-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(5): 191-196

doi:10.5923/j.food.20150505.02

Development of Macaroni from Blends of Wheat (Triticum aestivum), Barley (Hordeum vulgare L.) and Soybean (Glycine max) Flours

1Lecturer at School of Nutrition, Food Science and Technology, Hawassa University, Hawassa, Ethiopia

2Kality Food Complex Share Company, Addis Ababa, Ethiopia

Correspondence to: Zemenu Kerie, Lecturer at School of Nutrition, Food Science and Technology, Hawassa University, Hawassa, Ethiopia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Consumption of macaroni made from durum wheat flour was popular, but the low fiber and protein content of wheat flour which was most vital ingredients used for the production of macaroni was major concern in its utilization. Therefore the aim of this study was to incorporate soybean and barley flours on durum wheat flour and development of macaroni. Randomized complete block design (RCBD) was used to investigate the effect of level of soybean and barley on sensorial properties and complete randomized design (CRD) was carried out to study the effect of blending ratio on proximate and functional properties of macaroni. Macaroni was prepared in a ratio of durum wheat flour: barley: soybean; 100:0:0, 80:15:5, 70:20:10, 70:10:20, and 60:30:10 respectively. Crude protein, total ash and total crude fibers were determined using standard procedures. Water absorption and cooking loss were determined by cooking 100 gm of prepared macaroni with 1000 ml of water for 10 min. The sensory characteristics of prepared macaroni was also evaluated on the basis of appearance, colour, odour, taste, stickiness and over all acceptability using five point hedonic scale by fifteen panellists. The results indicated that incorporation of barley and soybean increases the water absorption capacity of macaroni due to higher fiber content of barley and protein content of soybean which absorbs more water as compared to macaroni prepared from durum wheat flour only. Addition of barley and soybean flours on durum wheat flour during macaroni preparation increases crude protein, fiber and ash contents while reducing the moisture contents. The macaroni prepared from blends of 15% barley, 5% soybean and 80% durum wheat flour have scored better sensorial acceptability. So it is advisable to the food processors to produce macaroni by adding less than 15% barley and 5% soybean flour to durum wheat flour, but increasing the quantity of barley flour above 15% and soybean flour greater than 5% reduces the organoleptic acceptability and functional properties.

Keywords: Blending ratio, Soybean, Barley, Durum wheat, Water absorption, Proximate, Cooking loss, Sensorial properties

Cite this paper: Zemenu Kerie, Samuel Girma, Development of Macaroni from Blends of Wheat (Triticum aestivum), Barley (Hordeum vulgare L.) and Soybean (Glycine max) Flours, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 5, 2015, pp. 191-196. doi: 10.5923/j.food.20150505.02.

Article Outline

1. Introduction

- The commercial manufactures pay great attention to the physiological benefits of foods, there should be plenty of opportunities for the use of crops such as barley and soybean products in human foods [1]. Macaroni and Pasta are the major processed cereal products used by most of the communities in Ethiopia.Soybean is a very rich source of essential nutrients and one of the most versatile food stuffs. It possesses good quality protein which is comparable to other protein foods and is suitable for all age’s infants to the elderly. The soy protein is highly digestible and contains all the essential amino acids except methionine which is relatively low but good source of lysine. Soybean protein products also contains a high concentration of isoflavones, up to 1g per 1kg [2].The health of soy proteins consumption related to the reduction of the risk for the reduction of cholesterol levels and menopause symptoms and the reduction of the risk for several chronic disease. The addition of soy protein is acceptable in almost all diets due to no cholesterol and absence of lactase [3]. Barley flour in which glucan has been concentrated 3 to 4 times more than the naturally occurring level [4] is expected to have physiological effects similar to other soluted soluble fiber and when partially substituted by wheat flour in traditional cereal products. Moreover, findings of [5] revealed that adding barley extractions and different types of barley flour to wheat flour improved the color and weight of produced product and the protein, fat, ash, crude fiber, beta glucan and arbinoxylans contents. It provides an excellent source of soluble dietary fiber for attenuating blood glucose and reducing low density lipoprotein cholesterols [6]. Soybean contains ferritin, a multimeric iron storage protein. Iron from soybean ferritin is much absorbed and bio-available, so it is recommended to be incorporated in the diet of people suffering from anemia [7].Therefore the aim of the current study was to incorporate barley and soybean flours on durum wheat flour for development macaroni and evaluating their effects on functional and sensorial properties. ObjectivesThe general objective of this study was to evaluate the effects of blending ratio of durum wheat, barley and soybean flours on functional, proximate and sensorial properties of macaroni. Specific objectives• To develop macaroni from durum wheat, barley and soybean flour blends• To determine the proximate compositions of macaroni• To evaluate the functional properties of the developed macaroni• To conduct sensorial characteristics

2. Materials and Methods

2.1. Sample Collection and Preparation

- Durum wheat flour of 25 kg was taken from Kality food Share Company which is found in Adiss Ababa, Akaki Kaliti district.

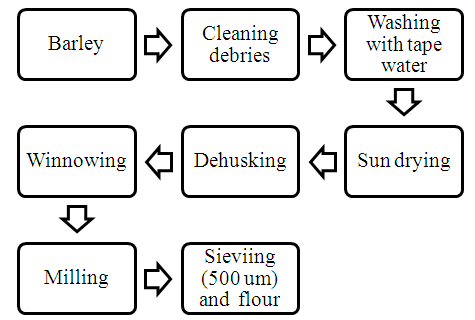

2.1.1. Preparation of Barley Flour

- 10 kg barley was purchased from local market and cleaned. The samples were washed with tap water and allowed to dry with sun energy for easier removal of husks. Then the samples were milled to flour with mechanical miller (Commercial Hammer Mill, Pfeuffer, Germany). The process followed [5] with minor modification.

| Figure 1. Flow chart for preparation of barley flour |

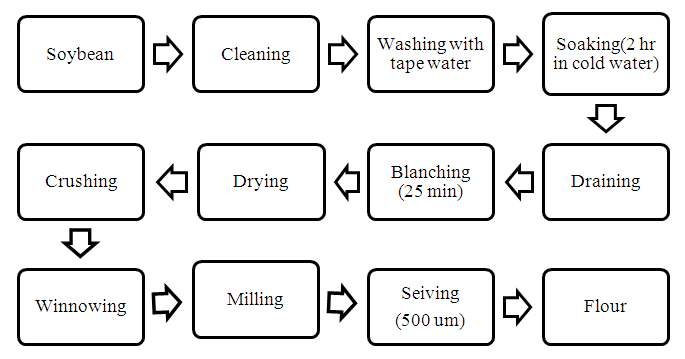

| Figure 2. Flow chart for preparation of soybean flour |

2.1.2. Preparation of Soybean Flour

- 10 kg of Soybean crops were collected from Hawassa agricultural research center, Hawassa Ethiopia. The samples were cleaned and soaked in cold water for 2 hrs. Then it was drained, blanched and dried so as to minimize anti-nutritional factors [8]. Finally the soybean flours were obtained following Figure 2.

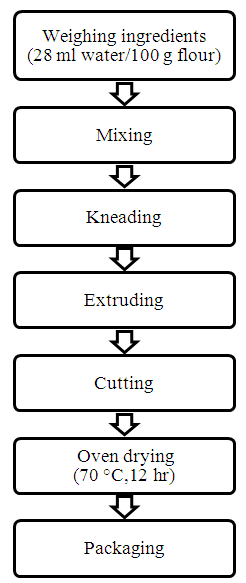

2.1.3. Development of Macaroni

- Macaroni development process was done following four critical steps. These are dough preparation, extrusion, cutting and drying. The dough was prepared using 5 blending proportions (blend 1= 100% wheat flour (WF) (control), Blend 2= 80% WF+15%barley flour (BF) +5% soybean flour (SF), Blend 3=70% WF +20% BF+ 10% SF, Blend 4=70% WF +10% BF +20% SF and Blend 5=60% WF+30% BF +10% SF). The blending proportions were done following Sawsan Y. et al. (2010) with major modification by incorporating soybean flour in addition to barley flour. After these blending proportions were made, 100 gm flour from each proportion was weighed and mixed with 28 ml of water. Then it was kneaded and extruded in accordance with the method described by [9]. The development process carried out as per the following flow sheet (Figure 3).

| Figure 3. Flow sheet of macaroni preparation process |

2.2. Determination of Functional Properties

- Cooking quality was determined namely water absorption capacity and cooking loss after cooking the macaroni. 100 gram of macaroni was cooked by 1000 ml for 10 minutes to do those functional properties using a slight modification of Marconi et al., 2000.

2.3. Proximate Analysis

- Moisture content, crude protein, total crude fibers and total ash were analyzed according to [10] standard procedures.

2.4. Sensory Evaluation

- The sensory evaluation of macaroni was carried out on the basis of appearance, color, odor, taste, stickiness and overall acceptability. A five point hedonic scale was used for evaluation of the product acceptability. Fifteen panelists were used for the sensorial evaluation. An equal amount of boiled macaroni from each proportion was served for all panelists in appropriate environmental condition.

2.5. Data Management and Analysis

- Randomized Complete Block Design (RCBD) was used to investigate the effect of level of soybean and barley on sensorial characteristics of macaroni and Complete Randomized Design (CRD) was carried out to study the blending effect on proximate composition and functional properties of macaroni. Statistical software package of SAS version 9.01 was used. The results were expressed as mean ± standard deviation. The mean separation technique was carried out using Fisher’s LSD (least significant difference) at p < 0.05 level of significance.

3. Results and Discussions

3.1. Functional Properties

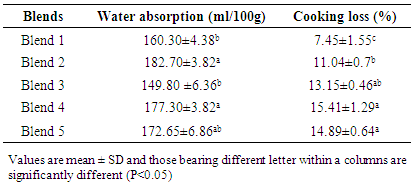

- Effect of blending ratio of durum wheat, barley and soybean flours on functional properties of macaroni was shown on Table 1. There was no significance difference observed on sample blend 5 at p < 0.05 for water absorption capacity. Blend 2 and blend 4 as well as blend 1 (control) and blend 3 were also not significantly different at p<0.05.

|

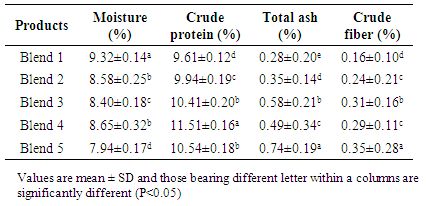

3.2. Proximate Compositions

- The results on Table 2 showed that incorporation of barley and soybean flours on durum wheat flour had a significant effect on proximate compositions of macaroni at p < 0.05. Accordingly, blend 1 (control) was significantly differ in all of the samples for all proximate compositions. Blend 2 and 4 were not significant for moisture and crude fiber contents at p < 0.05. And also blend 3 and 5 did not show significance difference for crude protein contents. Addition of barley flour reduces the increment of macaroni in weight and volume [11]. In the current study it was noticed also a decrement on moisture content of macaroni when barley and soybean flours incorporation increased. In the study of [12] it was noted that addition of 10, 20 and 30% barley flour increases protein, ash and fiber contents of macaroni. This was in agreement with the current findings.

|

3.3. Sensory Characteristics

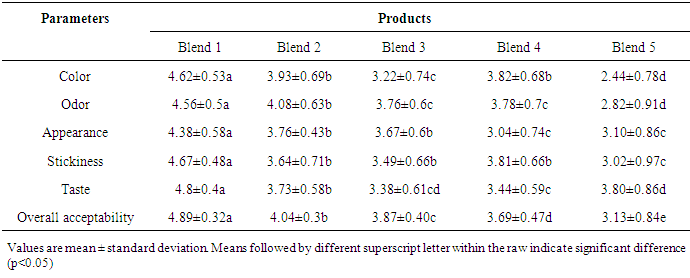

3.3.1. Color Acceptability

- Color is an important characteristic perceived by consumer for macaroni quality. Consumers prefer bright yellow translucent macaroni products. The effect of blending ratio of wheat, soybean and barley flour on color of the macaroni was shown on Table 3. All samples were significantly different except Blend 2 and 4 at p < 0.05. Blend 1 (control) and blend 2 had higher mean score which was 4.62 and 3.93 respectively and blend 5 had lowest mean score which was 2.44 for color. Increasing the amount of barley and soybean flour decreases the color acceptability of macaroni. This might be due to increasing the amount of barley decrease the brightness of the macaroni and increasing the amount of soybean flour changes yellow translucent color to brownish color. The brownish color of the macaroni was due to the browning reaction between soy protein and sugar [13].

|

3.3.2. Odor Acceptability

- The effect of soybean and barley flour incorporation on durum wheat flour at different ratio had significant effect on the odor of macaroni except blend 3 and 4. Blend 1 and 2 had higher mean score which was 4.56 and 4.08 respectively but blend 5 showed lower mean score which was 2.82. Increasing the amount of soybean decreased the odor acceptance due to the beany flavor of soybean and this was supported by [14].

3.3.3. Appearance Acceptability

- The effect of blending ratio of durum wheat, barley and soybean flour on appearance acceptability was shown on Table 2. The control (blend 1) was significantly different from all samples at (p<0.05). Blend 2 was more preferred by panelists in terms of appearance than other blends even though the control had higher mean score (4.38). Increasing the amount of soybean and barley flour reduces the appearance acceptability due to the lower quantity and quality of gluten as compared to durum wheat flour which have unique characteristics.

3.3.4. Stickiness Acceptability

- The results on Table 3 also showed that blend 1 and 5 had significant difference at (p<0.05) on stickiness acceptability, but blend 2, 3 and 4 had no significant difference on stickiness acceptability. The control had higher mean score of stickiness which was 4.67. Increasing the amount of soybean and barley reduce the stickiness of macaroni due to low gluten content of soybean and high fiber content of barley. Blend 1 (control) had more stickiness characteristics due to high amount of gluten in durum wheat flour which increases the sticky nature of macaroni.

3.3.5. Taste Acceptability

- Blend 1(control) had significantly different at (p<0.05) from all samples, but blend 3, 4 and 5 were not significant at (p<0.05). The control and blend 2 had higher mean score which was 4.8 and 3.75 respectively. However, blend 5 had lower mean score of taste acceptability which was 3.2. Macaroni made from blend 2 was preferred by the panelists than other blends. But blend 1 had high mean score value. This finding was in agreement with the work of [15].

3.3.6. Overall Acceptability

- The control and blend 2 had higher mean score which was 4.89 and 4.04 respectively. But blend 5 had lower mean score in overall acceptability. Increasing soybean and barley flour had negative effect on the overall acceptability of macaroni. The depression of overall acceptability was due to the darker color of macaroni as a result of barley [11] and beany taste and odor emanated from soybean.

4. Conclusions

- Incorporation of soybean and barley increases the water absorption capacity due to higher fiber content of barley and protein content of soybean which absorbs more water compared to the control. Increasing the amount of soybean and barley flour also increases the amount of solid loss due to lower protein quality found in barley and soybean flours. Addition of barley and soybean flours on durum wheat flour during macaroni preparation increases crude protein, fiber and ash contents while reducing the moisture contents. The macaroni prepared from blends of 15% barley, 5% soybean and 80% durum wheat flour have scored better sensorial acceptability.

ACKNOWLEDGEMENTS

- The authors would like to acknowledge Kality Food Share Company for providing the sample. And also we duly acknowledge the financial support of Hawassa University and School of Nutrition, Food Science and Technology for allowing us to do the product development and laboratory analysis.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML