-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(2): 75-81

doi:10.5923/j.food.20150502.01

Functional and Pasting Properties of Wheat / Plantain Flours Enriched with Bambara Groundnut Protein Concentrate

Kiin-Kabari D. B. , Eke-Ejiofor J. , Giami S. Y.

Department of Food Science and Technology, Rivers State University of Science and Technology Port Harcourt, Nigeria

Correspondence to: Kiin-Kabari D. B. , Department of Food Science and Technology, Rivers State University of Science and Technology Port Harcourt, Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Composite flour was prepared from wheat/plantain flours (0-40%) enriched with bambara groundnut protein concentrate (0-30%) and using 100% wheat flour as control. Functional and pasting properties of the composite flour were evaluated. The bulk density of the flour blends ranged from 0.34g/ml (100% wheat flour) to 0.47g/ml, (95% plantain flour and 5% protein concentrate) suggesting that plantain flour is heavier than other substituted samples. Oil and water absorption capacities showed that 95% plantain flour had the least values of 69.0% and 71.3%, respectively and increased significantly with increase in the levels of bambara groundnut protein concentrate. Foam capacity increased with increase in bambara groundnut protein concentrate added, however, foam unstability was significantly higher (65.1%) in sample with (95%) plantain flour and 5% bambara groundnut protein concentrate. Emulsion capacity increased significantly (P ≥ 0.05) from 32.4% to 64.1% and emulsion stability after 20h ranged from 26.8% to 48.7% showing a significant (P ≥ 0.05) increase with the increase in protein concentrate. Minimum nitrogen solubility of 40.0% and 40.4% were observed in flour blends with 100% wheat flour and 60% wheat flour, 25% plantain flour and 15% bambara groundnut protein concentrates, respectively while the maximum nitrogen solubility of 85% occurred in sample C at pH 12. A peak viscosity of 248.12 RVU which was significantly (P ≥ 0.05) different from other flour blends was observed in sample with 100% wheat flour (sample A) while the least peak viscosity of 219.63 RVU was recorded for sample with 40% wheat flour, 35% plantain flour and 25% protein concentrate (sample F). A hold period (Trough viscosity) ranged from 178.44 RVU (sample F) to 205.81 RUV (sample A), peak time of flour blends increased from 4.7min (Sample A) to 6.7min (sample F) which increased as the level of plantain flour and protein concentrate also increased. Pasting temperature also increased in similar pattern, ranging from 66.9℃ to 82.4℃.

Keywords: Functional properties, Pasting properties, Protein concentrates, Plantain flour

Cite this paper: Kiin-Kabari D. B. , Eke-Ejiofor J. , Giami S. Y. , Functional and Pasting Properties of Wheat / Plantain Flours Enriched with Bambara Groundnut Protein Concentrate, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 2, 2015, pp. 75-81. doi: 10.5923/j.food.20150502.01.

Article Outline

1. Introduction

- Functional properties are those physico-chemical properties of food proteins that determine their behaviour in food system during processing, storage and consumption [1]. Functional properties had been defined as the intrinsic physico-chemical characteristics which affect the behaviour of protein in food system during processing, storage and preparation [2]. They interact with other food components directly or indirectly affecting processing applications, food quality and ultimate acceptance. Proteins used in foods are required to possess critical functional properties such as water and oil absorption capacities, nitrogen solubility, bulk density, emulsifying and foaming properties [3]. These properties govern the suitability of novel proteins as food supplement as well as ingredients for fabricating new food products. Hydration of proteins is reported to be vital for several functional behaviours such as emulsification and foaming properties, viscosity and gelation [4]. Functional properties of plantain flour in bakery products have been reported by several researchers [5, 6, 7]. These studies were done using plantain flour obtained from green (unripe) plantain fruits. Saifullah et al., [8] suggested that the green pulp of plantain fruits could be utilized as a functional ingredient in starch rich products such as noodles. Giami and Alu [9], also studied the functional properties of plantain at different stages of ripening. Composite flour in baking performance using plantain flour substituted with wheat flour had been investigated by Onwuka and Onwuka [10], plantain, cassava/soybean flour blends for snacks and complementary food formulations [11]. These efforts again were aimed at improving the protein content in particular and the overall nutritional value of the products. Plant proteins are gradually gaining acceptance as food ingredients, these are often used to enhance nutritional value of formulated foods [12].Legumes and oilseeds contain very high protein but are less utilized. Bambara groundnut is one of these legumes and detailed compositional studies showed that the beans contain between 17-24% protein with a good balance of the essential amino acids and relatively high proportions of lysine (6.8%) and methionine (1.3%) [12, 13]. Chemical and physical properties of various flour blends with plantain had been investigated. Abioye et al. [14] studied the physico-chemical properties of soy-plantain flour and showed that 10% inclusion of soy flour with plantain was generally acceptable and increased the protein content of the flour. One limitation of the incorporation of bambara groundnut flour in baked products is the beany flavour associated with it. Therefore this study is aimed at preparing the protein concentrate from bambara groundnut flour and studying the functionality and pasting properties of different levels of protein concentrate with wheat/plantain flour blend.

2. Materials and Methods

2.1. Materials

- Unripe plantain fruits were harvested from the International Institute for Tropical Agriculture (IITA), High Rainfall Station Onne; near Port Harcourt, Nigeria. Bambara groundnut (Vigna subterrenea (L) Verde) seeds were purchased from markets in Enugu, Nigeria. The Rapid Visco Analyzer (RVA) model 3C, Newport Scientific PTV Ltd, Sydney located at IITA Ibadan was used for pasting properties.

3. Methods

3.1. Preparation of Plantain Flour

- Plantain fingers (agbagba cultivar) were peeled manually with the aid of stainless steel kitchen knives and the pulp was cut into uniform slices with thickness of about 1.5mm, soaked in 1.25% sodium metabisulphide solution for 5min, drained and dried in air circulating oven at 65℃ for 20h according to the method of Adeniji et al, [15] and earlier reported by Kiin-Kabari and Eke-Ejiofor [16].

3.2. Preparation of Bambara Groundnut Flour

- Bambara groundnut flour was prepared using the method described by Barimalaa et al, [17]. Briefly, the beans (black eye variety) were soaked for 24h in water and dehulled manually. The dehulled seeds were boiled for 10min (1:4 bean to water ratio) in a stainless steel pot, drained and dried at 50℃ in an air circulating oven for 19h. The dried samples were milled (Foss, Cyclotec 1093, Sweden), and sieved into flour using 0.25mm sieves.

3.3. Preparation of Protein Concentrate

- Protein concentrates from bambara groundnut flour was prepared using the alkaline wet extraction process described by Deshpande and Chenyan [18] with little modification as reported by Giami and Isichei [19], for fluted pumpkin seeds.

3.4. Preparation of Flour Blends

- Graded levels of bambara groundnut protein concentrates ranging from 0-30%, plantain flour ranging from 0-40% and wheat flour were formulated, properly mixed and labelled with 100% wheat flour (control). Commercial high quality wheat flour (Golden Crown Brand) was obtained from Nigerian Flour Mills Limited, Port Harcourt Nigeria.

3.5. Functional Properties

- Water and oil absorption capacities were determined on the composite flour blends using the method of Beuchat [20], bulk densities of the various composite flour samples were determined using the method described by Wang and Kinsella [21]) with slight modifications as reported by Arisa et al. [22] for plantain flour. Emulsification capacity and stability were studied using the method described by Beuchat [20] with slight modifications. Vegetable oil (corn oil) was used and the emulsion was determined at room temperature (28 ± 1℃). The stability of the emulsion was evaluated by keeping the emulsion at room temperature for up to 20h, and noting the separation of water in the graduated cylinders. Foaming capacity and stability were studied as described by Coffman and Garcia [23] with slight modifications. Two grams of each flour blend was whipped with 10ml of distilled water for 5min in a Kenwood blender (Model A907 D,ve) at high speed and poured in a 250ml graduated cylinder. The volume of foam at 30 seconds, after whipping was expressed as foam capacity and the foam volume over 10-120min as the foam stability for the respective time periods. The percentage volume increase was calculated.

3.6. Nitrogen Solubility

- Nitrogen solubility of the protein concentrates and the various flour blends were determined in the pH range of 2-12 at room temperature (28 ± 1℃), using the method described by Narayana and Narasinga Rao [24]. The nitrogen extracted was expressed as percent of the flour nitrogen.

3.7. Pasting Properties of the Flour Blends

- Pasting properties of the flour blends were characterized using the Rapid Visco Analyzer (RVA Model 3c, Newport Scientific PTY Ltd, Sydney) as described by Sanni et al., [25]. Five (5) grams of samples were accurately weighed into a weighing vessel, 25ml of distilled water was dispersed into a new test canister. Samples were transferred onto the water surface of the canister after which the paddle was placed into the canister. The blade was vigorously joggled up and down through the sample ten times or more until no flour lumps remained either on the water surface or the paddle. The paddle was properly centred into the canister and the measurement cycle initiated. Peak viscosity (RVA), Peak time (min), Peak temperature (℃), Trough (RVU), pasting temperature (℃) and final viscosity (RVU) were read on the instrument while breakdown and setback viscosities (RVU) were calculated.

3.8. Statistical Analysis

- The data obtained were analysed statistically with SAS 9.0, using one way analysis of variance (ANOVA). Means were separated by calculating the least significant difference (LSD) at (P ≤ 0.05).

4. Results and Discussion

4.1. Bulk Density, Oil and Water Absorption Capacities

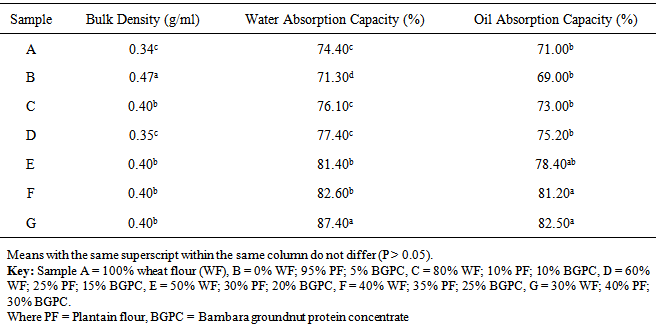

- The bulk density of the different flour blends ranged from 0.34 to 0.47g/ml with sample A (100% wheat flour) having the lowest value and sample B having the highest value of 0.47g/ml as shown in Table 1. The higher the bulk density, the denser the flour suggesting that 95% plantain flour is heavier than other substituted samples. Information on bulk density may be useful in packaging. This observation is similar to the finding of Abioye et al [14], who reported a bulk density of 0.46g/cm3 for 100% plantain flour. Substitutions with wheat flour and bambara groundnut protein concentrate flour blends decreased significantly (p < 0.05), the bulk density of other samples. Oil and water absorption capacities ranged from 69.0% to 82.5% and 71.3% to 87.4%, respectively. In both cases, 95% plantain flour had the least value of oil and water absorption capacities of 69.0% and 71.3%. The water holding ability of the blends increased with increase in protein content. This is in agreement with the report of Adebowale et al. [26], who observed that addition of soy-flour to plantain flour confers high water binding capacity which, in turn improves the reconstitution and textural abilities obtainable from plantain flour. Also, Kinsella, [27] had earlier reported that the ability of food materials to absorb water is sometimes attributed to the protein content. This suggests that increase in water absorption in the blends can be useful in bakery products such as bread, cakes, cookies that requires hydration to improve dough handling characteristics. The oil absorption capacity followed similar pattern as water absorption, increasing with increase in the level of protein concentrates in the blends.

|

4.2. Foam and Emulsion Capacities of the Flour Blends

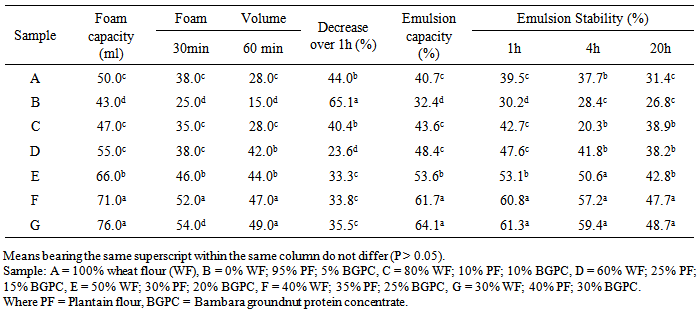

- Foam capacity, foam volume, emulsion capacity and stability of the composite flour blends are presented in Table 2. Foam capacity of the enriched flour lends ranged from 43ml to 76ml in samples B and G, respectively. Foaming increased progressively with increase in protein concentrates. The decrease in foam volume after 1h was highest in sample B (65.1%), indicating that the foam volume was unstable when compared to sample D (23.6%), sample E (33.3%), sample F and G (33.8% and 33.5%), respectively, which showed no significant differences (p ≥ 0.05). However, this instability in foam volume may be attributed to the fact that the proteins in sample B may not be enough to sustain the foam volume developed over a long time. The formation of a stable foam is very essential in the preparation of several traditional cowpea-based food products in Nigeria [28]. It has been reported by Mepba et al. [29] that the foam ability of a product is related to the rate of decrease of the surface tension of air/water interface caused by the absorption of protein molecules. Dickinson [30], observed that flexible protein molecules such as

casein, which can rapidly reduce surface tension, gave good foamability, whereas ordered globular protein molecules such as lysozyme; which is relatively difficult to surface denature gave low foamability.

casein, which can rapidly reduce surface tension, gave good foamability, whereas ordered globular protein molecules such as lysozyme; which is relatively difficult to surface denature gave low foamability.

|

4.3. Nitrogen Solubility

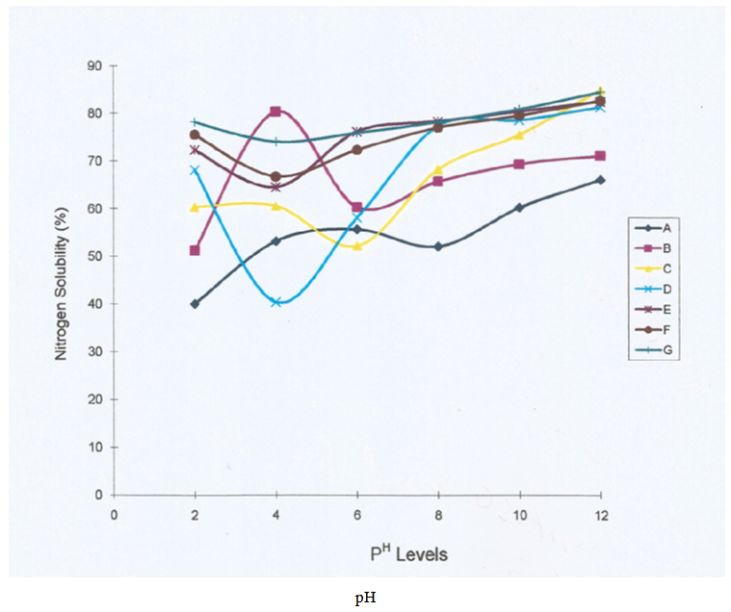

- Minimum nitrogen solubility of plantain flour sample enriched with bambara groundnut protein concentrates occurred in samples A and D with a nitrogen solubility of 40.0% and 40.4%, respectively as shown in Figure 1. These high values could properly be attributed to the presence of non-protein nitrogen. Apart from sample A (100% wheat flour), solubility dropped at pH 4 and increased in all the samples within the pH ranges of 6-12 with a maximum nitrogen solubility occurring in sample C (85%) at pH 12. The range of nitrogen solubility observed in this study is comparable to those reported by Giami and Alu [9], who reported that unripe plantain flour exhibited the highest solubility values (41-70%) in the pH range of 2-12. This is an indication that nitrogen solubility is dependent on pH and other factors such as salt concentration and processing methods [9]. In this study, it is clear that nitrogen solubility of the blends was improved upon the addition of bambara groundnut protein concentrates.

4.4. Pasting Characteristics of Plantain Flour and Blends

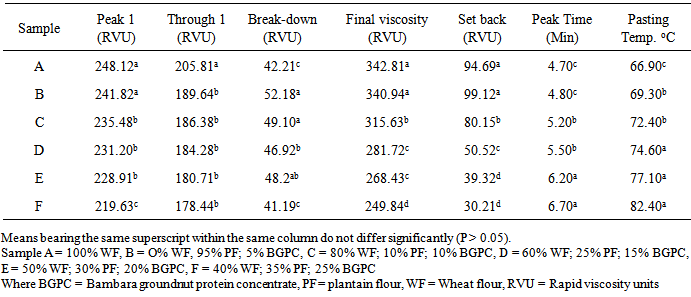

- A peak viscosity of 248.12 RVU which was significantly different from other flour blends was observed in sample A, while the least peak viscosity of 219.63 RVU was recorded in sample F as shown in Table 3. However, peak viscosity of the samples decreased with increase in protein concentrates. Peak viscosity which is the maximum viscosity developed during or soon after the heating portion of the pasting test was higher than the values reported for wheat flour and blended plantain flour by Arisa et al. [22]. This difference may be attributed to differences in plantain cultivars, or differences in analytical procedures and experimental conditions used. Peak viscosity is often correlated with the final product quality and also provides an indication of the viscous loads likely to be encountered during mixing [33]. The hold period (Trough) sometimes referred to as shear thinning, holding strength or hot paste viscosity is a period when the samples were subjected to a period of constant temperature and mechanical shear stress. It ranged from 178.44 RVU in sample F to 205.81 RVU (sample A). This result is in agreement with the work of Arisa et al. [22] who reported a trough viscosity value of 259.25 RVU for blended unripe plantain flour, and 186.75 RVU for plantain flour treated with sodium metabisulphide.

|

5. Conclusions

- Sample (B) with 95% plantain flour was heavier in bulk density and formed unstable foam which improved with increase in bambara groundnut protein concentrate. Minimum nitrogen solubility of 40.4% was observed in flour blends with 60% wheat flour, 25% plantain flour and 15% bambara product protein concentrate. Although peak and final viscosities decreased with increase in protein concentrate, peak time and pasting temperature increased with increase in plantain flour and bambara groundnut protein concentrates. These formations could be utilized in the preparation of baked products, such as cakes, cookies, bread and plantain paste (amala).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML