-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(2): 96-100

doi:10.5923/j.food.20150502.04

Quality Characteristics of Laboratory-Made Mortadella Meat Product

Alla M. Mohammed1, Abdel Moneim E. Sulieman2, Zakaria A. Salih1, Amir Mahgoub3

1Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Sudan

2Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

3Department of Clinical Nutrition, Faculty of Medical Sciences, University of Hail, Kingdom of Saudi Arabia

Correspondence to: Abdel Moneim E. Sulieman, Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Mortadella is a very popular ready-to-eat meat product in the world, used to prepare low cost sandwiches. In the presentstudy, thequality characteristics of mortadella products prepared at laboratory level were investigated through the determination of their microbial characteristics, chemical composition and sensorial characteristics. Most of the chemical components were in close agreement to the literature values. The microbiological analysis depicted the low counts of microorganisms present in the processed mortadella (H) in count of total bacterial, coliforms and yeast and mould which were 6.68×105, 2.27×104 and 1.81×102 (cfu/g), respectively, and all samples were devoid of any Staphylococcus aureus. However, the commercial mortadella (C1) contained relatively high counts of total bacterial, S. aureus , coliforms and yeast and mould which were 9.90×105, 2.73×104, 4.55×104 and 3.41×103 (cfu/g), respectively. The sensory analysis revealed that an acceptable quality of mortadella product can be produced under laboratory level, The mortadella manufactured in this study was preferred by the panelists as well as the commercial mortadella samples. The panelists detected no significant difference (P>0.05) in appearance, color, flavor and overall-acceptability among various mortadella samples, however, there was significant difference when comparing processed mortadella with the commercial samples. It is recommended to encourage utilization of mortadella which must be produced under controlled conditions using standard methods.

Keywords: Beef meat, Protein, Crude fibre, Coliform

Cite this paper: Alla M. Mohammed, Abdel Moneim E. Sulieman, Zakaria A. Salih, Amir Mahgoub, Quality Characteristics of Laboratory-Made Mortadella Meat Product, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 2, 2015, pp. 96-100. doi: 10.5923/j.food.20150502.04.

Article Outline

1. Introduction

- Meat products are widely consumed foodstuffs. In addition to appreciable sensory aspects, meat products have a relatively low price when compared to traditional in natura meat cuts. Mortadella is a cured, emulsified and stuffed meat product that provides lower social classes access to animal proteins, making the minimal recommended protein intake possible [1].Mortadella is an increasingly popular meat production in Sudan and neighboring countries because of its pleasant taste and texture, high nutritional value and ease of incorporation into sandwiches. In Sudan, mortadella is sold as cylindrical rolls incasing or sliced and vacuum packed [2]. Originally, mortadella was a traditional cured, cooked Italian sausage, but the version made in Sudan and neighboring countries is an emulsion type sausage. In Italy it was traditionally produced from horse meat, but is now produced from pork or beef or a mixture of these. The amount of fat added depends on the quality required. In addition, quality is related to the amount of muscle protein and, as the proportion of fat and collagen increase and protein decreases, quality are reduced. Addition of a fat emulsion improves the properties, including taste.In Arabic and Islamic countries, pork meat and its products are not consumed for religious reasons and mortadella is produced from beef or poultry meat. To date, however, there have been no investigations of the suitability of beef and sheep meat for the production of mortadella, the processing technology required, microbiological and chemical properties or changes in quality of the mortadella during storage or translation. This research discusses the technological conditions that are necessary for manufacturing the product in a way which ensures consistency of mortadella properties. As specific Sudanese standards are mandatory, care was taken to ensure that the manufactured mortadella was reproducible and met legal requirements. The raw meat, dough mix and the finished product were analyzed chemically and microbiologically, as these aspects are associated with product quality and stability. Micro-organisms associated with such a product and which affect its quality and safety has been identified by Tompkin [3]. Mortadella has similarities to frankfurters, bologna and other emulsion-based sausages and luncheon meats prepared from a range of ingredients, which contribute micro-organisms to the final product. Bacteria, yeasts and moulds may be associated with processed meats, but the former two groups are of most importance in microbial spoilage [4]. The bacterial flora of such products frequently includes staphylococci, micrococci and lactic acid bacteria [5]. The objective of the present study was to produce mortaedella meat product al laboratory level and evaluation of the product using microbiological and chemical methods as well as sensory evaluation.

2. Material and Methods

2.1. Materials

- Two brands of Mortadella (C1 and C2) samples were purchased from various supermarkets in Wad-Medani, Gezira, Sudan and kept at low temperature (6°C) pending analyses. The ingredients used to prepare the processed mortadella were also purchased from local market. All analyses of samples were held at Food laboratory, Department of Food Science and Technology, University of Gezira.

2.2. Preparation of Mortadella at the Laboratory

- Mortadella samples were prepared according to the standard procedure of Sudanese Standard Measurement organization (SSMO) for mortadella at the laboratory level. The process started with cutting about 517g of beef meat cut by sterilized knife and then minced to smooth chopped meat. After chopping, the ingredients were added respectively to the meat samples in emulsion machine, these ingredients included: 227g of ice, and 73g of plant oil and 20g of skimmed milk, 27.1g soya bean, 6g of garlic and pepper, cinnamon, sugar, 3g of Chinese kebab, 14g of salt, 0.4g of vitc, 0.27g of sodium nitrite and 45.3g of corn flour. Then the mixture was packed in cellulose packages. After packaging, the mixtures were subjected to heat treatment which included:Smoking for two hours, followed by heating water for cooking at 80°C for 40 minutes, then the samples were placed in the hot water for cooking. After that the samples were cooled in ice water for five minutes. Then the samples were packed sterilized sacks by using a packaging machine.

2.3. Microbiological Analysis

2.3.1. Preparation of Serial Dilutions

- Three grams of each sample of mortadella were weighed aseptically in sterile container and then blended with 180 ml sterile distilled water using sterile electric blender for two minutes to give 1/10 dilutions, 1 ml from standard dilution was transferred to 9 ml sterile distilled water to obtain 2nd dilution, this was repeated to obtain successive serial dilutions (10-2, 10-3, 10-4, 10-5, ...etc.) [6].

2.3.2. Total Viable Bacterial Count

- Bacterial viable count was conducted using the pour plate according to APHA [7] method, in which: 1 ml sample from each dilution was transferred aseptically by pipette to sterile petri dishes 15-20 ml of method at 45°C nutrient Agar was added carefully to the sample. Then mixed thoroughly and allowed to solidify, the plates were incubated at 37°C for 48 hours. The colonies were counted as “colony forming unit/g” i.e. C.F.U/g as mean value.

2.3.3. Detection of Coliforms

- The test was carried out by streaking loop-full with dilution sterile plate, which contained sterile and solidified MacConkey agar. Then the plates were inoculated at 37°C for 48 hours.

2.3.4. Enumeration of Yeast and Moulds

- The test carried out by using surface plating technique, in which 0.1 ml suitable dilutions was transferred by using sterile pipette into sterile duplicate plate containing 15-20 ml solidified sterile potato dextrose agar with 0.08 ml chloramphenicol as inhibitor for bacterial growth. Then the inoculum was spread over media using sterile blended glass rod. Then the plates were incubated at 28°C for 3-4 days the colonies were counted as colony 1.0 g.

2.4. Proximate Analysis of Mortadella

- Analysis of proximate composition of mortadella was carried out to determine the contents of moisture, ash, crude protein, crude fat and crude fiber according to AOAC [8] method. While the total carbohydrate content was obtained by calculation as the difference between the sum of the other major ingredients, namely moisture, ash, crude fiber, crude protein and fat from 100.

2.5. Determination of Minerals

- Potassium (K), sodium (Na) and calcium (Ca) and Iron (Fe) determinations were accomplished by means of flame photometer model (Corning 400) according to the AOAC [9] in which different concentrations (5, 10, 15, 20, 25 ppm) were prepared from stock solutions of Ca++, Na+, K+, Fe++ and Mg++ using the flame photometer the readings were taken and a graph was made. The sample was prepared by weighing 3 grams of sample were weighed into a clean pre- dried and weighed porcelain dish. The dish containing the sample was placed in a muffle furnace at 550°C and left burning for 5 hours at this temperature. Then, the dish with its content was weighed again after cooling in a desiccator to the room temperature and ash content was determined then ash was dissolved in distilled water and adding 10 ml HCl to make 100 ml. Then the absorption of the sample was measured and the concentration determined from the calibration, curve.The phosphorous was determined according to AOAC [10]. In which: 5g of mortadella samples was weighted and samples were ashed at 600°C over night to a white ash. Then cooled and 10 ml of 5 MHCL was added to the ash and boiled, then the solution was washed and filtered into a 100 ml volumetric flask with distilled water. Then neutralized by the drop-wise added of 0.88 ammonia (the volume of the solution at this stage should be 50-60 ml). and made just acid with diluted nitric acid, and 25ml of vanadate-molybdate reagent, were added and were diluted to the mark and measured the optical density after allowed to stand for 10 minutes. Then the concentration of P2O5 in the sample solution can be determined and the concentration of total phosphorus in the original sample was calculated as follows:Conc. of total phosphorous as P2O5 (in ppm) = Conc. Of P2O5 in sample solution x 1000/WWhere w = weight of the sample in g taken for ashing.

2.6. Sensory Evaluation

- The sensory quality of beef mortadella was assessed by 10 panelists chosen from the lab staff of the Department of Food Science and Technology, University of Gezira. Panelists were requested to evaluate color, flavor, juiciness, texture and overall- acceptability of the product using a nine point hedonic scale, with 1 indicating dislike extremely and 9 like extremely [11].

2.7. Statistical Analysis

- All scores of sensory evaluation were analyzed by using t-test. To determine the significant differences between means for each variable, least significant difference (LSD) test was used.

3. Results and Discussion

3.1. Proximate Composition

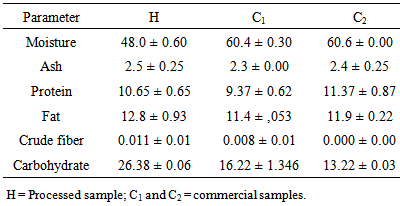

- Mortadella is a mixed-meat product whose characteristics are largely independent of the specific properties of the raw materials, breed of animal and breeding method. Instead, its characteristics are significantly affected by the formulation and amounts of the cuts used to make it, as well as some technological aspects, such as the use of certain ingredients and additives, and the processing parameters (temperatures and process timing). In present study the chemical composition of mortadella was shown in Table (1).

|

3.2. Mineral Content

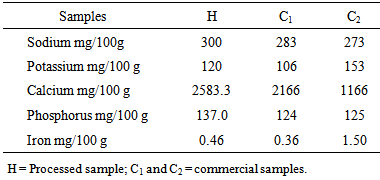

- The minerals of the processed mortadella (H) and commercial mortadella (C2 and C1) are presented in Table (2). The sodium content was observed to be higher in H (300 mg/100 g) followed by C1 (283 mg/100 g), and the lowest was found in C2 (273 mg/100 g). The potassium content in C2 (153 mg/100 g) was higher than those of H and C1 samples which were 120 mg/100 g and 106 mg/100 g, respectively. The calcium content in H C1 and C2 mortadella samples was found to be 2583.3 mg/100 g, 2166 mg/100 g and 1166 mg/100 g, respectively.

|

3.3. Microbial Analysis of Mortadella

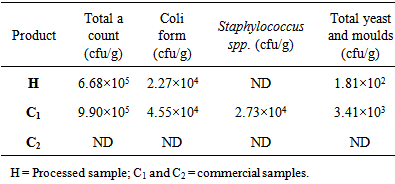

- Table (3) represent the microbial analysis results of the processed mortadella (H) and commercial mortadella produced (C1 and C2). The Harmful bacteria such as Salmonella, coliforms, E. coli as well as yeast and moulds were investigated. The results depicted the low counts of microorganisms present in the processed mortadella (H) in count of total bacterial, coliforms and yeast and mould which were 6.68×105, 2.27×104 and 1.81×102 (cfu/g), respectively, and all samples were devoid of any Staphylococcus aureus. However, the commercial mortadella (C1) contained relatively high counts of total bacterial, S. aureus, coliforms and yeast and mould which were 9.90×105, 2.73×104, 4.55×104 and 3.41×103 (cfu/g), respectively. These counts were higher than those obtained by Abdelmageed et al. [14] who reported that the total bacterial 102 (cfu/g) and ≤ 0 (cfu/g) of S. aureus, coliform and yeast and mould of beef burger. The contamination of the commercial mortadella samples may due to inferior quality of raw materials used, while good manufacturing practices were used in preparation of the mortadella (H) which efficiently maintains quality and safety of the product (H).

|

3.4. Sensory Evaluation

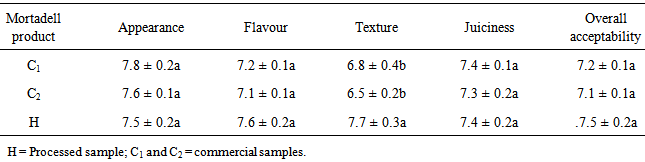

- Sensory evaluation of the processed mortadella (H) and commercial mortadella (LM) are shown in Tables (4). In general terms, a similarity between the panellists’ scores for the different parameters can be observed. Non-significant differences were found only in the texture attribute evaluated. The results of evaluation of appearance, color, flavor, juiciness, texture and overall acceptability indicate that in mortadella colour and flavour are effectively the most important organoleptic properties. And there is no significant difference (P>0.05) in appearance, color, texture, flavor and overall-acceptability among the processed mortadella (H) and commercial mortadella were observed, with a higher acceptance tendency for the processed mortadella (H) in the overall acceptability within the hedonic scale.

|

4. Conclusions

- In conclusion, an acceptable and microbiologically safe mortadella meat product can be produced under laboratory conditions considering all the formulations requirements could be accepted by the consumers. The beef mortadella manufactured in this study was preferred by the panelist compared with the commercial mortadella obtained from local market. The manufactured beef mortadella was performed according to the Sudanese standard measurement organization and under legislative demand concerning microbiological and chemical parameter except for fat levels of formulations prepared. Beef mortadella is preferred by many consumers due to its organoleptic properties and low cost because the raw materials used in its formulation allows for better use of this food material and for diversification of it. Production The produce under level of laboratory demanded control of conditions and using sterilize of equipment that to produce safety product. It is highly recommended to encourage utilization of mortadella which must be produced under controlled conditions using standard methods, it is also necessary to use clean and sterilized equipment to prepare or manufacturing mortadella product.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML