-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(6): 226-232

doi:10.5923/j.food.20150506.02

Bioavailability of Minerals in Cookies Developed from Blend of Moringa Leaf Powder and Wheat Flour for Iron Deficient Lactating Mothers

Gashaw Muluken Tessera1, Abebe Haile2, Esayas Kinfe2

1Hawassa City Administration Natural Resource and Environmental Protection Office, Hawassa, Ethiopia

2Hawassa University, School of Nutrition, Food Science and Technology, Hawassa, Ethiopia

Correspondence to: Gashaw Muluken Tessera, Hawassa City Administration Natural Resource and Environmental Protection Office, Hawassa, Ethiopia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In this study cookies were prepared from blend of Moringastenopetala leaf powder (MLP) with wheat flour for iron deficient lactating mothers. MLP and wheat flour were blended in the ratio of 0:100, 5:95, 10:90, 15:85 and 20:80 respectively by using mixture simplex lattice design. The main objective of the study was to evaluate the content of Phytate (PA), Tannin, Iron (Fe), Zinc (Zn), Calcium (Ca), Phosphorous (P), and bioavailability of Fe, Zn and Ca in terms of molar ratio in the cookies. The content of Fe (2.87 – 7.77 mg/100g), Zn (0.66 – 1.06 mg/ 100mg), Ca (69.73 – 486.78 mg), P (96.45 – 144.88 mg/100mg), Phytate (PA) (53.69 – 114.61 mg/100g) and tannin (9.36 – 66.48 mg/ 100mg) were significantly increased (P<0.05) as the blending ratio of MLP increased. The molar ratios of PA: Ca (0.014 – 0.050) and PA: Zn (7.99 – 11.64) was below the critical values 0.24 and 15.0 respectively while molar ratio of PA: Fe (0.99 – 1.59) was above the critical value 1.0 in all cookies except T2 (5% MLP) which is 0.99. Hence, Zn and Ca were bioavailable in all cookies while Fe bioavailability was more observed in T2 (5% MLP) than other treatments. Conception of 100 g cookies per day, satisfy 53.6% of RDA of lactating mothers. In general the study indicated that T5 (20% MLP blended) contain higher amount of Fe, Zn, Ca and P. However, T2 (5% MLP) was found to be the best in terms of bioavailability of Fe while Zn and Ca are bioavailable in all treatments.

Keywords: Moringa leaf powder, Bioavailability, Iron deficiency, Lactating mothers

Cite this paper: Gashaw Muluken Tessera, Abebe Haile, Esayas Kinfe, Bioavailability of Minerals in Cookies Developed from Blend of Moringa Leaf Powder and Wheat Flour for Iron Deficient Lactating Mothers, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 6, 2015, pp. 226-232. doi: 10.5923/j.food.20150506.02.

Article Outline

1. Introduction

- Among the bakery products, cookies are most significant. Cookies are a form of confectionary products usually dried to low moisture content. Compared to biscuit, they tend to be larger with a soft chewing texture. They are consumed extensively all over the world as a snack food and on a large scale in developing countries (29, 30).Every parts of Moringa stenopetala are used for different purposes, mostly providing a highly nutritious food for both humans and animals and medicinal purposes to prevent different diseases. It contains vitamins (A, B, C and E), minerals (Ca, Fe, Zn, P, Cu and others), essential amino acids, essential fatty acids (both omega-3 and omega-6 fatty acids) and phytochemicals [1, 3, 4]. Moringa leaf powder is an excellent nutritional supplement and can be added to any dish to increase macro- and micro-nutrients content of the foods. For healthy individuals, a few spoonful of Moringa leaf powder can be added to any meal to make it more nutritious. In case of pregnant women and lactating mothers, consuming fresh or dried Moringa leaf powder or pods can improve a mother’s health and reduce iron deficiency anaemia. Therefore, consumption of Moringa leaves powder (MLP) by adding to any dish has a potential to prevent a problems of malnourished population [5, 6].Bioavailability refers to how well a nutrient can be absorbed by the body and used to reduce micronutrient malnutrition. Minerals bioavailability can be affected by the presence of the anti-nutritional factors such as Phaytate, tannins and polyphenols in foods. The two most important techniques used to improve minerals bioavailability are reducing the Phytate content in the foods or adding extra minerals in the fortification and blending process [25, 7]. According to [9] study on iron bioavailability of vegetables indicated that cooking increases iron bioavailability of certain vegetables 2 to 10 times. The cooking enhancing effect can be achieved with different heating processes including boiling, stir-frying and hot-air drying. In the case of fresh Moringa leaves, drying and boiling improve iron bioavailability by 3 and 3.5 times, respectively. Cooking Moringa leaves also raised total available of iron. Absorption of plant-based iron is considered lower than that of iron from meat and it is greatly influenced by the interactions with enhancers and inhibitors. Calcium can inhibit iron absorption when fed as inorganic calcium compounds or when consumed in dairy products such as milk or cheese; the level of inhibition depends on the quantity of calcium consumed [10]. There are many techniques used to determine the bioavailability of minerals in the human body. One of the methods is by measuring the molar ratio of Phytate / minerals in the diet [18]. Most studies agreed to use Phytate / Fe >1 to predict bioavailability of Fe in the diet [21]. The suggested critical values that have been calculated; Phytate / calcium > 0.24 [21], Phytate / Zinc > 15 is associated with reduced zinc absorption and negative zinc balance [8] However, according to [8] 55% of Zn content of foods is expected to be absorbed if Phytate / Zinc ratio of foods is < 5 (High bioavailability); it would be 35% if the ratio is within the range of 5-15 (moderate bioavailability) and only 15% if it is >15 (low bioavailability). The [Calcium] x [Phytate] / [Zinc] > 0.5 [28]. The main objective of this study was to determine some anti-nutritional factors (Phytate & Tannins), some minerals (Fe, Zn, Ca and P) and their bioavailability for iron deficient lactating mothers.

2. Materials and Methods

2.1. Materials Collection

- Fresh Moringa stenopetala leaf was harvested in April 2014 from Hawassa city (about 275km south of Addis Ababa, Ethiopia) Betekinet Primary School compound. The species was identified and approved by a reference number of 086923 at Addis Ababa University National Herbarium. Special wheat flour produced by Eshet Flour Factory (located at Hassasa-Bale) and other ingredients were purchased from Hawassa city local markets. The raw materials were transported and cookies preparation was done to Hawassa University, School of Nutrition, Food Science and Technology laboratory. Iron, Zinc, Calcium and Phosphorus contents, anti-nutritional factors (Phytate and tannin) of Moringa leaves powder (MLP), wheat flour and developed cookies were analysed at Ethiopian Public Health Institute (EPHI) Addis Ababa, Ethiopia.

2.2. Moringa Leaf Powder Preparation

- Moringa stenopetala leaves powder (MLP) was prepared by sorting and cleaning the leaves from any extraneous materials by using tap water and ventilated in a shade area for two days at room temperature. It was dried in an oven at 100°C for 3 hours and powdered by using mortal and piston. The powdered leaf was sieved to remove unwanted matter by using 710 μm sieves size in a repeated manner to get fine powder. The difference in particle size between the coarse and fine powders (both Moringa powder and Wheat flour) was separated by using 250 μm sieves size to become uniformly mix MLP and Wheat flour with other ingredients. The Wheat flour and MLP were packed with HDPE plastic bags and stored in desiccators until baking cookies [10].

2.3. Preparation of Blends

- Five different blend proportions including control were premeditated based on simplex lattice design (Design Expert version 6.0.8 software). Out of 8 runs, 5 runs were selected for appropriate formulation of the composite flours as software generated. Blends were prepared using mixtures of wheat flour and MLP in the ratios of 100/0, 95/5, 90/10, 85/15 and 80/20 w/w respectively.

2.4. Ingredients

- Commercially available sugar, sunflower oil, water, ginger, baking powder, sodium chloride, vanilla were used for the study. The ingredients ratio in cookies preparation was done according to [15] with some modification.

2.5. Cookies Preparation

- Cookies were prepared by the procedure of [22]. After accurate weighing of sunflower oil (30mL), sugar (26 g), Baking powder (1 g), sodium chloride (0.9), Composite flour (100 g), Ginger powder(2.5 g) and vanilla (2mL) were mixed and stirred. The dough was kneaded for 9 minutes and sheeted to a thickness of 0.6 cm and cut using a cookies die of diameter 5.5 cm. Cookies were baked in a pre-heated oven at 180°C for11 minutes, cooled and evaluated for proximate analysis and sensory characteristics.

2.6. Minerals Analysis

- Iron, Zinc and Calcium content of formulated cookies were determined by using flame atomic absorption spectrophotometer (FAAS) (model AA - 300 Plus, Australia) and phosphorus content of formulated cookies was also determined by using UV-Vis Spectrophotometer (DU-64 Spectrophotometer, Beckman, USA) by using the procedure of [2].

2.7. Anti-nutritional Factor Analysis

- Phytate content of formulated cookies was determined by using the procedure of [11]and Tannin content of formulated cookies was determined according to the procedure of [13] vanillin- HCl methods.

2.8. Bioavailability Determination

- Bioavailability of minerals (Fe, Zn, and Ca) was determined by using the molar ratio of Phytate to minerals (Fe, Zn, and Ca) of formulated cookies [18] The moles of Phytate and minerals (Fe, Zn and Ca) were determined by dividing the actual weight of Phytate and minerals with their atomic weight or molar weight (Phytate = 660 g/mol, Fe = 56 g/mol, Zn = 65 g/mol, Ca = 40 g/mol). The calculated molar ratios were compared with critical values of Phytate: Calcium > 0.24, Phytate: Iron > 1 (21, 16), Phytate: Zinc > 15 [8] and [Calcium]*[Phytate]/ [Zinc] > 0.5 [28].

2.9. Data Analysis

- The data were evaluated by analysis of variance (ANOVA) using SAS software of version 9.1 (SAS Institute Inc. 2003). All the analyses were carried out by replicate and results were expressed as mean standard deviation (SD). Fisher’s (LSD) test was used to separate means and the significant was accepted at P < 0.05.

3. Results and Discussion

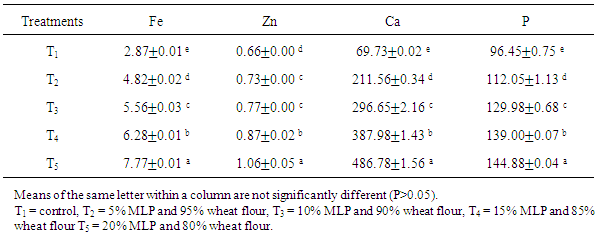

3.1. Minerals Analysis of Cookies

- The analysis result of Fe, Zn, Ca, and P in the formulated cookies ranged as 2.87 – 7.77 mg, 0.66 –1.06 mg, 69.73 – 486.78 mg and 96.45 – 144.88 mg respectively as shown in Table 1. Iron (Fe) and Zinc (Zn) are essential trace elements. Calcium (Ca) and Phosphorus (P) are also very important bone related macro elements in human nutrition (31).The maximum (7.77 mg) and minimum (2.87 mg) Iron (Fe) content was recorded for the cookies made from 20% MLP blended and control (100% wheat flour) cookies respectively. Statistically significant difference (P < 0.05) was observed among the treatments. When the amount of MLP increased in the blending ratio Fe contents of the cookies increased dramatically. This indicated that MLP contained more Fe content than wheat flour. The finding of this study is in close agreement with the work of [27] for the cookies blended from 0 to 15% of Moringa oleifera with wheat flour in the increment of Fe content from 1.9 to 6.23 mg/100g. The formulated cookies also have better Fe content as compared with the work of [34]. The consumption of 100g of MLP blended cookies per day could be estimated to satisfy 53.6 – 86.3% of Fe RDA for lactating mothers (9mg/day) [19]. Iron requirement during lactation is the sum of the requirement of the mother and that required for making up the iron lost in breast milk. Increase in thin body mass also requires iron, primarily for muscle myoglobin [24]. The minimum and maximum Zn content was recorded for T1 (100% wheat flour) (0.66 mg) and T5 (20% MLP and 80% wheat flour) (1.06mg) cookies respectively. Statistically, significant difference (P < 0.05) was observed among the formulated cookies. There was an increment of Zn content in the formulated cookies as MLP increased in the blending ratio, this pointed as MLP contains more Zn content than wheat flour. Similar result was observed in the finding of [33] who evaluated the mineral content of cookies developed from blend Wheat-Mungbean flour but the formulated cookies have less Zn content as compared with the work of [34]. The consumption of 100g of MLP blended cookies per day could be estimated to satisfy about 6.1 – 8.8% of Zn RDA for lactating mothers (12 mg/day) [19]. The consumption of these MLP blended cookies may contribute to build up normal growth and neurobehavioral development, immune and sensory function, antioxidant protection and membrane stabilisation. It also contributes to reduce the risk of inborn abnormality, low birth weight and other complications of pregnancy and delivery, such as impaired development and premature delivery [20].The least and the highest Ca content was recorded for T1 (control) (69.73 mg) and T5 (20% MLP) (486.78 mg) respectively. Statistically, significant difference (P < 0.05) was observed among the formulated cookies. This dramatic increment of Ca content in the formulated cookies was due to higher amount of Ca in MLP than wheat flour. Calcium is required for the normal development and maintenance of the skeleton. Low calcium intake has been associated with loss of bone mass (osteoporosis), resulting in bone fracture in older people, especially women (32). Calcium reserves in bone are affected by dietary calcium intake and calcium losses from the body in different cases, for example lactating mothers supply Ca to their baby during breast feeding. A lactating mother transfers approximately 260 mg per day of Ca to breast milk, this decreased maternal bone Ca flow in the body. She needs additional Ca supplementation in her diets [24]. Hence, this MLP blended cookies expected as good source of Ca and contributes to supply the required amount of Ca to their body during lactation periods. The formulated cookies have better Ca content as compared with the work of [34]. According to [19] report 100 g MLP blended cookies could be estimated to fulfil about 21.2 – 48.7% of the required Ca RDA (1000 mg) for lactating mothers.The minimum and maximum Phosphorus (P) content was recorded for T1 (96.45 mg) and T5 (144.88 mg) cookies respectively. Statistically, significant difference (P < 0.05) was observed among the formulated cookies. The increasing of Phosphorus (P) content in the formulated cookies with respect to the level of MLP ratio in the blend was due to high amount of P content in MLP than wheat flour. P is one of important minerals for bone and teeth related nutrients. The MLP blended cookies may satisfy 11.2 to 14.5% of the required P RDA for lactating mothers by consuming 100 g cookies per day; this helps the women to supply the daily required amount of P for her as well as her baby.

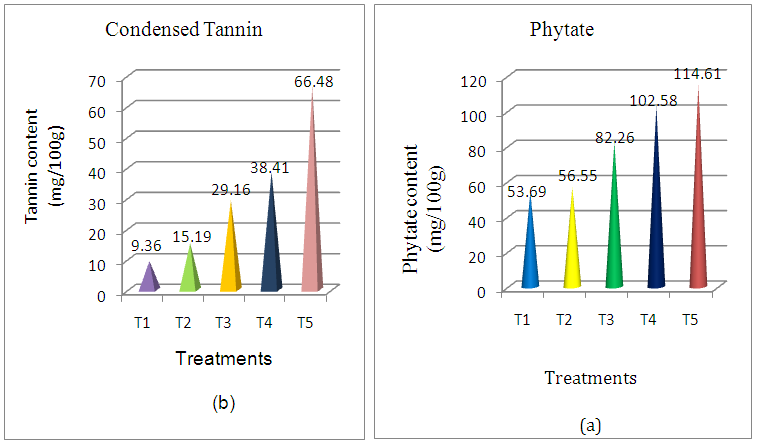

3.2. Anti-Nutritional Factors of Cookies

- The anti-nutritional factors of formulated cookies such as Phytate (PA) and condensed Tannin were analyzed. Their results were ranged from 9.36 to 66.48 mg/100g and 53.69 to 114.61mg/100g respectively as shown in Figure 1.

| Figure 1. Level of anti-nutritional factors / Phytate (a) and Tannin (b) /of Formulated Cookies |

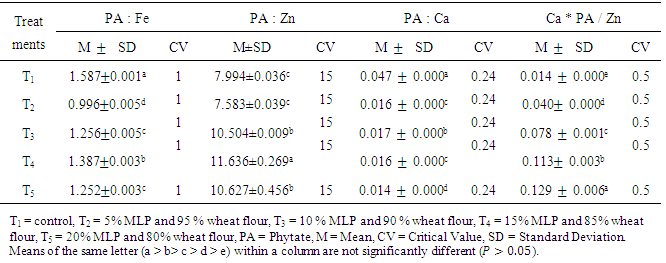

3.3. Bioavailability of Minerals in Cookies

3.3.1. Iron Bioavailability

- The minimum molar ratio of PA: Fe was recorded for the T2 (5% MLP blended) cookies (0.996) and the maximum molar ratio of PA: Fe was recorded for the T1 (control) (1.587). Significant difference (P < 0.05) was observed among the treatments. The results indicated (Table 1) that T1 (control) cookies showed very less Fe bioavailability compared with others, whereas T2 (5% MLP blended) showed the highest Fe bioavailability (0.996 < 1). The Fe bioavailability of other MLP blended cookies including control were poor, because of their molar ratio above the critical value (1) and the binding effect of Phytate (PA) on Fe may be high; whereas the Fe bioavailability of T2 (5% MLP) might be good because of PA: Fe molar ratio (0.996) below critical value with devoid of binding effect of PA on Fe. The measured molar ratio values of PA: Fe was increased gradually when MLP amounts were increased. So the bioavailability of Fe was less when more MLP added in the blending ratio and Fe absorption in the body may be affected by the binding property of PA. However, the formulated cookies cannot be concluded as high-Phytate foods as their molar ratio of PA: Fe was below 2 (PA: Fe > 2 means foods with high-Phytate content) [23]. The formulated cookies (PA: Fe = 0.996 – 1.587) has less molar ratio value compared with common cereal foods such as whole grain bread (the estimated molar ratio of PA: Fe = 26–64), Rye bread (whole meal) (estimated molar ratio of PA: Fe = 2 – 23) and Oatmeal (estimated molar ratio of PA: Fe = 17 – 22) according to [17]. Therefore, the bioavailability of Fe in these formulated cookies might be better than these cereal foods. Iron has a number of key functions within the body so one can get adequate amount of Fe in the food otherwise deficiency of Fe might be appeared. Deficiency of Fe (a person which has normal haemoglobin concentrations but no Fe stores in the body) ultimately leads to Fe deficiency anaemia (low haemoglobin concentration and low iron store), the most common cause of anaemia, a condition in which the blood lacks healthy red bloods cells required to carry oxygen, and which results in morbidity and death because of the lack of proper function of cells in the body (26). Therefore, among the formulated cookies, T2 (5% MLP blended) is the best source of Fe bioavailability and Fe might be easily absorbed within the gastrointestinal tract and expected to contribute to minimize Fe deficiency problems of lactating mothers as well as others by using calculated amount of cookies based on their RDA.

|

3.3.2. Zinc Bioavailability

- The molar ratio of Phytate: Zinc of the cookies ranged from 7.583 to 11.636 as presented in Table 2. The minimum value (7.583) was recorded for T2 (5% MLP blended) and the maximum value (11.636) was recorded for T4 (15% MLP blended). Statistically, Significant difference (P < 0.05) was observed among treatments. The PA: Zn molar ratio increased as the level of MLP increased in the formulation.According to [8] the foods with PA: Zn molar ratio greater than 15, between 5 and 15, less than 5 are considered as low (15%), moderate (35%) and high (55%) Zn bioavailability respectively. The molar ratios of all formulated cookies including control were between 5 and 15. Hence, the bioavailability of Zn in all treatments is at a moderate (35%) level. Therefore, the formulated cookies may be considered as good source of Zn for lactating mothers. The bioavailability result of Zn is similar with the work of [12] reported on cookies made from composite flour of Orange-fleshed sweet potato with wheat flour.

|

3.3.3. Calcium Bioavailability

- The minimum and maximum PA: Ca molar ratio was recorded for T5 (20% MLP blended) (0.014) and T1 (control) (0.047) respectively. Statistically, significant difference (P < 0.05) was observed among treatments. The molar ratio of PA: Ca in all formulated cookies was below the critical value of 0.24. The decreasing of molar ratio directs to increasing the bioavailability of Ca. This result indicated that the bioavailability of Ca may not be hindered by the PA content of the formulated cookies. Because the PA: Ca molar ratio in the cookies decreased as MLP amount increase in the blend ratio. Therefore, the formulated cookies may be considered as good sources of Ca for lactating mothers and it may contributes for them to maintain bone formation, blood clotting and muscle contraction. The minimum and maximum molar ratio was recorded for T1 (0.014) and T5 (0.129) respectively. Significant difference (P < 0.05) was observed among the formulated cookies. The level of MLP increased in the blending, the molar ratio of [Ca] * [PA] / [Zn] increased from 0.014 (T1) to 0.129 (T5) and the effect of PA on Zn appears to increase gradually. However, comparatively the [Ca] * [PA]/ [Zn] values of all formulated cookies were below the critical value, 0.5. This indicated that the ratio of [Ca]*[PA] / [Zn] is a better predictor for Zn availability. The molar ratio less than 0.5 means there would not be interferences in the availability of Zn in the formulated cookies. The inhibitory effect of PA on Zn absorption by forming a Calcium-Zinc-Phytate complex in the intestine makes less and soluble the Phytate complexes formed by either ion alone [26]. Therefore, Phytate has no effect on Zn bioavailability during minerals absorption in the gut; hence, the formulated cookies may be considered as good source of Zn.

4. Conclusions

- The bioavailability of Ca and Zn were below their critical values during increasing of MLP. But in 5%MLPblended (T2) cookies, Fe bioavailability was in acceptable range than others due to its molar ratio (0.99) below critical value (PA: Fe <1). Therefore, T2 (5% MLP blended) cookies have a potential to supply 53.6% of Fe to satisfy the RDA (9 mg/day) required by lactating mothers. In general, it might have a possibility to contribute better Fe content for lactating mothers to combat Iron deficiency problems.

ACKNOWLEDGEMENTS

- The authors would like to thank Hawassa University, School of Nutrition, Food Science and Technology and Ethiopian Public Health Institute for their help to carry out the experiment.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML