbohydrates for the remaining treatments were significantly different (P<0.05). Significant difference was not exhibited among C, T1 and T2 for gross energy. Similarly, no significant difference was observed between T3, T4, T5 and T6 (Table 2). As shown in the table 3, mean scores of Fe were significantly different (p<0.05) for all treatments. The Fe content of all the flat breads with amaranth was significantly higher than that of the control. This might be due to the higher Fe content in amaranth grain. There was no significant difference for Zn among the mean scores of C, T1 and T2. Similarly, no significant difference was observed among the mean scores of T3, T4, T5 and T6. Mean scores of Ca content has shown significant difference for all treatments. Amaranth grain has higher Ca content than maize. Soaking and steaming also had effect on its content. Mean scores of Phytate and tannin did not show significant difference. This might be due to the amaranth proportion blended was unable to bring significant difference (table 3). As indicated in the table 4, adding 10% amaranth to maize flour had no significant sensorial effect on the mean scores of the all sensory attributes of the flat breads. These findings could add amaranth flour for flat bread making up to 20%. The whole mean scores revealed that all the flat breads are acceptable, i.e. all the mean scores are above 3, which is neither like nor dislike. Incorporating amaranth flour to maize flour had no effect on the sensory attributes. Due to this, blending amaranth with maize flour should be encouraged since amaranth is a good source of micro and macronutrients (table 4).According to table 5, there was no significant difference due to treatment effects on amaranth. The microbial load increased as the storage time increased. Guidelines for ready-to-eat food of department of medical sciences, ministry of public health, Thailand, define that yeasts per gram must be less than 10,000 (less than 4 log cfu/g) and molds/g must be less than 500 (less than 2.7 log cfu/g). According to this guideline, the flat breads are in safe range for consumption for three days for yeast and mold. According to [21], ready-to-eat foods with total bacterial count between 0-103 are acceptable, between 104-105 is tolerable and; however, above 105 is unacceptable. According to this guideline, the flat breads are in safe range for consumption for three days regardless of the treatment methods and storage period.

|

|

|

|

|

4. Conclusions and Recommendations

- From the results above, it can be concluded that blending amaranth flour up to 20% is acceptable for all sensory attributes. It also boosts the nutritional value of the flat bread. Even though there were no significant differences among the treatments, pre-treating amaranth is advantageous in reducing anti-nutritional factors and making the flat-bread more palatable. Regarding the microbial load, storing the flat bread for more than 48 hours causes spoilage. The prepared flat bread has to be consumed before 48 hours to not be at risk of food poisoning. The treatment methods have no significant effects boldly because the blending ratios as well as the treatment methods (time-temperature combination) are not different as such. Based on the findings of this study, the researchers recommend the following points:• It is better to incorporate amaranth for flat bread preparation since it has better nutritional profile.• The prepared flat bread has to be consumed within 48 hrs of preparation to avoid food poisoning problem. • Further researches with wide range of blending ratio as well as treatment methods (time-temperature combinations) are recommended to see their effect on sensorial, microbial, nutritional and texture (hardness) of flat bread from maize and amaranth.

ACKNOWLEDGMENTS

- The authors would like to thank Hawassa University, Office of Vice president for Research and Technology Transfer financing this research work. The authors would like also to thank Hawassa University, School of Nutrition, Food Science and Technology for carrying out this experiment.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML