-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(4): 176-182

doi:10.5923/j.food.20150504.03

Rheological Properties and Bread Making Quality of White Grain Sorghum-Wheat Flour Composites

Thulani Sibanda , Thembekile Ncube , Nyasha Ngoromani

Department of Applied Biology and Biochemistry, National University of Science and Technology, Ascot Bulawayo, Zimbabwe

Correspondence to: Thulani Sibanda , Department of Applied Biology and Biochemistry, National University of Science and Technology, Ascot Bulawayo, Zimbabwe.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The effect of partial substitution of wheat flour with white grain sorghum flour on the rheological properties and bread making quality of the composites was investigated. Composite flours containing 10%, 20% and 30% sorghum were analysed for their physicochemical composition, dough rheological properties and sensory quality of the resultant bread. The addition of sorghum had a significant effect on protein, moisture and ash content of the composite flour. Sorghum addition resulted in a decrease in protein and moisture content and an increase in ash content. Farinograph analysis showed a reduction in the water absorption of the composite dough as a result of sorghum addition with consequent longer development times and reduced dough stability. Dough development time increased from 4.3 minutes for the control to 14 minutes with sorghum replacement of at least 20% with a consequent decrease in stability from 12.27 minutes to 8.13 minutes. Sorghum substitution in excess of 10% had the effect of producing cohesive dough with higher tenacity and reduced elasticity. At 30% sorghum addition, there was a complete loss of dough elasticity. There was a significant decrease in bread volume with sorghum replacement of higher than 20%. Although the compositing seemed to affect the dough rheology, the sensory analysis of the baked product indicated that there was no significant difference in the taste, flavour and texture of the composite bread. The incorporation of sorghum at 10% produces bread of similar quality to wheat flour. Although increasing wheat replacement negatively affects the physicochemical and rheological properties, the sensory quality of the bread remains acceptable.

Keywords: Sorghum, Wheat, Bread, Composite

Cite this paper: Thulani Sibanda , Thembekile Ncube , Nyasha Ngoromani , Rheological Properties and Bread Making Quality of White Grain Sorghum-Wheat Flour Composites, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 4, 2015, pp. 176-182. doi: 10.5923/j.food.20150504.03.

Article Outline

1. Introduction

- Bread is a world-wide basic food [1]. In Africa, although not historically part of the staple diet, its consumption has been increasing in recent years [2, 3]. The growth in consumption has been a result of several factors that include increased urbanisation, changes in lifestyles and a growing population [2, 4]. The rising consumption of bread in Africa has increased demand for wheat as an essential ingredient in bread making. With estimations that about 60% of the African population is projected to live in urban areas by 2050 [5], the demand for wheat based foods such as bread is expected to surge.At current rates, Africa produces only about 44% (27 million tonnes) of the wheat that it needs [6] with the balance being provided by imports. This dependence on imports has a huge impact on African economies, a situation made worse by the rising prices of wheat on the international market. Owing to concerns about the economic implications of dependence on wheat imports, there has been a growing interest in promoting the utilization of alternative sources of flour for partial substitution of wheat [7]. Several flours derived from cereals, roots, tubers and legumes have been tried in various proportions in the production of composite flour and bread [8 - 10]. The effects of this compositing often vary depending on the physicochemical composition and processing conditions of the flours [11, 12].Sorghum [Sorghum bicolour (L.) Moench] is an African indigenous crop and quantitatively the second most important cereal grain in Africa after maize [13]. Because of its good adaptation to hard environments and its good yield of production, sorghum is a prime cereal for the semi-arid tropical climate of many Sub-Saharan African countries [14]. As a locally cultivated cereal, sorghum grain is a potentially useful resource in wheat substitution and production of composite wheat products like bread. However, the potential use of this resource has not been tried in Zimbabwe where bread consumption has been increasing sharply in the past years. The acceptability of sorghum based products is also affected by the sorghum type and varietal differences influencing the physicochemical composition of the grains and the resultant products [15, 16]. Among the varietal differences that influence the physicochemical and functional uses is the tannin content and colour of the grain [17]. The presence of tannins on the seed testa and pericarp results in increased pigmentation [18], which affects the colour perception and sensory qualities of the product. In terms of bread quality, a high tannin content sorghum may increase astringency and impart negatively on bread sensory perception. White grain sorghum also classified as Type I sorghum is non-tannin sorghum [19] that produces flour that is light in colour with a low tannin content which may be compatible for use as a composite with refined wheat flour used for white bread production. This study investigated the potential use of sorghum flour from a non-tannin white grain variety grown in Zimbabwe as a wheat substitute in white composite bread production.

2. Materials and Methods

2.1. Preparation of Composites

- White grain sorghum of the variety Macia was obtained from the International Crops Research Institute for the Semi-Arid-Tropics (ICRISAT), Zimbabwe. The whole sorghum grains were milled using a hammer mill (Paterson Laboratory) with a 0.2 mm sieve to obtain flour used during the course of the study. The sorghum flours were used at 10%, 20% and 30% ratios to produce composites with standard white bread flour obtained from a commercial milling plant.

2.2. Determination of Protein, Moisture and Ash Content

- The protein, moisture and ash content of the composite samples was determined using a Near Infrared Reflectance Spectroscopy (Inframatic 8600 Flour Analyzer, Perten Instruments) following the standard ICC method (Standard Number 159 and 202). Approximately 50 g of each sample was filled into the sample holder of the spectrometer and pressed down using a glass bar. Results were read and recorded after 30 seconds.

2.3. Farinograph Analysis

- The water absorption and mixing characteristics of the composite doughs was done using the Farinograph-E instrument (Brabender, Germany) following the standard ICC method (Standard Number 115/1). A 300 g composite flour sample on a 14% moisture content basis was mixed with water at 30⁰C [20]. Water was added as the dough was mixed to a consistency of 500 BU (Brabender Units). The amount of water required to produce the 500 BU dough consistency was interpreted as the percentage water absorption, while the time it took the dough to reach the threshold was interpreted as the dough development time. The stability was read as the time it took to maintain the 500 BU dough consistency [21].

2.4. Measurement of Resistance of Dough to Extension

- The measurement of dough resistance to extension was done using the alveograph instrument (Chopin Technologies, France) following the standard ICC method (Standard Number 122) described by [20]. A sample of 250 g of the flour was mixed with 13.5 ml of 2.5% salt solution to form dough which was cut into 4.5 cm circular patties. The resistance to extension was tested by blowing the patties into a bubble that expands until it breaks [20].

2.5. Effect of Compositing on Bread Quality

- The sorghum-wheat composite bread was prepared using the straight dough method and a standard bread recipe which included the following ingredients; 100 % flour, 60% water at 25 ⁰C, 4.5% premix, 1% baker’s fat and 2% yeast. The ingredients were mixed for 15 minutes using a commercial mixer and allowed to ferment for 30 minutes. Proofing was carried out in a proofer at a temperature of 39⁰C and a humidity percentage of 80% for 90 minutes and the baking was done in an oven at 250⁰C for 25 minutes.

2.5.1. Measurement of Bread Volume

- The bread volume was measured as the cross sectional distance from the horizontal axis which divides the superior crust from the inferior crust following the method described by [22].

2.5.2. Sensory Analysis for the Baked Bread

- The bread samples were analysed for their taste, flavour, aroma and texture using a 10 member panel following the approach described by [22]. These attributes were rated on a 10-point hedonic scale as: 1 - 2 poor, 3 - 4 fair, 5 - 7 very good and 8 - 10 excellent [23].

2.6. Statistical Analysis

- ANOVA analysis using GraphPad Prism 6.0 was used to test for any significant differences in the flour composition, dough rheology and the bread quality at different levels of sorghum substitution. A significance level of 0.05 was used in each case.

3. Results

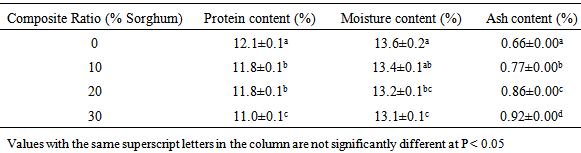

- Table 1 shows the effect of sorghum substitution on the composition of the resultant composite flours. The addition of sorghum resulted in a significant decrease in protein and moisture content while the ash content of the composites increased for all ratios of sorghum substitution.

|

|

|

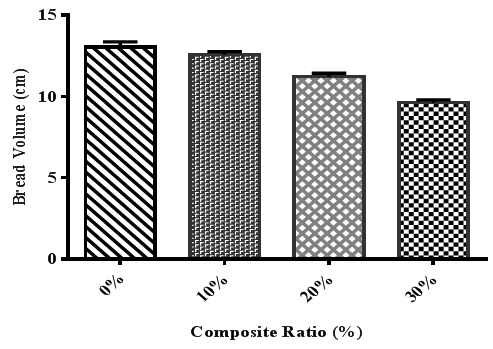

| Figure 1. Volume of composite flour bread |

| Figure 3. Crumb colour and pore regularity of cut product; from left, 100% white standard flour, 10% white sorghum, 20% white sorghum and 30% white sorghum |

|

4. Discussion

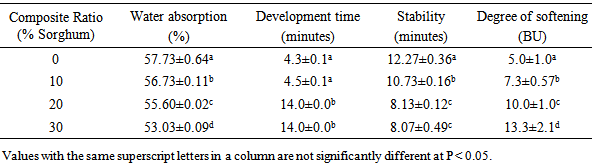

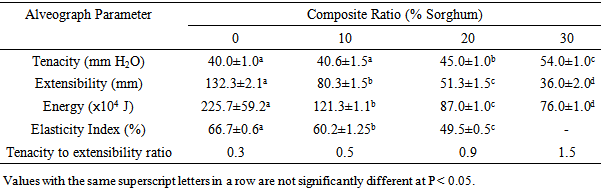

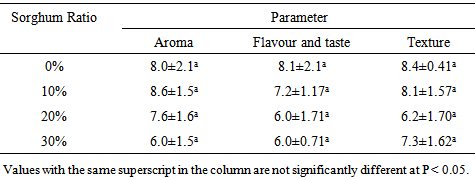

- The chemical composition of sorghum composite flours (Table 1) varied significantly from that of 100% wheat flour. The protein and moisture content significantly decreased with the level of sorghum substitution, while the ash content increased with the level of sorghum addition. The decrease in protein and moisture content of the composite flour might be due to the lower protein and moisture content of the sorghum flour which dilutes the protein and moisture content of the wheat flour. The protein content of sorghum grain differs greatly among varieties. A study of 44 grain varieties revealed a protein content varying from 8.61% to 16.48% [24]. The protein content of flour is an essential element in determining the rheological behaviour of the dough and subsequently the quality of the bread [25]. However the protein contents of the composites remained within the acceptable range of 10.5 to 14% needed for bread flour [26]. The increase in the ash content might be a result of the high mineral content emerging from the sorghum flour. Given that ash is primarily concentrated in the bran, the increased concentration in the composite flour could be a sign of bran contamination of the flour during milling of the sorghum grain [26]. Despite the decrease in moisture content with increase in sorghum content, sorghum wheat composite flours still produce flours within the acceptable moisture content for commercial wheat flour [25]. The Farinograph analysis showed that water absorption, dough development time and dough stability decreased with increase in sorghum content of the composite flour (Table 2). These findings are similar to observations by [27, 28] who observed that addition of rice bran to wheat flour reduces the water absorption, dough development time and dough stability. Considering that whole grain was used in producing the sorghum flour, it is likely that bran contamination of the flour could have resulted in increased fibre content which affects the water absorption capacity of glutens as they become more hydrophobic [27]. As a result, the dough absorbs less water which affects its stability and development. This then causes competition between starch granules and proteins within the flour for available water, which consequently impacts on the viscoelastic behaviour of the dough [29]. With a decrease in water absorption, there is an increase in the cohesiveness of the dough which explains the increased stability of the dough as the level of substitution increases. The dough development time measured as the time it took the dough to reach 500 BU consistency was significantly increased by the addition of sorghum above 20% from 4.3 minutes in the 100% wheat flour to 14 minutes for the 20% composite. The addition of the sorghum appears to affect the hydration property of the flour and therefore resulting in a longer development time. The increase in the dough development time coupled with the reduction of dough stability was indicative of the weakening of the gluten network configuration during the kneading [21]. This implies that composite doughs can not sustain long mechanical treatment processes. Alveographic results showed that the addition of sorghum to white standard flour causes an increase in dough resistance to deformation and a decrease in extensibility and elasticity. Consistent with the Farinograph results, as the water absorption capacity of the composite dough decreases, there is an increased interaction of glutens by hydrophobic interaction. This increases cohesiveness of the dough while reducing fluidity. As a result, the tenacity of the dough increased as the ratio of sorghum substitution exceeded 20%. Consequently the elasticity and extensibility of the composite dough also decreased. A significant decrease in dough extensibility and elasticity affects the baking strength of the dough especially in bread production where optimization of bread loaf volume is an essential quality determinant [30, 31].Bread volume decreased significantly with increasing sorghum substitution level (Figure 1). The decrease in composite bread volume can be attributable to the physicochemical changes in the composite flour which influences the rheological behaviour of the dough and subsequently bread volume. A strong correlation exists between the physicochemical composition of wheat flour and bread volume [32, 33]. As observed by [32], the protein content of flour, Farinograph water absorption, and alveograph tenacity and extensibility parameters have a strong correlation to bread volume and can be used as predicting indices. In this study, sorghum substitution showed a significant effect on protein content of the composite flours (Table 1), while the Farinograph water absorption also showed a significant decrease (Table 2). This had an effect of increasing resistance to deformation coupled with a decrease in elasticity as revealed by the alveograph analysis (Table 3). The increase in resistance to deformation is an indicator of the ability of the dough to retain gas during proofing and baking while extensibility represents the ability of the dough to extend without breaking down [34, 35]. The sensory analysis of the composite bread showed that bread of acceptable quality can be produced with up to 30% sorghum substitution. There was no significant difference in the texture of the bread made from the composite flours to those produced from 100% wheat flour (P > 0.05). The texture of the bread was rated as satisfactory to good by the panellists. Several studies have also made similar observations with cassava, plantain and soy bean composite bread [8, 36]. The texture of bread is a function of the water retention capacity of the functional ingredients of the bread such as proteins, starch and other hydrocolloids. It appears that the addition of sorghum although affecting the physicochemical composition of the flour and the dough, it does not affect the texture of the bread. The flavour and taste of the composite bread also showed on significant difference with 100% wheat bread (P > 0.05). Although some flavour compounds are intrinsically present in bread flour, the major source of the bread flavour is the fermentative and thermal reactions that occur during the bread making process [37]. This suggests that although the composition of the flour is altered by the addition of sorghum, the major precursors for flavour generation are not significantly altered. There was also no significant difference in the aroma scores for the 100% bread and the 10% and 20% composite breads. However, at 30% sorghum substitution, there was a significant effect on the aroma of the bread. The major odorants that influence bread aroma are volatile compounds derived during the fermentation and baking stages of the bread making process [38]. This indicates that the profile of volatile compounds derived from the composite bread may be similar to that of wheat bread.The findings of this study have important implications for the bread making industry in Zimbabwe. A wheat substitution of 10-20% can reduce the country’s wheat import bill while encouraging improved domestic output for sorghum grain both translating to positive economic gains for the country.

5. Conclusions

- The partial substitution of wheat flour with white sorghum flour affected the composition of the flour and rheological properties of the dough at sorghum concentrations in excess of 10%. The reduction in protein content results in the dilution of the glutens which affects the rheological behaviour of the dough. The increase in dough resistance and reduction in elasticity caused reduced gas retention ability and consequently affected bread volume. Notwithstanding the negative effects on the physicochemical and rheological qualities, this study shows that bread of acceptable sensory quality can be produced from wheat and white grain sorghum flour composites.

ACKNOWLEDGEMENTS

- The authors wish to acknowledge National Foods (Limited), Zimbabwe for providing facilities for analysis.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML