-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2016; 6(3): 49-54

doi:10.5923/j.food.20160603.01

Quality Characteristics of White Cheese (Jibna-beida) Produced Using Camel Milk and Mixture of Camel Milk and Cow Milk

Salma M. Siddig1, Abdel Moneim E. Sulieman1, 2, Zakaria A. Salih1, Abdelmuhsin A. Abdelmuhsin2

1Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Sudan

2Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

Correspondence to: Abdel Moneim E. Sulieman, Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Sudan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The objective of the present study was to assess the quality characteristics of white cheese produced using raw camel milk, and a mixture of camel milk and cow milk (1:1). The results show that the moisture, ash, protein, fat, lactose, total soluble solids (TSS) and pH of camel and cow raw milk were 87.31±3.20% and 85.00±0.07%, 1.95± 0.07% and 2.880±0.01%, 2.880±0.01% and 3.29±1.5%, 2.61±0.01% and 2.77±0.02%, 4.85±0.02% and 4.97±0.01%, 12.69±3.2% and 15.00±0.07%, 6.71±0.02 and 6.75±0.01, respectively. Cheeses were prepared by acidification using10% citric acid and by adding lactic acid bacteria (LAB) starter culture (5%). The cheese prepared by using starter culture had higher contents of protein, fat, total solids and minerals calcium, sodium and potassium. The sensory evaluation indicated that all cheeses were highly accepted by the panelists with preference to the cheese prepared by using starter culture which had been liked more as compared to that prepared by acidification process. It can be concluded that production of an acceptable quality white cheese (Jibna-beida) from a mixture of camel milk and cow milk is feasible. As camel cheese properties were improved by fortification of cow milk, the present study recommended production of cheese from camel milk and cow milk in order to obtain good quality product.

Keywords: Camel milk, Curd cheese, Starter culture, Sensory evaluation

Cite this paper: Salma M. Siddig, Abdel Moneim E. Sulieman, Zakaria A. Salih, Abdelmuhsin A. Abdelmuhsin, Quality Characteristics of White Cheese (Jibna-beida) Produced Using Camel Milk and Mixture of Camel Milk and Cow Milk, International Journal of Food Science and Nutrition Engineering, Vol. 6 No. 3, 2016, pp. 49-54. doi: 10.5923/j.food.20160603.01.

Article Outline

1. Introduction

- Camels (Camelus dromedarius) are considered to be a good source of milk and meat, and are used for other purposes such as transportation and sport racing. Camel milk has an important role in human nutrition in the hot regions and arid countries. This milk contains all the essential nutrients found in bovine milk [1]. The camel is of significant socio-economic importance in many arid and semi-arid parts of the world and its milk constitutes an important component of human diets in these regions. Camel milk has many nutritional and therapeutic properties, and has been used by many nations to cure many diseases. However, publications dealing with the composition of camel milk are relatively scarce and much of the information is approximate and fragmentary. It has been reported by many investigators that the average content of moisture, dry matter, lactose, protein, fat and ash is 85-87%, 3-5%, 12-14%, 2-5% and 06-09%, respectively [2-4].The history of the dromedary camel in the Sudan is even more obscure. It is believed to have entered the Sudan from Egypt. The oldest evidence is bronze figures of camel with a saddle found at Merwi and estimated to date between 25-15 B.C. [5]. Camels in the Sudan are spread in a belt configuration it extends between latitudes 12°-16°N.Most camel milk production in Sudan is consumed locally by families and/or converted to Garris (fermented camel milk product), and does not reach the urban markets because most of the camel herds are located in the arid and desert areas which are far from the commercial markets. Data on the actual amount of milk produced by Sudan camels are not very accurate for judging the milk yielding capability. Mainly because camels exist in desert areas with difficult accessibility calve are still suckling and, therefore, the actual volumes of milk secreted are higher than the figures presented among the different herds studied. On the other hand, milking frequency varies among the different camel nomads. Camel may be milked twice a day among the Rashaida tribe, and from two to five times or more among the other nomads [6].Sudanese white soft cheese (Jibna-beida) is a popular cheese type widely consumed by all the socioeconomic classes of Sudanese people. It is consumed in different ways, e.g. as a dressing for salads and Faba beans, or as a snack food, e.g. in sandwiches (Ali, 1987). It has been traditionally manufactured in different areas of Sudan. The production of cheese using camel milk as a major raw material is said to be difficult, even impossible [7-9]. It is surprising that although the majority of pastoral systems have produced at least one type of cheese, no traditional methods exist for making cheese from camel milk. Therefore, as a greater amount of camel milk is produced mostly in remote areas of Sudan, and in order to assure the arrival of this important nutritional and therapeutic product to all Sudanese people, this study has been initiated to investigate the production of white cheese from camel milk and a mixture of camel milk and cow milk and assessing its quality.

2. Materials and Methods

2.1. Materials

- Fresh whole camel and cow milk were obtained from local market at Wed Medani, central Sudan. Milk was immediately cooled to 5±1°C and transported to the laboratory of the Department of Food Science and Technology, University of Gezira.

2.2. Cheese Preparation

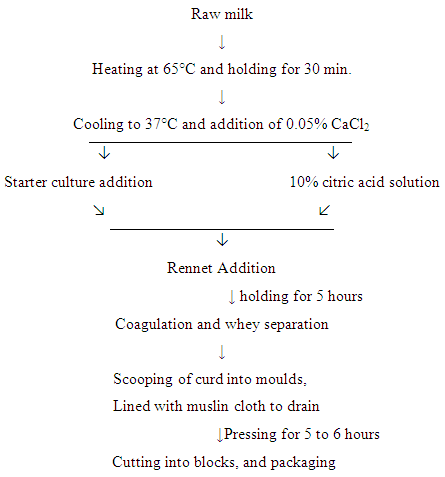

- Eight liters of camel milk and 4 liters cow milk were taken in stainless steel containers and heated to 65°C for 30 minutes. The temperature of milk was brought down to 40°C. Three types of cheese were prepared (Fig.1): the first type was prepared with addition of 10% citric acid to pure camel milk (PCM), the second type was prepared with addition of 10% citric acid to a mixture of camel milk and cow milk (1:1) (MCCM1), and the third type was prepared with the addition of 5% starter culture to a mixture of camel and cow milk (1:1) (MCCM2). After addition of either citric acid or LAB starter culture, rennet was added at the rate of 0.15 ml/litre of milk and mixed thoroughly. The milk was allowed to coagulate for 5 hours. After curd formation, the coagulum was cut and whey was drained off. The obtained coagulum was cut and scalding was done by gradually raising the temperature of the curd to 38°C within 30 minutes. The curd was moulded and pressed for 2-3 hours at room temperature (25°C). Cheese was removed from mould, packed, sampled and stored at 4°C for further investigation.

| Figure (1). Cheese production flow diagram |

2.3. Chemical Analysis

- Chemical analyses were conducted for the raw camel milk, cow milk and processed cheese samples. The contents of moisture, ash, protein, lactose, total soluble solids (TSS) and pH of the different samples were determined according to AOAC [10]. Fat content was determined according to Foley and Murphy [11].

2.4. Determination of Minerals

- For determination of minerals, cheese samples were weighed into a porcelain crucible and ashed in a muffle oven at a temperature of 450°C for 6 hours, then cooled in a desiccator. The ashes were then dissolved in an acidic aqueous solution (concentrated HNO3). Each sample was then transferred quantitatively to 250 ml volumetric flask, and distilled water was added to fill the flask and shaken many times. Then, the aqueous sample was diluted with strontium solution two times. Flame photometer (model Corning, 400) was used to determine the contents of potassium (K+), sodium (Na+) and calcium (Ca+) according to the AOAC [12]. The necessary equipment adjustments were accomplished.

2.5. Sensory Evaluation

- Sensory characteristics were determined by 10 panelists for judging the quality of the various cheeses using 9-point hedonic scale (1: Extremely bad, 9: Excellent) to assess color and appearance, flavor, texture, overall acceptance level. Sensory evaluation experiments were conducted in the sensory evaluation facilities of food analysis laboratory, Faculty of Engineering and Technology, University of Gezira. The samples to be used for sensory evaluation were randomly selected.

2.6. Statistical Analysis

- Statistical analysis of data was subjected to analysis of variance using Statistical Package for the Social Sciences (SPSS) program version 20.

3. Results and Discussion

3.1. Chemical Composition of Raw Camel and Raw Cow Milk

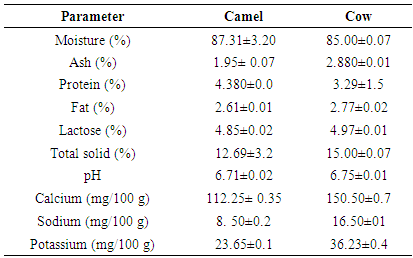

- The results of the chemical analysis of raw camel and cow milk used in cheese making are shown in (Table 1). Most of the tested chemical components of both camel milk and cow’s milk were comparable. The moisture content of camel milk (87.31%) was relatively higher than that of cow milk (85%), and both values were in close agreement to those reported by Sohail [13] which were 86.94% and 85, respectively. However, Awadelseid [14] gave a lower value for camel milk which was 83.30%. The most important factor affecting the overall composition of camel milk is water content. It has been clearly demonstrated that experiments which restricted drinking-water caused an increase in water content and a subsequent decrease in total solids [15] [16]. Seasonal climatic variations and water and feed availability had a similar effect [17].The ash content of camel milk and cow milk was 1.95% and 2.88, respectively. Ash content was higher than those reported by AL-Otaibi and El-Demerdash [18] and Mohamed et .al. [19] who gave a value of 1.1% and 0.72% in camel milk and cow milk, respectively. The protein content in camel milk was 4.38%. This result was higher than that reported by Abbas et al. [20] which was 3.3%, and falls within the range of 2.5-4.9% reported by Konuspayeva et. al., [21]. Variation in camel milk composition was discussed earlier. Moreover, camel breeds and seasonal conditions were found, in particular, to play a role in camel milk protein content. Protein content (casein and whey proteins) was found to be similar for camel milk of the same breed, such as Majaheim [22], but varied for other breeds. On the other hand, protein content of cow milk (3.29%) was less than that camel milk. The fat content was 2.61% for camel milk. This value was lower than that reported by Al-Otaibi El-Demerdash [18] (2013) (3.08%), he also concluded that the fat content can be reduced to 1.1 % in the milk of thirsty camels. However, cow milk contained a similar value for fat While it was (2.77%) which was lower than that reported by Mohamed et al. [19] (3.70%). The variation of fat content depends on the breed and feeding conditions. Studies on the structure and composition of fat globules revealed that have found small fat particles in camel milk [23] [24], more recent work indicates that fat globule size distribution is similar to cow's milk, with an average of 2.9 micrometres [25] [26]. The creaming properties of camel milk fat globules are poor, resulting from a deficiency in agglutinin that causes a very slow creaming rate at all temperatures [25]. The hydration status of the animals would determine the fat content of the milk, as well as the type of forage eaten.The lactose content was 4.85% and 4.97% for camel and cow milk, respectively. These values were in close agreement to those reported by Shahein et. al. [27] which were 4.80% and 5.30%., respectively. On the other hand, Webb et. al. (1974) reported extreme values ranging from 2.90 to 5.80% for camel milk compared with 4.40 to 5.80% for cow's milk.The total soluble solids (TSS), solid non-fat (SNF), pH and acidity (lactic acid%) of camel and cow raw milk were 12.69±3.2% and 15.00±0.07%, 10.09±3.2% and 10.04±0.07%, 6.71±0.02 and 6.75±0.01, and 2.59±0.01% and 3.52±0.02%, respectively.The concentration (mg/100) of minerals of raw camel milk and raw cow milk are shown also in Table (2). The concentration of Ca, Na and K was, 150.50, 16.50 and 36.50 mg/100g, respectively. However, these results disagreed with those obtained by Elamin and Wilcox [22] who reported values of 114mg/100g, 59 mg/100g and 156mg/100g Ca, Na and K, respectively. Fluctuations in mineral levels were proposed to be due to the differences in feeding, breed and water intake. Data shows that camel milk represented a good source of minerals. On the other hand; the mean of Ca, Na and k contents of cow milk was112.25, 8.50 and 23.50 mg/100g, respectively.

|

3.2. Quality Assessment of Cheese

- Production of cheese from camel milk is a difficult process under natural conditions. Camel milk is hardly coagulated, therefore, researchers used a mixture of camel milk and cow milk, the latter is commonly used for cheese production as it has a good power of coagulation. In addition the success was achieved when pH of milk was lowered and calcium chloride was added prior to rennet addition. Farah and Ruegg [28] reported that, because of differences in availability of K-casein, camel milk has more large casein micelles than does cow milk, which may relate to the poor rennet ability of camel milk.The quality assessment of the three kinds of fresh cheese which included determination of chemical and sensory characteristics is shown in Tables (2 and 3).

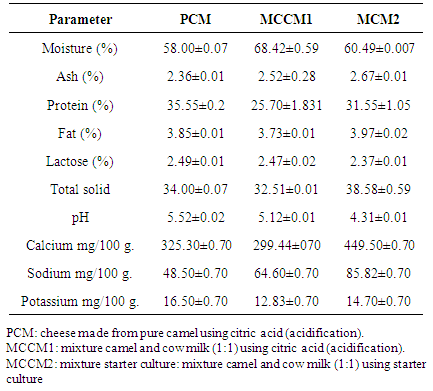

3.3. Chemical Composition of Cheeses

- Data in Table (2) present the chemical composition of the various cheese samples. These samples included: cheese made using 10% citric acid for pure camel milk (PCM), mixture of camel milk and cow milk (MCCM) with citric acid, (MCCM1) using 5% starter culture for mixture of camel milk and cow milk (MCCM2). The moisture content was 58.00% for PCM, this value is in line with those found by Haider (2004) which was 58.64-58.8% for pure camel milk cheese, however, the coagulation of camel milk-cow milk mixture with direct acidification resulted a cheese with higher moisture content (68.42%) than that coagulated with LAB starter culture (60.49%). On the other hand, these values were higher than those reported by Shahein et al. [27] which were 54.67% for a cheese made from a mixture of camel (60%) and cow milk (40%).The ash values were 2.36% for PCM, these results were higher than those reported by Derar et. al. [29] which were 1.46% for PCM, while they were 2.52% and 2.67%, in MCCM1 and MCCM2, respectively. The protein contents in PCM, MCCM1 and MCCM2 were 35.55%, 25.70 and 31.55%, respectively. These results were higher than that reported by Haider [30] and lower than that reported by Awadelseid [14] which were 47.98% and 21.30%, respectively.The fat (%) in PCM, MCCM1 and MCCM2 were 3.85%, 3.73 and 3.97%, respectively, these results were extremely lower than those reported by Yonas et al. [31] which were 12.90% and 13.40%. The variation in fat content in this study could be attributed to several factors like breed, individuality of animal, type of feed, health and age of the animal when the milk was taken. The Lactose (%) in PCM, MCCM1 and MCCM2 was 2.49%, 2.47% and 2.37%, respectively. However, these results are in line with that found by Haider [30] which was 2.55%. While the total solid (%) were 45.00%, 32.51±0.01 and 38.58% in PCM, MCCM1 and MCCM2, respectively. These results are in line with those found by Haider [30] and Shahein et al. [27] and Yonas et al. [31] which were 44.36%, 34.03% and 39.90%, respectively. The increase of total solids of PCM compared to MCCM1 and MCCM2 could be due to the reason that the camel milk had lower total solids (12.69%) as compared to the total solids content of cow milk (15.00%). On the other hand, the pH was 5.52, 5.12 and 4.31 in PCM, MCCM1 and MCCM2, respectively. These results were in close agreement with those reported by Yonas et al. [31] which were 4.87 and 5.27 and also Haider (2004) which were 4.90 and 5.80. The variation of pH values of various cheese samples could be attributed to the variation in composition and properties of milk. The relatively high pH many enhance the growth of spoilage of harmful microorganisms in such type of cheese, so the production of camel cheese with direct acidification my create a health risk to cheese consumers The mineral contents of PCM, MCCM1 and MCCM2 are also shown in Table (2). The major salt constituents were Calcium (Ca) Sodium (Na) and potassium (K) their concentrations were, 325.30, 299.44 and 449.50 mg/100 g, respectively for Calcium (Ca), 48.50, 64.60 and 85.50 mg/100 g for Sodium (Na) and 16.50, 12.83 and, 14.70 mg/100 g for potassium. The results indicated relative increase in calcium in MCCM2 as compared with those of PCM and MCCM2. On the other hand; the results indicated relative decrease of potassium in PCM as compared with those of MCCM1 and MCCM2.

|

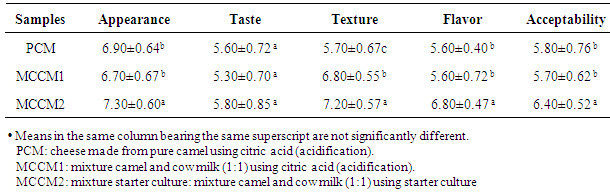

3.4. Sensory Evaluation

- The result of sensory evaluation of various cheeses is shown in Table (3). The sensory evaluation indicated that all cheeses were highly accepted by the panelists with preference to the cheese prepared by using starter culture which had been liked more as compared to that prepared by acidification process. The appearance, texture, flavor and acceptability of cheese prepared by using starter culture (MCCM2) was significantly different from those prepared using either pure camel milk (PCM) or camel milk and cow milk mixture coagulated with direct acidification (MCCM1)

|

4. Conclusions

- The results obtained from the study showed that most of the chemical components of camel and cow milk and cheese were in close agreement to the data in the literature with slight variations. The results of cheese made from pure camel milk and mixture milk indicated that a good fresh soft white cheese could be produced using mixture of camel and cow milk which is coagulated by means of either citric acid or LAB starter culture with preference to the latter. The white cheese made from camel milk with direct acidification and without use of starter cultures had high moisture and very high pH, which could cause serious health problems by growth of pathogens. So it is highly recommended to make cheese with the use of starter cultures. However, future research should be done to improve the quality of camel milk cheese.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML