-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2017; 7(2): 29-31

doi:10.5923/j.food.20170702.01

Improvement of the Process of Cottonseed Oil Refining

M. Siradze, I. Berdzenishvili, G. Jokhadze

Georgian Technical University, Tbilisi, Georgia

Correspondence to: I. Berdzenishvili, Georgian Technical University, Tbilisi, Georgia.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The process of alkaline refining of cottonseed oil is studied and the methods of increasing the yield of neutralized oil are offered. It was revealed that during the refining process of cottonseed oil an increase in the temperature of the process causes a transfer of additional 2,2% oil into waste. It is shown that the neutralized oil yield increases slightly without drying of hydrated oil, while drying improves the degree of refining.

Keywords: Refining, Cottonseed oil, Neutralization, Hydration, Phosphatides, Yield

Cite this paper: M. Siradze, I. Berdzenishvili, G. Jokhadze, Improvement of the Process of Cottonseed Oil Refining, International Journal of Food Science and Nutrition Engineering, Vol. 7 No. 2, 2017, pp. 29-31. doi: 10.5923/j.food.20170702.01.

1. Introduction

- Fats and oils are the organic substances that form an essential part of the human diet and also are useful in many industries. As a rule, natural fats and oils contain some impurities. Their amount and composition vary over a wide range and depend on the type and quality of oilseeds and crude oil, the method of oil production and the process for refining vegetable oil [1-3]. To remove impurities from oils and fats, they use refining – purification of crude fat/oil from the substances accompanying triglycerides by hydration, neutralization, bleaching and deodorization [1, 4-6]. Any method of removal of phosphatides and free fatty acids should satisfy the maximum selectivity of interaction of these components with reagents. The processes of hydration and neutralization are performed so that to guarantee the highest rate of reactions, minimal interaction between reagents and glycerides, fast and complete separation of formed phases, and the maximum extraction of neutral fat from the products of hydration and neutralization [4, 6, 7]. In the technology of vegetable oil refining, the most frequent violation of the technological conditions of alkaline neutralization of free fatty acids is the violation of the temperature conditions of oil cooling before feeding of alkali [7, 8]. In this connection, it was important to examine the effect of the temperature factor on the cottonseed oil yield.

2. Methodology

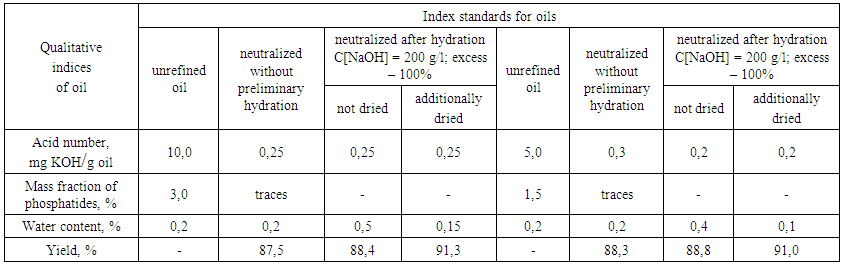

- Cottonseed oil refining was carried out in laboratory. We used crude cottonseed oil having acid value of 10 and 5 mg KOH/g oil. The acid number is a common parameter in the specification of fats and oils. It is defined as the mg of KOH required to neutralize the fatty acids present in 1g of oil [9, 10]. This indicates the degree of purity of fat, which is purer with lower values of this number. The concentration of NaOH required for neutralization was 200 g/l, excess – 100%. Neutralization was performed, and the percentage yield of neutralized oil was determined. There was also carried out the hydration of crude cottonseed oil with the aim to study the influence of the hydrated oil moisture on the neutralized oil yield.Water content or moisture content describes the quantity of water contained in an oil sample [11]. It is expressed in terms of the mass of water per unit mass of crude oil (often as a percentage). The measurement of water content was made using a known volume of crude oil and a drying oven.

3. Results and Discussion

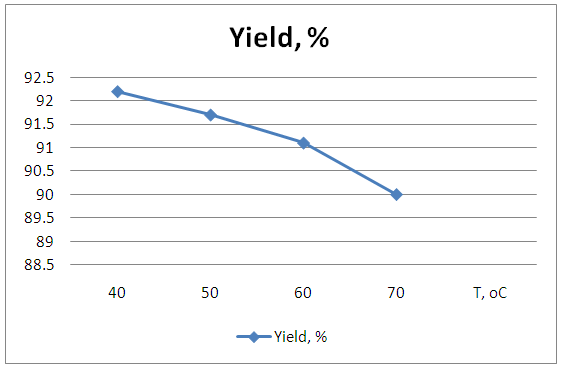

- It should be noted, that experimental studies performed even with periodic method of cottonseed oil refining, will clearly set the value of technological parameters for the neutralization of cottonseed oil [6, 12]. The former is a temperature of the oil supplied to the refining. It is particularly important that the oil after receiving it (when leaving the forpress) should be cooled immediately to temperature 20-22°C.The obtained results shown in the Fig. 1 confirm the inadmissibility of increasing the temperature during the neutralization of cottonseed oil, since this factor causes a transfer into waste of additional 2,2% of neutral oil.

| Figure 1. The influence of temperature on the yield of neutralized oil |

| Table 1. Effect of excessive moisture on oil refinability |

4. Conclusions

- During the process of neutralization of cottonseed oil, it was determined that an increase in the process temperature causes the transfer into waste of additional 2,2% of neutral oil. During neutralization of additionally dried hydrated oil, the cottonseed oil yield increases by 2,7-3,8%, whereas without drying – by no more than 0,5-0,9%.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML