-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(5): 197-202

doi:10.5923/j.food.20150505.03

Physico-Chemical, Starch Fractions and Dietary Fibre of Biscuits Produced from Different Levels of Substitution of Wheat Flour with Plantain Flour

David Barine Kiin-Kabari , Sunday Yorte Giami

Department of Food Science and Technology, Rivers State University of Science and Technology, Port Harcourt, Nigeria

Correspondence to: David Barine Kiin-Kabari , Department of Food Science and Technology, Rivers State University of Science and Technology, Port Harcourt, Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

The potential of unripe plantain (Musa paradisiaca) flour as a functional ingredient in biscuit formulation was investigated using different blends of wheat and plantain flour. Proximate composition and sensory qualities of different levels of substitutions (10%, 20%, 30% and 40%) of wheat blends were also investigated with 100% wheat flour and 100% plantain flour as controls. Sensory studies were used to determine the level of substitution that produced acceptable products. Proximate analysis of the product showed a decrease in protein as the level of substitution of plantain flour increased in all the samples. Carbohydrate, however, increased as the level of plantain flour increased in the samples from 68.75% (sample A) to 76.12% (sample F). Moisture content of the composite biscuit ranged from 11.80% (sample A) to 10.18% (sample F) and there was no significant (p ≥ 0.05) difference up to 20% plantain flour substitution with wheat flour. This same trend was observed in the fat content of the composite flour biscuits. Ash ranged from 1.18% in sample F to 1.91% in sample A. All physical properties of the composite biscuit decreased with increase in the level of plantain flour when compared to 100% wheat flour (sample A). The percentage total starch (TS) was significantly (p ≥ 0.05) higher in 100% wheat flour compared to other samples. Resistant starch (RS) increased from 8.96% (sample A) to 19.49% (sample F) while digestible starch (DS) decreased from 38.17% (sample A) to 18.93% (sample F). Dietary fibre (DF) increased significantly from 12.03% (sample A) to 25.77% (sample F) as level of plantain flour increase in the formulation. The study showed a high resistant starch and dietary fibre associated with increase in plantain flour and therefore unripe plantain flour can serve as a functional ingredient in biscuit production with an overall acceptability of 80:20 wheat/plantain flour blends.

Keywords: Potential, Unripe plantain, Functional ingredient, Biscuit, Formulation

Cite this paper: David Barine Kiin-Kabari , Sunday Yorte Giami , Physico-Chemical, Starch Fractions and Dietary Fibre of Biscuits Produced from Different Levels of Substitution of Wheat Flour with Plantain Flour, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 5, 2015, pp. 197-202. doi: 10.5923/j.food.20150505.03.

Article Outline

1. Introduction

- Wheat flour production in Nigeria has fallen down due to the climatic conditions as a result; foreign exchange is spent annually for wheat importation [1]. Efforts have been made to promote the use of other locally grown crops to replace a portion of wheat flour thereby reducing the demand for imported wheat [2]. Plantain (Musaparadisiaca) is plant producing fruits that are starchy at maturity and need processing before consumption [3]. It can be processed into more durable products such as flour that can be stored for later use [4]. It is widely grown in the Southern States of Nigeria and it is used both in Nigeria and many African countries as an inexpensive source of calories, excellent for weight control and slow in the release of

-carotene (pro-vitamin A) as reported by Ogazi [5]. The use of unripe plantain flour as a functional ingredient in biscuit formulation is another way of promoting the consumption of functional foods as recommended by world nutrition bodies to avert different health problems related to wheat consumption, such as celiac disease (life-long intolerance to wheat gluten characterized by inflammation of the proximal small intestine), diabetes and coronary heart diseases. A recent WHO recommendation is to reduce the overall consumption of sugar and foods that promotes high glucose responses [6]. A current trend in nutrition is the consumption of low carbohydrate diets, including slowly digested food products, as well as an increased intake of functional foods [7]. Functional foods are referred to as foods containing ingredients that aid specific body functions in addition to being nutritious. Though, a number of definitions have been given, the general opinion is that functional food is any healthy food similar in appearance to conventional foods, consumed as part of a usual diet and claimed to have a physiological benefit like health - promoting or disease preventing properties beyond the basic function of supplying nutrients [8]. Kiin-Kabari et al., [9] studied the physico-chemical and pasting properties of starches from three cultivars of plantain and observed that the starches extracted could be utilised in plantain based food products. The food professionals/industries are faced with the challenge of producing food products containing functional ingredients in order to meet the nutritional requirements of individuals with health challenges. Plantain flour may serves as a functional ingredient, because it is rich in resistant starch and may have interesting functional properties for use in foods including high fibre content and low volume with improved sensory properties such as texture and appearance when compared to products rich in traditional fibre [10]. Ebere et al., [11] studied on the physico-chemical and sensory properties of cookies prepared from wheat flour and cashew-apple residue and observed that the addition of this residue increased the fibre content of the cookies with high sensory acceptability. Dietary fibre in human diets lowers serum cholesterol, reduces the risk of heart attack, colon cancer, obesity, blood appendicitis and many other diseases [12]. There is need to develop biscuits with dietary fibre, resistant starch with high nutritional quality. Biscuit can serve as vehicle for delivery of important nutrients if made readily available to the population [13]. The aim of this study was to prepare biscuit from different levels of wheat/plantain flours, determine their physical and chemical compositions including starch fractions and dietary fibre of the composite biscuit and also show the sensory properties compared to the control (100% wheat flour).

-carotene (pro-vitamin A) as reported by Ogazi [5]. The use of unripe plantain flour as a functional ingredient in biscuit formulation is another way of promoting the consumption of functional foods as recommended by world nutrition bodies to avert different health problems related to wheat consumption, such as celiac disease (life-long intolerance to wheat gluten characterized by inflammation of the proximal small intestine), diabetes and coronary heart diseases. A recent WHO recommendation is to reduce the overall consumption of sugar and foods that promotes high glucose responses [6]. A current trend in nutrition is the consumption of low carbohydrate diets, including slowly digested food products, as well as an increased intake of functional foods [7]. Functional foods are referred to as foods containing ingredients that aid specific body functions in addition to being nutritious. Though, a number of definitions have been given, the general opinion is that functional food is any healthy food similar in appearance to conventional foods, consumed as part of a usual diet and claimed to have a physiological benefit like health - promoting or disease preventing properties beyond the basic function of supplying nutrients [8]. Kiin-Kabari et al., [9] studied the physico-chemical and pasting properties of starches from three cultivars of plantain and observed that the starches extracted could be utilised in plantain based food products. The food professionals/industries are faced with the challenge of producing food products containing functional ingredients in order to meet the nutritional requirements of individuals with health challenges. Plantain flour may serves as a functional ingredient, because it is rich in resistant starch and may have interesting functional properties for use in foods including high fibre content and low volume with improved sensory properties such as texture and appearance when compared to products rich in traditional fibre [10]. Ebere et al., [11] studied on the physico-chemical and sensory properties of cookies prepared from wheat flour and cashew-apple residue and observed that the addition of this residue increased the fibre content of the cookies with high sensory acceptability. Dietary fibre in human diets lowers serum cholesterol, reduces the risk of heart attack, colon cancer, obesity, blood appendicitis and many other diseases [12]. There is need to develop biscuits with dietary fibre, resistant starch with high nutritional quality. Biscuit can serve as vehicle for delivery of important nutrients if made readily available to the population [13]. The aim of this study was to prepare biscuit from different levels of wheat/plantain flours, determine their physical and chemical compositions including starch fractions and dietary fibre of the composite biscuit and also show the sensory properties compared to the control (100% wheat flour). 2. Materials and Methods

2.1. Materials

- Two bunches of green plantain fruits (Musaparadisiaca) ‘agbagba’ cultivar was obtained from Rivers State Agricultural Development Project (ADP) Port Harcourt, Rivers State, Nigeria. Other baking ingredients such as butter, salt, sugar, honey, baking powder, ginger, wheat flour (Golden Penny brand) and eggs were obtained from Everyday Supermarket, GRA, Port Harcourt, Nigeria.

2.2. Preparation of Plantain Flour

- The method of Adeniji et al., [14] was used in the preparation of plantain flour. The mature green plantain fruit bunches was cut into individual fruits, washed, peeled and sliced into approximately 2mm thick using the stainless steel knife. Sodium metabisulphite solution (1%) was prepared. The plantain slices were soaked in the 1% sodium metabisulphite for l0min after which the slices were drained and then dried in the oven at 65°C for 12h. The dried slices were milled using a commercial milling machine then packed in a polythene bag, sealed and kept at a room temperature (28°C ± 2) until used.

2.3. Determination of Dietary Fibre of Biscuits from Composite Flour

- The method of AOAC [15] was used for dietary fibre determination. One (Ig) gram of the sample was weighed with a conical flask and 0.05g of enzyme α - amylase from porcine pancreases (cat. No 3176, Sigma – Aldrich, U.S.A) was added, then 40ml of buffer solution added and stirred thoroughly, the sample was heated for 15 min at 70°C cooled to 60°C and 0.0Ig pepsin enzyme added and incubated for 30 min at 70°C. A portion of 0.05g of amyloglucosidase was added and heated for 30 min at 70°C. The sample was brought out from the water bath after 30 min and allowed to cool, then filtered into a conical flask with a filter paper, washed and 20ml of distilled water added. The sample residue was dried for 30 min, the weight of the filter paper was taken and then ashed and protein analysis was done on the sample, using the Kjaldahl method. The dietary fibre calculated as follows: Dietary fibre = Weight of Residue - Weight of Protein + Ash.

2.4. Determination of Starch Fractions of Biscuits from Composite Flour

2.4.1. Total Starch (TS)

- The total starch was determined according to the method of Goni et al., [16]. The biscuit samples were weighed (25mg) and dissolved in 6ml of 2M KOH and shacked vigorously for 30min. A stock solution of α – amylase was prepared by mixing 20mg of the enzyme (cat. No A – 3176, sigma – Aldrich, U.S.A) with 50ml of 0.2m phosphate buffer (pH 6.9). One (1ml) of the α – amylase solution was added to the sample suspension and incubated at 37oCfor 45min in a shaking waterbath. After incubation, 1ml of 3 – 5 dinitrosalicylic acid was immediately added and the mixture was heated for 5min to inactivate the enzymes. The solution after cooling was centrifuged for 10min at 3000xg. The glucose concentration in the supernatant was determined using Glucose Assay Kits and the Glucose concentration was converted to starch by multiplying the glucose by a factor of 0.9.

2.4.2. Resistant Starch (RS)

- This was determined according to the method of Goni et al., [16]. One hundred (100) mg of each sample was incubated with pepsin (cat. No p 6887) solution containing 20mg of pepsin for 60min at 240°C. The starch was hydrolysed by adding the enzyme solution containing 40mg of α – amylase and incubated at 37°C for 120h. After hydrolysis, samples were centrifuged and the supernatant discarded. The residue was for starch as earlier described.

2.4.3. Digestible Starch (DS)

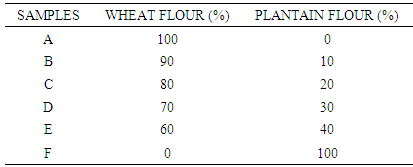

- The digestible starch was taken to be the difference between the total starch and the resistant starch as reported by Frei et al., [17] and Capriles et al., [18].Unripe plantain flour (PF) and wheat flour (WF) were mixed in different proportions as shown in Table 1 with 100% wheat flour (WF) as control. The blends were thoroughly mixed in a bowl by hand for 3 min to achieve uniform blending. The flour, ingredient such as fat, honey and nutmeg was mixed together in a bowl according to the method of Oyewole et al., [19]. Sugar and other ingredients (baking powder, egg, and flavour) were mixed until smooth dough was formed. The dough was rolled out thinly on a stainless steel table, cut into size using a pastry cutter, gently transferred into an already greased pan and baked in the oven at 180°C for 15 min.

|

2.5. Proximate Composition of the Composite Biscuit

- Moisture content, total ash, fat and crude protein was determined according to AOAC [15]. Carbohydrate content was determined using the method of Clegg Anthrone reported by Osborne and Voogt [20].

2.6. Physical Properties of Composite Biscuit

- The physical properties of the composite biscuit was measured using the method reported by Giami and Barber, [21] for fluted pumpkin cookies. The parameters measured include weight, height/thickness, diameter and spread ratios. The diameter and height were measured using micrometer screw guage and venire calipers, respectively; while the spread ratio was calculated by dividing the diameter by the height. Five biscuits were randomly selected and the mean values reported.

2.7. Sensory Evaluation

- Biscuit samples were subjected to sensory evaluation within 48h of baking. The following attributes namely. Taste, aroma, texture, appearance and overall acceptability were assessed on the biscuit samples. A questionnaire was drafted and distributed to assess these attributes using 9 - point hedonic scale which ranged from 9 = dislike extremely to 1 = like extremely [22]. Twenty panellists consisting of students and members of Food Science Department of Rivers State University of Science and Technology, Port Harcourt, Rivers State, Nigeria who are familiar with biscuit were involved in the assessment. The panellists were instructed to rinse their mouth with water after tasting each biscuit sample.

2.8. Statistical Analysis

- Statistical Package for Social Science (SPSS) Data Editor Version 20.0 (2011) was used to analyse the proximate composition and physical characteristics of wheat/plantain flour biscuit and the starch fraction/dietary fibre.

3. Results and Discussion

3.1. Proximate Composition

- Proximate composition of biscuits prepared from wheat/plantain flour blend is presented in Table 2. The moisture content of the biscuits ranged from 10.18% (sample E & F) to 11.80% (sample A). The moisture content decreased slightly with increase in plantain flour added. This observation is similar to the work of Adebowale et al., [23] who reported a ranged of moisture content between 10.24% (100% wheat flour) and 11.11% (80% substitution with sorghum). Crude protein and fat contents were observed to decrease significantly with increase in plantain flour while carbohydrate increased with increase in the level of plantain flour added. The ash content obtained ranged from 1.91% to 1.18% and in agreement with the values recommended by Nigerian Industrial Standard (NIS) reported by SON [24]. This specified that good quality biscuit should have a maximum ash content of 2.0%. Similar observation had been reported by other researchers [25, 26].

|

3.2. Physical Properties of Wheat – Plantain Biscuits

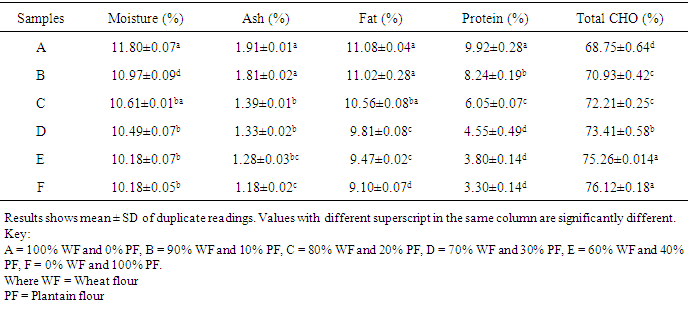

- Physical properties of the composite biscuit blends are presented in Table 3. The weight, diameter, height, thickness (width) and spread ratioranged from 3.35 – 3.80cm, 0.20 – 0.50cm, 5.60 – 6.80cm and 11.15 – 12.33, respectively and all physical properties decreased with increase in the level of plantain flour when compared to the control (sample A). The weight ranged from 3.20 – 3.46g, also decreasing with increase in the level of plantain flour. This may be attributed to the fact that plantain contains a higher amount of fibre as reported by Allen et al., [27].

|

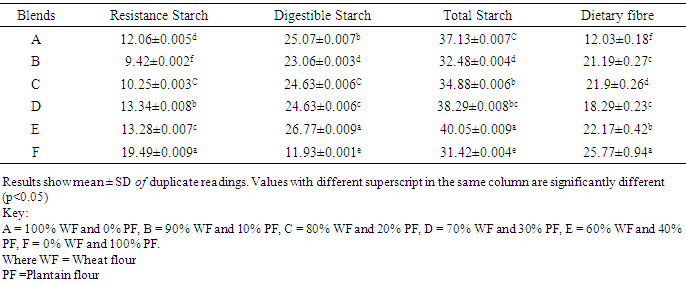

3.3. Starch Fractions and Dietary Fibre

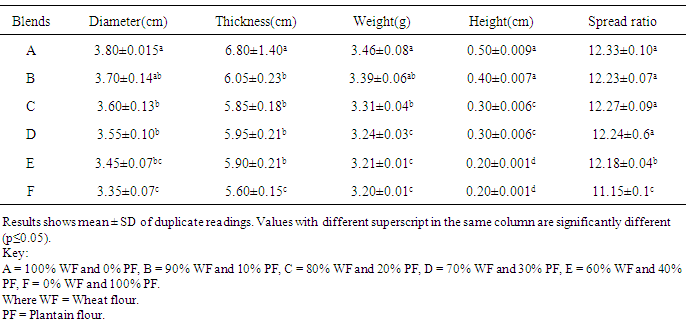

- The percentage total starch was significantly higher in 100% wheat flour (sample A) compared to other samples as shown in Table 4. However, total starch decreased with increase in plantain flour with the lowest (38.42%) recorded in sample F. Resistant starch (RS) was observed to increase from 8.96% to 19.49% with increase in the level of supplementation of plantain flour whereas digestible starch (DS) decreased from 38.17% (sample A) to 18.93% (sample F). These observations are in agreement with the report of Ayodele and Erema [28]. Unripe plantain starches had been reported to have small concentration of free sugars and rapidly digestible starch [29]. The results also agreed with the work of Oboh and Erema [30] which showed that processing of unripe plantain meals alters the physical form of carbohydrates. The dietary fibre content of the wheat/plantain biscuits increased from 12.03% (sample A) to 25.77% (sample F). This shows a progressive significant increase between the samples with increase in the level of plantain flour added. This observation is beneficial in human nutrition. A lot of researchers had shown the importance of high fibre diet, Nugent [10] reported that resistant starch has an interesting functional relationship with dietary fibre. This statement confirmed in this work as shown in Table 4. Also, Rehinan et al., [12] observed that dietary fibre in human nutrition lowers serum cholesterol, reduces the risk of heart attacks and other metabolic diseases. The bulking effect of fibre in the diet, especially effects on stool volume, softness frequency and regularity of elimination are thought to be the results of high water binding capacity of fibre [31].

|

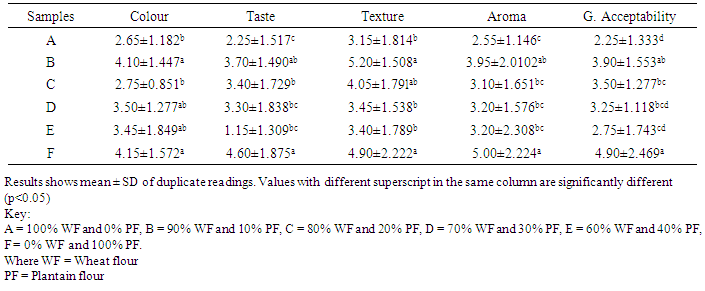

3.4. Sensory Properties of Composite Biscuit

- Results of sensory properties of biscuit prepared from wheat and plantain flour blends are presented in Table 5. There was no significant (P ≥ 0.05) difference in colour of the biscuit with 20 % plantain flour compared to 100% wheat flour. Aroma, texture, colour and general acceptability of the composite biscuit were observed to decrease with 100% plantain flour having the lowest values. However, taste of the biscuits was observed to increase progressively with increase in plantain flour with 100% plantain flour having the highest value of 6.6. The decrease in texture may be attributed to the presence of gluten in wheat flour that resulted in the formation of elastic dough. Similar observation was reported by Chinma et al., [32] on cookies prepared from plantain/wheat composite flours. The overall acceptability showed that there was no significant (p ≥ 0.05) difference in biscuit made from 20% plantain flour and 80% wheat flour compared with 100% wheat flour. An overall acceptability score of 7.3 and 8.0 had been reported by Kiin-Kabari and Giami [33] for 100% plantain flour and 100% wheat flour, respectively in production of cookies.

|

4. Conclusions

- Total starch in the biscuit samples decreased with increase in the level of unripe plantain flour while dietary fibre, resistant starch increased up to 25.77% and 19.49%, respectively in biscuit sample with 100% plantain flour. However, biscuit prepared with 80:20 wheat/plantain flour was acceptable with regards to aroma, texture, colour and overall acceptability. Therefore, unripe plantain flour can serve as a functional ingredient in biscuit production.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML