-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2016; 6(4): 87-101

doi:10.5923/j.food.20160604.03

Formulation of Maize – Based Complementary Porridge Using Orange - Fleshed Sweet Potato and Bean Flour for Children Aged 6-23 Months in Kachabira Woreda, Southern Ethiopia

Yibeltal Jemberu1, Menen Zegeye2, Pragya Singh2, Hiwot Abebe2

1Action Contre La Faim (ACF), Addis Ababa, Ethiopia

2School of Nutrition, Food Science and Technology, Hawassa University, Hawassa, Ethiopia

Correspondence to: Yibeltal Jemberu, Action Contre La Faim (ACF), Addis Ababa, Ethiopia.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Micronutrient deficiency, especially vitamin A, among infants is a major nutritional concern in developing countries. The aim of this study was to improve the vitamin A contents of the staple maize-based complementary porridge. For this study experimental study design was used. It comprised formulation of three maize based (Zea mays L.) complementary porridges using flours of haricot bean (Phaseolus vulgaris) and OFSP (Ipomea batatas L.). The maize grains were soaked overnight and roasted sparingly, the beans were soaked overnight and roasted for 15 minutes and fresh OFSP roots were sliced and sundried to produce chips. The control complementary porridge was prepared from 100% raw maize flour. The proportions (%) of maize (processed): bean: OFSP flours were 50:25:25, 45:25:30 and 40:25:35 for the three formulated porridges. Sensory evaluation was done at laboratory level and at community level. Complementary porridges were analyzed for proximate composition using AOAC (2000) methods, β-carotene content was determined using an open column chromatography method and viscosity values (cp) were determined at 20% (w/v) dry matter concentration using a Brookfield (Model DVI+) viscometer. Results revealed that all the formulated porridges were organoleptically accepted. On fresh weight basis, the complementary porridges in which OFSP was incorporated provided significantly (p<0.05) higher vitamin A (30.45 μg RAE/- 85.52 μg RAE per100 Kcal) than the control which provided 0.00 μg RAE per100 Kcal. The three formulated porridges were also observed to have significantly (p<0.05) higher values of crude protein, but significantly (p<0.05) lower value of viscosity compared to the control. Incorporating flours of OFSP and haricot beans in maize flour is a potential way to increase the nutritive value of traditional complementary foods prepared from maize in the study area.

Keywords: Micronutrient deficiency, Vitamin A, Complementary foods, Orange fleshed sweet potato, Haricot bean, Kachabira Woreda, Zea mays L, Phaseolus vulgaris, Ipomea batatas L, Organoleptically

Cite this paper: Yibeltal Jemberu, Menen Zegeye, Pragya Singh, Hiwot Abebe, Formulation of Maize – Based Complementary Porridge Using Orange - Fleshed Sweet Potato and Bean Flour for Children Aged 6-23 Months in Kachabira Woreda, Southern Ethiopia, International Journal of Food Science and Nutrition Engineering, Vol. 6 No. 4, 2016, pp. 87-101. doi: 10.5923/j.food.20160604.03.

Article Outline

1. Introduction

- Micronutrient deficiencies are common in many developing countries and are typically due to inadequate food intake, poor dietary quality, poor bioavailability and/or the presence of infections. Micronutrient status can affect health outcomes such as child survival, growth and development either directly or indirectly through interactions with each other increasing food intake owing to improved appetite, and reducing morbidity [1]. Vitamin A deficiency (VAD) is a major nutritional concern in poor societies, especially in lower income countries. Xerophthalmia is the most specific VAD, and is the leading preventable cause of blindness in children throughout the world [2]. In preschool children; VAD can lead to increased risk of mortality and morbidity and to blindness [3]. It is also known to impair numerous functions and, as a result, can lead to many health consequences to which infants, young children and pregnant women appear to be at greatest risk [2]. Among the deficiencies of vitamins and minerals examined globally, the largest disease burdens were attributed to vitamin A and zinc deficiencies. Vitamin A deficiency in newborn babies, infants, and children resulted in about 6% of under-5 deaths, 5% of under-5 DALYs, and 1·7% of total DALYs [4]. Africa has the greatest number of preschool-age children affected with night blindness (2.55 million) which corresponds to almost half of the children affected in the world [2]. In Ethiopia, vitamin A deficiency continues to be a major public health problem despite the various intervention measures since 1989 [5]. The fifth nutrition situation report of the Standing Committee on Nutrition of the United Nations indicates that the prevalence of xerophthalmia in Ethiopia is the highest in the world [7]. In addition above 6,000,000 pre-school children are estimated to have serum retinol <0.70 μmol/l indicating that vitamin A deficiency is a severe public health problem [2]. A result of a national survey that was conducted in 2005 in nine of the 12 administrative zones of Ethiopia where EOS has been launched show the average prevalence rate for Bitot’s Spots in pre-school children to be 1.7% [14]. Another study estimated a 33.9% national prevalence of subclinical VAD in children 0-24 months old [6].The introduction of foods like meat, fish, poultry and eggs in the diet of infants and young children is late and only few consume them. At the age 6-23 months, only one in ten children consume meat, fish, shellfish, poultry or eggs [9].The three most common strategies for combating VAD are distribution of vitamin A supplements, food fortification, and food-based approaches that aim to increase access to and intake of vitamin A-rich foods [10]. Among these strategies, dietary diversification/modification may be more sustainable, economically feasible, and culturally acceptable than supplementation or fortification and can be used to alleviate several micronutrient deficiencies simultaneously without risk of antagonistic interactions [11].OFSP have emerged as one of the most promising plant sources of vitamin A and stand to be a cheaper and a complementary source of vitamin A to the rural and urban poor families. Sizeable studies conducted in other countries have given evidence that OFSP could play an imperative role in mitigating the impacts of VAD in populations where the problem is considered to be a significant public health importance. The bio-efficacy study recently completed in South Africa has demonstrated that the daily addition of as little as 100 g of OFSP to the diet could prevent vitamin A deficiency in children [12]. Orange Fleshed Sweet Potato (OFSP) has not been incorporated in the standard complementary feeding recipes recommended for children 6-23 months old recommended by the Ministry of Health of Ethiopia [13]. The present study was, therefore, one of the first of its kind in assessing the utilization of OFSP for the formulation of complementary food for Ethiopian infants and young children.

2. Materials and Methods

2.1. Description of the Study Area and Period

- The study was conducted at Kachabira woreda which is one of the 77 Woredas of Kembata Tembero Zone. Kembata Tembero Zone is bordered on the South by Semien Omo, on the North West by Hadiya, on the North by Gurage, on the East by the Oromia Region, and on the South East by Badawacho, an exclave of the Hadiya Zone. The major produced crops in the Zone include maize, sweet potato, taro, haricot bean, enset, sorghum, teff, ginger and coffee [15]. Kachabira Woreda has an estimated area of 277.5 square kilometers; this Woreda has an estimated area of 277.5 and estimated population density of 618.7 people per square kilometer, which is greater than the Zone average of 429.40. Nearly above 85% of its population is rural [16]. Laboratory level sensory evaluation and maternal acceptability tests were carried-out on May 11-13, 2011 and July 16-20, 2011 respectively. Chemical analysis of food was conducted in Ethiopian Public Health Institute (EPHI) in November, 2011.

2.2. Selection of Raw Materials

- Preliminary work was carried out to survey foods commonly consumed by children 6-23 months of age in the area. This information was obtained through informal interviews, market surveys and documents on the livelihood profiles of the study area. Accordingly, maize (Zea mays L) was selected as a staple ingredient while haricot bean (Phaseolus vulgaris), and orange fleshed sweet potatoes (Ipomoea batatas) was supplementary ingredients to formulate complementary foods for the present study. Mature OFSP roots were obtained from Wondogenet, one of the sites where the crop has been introduced by CIP. While haricot bean and maize seeds were purchased from local market at Shinshicho town of the Kachabira Woreda.

2.3. Chemicals and Reagents

- All chemicals and reagents used in laboratory analyses were of analytical grade.

2.4. Processing Ingredient Flours

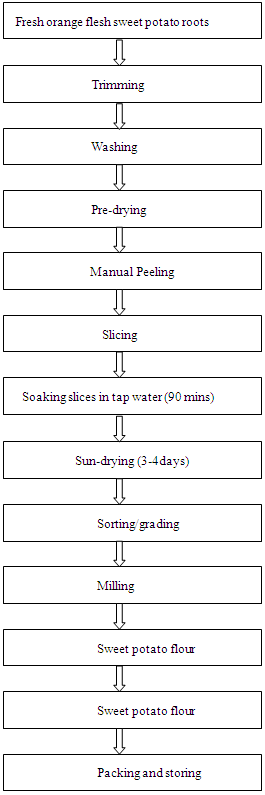

2.4.1. OFSP Flour

- Mature, fresh, healthy and medium-sized roots of same OFSP variety (Tula) were selected. A knife was used to trim all the unwanted portions of the roots. A hand brush was used to thoroughly scrub and wash the skin of roots in clean tap-water. Afterwards, the roots were peeled using a knife and a slicer was used to cut the roots into thin pieces that dry fast. Slices were soaked for 90 minutes in excess tap-water (twice the volume of slices) before the water was drained-off and slices were sun-dried for 3-4 days. The drying chips were continuously kept turning and thinly spread while being dried chips were dried to moisture content of 12%. This was subjectively determined if it was not possible to squeeze out moisture from pieces, the chips were brittle and break easily without being knead-able. Discoloured and under-dried chips were sorted by hand and removed. Dried chips were milled using a traditional hammer made from stone to the required particle size. The flour was allowed to pass through a laboratory test sieve (AXEL KISTNER, London, England) of 1.00 mm aperture size. The OFSP flour sample was manually packed in black plastic polythene bags that were then sealed using a heat sealer. Packed OFSP flour samples were stored in cool dry place.

| Figure 1. Flow chart of flour preparation from orange fleshed sweet potato [17] |

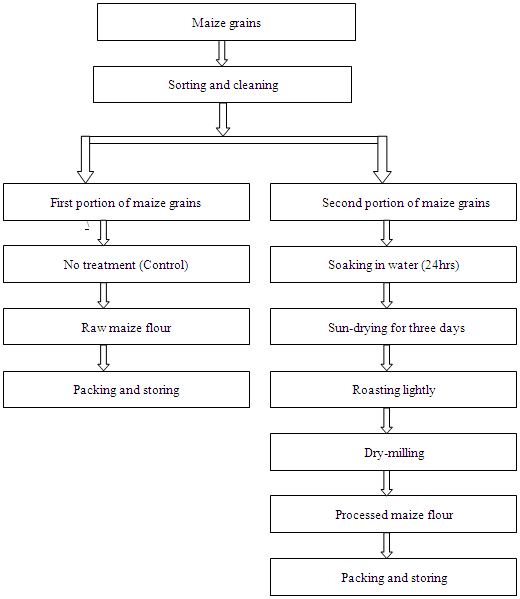

2.4.2. Maize Flour

- Maize grains were winnowed and hand sorted to remove stones, leaves, stalks, grains that were broken, undersized or immature. Following this, the cleaned maize grains were divided into two portions. The first portion of maize grains was not subjected to any form of treatment and was used as a control. The second portion of maize grain sample was hand washed thrice with tap water. It was later soaked at room temperature for 24 hours in excess tap water (three times the volume of the maize grains). The steeping water was drained off, the maize grains were washed three times using tap water and sun-dried for three days. The dried maize grain sample was then roasted sparingly in order to improve the taste and odor. Both samples of maize grains were separately milled using a commercial hammer mill to pass through a 1.00 mm aperture size laboratory test sieve (AXEL KISTNER, London, England) to obtain a fine powder. The milled samples were then separately packed in airtight polythene plastic bags. The bags were stored at room temperature until laboratory analysis.

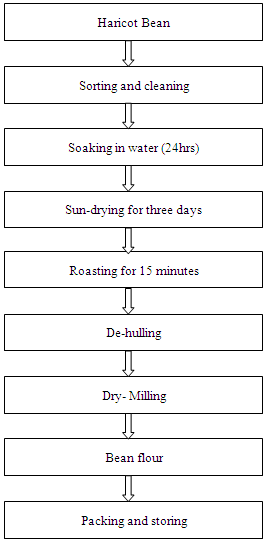

2.4.3. Bean Flour

- Defective grains (with holes), stones, dried pods and other debris were removed from the beans. The beans were then washed and soaked at ambient temperature in tap water for 24-hours. This was done to remove some of the anti- nutritive factors such as trypsin inhibitors and haemaglutinins present in the beans. The soaked beans were then placed in a nylon sieve and allowed to drain. The beans were then sun-dried after which they were roasted for 15 minutes to further reduce anti- nutritive factors in beans, improve the flavor, increase digestibility and shorten cooking time of the final product. The roasted beans were de-hulled using a commercial de-huller and winnowed to remove the bran from the beans. The bean sample was afterwards milled into flour and passed through a laboratory test sieve (AXEL KISTNER, London, England) of 1.00 mm aperture size to obtain smooth and consistent particle sizes. The bean flour sample was manually packed according to the required weight of flour in plastic polythene bags. The bags were sealed using heat sealer and stored at room temperature till it was used for analysis.

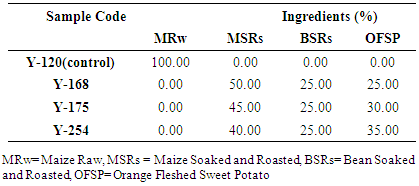

2.5. Composite Flour Formulation

- The proportions of OFSP flour was determined on the basis of the recommended daily intakes (RDI) for vitamin A for children 6-23 months old [19] and the guideline for fortification of complementary foods [20]. The RDI for vitamin A was established to be 400 mg RE/day for children 6-23 months. It is suggested that when a food is supplemented with one or more nutrients, the total amount of the added vitamin(s) and/or mineral(s) contained in 100 g of the food on a dry matter basis should be at least 2/3rd of the reference daily requirements [20]. For the current study the proportion of OFSP flour was determined in such a way that the vitamin A content ( as mg RE - on dry weight basis) of – OFSP composite flour be above 90% of the RDI for children 6-23 months. Accordingly the level of OFSP in the composite flour mix (% on dry weight basis) was made to be 25%, 30% and 35%.

| Figure 2. Flow chart for the processing of maize flour [18] |

|

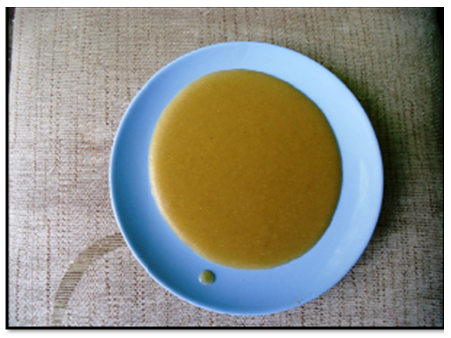

2.6. Preparation of Complementary Porridges

- Ÿ A 100 grams of ingredients with different proportion were put and mixed together in three bowls: orange fleshed sweet potato, soaked and roasted maize, soaked and roasted bean flour and one bowl with raw maize flour onlyŸ The ingredients in each bowl were mixed until they became uniform and sieved by similar sieve having aperture size of 1.00 mm Ÿ Use about 2-3 coffee cups (250 ml) of boiled water in oven and add ingredient while starring it till it become semi soildŸ One teaspoon (5g) of vegetable oil was added and cooked for 15 minutes then put out of the ovenŸ Finally, Iodized salt was addedŸ Immediately after cooking, the porridge samples were transferred to aluminium pans Ÿ The samples were sealed in polyethylene bags and frozen at –4°C until freeze-dried for further analysis.

| Complementary porridge coded Y-120 (100% maize flour (control)) |

| Complementary porridge coded Y-168 (50% maize flour; 25% bean flour; 25 % OFSP flour |

| Complementary porridge coded Y-175 (45% maize flour; 25% bean flour; 30 % OFSP flour |

| Complementary porridge coded Y-254 (40% maize flour; 25% bean flour; 35 % OFSP flour |

| Figure 3. Flow chart for the processing of bean flour [18] |

2.7. Sensory Evaluation and Nutrient Analysis

2.7.1. At the Laboratory Level

- Developed products were evaluated thrice for their sensory characteristics by a panel of 15 subjects. The panelists were randomly selected from students and staff of Hawassa University, School of Nutrition, Food Science and Technology. Random selection was made from a list of candidates who were willing to take part in the sensory evaluation activity. Individuals who were apparently not healthy were, however, excluded. Sensory evaluation was done when the porridge attained the normal temperature at which it was normally consumed at household level. Porridge in identical glass bowls were coded in three digit numbers for the presentation to panels of judges. A glass of tap water was provided for panelists so that they rinse their mouths between samples. Panelists were instructed to score each porridge sample for appearance, color, flavor, taste, consistency/ mouth feel and overall acceptability using a nine point hedonic scale (9 like extremely, 8 = like very much, 7= like moderately, 6 = like slightly, 5= neither like nor dislike, 4= dislike slightly, 3= dislike moderately, 2 = dislike very much and 1= dislike extremely) [21].

2.7.2. At community Level (Maternal Acceptability)

- Community level acceptability test of the four different samples of porridges was carried out by 50 mothers-child pairs who were randomly recruited from among mothers with a child 6-23 months. Each participant tested the three formulated complementary porridges as well as the control porridge once a day for three consecutive days. On a test day, each mother was given only two complementary porridge samples (100 g portion of each) to her child in the morning and the remaining two complementary porridges were tested in the afternoon session in the same manner. Mothers evaluated the porridges for color, appearance, flavor, taste, consistency/ mouth feel and overall acceptability using five-point hedonic scales, where 5 = like very much, 4 = like a little, 3 = neither like nor dislike, 2 = dislike a little and 1 = dislike very much [22]. Three people were employed to interview the mothers and write their ratings for the sensory attributes. Mothers were instructed to test samples and rinse their mouths with water between samples to minimize any residual effect.

2.7.3. Chemical Analysis of Complementary Porridges

- Nutrient contents of the four products were analyzed. All determinations were carried out in triplicate and all chemicals and reagents used in laboratory analysis were of analytical grade. Polyethylene bags were used for the collection and storage of the samples. Food samples were kept in refrigerators until analysis was done. These are crude protein, crude fat, crude fiber, total ash and moisture were analysed using AOAC (2000) [23] and total carbohydrate by difference. Open column chromatography method was used to determine the values of β-carotene [24].

2.8. Viscosity Measurement of Complementary Porridges

- The porridges were prepared in glass beakers in a 20% (w/v) concentration. Cooked porridge was then placed in a water bath maintained at 40°C (the temperature at which viscosity measurement was taken). Brookfield Viscometer (Model DVI+) was used to measure the porridge viscosity (in centipoises, cps) using spindle number 4 at a shear rate of 50 revolution per minute (rpm).

2.9. Statistical Analysis

- Data was analysed by the one way analysis of variance (ANOVA) model using the SPSS software program, version 16.0.0 for windows. Fisher’s Least Significance Difference (LSD) test was used to determine the significance of mean differences of scores for color, appearance, flavor, taste, consistency /mouth feel and overall acceptability. The level of statistical significance was set at p<0.05. The results were reported as an averaged value (mean ± standard deviation).

2.10. Ethical Consideration

- Ethical clearance was obtained from the Institutional Review Board (IRB) of Hawassa University. The purpose of the study was explained in detail to each study participant and individual consent was taken from the mothers and panelists who took part in the sensory evaluation of complementary porridges.

3. Results

3.1. Sensory Evaluation at Laboratory Level

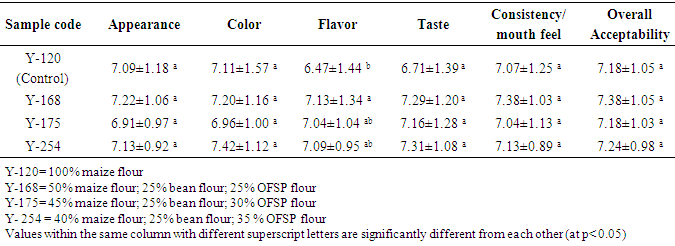

- Mean sensory scores of complementary porridges produced from 100% maize flour (traditional maize porridge) and composite flours of maize-bean-OFSP at different proportions are shown in Table 2. Mean scores and standard deviations, on the nine-point hedonic scales, for the appearance of the four different samples ranged from 6.91±0.97 to 7.22±1.06 indicating that all of them were liked moderately. Likewise, the color, taste, consistency /mouth feel and overall acceptability were liked moderately for the four different samples of porridges. There was no significant difference (P > 0.05) for the sensory scores of appearance, color, taste, consistency/ mouth feel and overall acceptability among the four different samples of porridge. The mean sensory score for flavor of porridge sample Y-168 was, however, statistically higher as compared to the control maize based porridge (Y-120) at 5% level of significance.

|

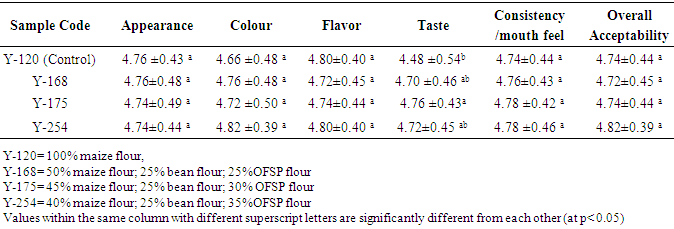

3.2. Sensory Evaluation at the Community Level (Maternal Acceptability) Scores

- Maternal acceptability of the four samples of porridges were expressed as mean scores and standard deviations for the sensory attribute shown in Table 3. Mean scores and standard deviations, on the five-point hedonic scales, for the appearance, color, flavor, consistency/ mouth feel and overall acceptability of the four different samples of porridge ranged from 4.66 ± 0.48 to 4.82 ± 0.39 showing that all of them were liked very much. In addition, no significant differences (P >0.05) were observed in the mean sensory scores for appearance, color, flavor, consistency and overall acceptability among the four different samples of porridge. The taste of porridge sample Y-175, with sensory score of mean of 4.76 ±0.43, was most preferred (liked very much) by mothers. In contrast, the taste of porridge sample Y- 120 (100% maize) was least preferred with mean score of 4.48 ±0.54 by mothers. The mean score given by mothers for the taste of porridge sample Y-175 was found to be significantly higher (P<0.05) than the control porridge sample, Y-120 (100% maize).

|

3.3 Chemical Analysis

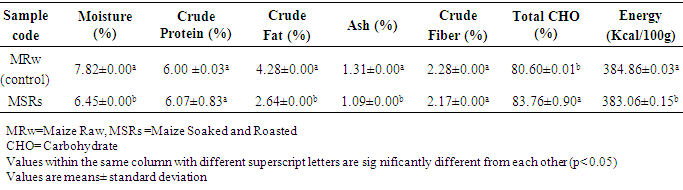

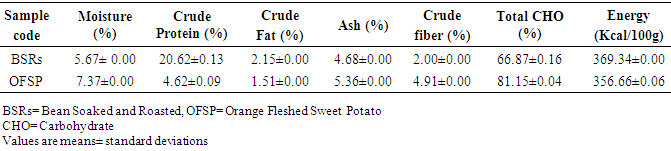

3.3.1. Proximate Composition of Ingredient Flour Samples

- Results on proximate composition of raw and processed (soaked for 24 hours and lightly roasted) maize flours are presented in Table 4. The moisture content of raw maize flour (MRw) was found to be 7.82% and this was significantly higher (p<0.05) than the moisture content value (6.45%) of maize flour prepared from maize grains that were soaked for 24- hours and slightly roasted (MSRs). Processed maize flour (MSRs) was recorded to have slightly higher value of crude protein (6.07%) compared to the observed.

|

|

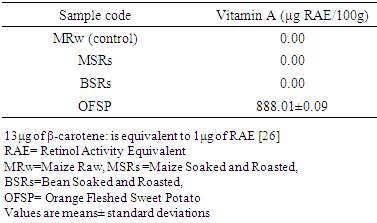

3.3.2. Vitamin A contents of Ingredient Flour Samples

- Shown in Table 6 are values of vitamin A contents of the four different samples of flours. A conversion factor of 13μg of β-carotene: 1μg of Retinol Activity Equivalent (RAE) was used for the present study [25]. The value of vitamin A contents of maize flours (MRw and MSRs) and bean flour (BSRs) was observed to be zero. The value of vitamin A for OFSP flour was reported to be 888.01 RAE/100g.

|

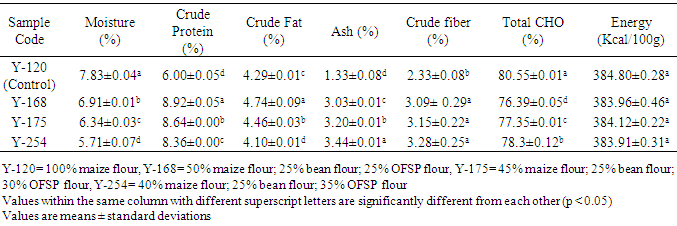

3.3.3. Proximate Composition of Complementary Por Ridges

- Results proximate compositions of the different samples of complementary porridges (on the dry-weight basis) are presented in Table 7. The control porridge (Y-120) was observed to have a significantly (P<0.05) higher moisture content compared to the three porridge samples in which OFSP and bean flours were incorporated (Y-168, Y-175 and Y- 254). All the three formulated porridge samples were found to have a significantly higher values of crude protein than the control (P<0.05). As the proportion of supplemented OFSP flour increased in the order of 25%, 30% and 35% for porridge samples Y-168, Y-175 and Y-254, a significantly (p<0.05) decreasing trend in the values of crude protein was noted as 8.92%, 8.64% and 8.36% respectively. The values for crude fat of formulated porridge samples, except Y-254, were significantly higher than the control (p<0.05). Values for crude fiber was significantly higher in all formulated porridges than the control (p<0.05). In contrast, the total carbohydrate content of the control porridge sample was observed to be significantly higher that all formulated porridge samples (p<0.05). No significant difference was noted in the gross energy (Kcal/100g) provided by all the four samples of porridge (p>0.05).

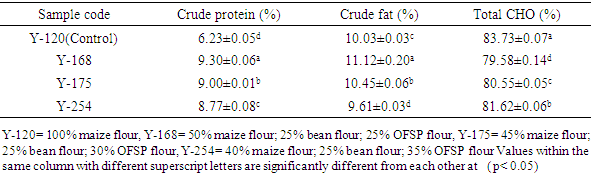

3.3.4. Percentage in Contribution of Crude Protein, Crude Fat and Total CHO from the gross Energy of Complementary Porridges on Dry – Weight Basis

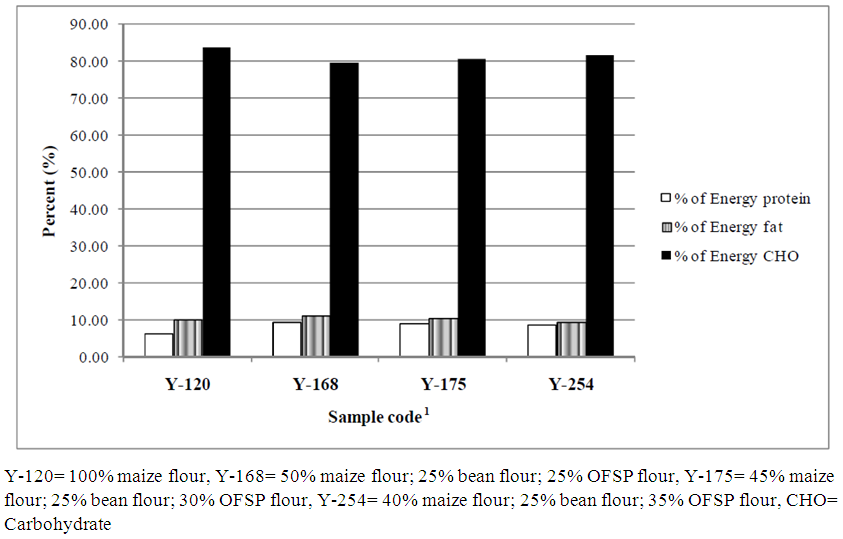

- The contribution (as %) of crude protein, crude fat and total carbohydrate (CHO) from the gross energy of the control and formulated porridges are presented in Table 8 and figure 4. The percentage of gross energy (6.23%) provided from protein was significantly lower for the control than the percentages from formulated porridges (p< 0.05). Sample coded Y- 168 was found to provide the highest percentage of energy from protein (p<0.05). The contribution of gross energy (as %) from fat ranged from 9.61% to 11.12% for porridge samples coded Y-254 and Y-168 respectively. Percentage contribution of total carbohydrate as a source of gross energy was significantly higher for the control than formulated samples of porridges (p<0.05).

| Figure 4. Percentage (%) in the contrition of protein, fat and CHO from the gross energy of complementary porridges on dry – weight basis |

|

|

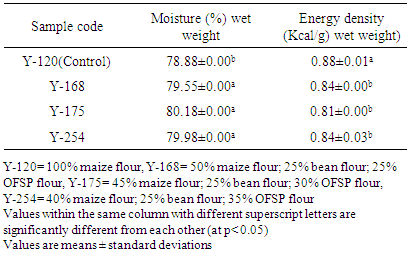

3.3.5. Moisture (%) and Energy Density (Kcal/g) of Complementary Porridges on Wet – Weight Basis

- The values of moisture (%) and energy density (Kcal/g) of porridges on wet-weight basis are presented in Table 9. The result showed that the control porridge had significantly highest moisture and energy density values compared to all the formulated porridges (p<0.05).

|

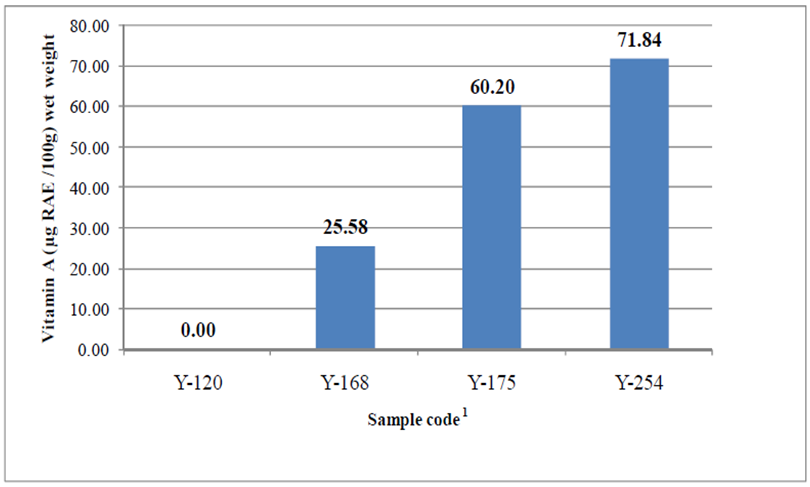

3.3.6. Vitamin A Contents of Complementary Porridges

- Results on the vitamin A contents of porridges (as served) are presented in Figure 5. All the values are expressed as Retinol Activity Equivalent (RAE) per 100 g of the samples. The vitamin A content of the control porridge was recorded to be 0.00 RAE/100g. The values of vitamin A (RAE/100g) were observed to be 25.8, 60.2 and 71.4 for porridges in which 25%, 30% and 35% OFSP flour (on dry weight) basis was incorporated respectively. Values of the three formulated porridges were also observed to be significantly different from each other.

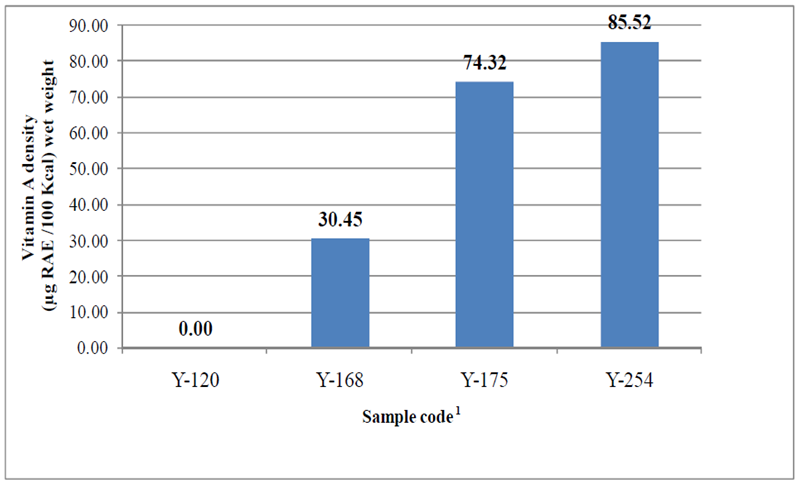

3.3.7. Vitamin A Density (μg RAE3/100 Kcal) of Complementary Porridges on Wet – Weight Basis

- Figure 6 provides information of the vitamin A density values (μg RAE/100 Kcal) as the porridges were served. The calculated values (μg RAE/100 Kcal) of vitamin A densities were in the range of 30.45-85.52 for OFSP incorporated porridges. In contrast, the control porridge was found to have a 0.00 value of vitamin A density.

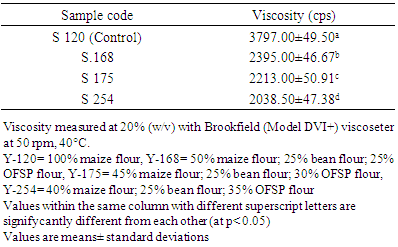

3.3.8. Viscosity of Cooked Complementary Porridges at 20% Dry Matter Concentration

- Results on the viscosity of porridges at 20% dry matter concentration are presented in Table 10. The observed values of viscosities were below 3000 cps (Centipoises) for the three formulated porridges, except for the control porridge (Y-120). Among the four porridge samples a significantly (p<0.05) highest viscosity value (3797 cps) was observed for the control. Within the three formulated porridges, the values of viscosities significantly decreased as the proportion of OFSP increased in the order of 25%, 30% and 35% for the formulated porridges coded Y-168, Y- 175 and Y-254 respectively (p<0.05).

|

4. Discussions

4.1. Sensory Evaluation by Panellists and Mothers

- Improvement in the dietary quality rather than quantity was indicated to be the key aspect of complementary foods for children 6-24 months old [26]. It is impossible to offer a blended complementary food unless it is acceptable to both the mother and the child. Organoleptic (taste, odor, texture, appearance), economic and cultural acceptability are all important in this regard. Sensory qualities of complementary food formulations corresponding to food preferences of infants are of the highest importance apart from sufficient energy density and nutrients that the complementary foods should provide [27]. Sensory evaluation is easy in its principle but its implementation in the field is often complicated because of low literacy among the rural mothers and the difficulty for them to understand some sensory testing methods [28, 27]. Sensory evaluation for the present study, therefore, was done on two different groups of panellists. These were namely panellists from Hawassa University, School of Nutrition, Food Science and Technology on one hand and mothers with children 6-23 months of age on the other hand. Formulated porridges were accepted by both groups of panellists and no single product was rejected (Table 2 and 3). Similarly another finding indicated that different formulations of gruels prepared from composite flour of Quality Protein Maize (QPM), bean and OFSP were all accepted by panelists [29]. The current findings were also in agreement with a study in which incorporating OFSP flour at 20%, 40% and 60% proportions to maize-soya bean flour (4:1) for formulating complementary food were acceptable [30]. A study showed that the addition of sugar and oil in formulated complementary foods improves the sensory attribute of the foods and thereby contributes to their higher acceptability [27]. The addition of vegetable oil in the present study, likewise, could be mentioned as an important contributing factor for the observed acceptability of all formulated porridges. Compared to the control unprocessed 100% maize-based porridge, porridges in which bean and OFSP flours were incorporated were more liked for their flavor and taste by panellists at laboratory and community levels, respectively. Another study also reported the increase in sensory rating for flavor with increase in the proportions of OFSP flour incorporated [30]. Additional probable explanation for this is the use of roasted ingredients, namely maize and bean, used for formulating test porridges. Greater acceptability of porridges using roasted bean and/or maize was also observed by a study compared to the samples in which the ingredients were not roasted [29]. Roasting (dry heating) is known to enhance the flavor and the taste of the food through dextrinization of starch [20]. Household food processing, such as those employed for the present study (soaking and roasting) have already been reported for their strong benefit in improving the organoleptic properties of processed food products [18].

4.2. Chemical Analysis of Porridge

4.2.1. Proximate Composition

- The moisture contents of ingredient flour samples (MRw, MSRs, BSRs and OFSP) obtained in this study were below 10% (Table 4 and 5). Such low moisture content of flours prevents microbial activity and extends the shelf life of the flours [31]. The values (as %) of crude fat, crude fiber, ash, total carbohydrate and gross energy obtained by the present study for raw maize flour were comparable with the values in the EFCT [32]. However, protein value of raw maize flour recorded for the current study was lower than that of the EFCT [32]. In the present study, maize flour that had been soaked for 24 hours and roasted slightly (MSRs) had slightly higher crude protein but considerably lower fat content compared to raw maize flour sample (MRw) (Table 4). This finding was in agreement with the observation made by an earlier study [33]. The observed values (as %) of crude fat, ash, total carbohydrate and gross energy in the present study for haricot bean flour (Table 5) were comparable with the values obtained by previously conducted studies on improved bean (Phaseolus vulgaris L.) in Ethiopia [34] and East Africa [35]. However, the crude fiber content of bean flour in the current study (Table 5) was lower compared to the previously reported values [34, 35] and this could be attributed to the processing like de-hulling used for the present study. The value of crude protein recorded for OFSP flour (Table 5) in the present study was comparable with the finding who reported a 4.2% (dry weight) protein value for sweet potato [36]. However, the observed value of crude fiber of OFSP flour (Table 5) in the present study was lower compared to what was reported to be 3.99% (dry weight) previously [36]. The values of moisture, crude protein and crude fat were observed to decrease with increase in the proportion of OFSP flour in the formulated porridges for the current study (Table 7). This was in agreement with the observation of a previous study [30]. Unlike the findings, who reported a decrease in the amount of crude fiber and ash with an increase in the OFSP flour proportions [30], in the current study the values of crude fiber and ash were observed to increase with the increase in OFSP flour proportions. The increasing trend of crude fiber and ash contents of formulated porridges with increase in the proportion of OFSP flour observed for the current study could be attributed to the high value of crude fiber and ash of the OFSP flour component of the ingredients used for the formulation of composite flours (Table 5).From six months onwards the breast milk alone is no longer sufficient to meet all nutritional requirements of children. Thus, children need to consume complementary foods of semisolid consistency with adequate energy and nutrient densities to supplement breast milk [37, 38]. The minimum desirable level of energy that complementary foods should provide was suggested to be 370 kcal/100 g (on dry-weight basis) [39]. On dry - weight basis, the calculated energy values (dry-weight) of the three formulated porridges of the current study were above this minimum recommended energy level (Table 7). The energy values (dry-weight) of the three formulated porridges of the present study were also higher than the energy values (dry-weight) of all standard maize-based porridges recommended by the Ministry of Health of Ethiopia [13]. In developing countries, the average expected energy intake from complementary foods per day is approximately 200 kcal at 6–8 months, 300 kcal at 9–11 months and 550 kcal to 12–23 months [40]. Besides, complementary foods with an energy density of below 0.6 Kcal/g are considered to have a low energy density [40]. For the present study, the energy density (wet weight) provided by the three formulated porridges as served was within the range of 0.81 Kcal/g - 0.84 Kcal/g (Table 9). The three formulated porridge sample for the current study were found to have an energy density that is above the cut-off point on wet weight basis. The value of energy density (0.81-0.84 Kcal/g wet weight) of the present study was higher than the reported 0.48 Kcal/g (wet weight) and 0.53 Kcal/g (wet weight) for legume supplemented and traditional maize-based complementary foods respectively in South Ethiopia [28] and the higher energy density (Kcal/g wet weight) of the present study compared to the latter study [28]) could likely be explained for the use of more water by the latter study to make the formulated maize-based porridges have the level of consistency preferred by mothers in the study area.The combined use of cereals and legumes is one way to improve the protein quality of complementary foods in developing countries [41, 20]. Incorporation of 25% (dry-weight basis) bean flour in the present study for formulating porridge samples coded Y-168, Y-175 and Y-254 increased the crude protein contents (% dry-weight) by 48.67%, 44% and 39.33% respectively as compared to the control. According to another finding supplementing 30g (dry weight) of broad bean to a traditional maize-based complementary food was observed to increase the protein content (dry weight) of the food from 8.82% to14.07% [28].The maximum value of protein (8.92% dry weight) obtained by the present study (Table 7) was, however, lower than the reported 14.07% (dry weight) by a similar study [28].This observed difference in improving the protein content (%) of the final products could probably be explained for the higher protein content of the control traditional porridge and the use of higher amount of legume to supplement maize flour was used [28]. The values of protein contents (% dry weight) of the three formulated porridges in the current study were, however, found to be higher than the protein contents (% dry weight) of all the standard maize-based porridges of the Ministry of Health of Ethiopia [13]. Protein-to-energy ratio provides an indication of the protein sufficiency in the diet and illustrates an appropriate balance of protein to energy. This ratio represents the energy contribution of protein in relation to the total caloric value of the food product (% protein kcal) [42]. The desirable protein-to-energy ratio for cereal based complementary foods was reported to be 10–13 [39], while the minimum protein-to-energy ratio was suggested to be 6.3% [43]. In the present study, ratios for the protein-to-energy for the three formulated porridges were well above the minimum (6.3%) (Table 8 and Figure 4). However, the control porridge had a protein-to-energy of just below the minimum (6.3%). The protein-to-energy ratio of the three formulated porridges of the current study was found to be close to but below the lower limit of the recommended protein-to-energy ratio of 11-13 [39]. Increasing the legume component of the formulation to 30% might be important to further increase the calculated protein-to-energy ratios of porridges formulated by the present study.The crude fiber content of the supplementary food should not exceed 5 g per 100 g dry matter [41, 20]. Values of crude fiber of the three formulated porridges of the current study were within this limit (Table 7). The higher fiber contents of formulated porridges as compared to the control porridge could be attributed to the legume and OFSP components of the formulation which had higher crude fiber contents compared to maize flour.To achieve at least 30% of energy from fat in the total diet, the amount of fat needed from complementary foods (assuming average breast milk intake) is zero at 6–8 months, approximately 3 g day-1 at 9–11 months and 9–13 g day-1 at 12–23 months, or 0%, 5–8% and 15–20% of the energy from complementary foods respectively [40]. For the present study, the percentages of energy from fat (9.61%- 11.12% on dry weight basis) (Table 8 and Figure 4) were found to be higher than the limit set for children aged 9-11 months and below the recommended limit for children aged 12-23 months.

4.2.2. Vitamin A

- The observed values of vitamin A for maize flours and bean flour were (Table 6) in line with the reported values in the EFCT [32]. The data with regard to OFSP flour, however, was lower compared to the reported above 1,500 RAE/100 of OFSP flour by another investigator [44]. This could be attributed to different factors like the difference in the variety of the fresh roots, processing, storage etc. Several researche groups reported variable carotenoid losses in the production of sweet potato flour, being affected by the variety utilized, size and shape of the pieces submitted to drying, and the drying method and condition [45]. Similarly according to [46] study the β-carotene concentrations vary with growing, harvesting, and storage conditions. For the current study, as significant improvement in the vitamin A content of formulated porridge was attained by incorporating OFSP flour on the control maize-porridge with a zero value of vitamin A. The observed value of vitamin A (0.00 RAE/100) for the control maize was in agreement with what was reported, that most commonly consumed cereal –based porridges in East Africa have no vitamin A content per 100g edible portions of the foods [47]. Different studies conducted previously have documented the role of OFSP in improving the vitamin A contents of complementary foods and/or porridges [48, 30, 49, 50, 29],The dietary quality of complementary foods can be compared by their nutrient densities which are an expression of their nutrient content per 100Kcal [11].The vitamin A density values (μg RAE/100 Kcal) of 31, 30 and 23 are suggested to be desirable for complementary foods of children aged 6-8, 9-11 and 12-23 months old respectively [51]. Among the three formulated porridges in the present study, the vitamin A density value of 30.45 μg RAE/100 Kcal (Figure 6) for porridge coded Y-168 (25% OFSP flour supplemented on dry weight) was found to be comparable with the suggested vitamin A density values by [51]. The remaining two formulated porridge samples were observed to have a higher vitamin A density values (μg RAE/100 Kcal) as compared to the desired values of densities for vitamin A [51]. A study had previously reported a value of vitamin A density of 53.5 μg RAE/100 Kcal by supplementing pumpkin to improve the vitamin A content of corn based complementary foods in South Ethiopia [28]. Among the three formulated porridges in the current study, vitamin A density values of Y-175 and Y-254 in which OFSP flour was incorporated at 30% and 35% respectively were higher compared to the values obtained by supplementing pumpkin to corn based complementary food in South Ethiopia [28]. Considering a 400μg RE/day DRI for children aged 6-23 months old a 100 Kcal serving of porridge coded Y-168, Y-175 and Y-254 would provide 7.61% and 18.58% and 21.31% of the DRI, respectively.

4.3. Viscosity

- Viscosity is a property of flour to resist in their free flow. The typically high viscosity (and thus, low energy density) of cereal gruels consumed by infants in many developing countries has been viewed as a cause of low energy intake [40]. A viscosity value of 1000-3000 cps is suggested to be the appropriated consistency of complementary foods that is easy-to-swallow and thus suitable for infant and child feeding [52, 53]. For the present study, the values of viscosities for the three formulated porridges (Table 10) were below the recommended upper limit of viscosity value (3000 cps) [52, 53]. Another important observation of this study was the reduction in viscosity values of formulated porridges with the increase in the proportion of OFSP flour. The findings of the current study were in agreement with a previously done investigation [30] in which a mixture of maize-soya bean flour (4:1) was prepared and blended with 20%, 40% and 60% OFSP flour and the increase in the amount of OFSP flour proportion significantly reduced the viscosity of maize-soya complementary porridges in which OFSP was incorporated. The observed reduction in the viscosity of formulated porridge of the current study might partly be due to the result of starch degradation caused by the action of the α-amylases that have developed/activated during the soaking process. The α-Amylase hydrolyzes starch to dextrin and maltose, which reduces the viscosity of thick cereal porridges and enhances their energy and nutrient densities [54]. Similar observation was made previously in which porridge cooked from meal prepared from maize grain that had been soaked for 24 hours (pH 4.5) showed a lower viscosity than that prepared from dry maize flour (pH 6.2) [55]. Another likely reason for the observed reduction in the viscosity of formulated porridges compared to the control traditional porridge is the high content of simple sugars in the OFSP flour that proportionally substituted the starchy and insoluble maize flour. Glucose and fructose are the only monosaccharides found in sweet potato with a slightly higher concentration of glucose. The same explanation could also be given for the reduction in viscosity with increase in the proportion of OFSP flour within the formulated porridges.

5. Conclusions

- The study revealed that maize-based complementary porridges supplemented with 25% roasted haricot bean and OFSP (25%-35%) had all acceptable sensory qualities. Besides, the addition of OFSP and haricot beans is a potential way to increase the nutritive value of traditional complementary foods prepared from maize in the study area. This provides a low cost vitamin A and protein supplemented complementary food especially for poor parents who would otherwise not afford animal source and/or commercial complementary foods.

6. Recommendations

- Ÿ Availability of OFSP and the awareness of mothers/care giver on its nutritional importance should be improved in the study area.Ÿ More research is required to incorporate OFSP flours in other recipes for various age groups using locally available food groups in the study area.

ACKNOWLEDGEMENTS

- The authors’ appreciation goes to the International Potato Center (CIP) which totally supported our research financially. We would also like to express our profound gratitude to Dr. Kebede Abegaz for his technical and managerial guidance in our project. We also sincerely appreciate the suggestions and assistance of Mr. Dejene Hailu, Mr. Alehegn Worku, Mr. Tafesse Bosha and all technical and administrative staff of School of Nutrition, Food Science and Technology-Hawassa University. We are indebted to extend our acknowledgement to Mr. Birhanu Gebermichael, head of Kachabira Woreda Agriculture office for all his supports and facilitations that helped us a lot during our stay in the Woreda. We also would like to express our deepest gratitude to EPHI and all its staff for their enthusiastic collaboration while the research work was carrying out in the laboratory of the institute. To all too numerous to mention, we say thank you all.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML