-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2016; 6(5): 112-120

doi:10.5923/j.food.20160605.02

Effect of Ingredients Ratio on Physicochemical and Sensory Properties of Sorghum, Maize and Soya Protein Concentrate Blend Extrudates

Dlamini N. S., Solomon W. K.

Department Food and Nutrition Sciences, Faculty of Consumer Sciences, University of Swaziland, Luyengo, Swaziland

Correspondence to: Solomon W. K., Department Food and Nutrition Sciences, Faculty of Consumer Sciences, University of Swaziland, Luyengo, Swaziland.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This study was conducted to develop a sorghum-based ready-to-eat breakfast cereal and determine the effect of formulation on the physical properties and acceptability of the extrudates. Sorghum flour was blended with maize flour and enriched with soybean protein concentrate (SPC) at different proportions. The proportion of sorghum flour ranged from 50 to 90% whereas the proportion of maize flour and SPC ranged from 0 to 20%. Cocoa powder and sugar were kept constant at 5% each. Extrusion was done at barrel temperature of 140°C and screw speed of 290 rpm. The proportion of the ingredients affected the water solubility index (WSI) and water absorption Index (WAI) significantly (p<0.05). WAI increased with increase in the proportion of sorghum flour whereas the WSI index decreased with increase in proportion of sorghum flour. The Bulk density (BD) and expansion ratio (ER) were not significantly (P>0.05) influenced by the proportion of the ingredients. The results of the study revealed that sorghum-based ready to eat breakfast cereal can be acceptable and the most accepted sample was the control (90% sorghum flour) followed by the sample with 80% sorghum flour and 5% maize flour and 5% soy protein concentrate. The 5% additions of soy protein concentrate resulted in acceptable product and at the same time enrich the product with adequate protein level.

Keywords: Sorghum, Extrusion, Breakfast cereals

Cite this paper: Dlamini N. S., Solomon W. K., Effect of Ingredients Ratio on Physicochemical and Sensory Properties of Sorghum, Maize and Soya Protein Concentrate Blend Extrudates, International Journal of Food Science and Nutrition Engineering, Vol. 6 No. 5, 2016, pp. 112-120. doi: 10.5923/j.food.20160605.02.

Article Outline

1. Introduction

- The market share of ready-to-eat breakfast cereals and snacks are growing almost everywhere in the world [1, 2]. These foods are prepared from natural ingredients or components to yield products with specified functional properties and can be used as a vehicle for incorporating nutrients that have health benefits [3]. Sorghum (Sorghum bicolor (L.) Moenchis) has been the staple crop in many African countries for years. It is a semi-arid crop grown in most parts of the world and which has been explored in the production of many traditional and novel foods. It is the world’s fifth most important cereal crop after maize, wheat, rice and barley. The rate and extent of digestion of the starch in sorghum, particularly cooked sorghum, is low [4]. Thus sorghum seems to be a more sustained source of energy than, for example, maize making it suitable for people who are at risk from type II diabetes. A very important nutritional feature of sorghum grain is that many varieties contain substantial quantities of phenolic compounds that have strong antioxidant activity [5, 6]. However, sorghum has a low protein content and quality, particularly with respect to lysine [7]. An apparently unique feature of sorghum protein is that its digestibility is substantially reduced when the flour is wet cooked to make a food product such as a porridge or bread [8]. Consumption of sorghum in Swaziland is limited to traditional foods and has become monotonous to the consumers. Thus there is a need to diversify the utilization of sorghum through developing new products. As a carbohydrate source, maize is extensively used in the production of snack food by extrusion technology. Maize proteins are considered to have low nutritional quality because zein, the main protein fraction in maize, has low concentrations of the essential amino acids like lysine and tryptophan [9]. Food extrusion has been widely used to produce ready-to-eat cereals and snacks foods. Extruded snack products are predominantly made from cereal flour because of their good expansion characteristics. However, extruded food products produced from cereals tend to be low in protein and have a poor biological value because of their limited essential amino acid contents [10]. Many snack foods have low nutrient densities and are often fortified with proteins [11, 12]. Extrusion cooking is a short-time high-temperature cooking process during which food is subjected to high shear pressure at a temperature of up to 150°C for 20–30 s. Extrusion cooking is associated with improved protein digestibility and bioavailability of sulphur-containing amino acids [13, 14].Soy beans contain high quality proteins providing high biological value protein with all essential amino acids. It is also a good source of fibre and a rich source of minerals, especially calcium and magnesium. It has the ability to lower bad cholesterol, reduces risks of heart diseases and certain cancers. However, despite these nutritional and health benefits consumption of soy bean remains low because of the limited variation of soybean products. Among the many available protein-rich food sources, soya is one of the foods that have immense nutritional importance [3]. Addition of soybean can act as a good source of protein in formulated food products besides offering other functional, nutritional and health benefits. A sorghum, maize and soy concentrate blend can be used to produce a ready to eat breakfast cereal. The resulting blend improves the nutrition of the product in terms of the main components starch and protein. Studies on extruded products have been reported by blending sorghum with protein sources [15-22] or maize with protein sources [2, 3, 14, 19, 20]. However, report on sorghum-maize blend enriched with a protein sources is scanty in literature. The purpose of the study was to formulate a ready to eat breakfast cereal from sorghum-maize flour blend, enriched with soy protein concentrate and study the effect of the blending ratio on the physicochemical and sensory quality of the composite extrudates.

2. Material and Methods

2.1. Sample Preparation

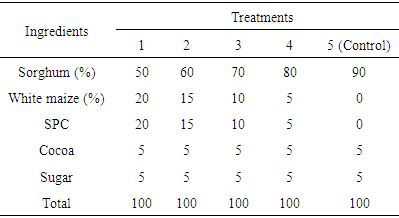

- Sorghum, white maize flour, soybean protein concentrate, cocoa powder and sugar were provided by the Swaziland Milling Company in Matsapha, Swaziland where the experiment was conducted. The ingredients were rationed at different proportions in percentages. The proportions used were based on preliminary studies and experience form similar products in the company. The percentages were then converted to kilograms and ingredients were weighed using a mass scale and mixed manually as shown in Table 1 for five different treatments.

|

2.2. Extrusion Cooking and Toasting

- A laboratory testing co-rotating twin-screw extruder (SYSLG30-IV, Jinan Saibainuo Food Machinery, Shandong, China) consisting of four independent zones of controlled temperature in the barrel was used to carry out extrusion cooking. The extruder was fed at a rate of 18 kg/hour. The temperature of zone 1, 2, 3 and 4 was set at 32°C, 38°C, 80°C and 140°C, respectively. The length to diameter ratio of the extruder barrel was 20:1 while the diameter of the screw was 30 mm. The screw speed was 290 rpm and screw axial distance was 26 mm. The pressure was at 6.5 mPa. After stable conditions were achieved the extrudates were collected beneath the cutter and transferred to drying pans for toasting. The extrudates were arranged on a tray and subsequently toasted in an air convection oven (Novosibirisk-2, Cibelectroterm, Russia) at the temperature of 120°C for an hour. The samples were allowed to cool before packaging in a flexible material and kept till further use. Dried samples were stored in air tight plastic containers at room temperature until analysis.

2.3. Determination of Proximate Composition

- The samples were subjected to proximate (moisture, protein, fiber, ash, fat and carbohydrate) analysis using AOAC methods [25]. Moisture Determination was carried out by oven drying method. The sorghum RTE breakfast cereal samples were first milled using a cyclone sample mill. The samples were dried using convective air oven set at 105 ± 2°C for 3 hours. Crude protein was done by the Kjeldahl method in a Kjeltec system with acid (sulphuric acid) digestion of the sample and then an alkaline (sodium hydroxide) distillation using a nitrogen-to-protein conversion factor of 6.25. Crude fat was determined using hexane extraction in a Soxlet apparatus. Crude fibre was determined as the combustible and insoluble organic residue obtained after the sample was subjected to acid digestion and then alkaline distillation. Ash was quantified as the inorganic residue present after incineration at 550C until loss of organic matter. Carbohydrate content of food was determined by ‘difference’. That was by deducting the moisture, ash, protein, fiber and fat from the total weight.

2.4. Bulk Density

- The bulk density was determined by measuring the actual dimension of the extrudates. The diameter of the extrudates were measured using a digital vernier caliper (JT 302N, England), while the length was measured with the aid of a metric ruler. The weights per unit length of the extrudates were determined by weighing measured lengths. The bulk density (BD) was then calculated using the following formula:

Where: BD = Bulk density (g/cm3)d = Diameter of the extrudate (cm)L = Length per gram of the extrudate (cm/g).

Where: BD = Bulk density (g/cm3)d = Diameter of the extrudate (cm)L = Length per gram of the extrudate (cm/g).2.5. Expansion Ratio

- The ER of the dried extruded rod was measured as the ratio of the cross-sectional area of the extruded rods to that of the die hole through which it was extruded [24].

2.6. Water Absorbing Index and Water Solubility Index

- Water absorption index (WAI) of the flour and extruded product were determined according to AOAC [25]. A 1.25 g sample was placed in 20 mL centrifuge tube and suspended in 15 mL distilled water. The sample was incubated into shaking water bath at about 25°C for 30 minutes and was centrifuged at 3000 g for 5 minutes. Mass of the sample was determined before and after decantation of the clear supernatant of centrifugation. The WAI was calculated as grams of adsorbed water per gram of dry sample mass (1.25 g). The clear supernatant of the centrifugation was transferred into pre-dried (105°C) and weighed glass beaker (50mL) for the estimation of the water solubility index (WSI). The supernatant preserved from WAI measurement was evaporated at 105°C overnight. The WSI was calculated as a percentage of dry residue to the original mass used to estimate WAI. The result was expressed as a percentage.

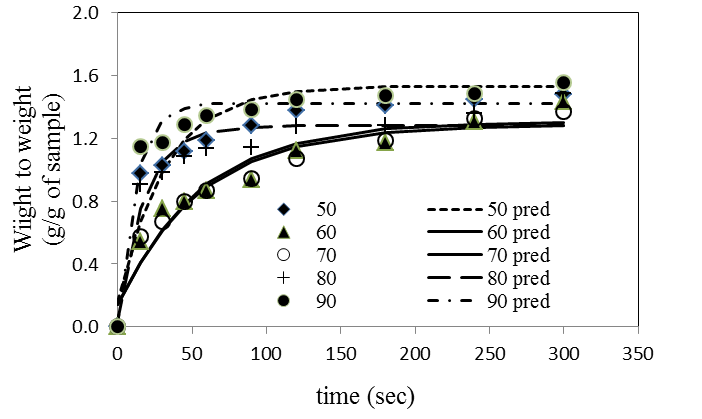

2.7. Rehydration test

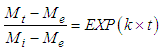

- About 2 g samples were kept in empty beakers and conditioned to the rehydration temperature of 25C in hot air oven before each test [26, 27]. After conditioning, 100 ml whole milk at 25C was poured into the beakers and then placed in constant temperature water bath (Model labcon, Lab marketing services, Malraisburg, South Africa) set at 25C (± 1C). The rehydration temperature falls in the ranges used in earlier moisture uptake studies of breakfast cereals [28-32]. At time intervals ranging between 15 to 60 seconds, the beakers were removed from the water bath and drained and the samples were weighed using analytical balance. The samples were then dried in hot air oven at 130C for 4 hrs based on preliminary studies and literature [33-34] to determine the moisture content. Each test was repeated to determine mean values. The following equation was used to fit the rehydration data.

Where;Me = equilibrium mass gain (g/g); Mt = mass gain at time, t (g/g); Mi = initial mass (g/g); t = hydration time (s)k= hydration rate constant (s-1).

Where;Me = equilibrium mass gain (g/g); Mt = mass gain at time, t (g/g); Mi = initial mass (g/g); t = hydration time (s)k= hydration rate constant (s-1).2.8. Sensory Evaluation

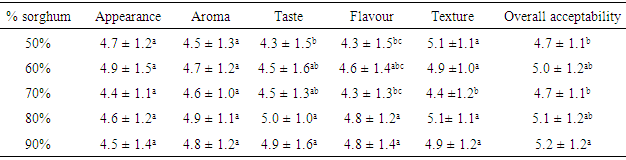

- Sensory evaluation was carried out using a panel made up of 50 members, drawn from staff and students of the University of Swaziland, Luyengo Campus. Attributes such as appearance, aroma, taste, flavor, texture and overall acceptability were evaluated. An acceptance test was conducted whereby each panelist was presented with a seven point hedonic scale form (1 = dislike extremely 2 = dislike very much 3 = dislike, 4 = neither like nor dislike, 5 = like, 6 = like very much, 7 = like extremely) to indicate their level of liking of the product. Samples were served at 15 g per sample in a randomized order. Data obtained was analyzed using Statistica version 8 in order to determine the mean scores for the degree of liking among the samples.

2.9. Data Analysis

- All data obtained was analysed using Statistica Version 8. The experiment was replicated three times and means and standard deviations were reported in all the results. ANOVA was used to compare means and significance was accepted at 0.05 probability level.

3. Results and Discussion

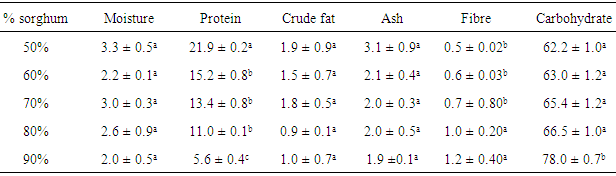

3.1. Moisture Content

- There was no significant difference (p > 0.05) between mean moisture content the samples from the different treatments (Table 2). Sample with 50% sorghum had the highest moisture content with a mean of 3.3 and sample with 90% sorghum had the lowest moisture content with a mean of 2.0. The high moisture content of sample with 50% sorghum may be due to the high amount of soybean protein concentrate added which resulted in a high protein content thus increased moisture absorption while the low moisture content of sample with 90% sorghum could be due to the exclusion of soybean protein concentrate in the formulation. Low moisture content of the sorghum RTE breakfast cereal is important because it will help in extending the shelf life by inhibiting the development of contaminating microorganisms whose growth and activities are favored by presence of moisture.

|

3.2. Proximate Composition

3.2.1. Protein

- The crude protein content of samples under different treatments are given in Table 2. There was a significant difference (p < 0.05) in the protein content between samples. There was also a significant difference (p < 0.05) between sample with 90% sorghum and the other samples. The sample with 50% sorghum had the highest protein content with a mean of 21.9 and sample with 90% sorghum had the lowest protein content with a mean of 5.6. The variations in the crude protein content may be due to the ingredients used in their formulations. The sample containing a high amount of soybean protein concentrate (sample with 50% sorghum) had significantly (p<0.05) higher protein content than other samples with medium to lower levels of soybean protein concentrate. This implies that addition of soybean protein concentrate to the formulations increased the protein content of the cereal. Therefore, blends of sorghum flour, maize flour and soybean protein concentrate produced nutritious ingredients suitable for a ready- to-eat breakfast cereal with good retention of lysine.

3.2.2. Crude Fat

- The crude fat content of samples under different treatment are presented in Table 2. There was no significant difference (p > 0.05) between all samples. The sample with 50% sorghum had the highest crude fat content with a mean of 1.89 and samples with 80 and 90%% sorghum had the lowest comparable crude fat content with a mean of about1.00. The fat content increased with addition of soy protein concentrate and ranged from 0.9 to 1.9%, suggesting that they are good sources of a low fat diet needed by the body for optimum health but does not meet acceptable macronutrient distribution range (AMDR) for total fat intake which ranges between 20% and 35% of energy. This may probably be due to the use of de-fatted soybean concentrate and the low fat content of both sorghum and maize flours.

3.2.3. Ash

- There was no significant difference (p > 0.05) in the ash content between all samples (Table 2). The ash content which is the residue remaining after destroying the organic matter, ranged from 1.9 to 3.1%. The sample with 50% sorghum had the highest ash content with a mean of 3.1 while sample with 90% sorghum had the lowest ash content with a mean of 1.9. Samples with high maize flour and sorghum flour contents had the highest values. This could be due to the extrusion process that concentrated the organic materials of the starch in the formulations. The samples contained sufficient amount of ash implying that they are rich in mineral elements.

3.2.4. Crude Fiber

- There was no significant difference (p > 0.05) between sample with 50, 60 and 70% sorghum (Table 2). However they were significantly different (p < 0.05) from those with 80 and 90% sorghum. The sample with 90% sorghum had the highest crude fibre content with a mean of 1.2 implying that addition of sorghum ingredient to the breakfast cereal increased their fibre contents and the sample with 50% sorghum had the lowest crude fibre content with a mean of 0.5. The sorghum-based RTE breakfast cereal make them to have a great potential for application as diabetic food, because of the fibre source in their formulation that could be modified to generate a near perfect recipe for production of diabetic snacks.

3.2.5. Carbohydrate

- There was a significant difference (p < 0.05) between the sample with 90% sorghum and the other samples (Table 2). Sample with 90% sorghum had the highest carbohydrate content with a mean of 78% while sample with 50% sorghum had the lowest carbohydrate content with a mean of 62.2%. This implies that sorghum-based breakfast cereals are good sources of energy needed for normal body metabolism.

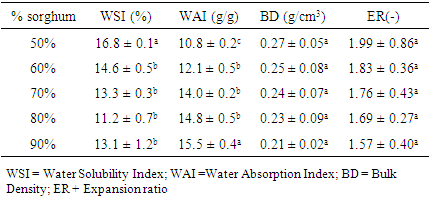

3.3. Water Absorption Index

- The Water absorption index (WAI) is an indicator of the ability of flour to absorb water. Water is absorbed and bound to the starch molecules inducing change in the starch molecule structure [35, 36]. WAI was significantly (p<0.05) influenced by the composition of the ingredients (Table 3). WAI increased with increase in proportion of sorghum flour and with decreased soya flour. The sample with the highest water absorption index was sample with 90% sorghum with a mean of 15.5 and the sample with the lowest was sample with 50% sorghum with a mean of 10.8.

|

3.4. Water Solubility Index (WSI)

- Water Solubility Index (WSI) is related to the quantity of soluble molecules which is associated with the conversion of starch during extrusion. There was a significant difference (p < 0.05) in WSI among samples under different treatments (Table 3). WSI decreased with increase in sorghum flour content and decrease in maize flour and SPC content. The sample with 50% sorghum had the highest WSI with a mean of 16.8 while the lowest was sample with 80% sorghum having a mean of 11.2. At lower WSI there is minor degradation of starch and such condition leads to less numbers of soluble molecules in the extrudates. At a higher water solubility index such as in the sample with 50% sorghum, there is higher degradation of starch leading to more number of soluble molecules in the extruder. The difference in the WSI is associated with the difference in the extent of starch degradation in maize and sorghum flour [36]. Studies reported increased WSI with increase in cowpea content in sorghum-cowpea blend extrudates suggesting that WSI was not only due to starch content but also due to water-soluble components, like proteins [16]. The negative correlation of WAI and WSI has been reported in earlier studies. A positive interaction effect between soy and sorghum has also been reported which is attributed to their protein content that increased the WSI.

3.5. Bulk Density

- There was no significant difference (p > 0.05) between all samples (Table 3). Sample with 50% sorghum had the highest bulk density with a mean of 0.27 while sample with 90% sorghum had the lowest bulk density with a mean of 0.21. These values are in the ranges reported in literature for sorghum-based extrudates [19, 22]. Addition of soybean protein concentrate decreased lateral expansion and increased bulk density in the samples. A similar trend of increase in bulk density was reported in sorghum extrudates containing increasing amounts of cowpea flour and other protein sources [16, 18]. Addition of protein sources to sorghum-based extrudates has been reported to increased piece density [19, 22]. The authors attributed the decrease in the bulk density to the dilution effect of soya on starch, which may affect the extent of starch gelatinization. Although addition of soy-flour is nutritionally desirable since it increases the protein content of the extrudates, its reduction of the expansion is detrimental for products like puffed snacks where low density and being porous is an important quality attribute.

3.6. Expansion Ratio

- The expansion ratio of extrudates under different treatments are presented in Table 3. There was no significant difference (p>0.05) in the expansion ratio due to the different proportions of the ingredients. However, there was a general decreasing trend in the expansion ratio due to increase in sorghum and decrease in CSP and maize flour content. The same trend was reported for extrudates made from sorghum-maize blends enriched with defatted soy flour and whey protein isolate where increased in corn flour resulted in increased expansion ratio [19]. The authors argued that increasing the level of corn flour and decreasing the level of sorghum protein will facilitate formation of starch matrix and increase water tapping thus increasing expansion. An earlier study reported a decreases in expansion ratio of with increase sorghum content and associated the effect to high starch-protein interactions and formation of intermolecular dislphide bonds in the protein upon heat treatment that renders swelling of extrudates and low expansion [18]. The high fiber content of sorghum could also be a reason for reduced expansion [19]. The results in Table 3 indicate that expansion and bulk density are not related as expected where high density to be associated with low expansion. Earlier studies had reported the trend observed in this study. Such trend was attributed to the fact that expansion ratio considers expansion only in the direction perpendicular to extrudate flow, while unit bulk density considers expansion in all directions [15, 37].

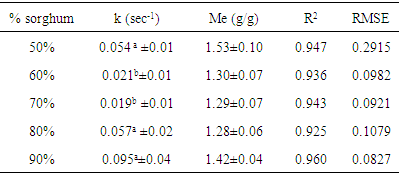

3.7. Rehydration Kinetics in Milk

- The rehydration data of extrudates processed using different compositions are presented in Fig. 1. Hydration occurred at higher rate at the early stages (45 to 60 sec) of the rehydration process followed by decreasing rate and finally tending to cease at prolonged hydration time indicating the rehydration approached equilibrium condition. As the process of hydration proceeds, the water content of the extrudates increased thereby decreasing the water absorption rate. Similar characteristic water absorption trends have been reported for ready-to-eat and puffed breakfast cereals immersed in water or milk [28-32, 34].

| Figure 1. Predicted and experimental values weight gain of extrudates with different sorghum concentration |

|

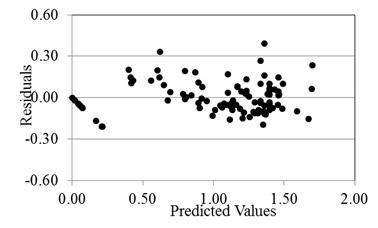

| Figure 2. Distribution of residuals |

3.8. Sensory Evaluation

3.8.1. Appearance

- There was no significant difference (p > 0.05) between all samples (Table 5). This could be attributed to the same die plate and the same type of ingredients used except for the control which lacked soybean protein concentrate and maize flour. The sample which was most accepted by consumers according to appearance was sample with 60% sorghum with a mean of 4.9 and the least accepted was sample with 70% sorghum with a mean of 4.4.

|

3.8.2. Aroma

- There was no significant difference in the mean aroma (p > 0.05) between all samples (Table 5). The sample that was most accepted by consumers was sample with 80% sorghum with a mean of 4.9 and the least accepted was sample with 50% sorghum with a mean of 4.5. The only more pronounced aromatic ingredient in all samples was the cocoa powder. As the percentage of cocoa powder was kept constant in all samples, no significant differences of aroma between samples were expected. Raw materials undergo physical and chemical modifications such as gelatinization, breakdown of starch, denaturation of proteins and interactions between them resulting from high temperatures and pressure with a shearing effect during extrusion. These changes affect sensory properties such as aroma of products [41].

3.8.3. Taste

- There was a significant difference (p < 0.05) between sample with 50% sorghum and sample with 80% sorghum (Table 5). There was a significant difference (p < 0.05) between samples with 50% sorghum and sample with 90% sorghum. The sample with 80% sorghum was most accepted by consumers with a mean of 5.0 and the least accepted was sample with 50% sorghum with a mean of 4.3. Taste comprises of sweet, salty, bitter. Only the sweet and bitter taste profiles are applicable in this case. There were significant differences between samples while the same amount of sugar (5%) was added in all treatments. On one hand it can be due to the different amounts of milk added by the panelist when evaluating the breakfast cereal sample. On the other hand it could be due to individual differences between panelists in perception of sweetness. The milk temperature was playing a role as well. The individual differences are especially true for bitterness as according to some surveys/investigations only 30% of the people have a sense for bitterness. One more reason could be, although all extrusion parameters were kept constant there were some variations in the temperature of some extruder zones or water dosage into the extruder barrel that caused local overheating which then resulted to the bitter taste [41].

3.8.4. Flavour

- There was a significant difference (p < 0.05) between sample with 50% sorghum and sample with 80 and 90% sorghum (Table 5). There was also a significant difference (p < 0.05) between sorghum with 70% sorghum and sample with 80 and 90% sorghum. There was no significant difference (p > 0.05) between other samples. The samples that were most accepted by consumers were samples with 80 and 90% sorghum, at a mean of 4.8. The least accepted were samples with 50 and 70% sorghum with means of 4.3. Sorghum has got a specific flavor profile that is hard to mask, especially in case of fruit flavourants but this grain is perfectly combining with cocoa flavor and that is the reason it was used as a flavorant. Samples with 50, 60 and 70% sorghum contain maize flour and soybean protein concentrate where the cocoa flavour is probably masked by those ingredients and became less intense. Furthermore, the sorghum flavour profile was minimized at the high pressure zone of the barrel since most chemical reactions occur in the high-pressure zone of the barrel. Since most chemical reactions occur in the high-pressure zone of the barrel, thermally labile compounds such as flavors and vitamins may be injected immediately before the die to minimize exposure to heat and shear [42]. This confirms that indeed the high pressure zone of the barrel has an effect on flavor.

3.8.5. Texture

- There was a significant difference (p < 0.05) between sample with 70% sorghum and sample the other samples (Table 5). The most accepted by consumers were the sample with 50 and 80% sorghum at means of 5.1 and least accepted was sample with 70% sorghum with a mean of 4.4. Texture is a very complex sensory attribute. It influences a flavour release in the mouth during mastication (chewing) when combined with a fluid like milk. The human textural preferences and perceptions are again very individualized. In case of breakfast cereals with milk staying crunchy longer is probably generally preferred. That explains the higher than expected results for the samples with 50 and 60% sorghum that contain higher levels of protein from maize flour and especially soy protein concentrate. During extrusion the protein was denatured, forming a protein network. That protein network entrapped the gelatinised starch molecules resulting in a crunchier texture. Moreover, a study reported that an increase in temperature of maize starch made it possible to obtain a texture with higher porosity and greater fragility [43]. These changes in product characteristics are a result of modification of the starch and protein components under high temperature.

3.8.6. Overall Acceptability

- There was a significant difference (p < 0.05) between sample with 90% sorghum and all other samples (Table 5). The samples that were most accepted by consumers were the sample with 80% sorghum at a mean of 5.1 and the sample with 90% sorghum (the control) at a mean of 5.2. The least accepted were samples with 50% and 70% sorghum at mean 4.7. This therefore means that the formulation consisting of 90% and 80% sorghum would be the most acceptable product to consumers.

4. Conclusions

- The effect of formulation on the physical properties and acceptability of the sorghum-based ready-to-eat extrudates was studied. The physicochemical and sensory attributes were significantly influenced by the composition of the extrudates. WAI increased with increase in the sorghum flour composition whereas WSI and bulk density decreased with increase in sorghum flour content. The sample with 90% sorghum was most accepted by consumers followed by that with 80% sorghum and soy 5% protein concentrate. The water absorption and hydration kinetics data also indicated that soy concentration should be used at low level. This indicates that the amount of soy protein concentrate added to the breakfast cereal should be kept low (about 5%) because it has an effect on the sensory attributes of the breakfast cereal. However, this low level enriches the product with adequate protein.

ACKNOWLEDGEMENTS

- The authors wish to acknowledge the Swaziland Milling Company for supplying the raw materials and allowing their facility to conduct extrusion tests.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML