-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(3): 121-129

doi:10.5923/j.food.20150503.03

Effect of Blending Ratio and Processing Technique on Physicochemical Composition, Functional Properties and Sensory Acceptability of Quality Protein Maize (QPM) Based Complementary Food

Beruk Berhanu Desalegn, Kebede Abegaz, Esayas Kinfe

School of Nutrition, Food Science and Technology, Hawassa University, Southern Ethiopia

Correspondence to: Beruk Berhanu Desalegn, School of Nutrition, Food Science and Technology, Hawassa University, Southern Ethiopia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

In developing countries like Ethiopia, complementary foods are usually made from plant sources with high anti-nutrients content using less modification techniques in order to increase its nutrient density. The purpose of this study was to evaluate effects of blending ratio and processing technique on physicochemical composition, functional properties and sensory acceptability of Quality Protein Maize (QPM) Based Complementary porridge. Flavor optimization using sensory evaluation was done on seven different blending proportions of QPM and chickpea before the development of complementary porridge. Porridge prepared from 50:50 and 60:40 QPM and chickpea blends were selected during the flavor optimization. Based on that, 72gm of 50:50 or 60:40 blends of raw, germinated or soaked QPM and chickpea, 18gm of OFSP and 10gm of red teff were used for complementary food formulation. The 72:18:10 formulations were based on the Recommended Daily Allowances (RDA) for children aged 6-24 months. The 2x3 factorial experimental design was used. Sensory evaluation of porridge was done at the laboratory level using nine points’ hedonic scales and viscosity was measured at 15%w/v concentration. Increment in chickpea content slightly increased fat and reduced viscosity of complementary porridge. Germination and soaking improved complementary porridges by reducing phytate (17-39%) and tannin (21-77%) contents and viscosity (27-40%). All complementary porridges prepared in this study were accepted at laboratory (6.25 to 6.80) level using nine point hedonic scales and satisfy the minimum RDA for energy and protein and 2/3 of RDA for iron (7mg) and zinc (3mg). QPM based CFs prepared from 72 (50:50) of germinated QPM and chickpea was chosen by its high nutrient content, bioavailability and functional properties among the six products. Nutritionally improved and energy rich CFs can be prepared from a blend of QPM, chickpea, Orange Flesh Sweet Potato (OFSP) and red tef.

Keywords: Complementary food, Anti-nutrients, Soaking, Germination, Blending, QPM, Chickpea, OFSP, Tef, Porridge, Sensory acceptability

Cite this paper: Beruk Berhanu Desalegn, Kebede Abegaz, Esayas Kinfe, Effect of Blending Ratio and Processing Technique on Physicochemical Composition, Functional Properties and Sensory Acceptability of Quality Protein Maize (QPM) Based Complementary Food, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 3, 2015, pp. 121-129. doi: 10.5923/j.food.20150503.03.

Article Outline

1. Introduction

- Child malnutrition, a deviation from the norm in a child growth and development, can be manifested as under or over nutrition and affects physical growth, morbidity, mortality, cognitive development, reproduction, and physical work capacity [1, 2]. Lack of food, improper infant and child feeding practices critically affects child growth, development and survival when coupled with high rates of infections during the first two years of life [3]. In Ethiopia the most common forms of malnutrition are protein-energy malnutrition (PEM), vitamin A deficiency, Iodine deficiency disorders, and Iron deficiency anemia [6, 7, 8]. According to [6], the prevalence of stunting in under five aged Ethiopian children is forty four percent; of which twenty one percent is severely stunted whereas twenty nine percent of children are underweight and wasting affected ten percent of children with same age group. The prevalence of anemia in the age group of six to fifty nine months of children is forty four percent. Among different regions where the problem of malnutrition contributes highly to the national figure, southern Ethiopia has a prevalence of stunting (44.1%), underweight (28.3%) and wasting (7.6%) [6]. Weaning period is the most critical period in a child’s life as an infant’s transfer from nutritious and uncontaminated breast milk to the regular family diet with chance of vulnerable to malnutrition and disease [9, 50]. According to the WHO definition, a complementary food is normally a semi-solid food that is used in addition to breast milk and not to replace it and started at the age of six months. In southern Ethiopia, traditional complementary foods are usually made of cereals/root crops may be low in both macro and micronutrients like protein, vitamin A, zinc and iron. Furthermore, these cereal/root crops based complementary foods produced have high concentrations of fiber and anti-nutrients which reduced the bioavailability of existing nutrients and less in nutrient density due to the gelatinization of starch which immediately fill the stomach of small children. Beside this the availability and consumption of commercial infant formula are very less throughout the country which accounted 1.78% [6]. In order to reduce these problems, producing complementary food from locally available low priced food items, nutritious, acceptable using various traditional food processing techniques like soaking, germination, roasting, milling, drying and fermentation is recommendable [9, 10, 11]. Hence, in this study the effect of blending ratio and processing technique on physicochemical composition, functional properties and sensory acceptability of Quality protein Maize based complementary porridge was examined.

2. Materials and Methods

2.1. Sample Collection and Preparation

- Chickpea ((Cicer arietinum L.) kabulli variety) and red teff ((Eragrostis Teff (Zucc. DZ-0199 variety)) Trotter) were collected from Debre-zeit agricultural research centre whereas QPM ((Zea mays Linaeus.) BHQPY-545 variety), and ((Ipomea batata (L.) Lam.) Tulla variety) were collected from Bako agricultural research centre, and Awassa agricultural research centre, respectively. All grains, which were used in this study passed through winnowing and hand sorting in order to remove stones, dust materials, glumes, stalks, and broken, undersized and immature grains. Likewise, the root of OFSP which was matured, undamaged and appropriate sized was used for flour production. The QPM grain was then divided into three as control, soaked for one day or soaked in one day in clean tap water, drained and germinated for a day. On a similar fashion, chickpea grain was also divided into three as control, soaked for one day or soaked in one day in clean tap water, drained and germinated in two days. Following this, the grains and sliced OFSP were sun dried (average daily T during sun drying was between 22 to 24.5C). Based on the composite flours, porridges were prepared at 15%w/v concentration of flour with water. Additionally, 1%w/w of iodized salt was added on flour and 4g edible oil.

2.2. Experimental Design

- The experiments were conducted at two levels. First, flavor optimization (sensory evaluation) was carried out using nine point hedonic scales with thirty panelists at laboratory level in order to reduce the undesirable beany flavor which comes mainly from legumes while blending with cereal/root crops [12]. Composite flours were prepared from 80:20, 70:30, 60:40, 50:50, 40:60, 30:70 and 20:80 blends of QPM and chickpea. Porridge was prepared from the composite flours and among the seven porridge prepared, 60:40 and 50:50 QPM-chickpea were selected. Based on the flavor optimization result, six QPM based complementary flours were prepared from 72% of QPM-chickpea blends, 18% OFSP and 10% red teff. These are CB1 (unsoaked and ungerminated 43g QPM and 29g chickpea, 10g red teff and 18g OFSP), SB1(soaked 43g QPM and 29g chickpea, 10g red teff and 18g OFSP), GB1(germinated 43g QPM and 29g chickpea, 10g red teff and 18g OFSP), CB2 (unsoaked and ungerminated 36g QPM and 36g chickpea, 10g red teff and 18g OFSP), SB2(soaked 36g QPM and 36g chickpea, 10g red teff and 18g OFSP) and GB2 (germinated 36g QPM and 36g chickpea, 10g red teff and 18g OFSP). The composition (72%:18%:10%) of QPM-based complementary flour ingredients for this study was based on the minimum RDA of energy which is 1554kJ/100gm equivalent to 370kcal/100gm, protein 10.9gm/100gm, 2/3 of the daily requirement for minerals and vitamins 4.21mg of iron/100gm and 270µg of vitamin A/100gm for children aged 6-23 months old respectively [11, 13, 15].

2.3. Physicochemical and Functional Analysis

- Proximate compositions like moisture content, crude protein, crude fat and total ash were analyzed using standard method [22]. The carbohydrate contents were determined by differences. Gross energy’s of complementary flours were also calculated by using the Atwater’s conversion factor, 16.7 KJ/g for protein and carbohydrate and 37.4 KJ/g for fat. The mineral contents were analyzed by the procedure of [23] using an Atomic Absorption Spectrophotometer. Condensed Tannin and phytate contents were determined by the method used by [32, 59]. The bioavailability of minerals (zinc and iron) was expressed as molar ratio of phytate and mineral (Fe or Zn). The mole of phytic acid was calculated as measured value of phytic acid divided by molecular weight of phytic acid (240) whereas the mole of mineral (Fe or Zn) was calculated as measured value of the mineral divided by individual mineral molecular weight (Fe: 56, Zn: 65) [61]. The ß-carotene was analyzed by open column chromatography spectrometer method [56]. The functional properties like bulk density, water absorption capacity and oil absorption capacities of complementary flours were also determined by [4, 5, 21]. The viscosities of porridges were measured at 15% w/v of water using a Brookfield Viscometer (Model DVII Rheometer V2.0 RV; Middleboro, Massachusetts, USA). The porridges were placed in a water bath maintained at 40°C (heating temperature) and its viscosity was measured at this temperature. The cooked gruel was poured into the Viscometer beaker, cooled to 40C and viscosity was measured (in centipoises, CP) using spindle number 7 at a shear rate of 50 revolutions per minute (RPM). Within 5 minutes, the average of the maximum and minimum viscosity reading was recorded [24].

2.4. Sensory Evaluation

- Sensory acceptability was conducted in laboratory using nine point hedonic scales with thirty panelists. Triplicate porridge samples were prepared for the six complementary flours, coded with three digit numbers and assessed for its appearance/color, flavor, taste, consistency/mouth-feel and overall acceptability.

2.5. Statistical Analysis

- The data collected from flours and porridges were subjected to analysis of variance (ANOVA) by using SAS 9.1 software. The mean separation values were determined using a Fischer LSD test. Significant differences were defined at p<0.05.

3. Results and Discussions

3.1. Proximate Composition of QPM based Complementary Flours

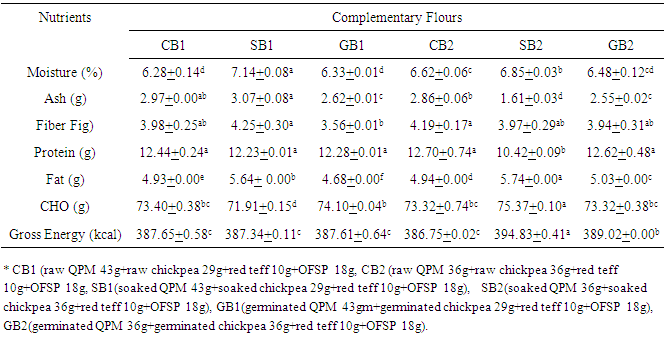

- According to Table 1, the moisture contents of complementary flours were in the range of 6.28 to 7.14%. Flours with lower content of moisture (<10%) is suitable for inactivation of microbes as a result the shelf life of flours can be extended. Complementary flours prepared from soaked quality protein maize and chickpea had significantly (p<0.05) higher moisture contents than controls and complementary flours prepared from germinated one. This could be due to retention of more water in soaking. The ash contents of complementary flours in this study were between 1.61 to 3.07%, which is comparable with infant formula prepared from Germinated popcorn, Bambara groundnut and African locust bean (1.1 to 3.2%) [25]. A similar result was also reported in study conducted on germinated finger millet [26]. Fiber contents of complementary flours were in the range of 3.56 to 4.25%, which is higher than study conducted in complementary food prepared from malted cereals and legumes [27]. This could be dehulling of husks did not carried out in this study, which is supported by [28, 29]. Germination decreased the fiber content of complementary flours from 3.98 and 4.19% to 3.56 and 3.94%, respectively. This observation is in agreement with the previous studies conducted on complementary food prepared from germinated maize and chickpea [30, 16]. The protein contents of the formulated complementary flours were in the range of 10.42 to 12.70%. This result is lower than complementary food prepared from maize, barley and broad bean mixes and germinated maize based complementary food [30, 31]. These could be due to incorporation of chickpea which is known to be inferior in its protein content than most legumes. On the contrary, the protein contents of this study are higher than study conducted on maize based complementary porridge and daily recommended value in World Bank Infant and Young Child Feeding projects for children aged between 12 to 23 months [19, 32]. It could be due to higher amount of legumes incorporated in this study. In raw and germinated complementary flours the protein contents were increased while the amount of chickpea increased. Similar finding was observed when soybean added to QPM [34]. Soaking of QPM and chickpea decreased the protein content of complementary flours, which could be due progressive solubilization and leaching out of the nitrogenous substances during soaking of the legumes [33].

|

|

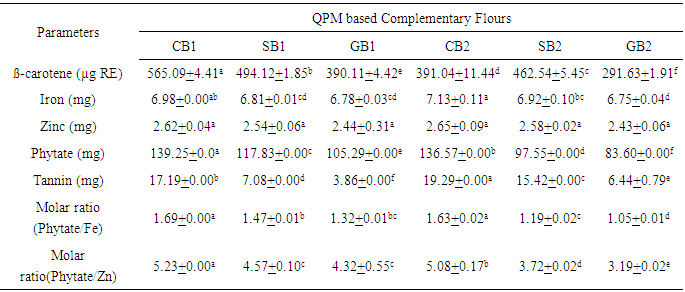

3.2. Micronutrients and Anti-nutrients of QPM based Complementary Flours

- The recommended daily allowance (RDA) of iron for children aged 1-3years old is 7mg [18]. According to [13], CF which satisfied two third of minerals and/or vitamins RDA is acceptable. The iron content in this study was in the range of 6.75 to 7.13mg per 100gm which fulfilled the minimum RDA. Iron contents showed a decrement while germination and soaking were used as processing methods in this study (Table 3). Similar decrements were observed in Nigerian ‘furra’, finger millet, cassava: soya bean mixed complementary food and chickpea [16, 26, 41, 42]. Opposing results were seen in studies conducted on germinated sorghum and soaked soya bean [43, 50]. The amount of zinc in this study was in the range between 2.43 to 2.65mg per 100gm which fulfilled 81 to 88.34% of the RDA for children aged 1-3 years is 3mg [18]. Though the amount of zinc in raw, soaked and germinated CF were not significantly different (p<0.05), but there were slight increment while the amount of legumes increased. Similar finding was seen in Cocoyam-based recipes enriched with cowpea flour [12]. Germination and soaking decreased the amount of zinc in the complementary flours, which is supported by a studies conducted on chickpea and finger millet [16, 26]. This could be due to leaching out of minerals while soaking was used alone or before germination. In contrast germination and soaking increased the amount of zinc in soya bean and sorghum [43, 50].Soaking and germination decreased phytate and tannin content of grains or legumes; this could be due to the activation of endogenous phytate enzyme and the leaching out of tannin into the water [45]. In the present study, the effect of soaking exhibited 15.38 and 28.38% reduction of phytates in CFs while the amount of chickpea increased. According to [26], the amount of phytate decreased in finger millet was in the range of 8.51 to 17.43%. The higher amount of phytate loss in the present study could be the time used for soaking was twofold greater than study in finger millet [44]. Likewise, germination significantly (p<0.05) decreased the amount of phytate in this study. Similar finding were seen in studies conducted on Nigerian “furra”, chickpea, sorghum, maize and finger millet [26, 42, 46, 50]. Results obtained in the present study indicated that while the amount of chickpea increased in CFs, the amount of phytate in all processing method used for preparation of complementary flours reduced significantly (p<0.05). This could be the presence of higher amount of phytate in QPM than chickpea [16, 17]. In this study the amount of tannins were significantly decreased (p<0.05) as soaking and germination were used with 58.81 to 21.06% and 79.99 to 24.62% respectively. The amount of tannin decreased in finger millet was comparable for soaked (16.61 to 32.33%) and germinated (21.03 to 80.06%), 74.08 to 79.93% in germinated lotus seed and 43.43% loss of tannin observed in germinated chickpea [16, 26, 44]. The amount of tannin was increased from 17.19 to 19.29%, 7.08 to 15.42% and 3.86 to 6.44% for CF prepared from raw, soaked and germinated ingredients consecutively while the substitution of QPM by chickpea increased. This may be due to the fact that relatively high amount of tannins existed in chickpea than QPM [16, 17]. The bioavailability of zinc in the complementary flours prepared in this study were in the range of 3.19 to 5.23 and below the acceptable maximum value which is fifteen, whereas the bioavailability of iron was around the acceptable maximum value one and existed in the range of 1.05 to 1.69 [61].The amount of β-carotene in this study was in the range between 291.63 and 565.09 μg per100gm and equivalent to Vitamin A in between 48.6 and 94.4 μg RE when it is converted as 6 μg of beta carotene equivalent to 1 μg RE of vitamin A [47]. These results are below the mean daily requirement of vitamin A (190 to 200 μg RE), RDA (400 μg RE) for children aged 7 to 36 months. The lower amount of β-carotene of complementary flours in the present study could be due to less amount of OFSP were incorporated and most some β-carotene was lost due to storage of flours for forty five days before analysis. The results of this study are supported by study conducted in Uganda in which 70% loss of β-carotene was observed in dried chips after four months storage [48]. In the current study the amount of vitamin A significantly (p<0.05) decreased while the amount of chickpea increased with soaking and germination.

|

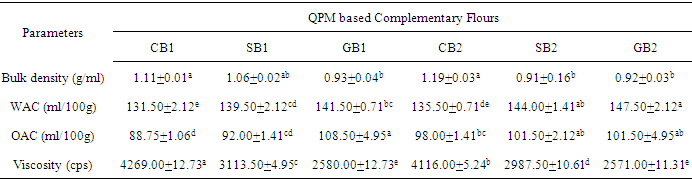

3.3. Functional Properties of QPM based Complementary Flours and Porridge

- The functional properties determine the application and use of food material for various food products. The bulk density values were found to be between 0.91 to 1.19gm per ml. Comparable results were observed in Nigerian “Ogi” and maize (un-malted and malted) with value 0.71 to 1.10gm per ml and 0.86 to 1.17gm per ml respectively. This value is slightly higher than sweet potato: soya bean based complementary flour (0.56 to 0.96gm per ml), popcorn based complementary flour (0.56 to 0.86gm per ml) and Soya bean: maize Flour (0.61 to 0.73gm per cm3) [25, 39, 49]. CF prepared from germinated and soaked ingredients showed a decrement in bulk densities while the amount of chick pea incorporated increased in the present study. Similar results were seen study conducted on Soya bean: maize and sweet potato: soya bean based flour [39, 49]. In the present study, soaking and germination reduced bulk densities of complementary flours. Similar trend were seen on maize and finger millet flours [46, 51]. Water absorption capacity (WAC) of complementary flours in this study were between 131.50 to 147.50ml per 100gm. Comparable result was exhibited on QPM: soya bean blends complementary food (126.13 to 146.6%), lotus seed (120 to 175 ml per 100gm) and millet flour for porridge production (130 to 138%). Germination and soaking of QPM and chickpea increased the amount of water absorbed in CFs prepared in the present study. Similarly, increased WAC was recorded in malted maize: defatted sesame blended flour, germinated lotus seed, wheat and millet flours [17, 44, 46, 52]. WAC of CFs in the present study was also increased while the amount of chick pea increased in the present study. This result is agrees with finding on soya bean-maize flour blended cookies and soya: plantain flour [39, 53]. High oil absorption capacity is important for increasing energy density of complementary foods. The oil absorption capacities (OAC) of flours in this study were between 88.75 to 108.5ml per 100gm. Higher amount of OAC was determined in lotus seed (137 to 165 ml per 100gm) and cowpea, pigeon pea, peas and mung bean protein isolates (113 to 168 %). This higher result could be observed due to less amount of fat contents recorded, which is supported by a study conducted on defatted and full fat Mucuna bean [54]. Germination of QPM and chickpea increased the OAC of CFs in this study, which is supported by a study on pearl millet [57]. Similarly, increasing the amount of chickpea in CFs increased the capacity of flours to absorb oil per 100gm which is agreed with cocoyam: soybean: crayfish flour blends [55]. Viscosity is the most important determinant of energy density [50]. Complementary porridges prepared in developing countries are known with high viscosity which can limit the energy and nutrient need of children. At 15% w/v of complementary flours with water, the viscosities of complementary porridges were between 2571 to 4269 cps. Germination and soaking significantly (p<0.05) reduced viscosities which were 37.53 to 39% and 27.07 to 27.42% respectively in the present study. Similar decrement was seen in porridges prepared from germinated maize fortified with defatted sesame, germinated maize [50, 51]. Viscosity also decreased while the amount of chickpea increased in the complementary flours of this study. Addition of bean on maize, increasing the substitution of soybean on plantain showed agreed result with present study [20, 53].

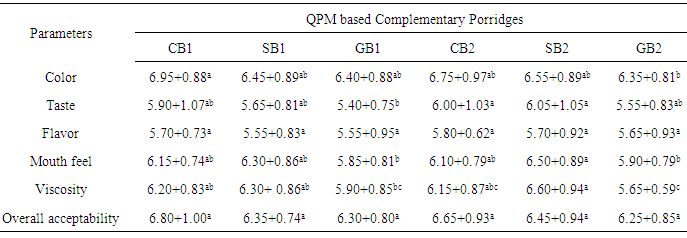

3.4. Sensory Evaluation of Complementary Porridge

- Sensory evaluation result of QPM based complementary porridges at laboratory showed; parameters like color, taste, flavor, texture, and overall acceptability were negatively affected by processing like soaking and germination. Similar results were observed in complementary porridges prepared from sorghum in Ethiopia [50]. Complementary porridges prepared in this study were liked moderately at laboratory level (6.25 to 6.80) using nine point’s hedonic scales. The overall acceptance of complementary porridges in this study is lower than study conducted in silte, southern Ethiopia on maize based complementary porridge [20]. This could be cereals and legumes used in this study were not roasted which can improve organoleptic properties and acceptability of foods [58, 60] (Table 4).

|

4. Conclusions

- Substitution of QPM with chickpea up to 50% is accepted by flavor optimization. Increasing the amount of chickpea on QPM for complementary food preparation improved fat, protein, zinc and iron contents. Germination and soaking of QPM and/or chickpea also increased bio availability of nutrients by reducing phytate and tannin contents. Furthermore, it increased the nutrient density by decreasing viscosity of complementary foods. All QPM based complementary foods prepared in this study was accepted at community level and fulfilled the minimum RDA for energy (370kcal) and protein (10.9gm), 2/3 RDA of iron and zinc which is acceptable and contribute up to 50% of vitamin A mean daily requirements for children with the age range of 6 to 36 months. Therefore, in this study nutritionally improved complementary foods are prepared from a blend of QPM, chickpea, OFSP and red teff.

ACKNOWLEDGMENTS

- The authors would like to thank Hawassa University, NORAD project and the American people through the United States Agency for International Development (USAID) under Agreement No.AID-243-A-11-00017 for financing this research work. The authors would like also to thank Hawassa University, School of Nutrition, Food Science and Technology and Ethiopian Health and Nutrition Research Institute for carrying out this experiment.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML