-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2015; 5(1): 15-23

doi:10.5923/j.food.20150501.03

Effect of Clove Oil on Physicochemical and Microbiological Characteristics of Egyptian Ras Cheese (Romy) during Storage

El-Fadaly H. A.1, M. N. F. Hamad2, S. M. L. El-Kadi1, A. A. Habib1

1Agric. Microbiology Dept., Fac. of Agric., Damietta Univ., Damietta, Egypt

2Dairy Science Dept., Fac. of Agric., Damietta Univ., Damietta, Egypt

Correspondence to: M. N. F. Hamad, Dairy Science Dept., Fac. of Agric., Damietta Univ., Damietta, Egypt.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Substances to fungal decontamination of Ras cheese during storage by using some natural substances. Egyptian Ras (Kefalotyri or Romy) cheese was manufactured from standardized buffaloes' and cows' milk (3.5% fat) with modified traditional method and dry salting around forty-five day. After complete salting process, the cheese wheels were painted on external surface of wheels (approximately 2–3 Kg) by clove oil and ripened at 59.9°F (15.5ºC) for three months. Weight and volume of Ras cheese wheel decreased gradually until the end of the storage period (3rd month) after salting. The untreated wheels decreased in the volume compared with the treated ones with clove oil. The moisture (M%) was gradually decreased for untreated and treated Ras cheese, in the end of the storage period, while the fat on dry matter (F/DM%), salt/cheese serum%, total nitrogen TN%, soluble nitrogen on total nitrogen SN/TN% and non-protein nitrogen on total nitrogen NPN/ TN% tended to increase with advanced storage. The total bacteria count (TBC), yeast and fungi (Y&F) were very high in the beginning of Ras cheese manufacture, while, after salting these values of (Y&F) were decreased in the wheels collecting from the surface and the middle of Ras cheese wheels, these values were decreased because of salting processing. The treatment with clove oil reduced the (TBC) and (Y&F) in the surface of both treatments after 1st, 2nd and 3rd month of ripening, while, the treatment without oil increased gradually of the (TBC) and (Y&F) in the surface of both treatments after the end of the storage. It was observed that, there were no observed fungi on the surface of both treatments which treated with clove oil during storage period. The texture and appearance scores were not significantly (p≤0.05) different in treated and untreated Ras cheese samples during ripening periods. Both treatment of both treatments have high significant (p≤0.05) of flavor after 3rd month of ripening in both treatments. This observation, encourage to use this oil for the further studies and it will be used in the commercial scale, as well as, this oil considered an antifungal edible coatings oil and improve the shelf life of cheese. Point of view study can recommend use of volatile oils of medicinal plants as natural substances to prevent and overcome the fungal contamination on Ras cheese during ripening period this is may be very useful from economic point of view.

Keywords: Egyptian ras cheese, Physico-Chemical properties, Microbiological examination and organoleptic properties

Cite this paper: El-Fadaly H. A., M. N. F. Hamad, S. M. L. El-Kadi, A. A. Habib, Effect of Clove Oil on Physicochemical and Microbiological Characteristics of Egyptian Ras Cheese (Romy) during Storage, International Journal of Food Science and Nutrition Engineering, Vol. 5 No. 1, 2015, pp. 15-23. doi: 10.5923/j.food.20150501.03.

Article Outline

1. Introduction

- Ras cheese is an Egyptian hard cheese made from cows and buffalos milk, the composition of the cheese has been described by [23], it is required a long period of time to develop the full flavor and texture of ripened cheese [14]. The dry cheeses are placed in ripening rooms in the production area, where ripening takes place at a nearly constant relative humidity (90–95%) and temperature (9–12°C).Penicillium verrucosum, P. commune, Aspergillus flavus and A. niger isolated from Ras cheese by [13]; [20]; [12] and [3]. Some Aspergillus sp. is xerophilic fungi and is responsible for many cases of food and feed contamination.Clove oil is extracted from Eugenia caryophyllata (also known as E. aromatica, E. carophyllus and Syzygium aromaticum) of the Myrtaceae family. The main chemical components of clove oil are eugenol, eugenol acetate, ISO-eugenol and caryophyllene [6] and [17]. The inhibitory effect of clove on growth and aflatoxin production by A. flavus has been reported. In maize grain, clove oil was effective against aflatoxin formation by A. flavus after 10 days under favourable conditions for mycotoxin production. The ability of oregano oil to inhibit growth of A. flavus, A. ochraceus and A. niger has been evaluated previously [33].The mode of action of essential oils as antimicrobial agent are depending on multi target mechanisms such as; damage bacterial cell due to disruption of cytoplasmic membrane, electron flow, active transport and coagulation of cell contents. Several previous reports were focused on the antimicrobial properties of essential oils. In fact, many essential oils are known to be active against a wide variety of microorganisms, including Gram-positive and Gram-negative bacteria and fungi. Toxic effects on membrane structure and function have been generally used to explain the antimicrobial action of essential oils, as a result of their lipophilic character, which preferentially partition from an aqueous phase into membrane structures. This results in membrane expansion, increased membrane fluidity and permeability, disturbance of membrane- embedded proteins, inhibition of respiration, and alteration of ion transport processes [32]. Clove essential oils were used for inhibitory activity against important spoilage microorganisms of intermediate moisture foods. It has been listed as a ‘‘Generally Regarded As Safe’’ substance by the United States Food and Drug Administration when administered at levels not exceeding 1500 ppm in all food categories [18]. Additionally, the World Health Organisation (WHO) [18] has established the acceptable daily human intake of clove oil at 2.5 mg/kg body weight for humans. It is safe, effective, and relatively inexpensive. In addition, humans have used clove oil for centuries, as an anaesthetic for toothaches, headaches and joint pain. The consumption of clove oil can reduce many health risks. Also, it is used throughout the world for applications ranging from food flavoring. It was found to be an effective antioxidant in vitro assays including reducing power and superoxide anion radical scavenging, hydrogen peroxide scavenging and metal chelating activities. It can be used for minimizing or preventing lipid oxidation in food and prolonging the shelf life of food and pharmaceuticals [18]. Clove oil is considered as the most common herbs with strong antimicrobial activity. The addition of essential oils containing chemical compounds such as carvacrol, cinnamaldhyde, eugenol and camphor which are identified as the major chemical components responsible for exerting antimicrobial activity. Some scientists confirmed the antimicrobial activity of essential oils from oregano, thyme, sage, rosemary, clove, coriander, garlic and onion against both bacteria and molds [27].The aim of this study was examined the inhibitory effect of clove oil against the microbial growth naturally on the Ras cheese wheels during the storage period (three months). Physical properties, organoleptic properties, microbiological examination and chemical composition of Egyptian Ras cheese was also studied.

2. Materials and Methods

- Fresh whole cows’ and the buffaloes’ milk that used in this study was obtained from El-Ghazy laboratory, Elsawalem, Damietta, Egypt. Local rennet 0.7N, “Elamel Elmasry“ was obtained by Ayman Haekel Company. Iodized salt, produced by El-Nasr Saline’s Co, Alex. was used. Other pure chemicals for measuring acidity, fat, protein, etc.…, were obtained from El-Gomheria Chemical Company, Mansoura, Egypt. Commercial clove oil was purchased from a local market, namely Cloves tested for their effect on fungal growth.

2.1. Ras Cheese Making

- In an attempt to imitate the widely used method among the cheese manufacture in El-Ghazy laboratory, Elsawalem, Damietta for making Ras cheese. The procedure suggested by [1] and [2] for making Ras cheese was adopted. Standardized milk (3.5% fat) was heated to 32ºC and sufficient rennet was added in the proportion of 2.5g per 100kg milk to complete coagulation in 30 – 40 minutes. The coagulum was cut into small pieces about the size of chickpea grains and then vigorously stirred. The temperature of the vat was then raised to 45ºC over a period of around 40 – 50 minutes, and gently stirring was maintained throughout. After the curd had settled, the whey drained out (acidity≈0.14%), salt was sprinkled over the curd at a ratio of 1% (w/w), and the curd was manually pushed to the sides of the fat. Molds, lined with cheesecloth, were filled with sufficient curd to produce one finished cheese, and manual pressure was applied to expel some of the remaining whey. Light mechanical pressure follows over the next four hours at which point the cheese was reversed in the press and left under pressure for overnight (approximately 18 hours) (Fig. 1). The cheese wheels were then removed from the moulds and cloths and placed in the salting chamber (Fig. 2). After draining for a further day at ambient temperature, the surfaces of each cheese wheels were coated with a small amount of dry salt (Fig. 3).

| Figure 1. Ras cheese in moulds during pressing process |

| Figure 2. Fresh Ras cheese wheels in the salting chamber |

| Figure 3. Salting Ras cheese wheels |

2.2. The Sampling Procedure

- The sampling procedure during the time of the experiment was as following: Eight cheese wheels were made in this experiment. The first one, was used as a control and will be referred to it in the following experiment as salting zero time. Then, the seven cheese wheels removed to the salting chamber. At the end of the dry salting process (45 day), the second cheese wheel was used as a control also, but will be referred to it in the following experiment as salting 1.5 months. The six cheese wheels were divided into two groups, the first group, was treated with clove oil by painting the surfaces of each cheese wheel and the second group were bot treated with clove oil. All six cheese wheels were stored at 15.5ºC for three months in a digital incubator. Thereafter, samples were taken after one, two and three months. Two samples were taken from every cheese wheel for the microbiological examination. The first sample was taken by scraping the cheese wheel's surface under aseptic conditions and the second sample was taken from the middle of the cheese wheel by cutting it using a sterilized knife.

2.3. Chemical Analysis

- Ras cheese was analyzed for total solids (TS), fat, total nitrogen (TN), soluble nitrogen (SN) and non-protein nitrogen contents (NPN) according to [26]. Salt contents of Ras cheese were estimated using the Volhard method according to [30].

2.4. Microbiological Analysis

- Poured plate method was used, one ml of suitable folds serial dilutions of all cheese samples were inoculated onto a plate containing potato dextrose agar (PDA) medium (three replicates). Approximately fifteen ml of PDA medium at about 50°C was poured in each plate, then thoroughly mixed and left for solidification. The plates were incubated at 25°C for 5 days. After the incubation period, developed colonies were counted per each plate. The mean count of plates was recorded to represent fungal count [4]. Total bacterial count of Ras cheese was determined according to [4] using nutrient agar medium [10]. It consists of (g/L): beef extract 3 g; peptone, 5 g; agar agar, 15 g; distilled water 1 L and sterilized by autoclaving at 121ºC for 15 min. The pH was adjusted to 6.8, plates were incubated at 30°C for 3 days before counting.

2.5. Sensory Evaluation

- This was carried out by at least 30 panelists and staff (both sexes, ages ranging between 18 and 65 years old) in Dairy science and Microbiology Departments, Faculty of agriculture, Damietta University, according to the scheme recommended by [23], taking into consideration the maximum attainable scores were 60 points out of 100 for flavour, 30 points for body and texture and 10 points for the general appearance.

2.6. Statistical Analysis

- PROC GLM procedure of the Statistical Analysis Systems [31] was used to analyze the Least-Squares Means (LSM) and Standard Errors (SE) for different treatments and the differences between means were detected by Duncan`s Multiple Range Test [11].

3. Results and Discussion

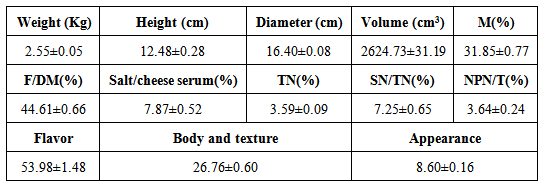

- Average wheel weight (Kg), wheel height (cm), wheel diameter (cm), wheel volume (cm3) was 2.55±0.05, 12.48±0.28, 16.40±0.08 and 2624.73±31.19, respectively. Average percentages of M, F/DM, salt/cheese serum, TN, SN/TN and NPN/TN were 31.85.60±0.77, 44.61±0.66 and 7.87±0.52, 3.59±0.09, 7.25±0.65 and 3.64±0.24, respectively (Table 1), while, the average of Ras cheese flavor and body and texture and appearance scores were 53.98±1.48, 26.76±0.60 and 8.60±0.16, respectively (Table 1).

|

3.1. Physical Properties of Treated and Untreated Ras Cheese Wheels with Clove Oil during Storage Period

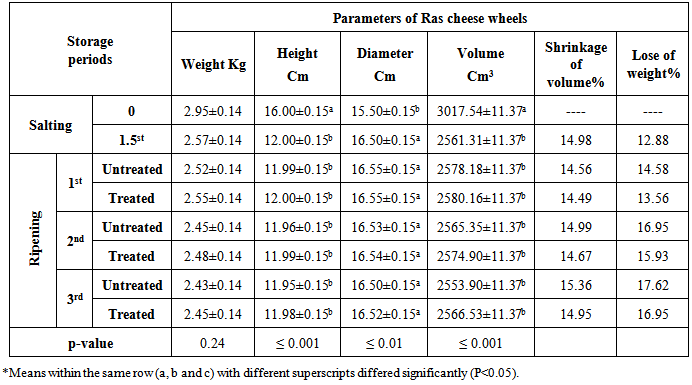

- Table 2 shows the changes in the physical examination of Ras cheese wheels during storage. Weight and volume of Ras cheese wheels were varied according to the treatment of salting, where the weight of the Ras cheese wheel decreased from 2.95±0.14 kg in the fresh Ras cheese wheel to 2.57±0.14 kg in the wheel after salting, and the loss of weight was 12.88%. The weight of untreated Ras cheese wheels with clove oil was 2.52±0.14, 2.45±0.14 and 2.43±0.14 after 1st, 2nd and 3rd months, respectively, but the weight of treated Ras cheese wheels with clove oil was 2.55±0.14, 2.48±0.14 and 2.45±0.14 over the same period, respectively. Similar finding were reported [15].

|

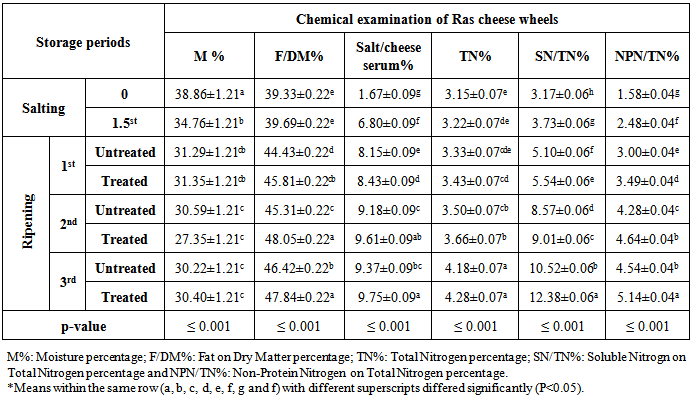

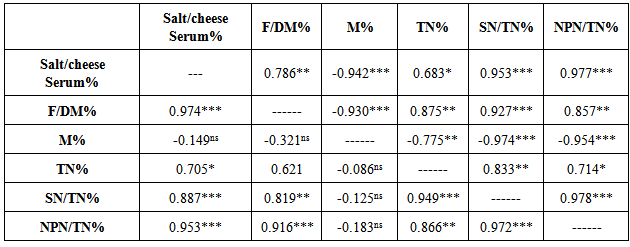

3.2. Chemical Examination of Ras Cheese

- The changes in M%, F%, Salt/cheese serum%, TN%, SN/TN% and NPN/TN% of Ras cheese wheels from different treatment followed the pattern of changes during ripening (Table 3). The average moisture of fresh Ras cheese was 38.86±1.21 compared to 30.22±1.21 and 30.40±1.21 for untreated and treated Ras cheese wheels after 3 months of ripening after salting. The reason for this loss may be attributed to the second stage of salting, done during this period, thus the moisture content tended to decrease. The examination of market Ras cheese, had a mean moisture of 34.82% [34].

|

|

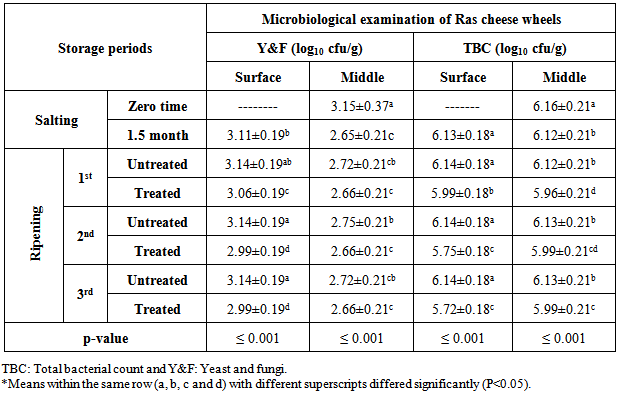

3.3. Microbiological Examination of Ras Cheese during Storage

- Results of microbiological examination of Ras cheese during storage are presented in Table 5. Results showed that, the total bacterial count (TBC) and the total yeast and fungi count of Ras cheese wheels were varied according to the treatment of salting and clove oil. The count of total bacteria, yeast and fungi were very high in the beginning of Ras cheese manufacture being 6.16±0.21 and 3.15±0.37 (log10 cfu/g), respectively. After salting (1.5 month) the values of total yeast and fungi count were decreased to 3.11±0.19 and 2.65±0.21 (log10 cfu/g) in the wheels collected from the surface and the middle, respectively, while, the total bacterial count collected from the surface and the middle of Ras cheese wheels were 6.13±0.18 and 6.12±0.21 (log10 cfu/g), respectively.

|

| Figure 4. Untreated and treated Ras cheese wheels with clove oil after one month and stored at 15.5ºC |

| Figure 5. Untreated and treated Ras cheese wheels with clove oil after two month and stored at 15.5ºC |

| Figure 6. The fungal growth between Untreated and treated Ras cheese wheels with clove oil after two month and stored at 15ºC |

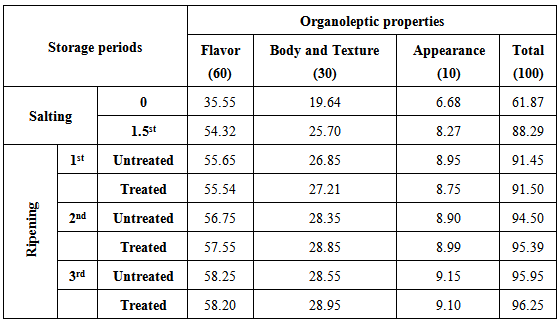

3.4. Organoleptic Properties of Treated and Untreated Ras Cheese Wheels with Clove Oil during Storage Period

- The organoleptic properties of Ras cheese depend mainly on the method of manufacture, type of milk used for cheese making, salt concentration added and the conditions of storage [2]. Data presented in Table 6 show the organoleptic evaluation of Ras cheese wheels during the storage period. Data revealed that treated and untreated cheese with clove oil significantly improved flavour, body and texture of the 2, 3 months old Ras cheese. The points given for flavour were the highest in cheese after three months. The corresponding scores at the end of ripening period were 58.25 and 58.20 out of 60 points. The present results agree with the results reported before [7], who found that the proteolysis products play an important role in the flavour of cheese by the contribution either directly to cheese taste or indirectly as precursors of flavour components.Regarding the body and texture (Table 6), the aforementioned trend of results was also noticed. The corresponding scores at the end of the ripening period were differed significantly and reached average values of 28.55 and 28.95 out of 30 points, respectively. In general, an improvement in body and texture was noticed by the increase in ripening time for all cheese samples. This trend of results agrees well with that mentioned [7] for abundance cheese (French type). They were able to establish significant relationships between the texture's properties and the rheological properties linked firstly to the fatty acids composition and proteolysis and secondly to the pH of mature cheese.

|

4. Conclusions

- Generally, it was observed that, there was no difference between Ras cheese wheels which treated with clove oil and untreated in the organoleptic properties. At the same time, the treatment of clove oil reduced the fungal growth. This observation, encourage to use this oil for the further studies and it will be used in the commercial scale, as well as, this oil considered an antifungal edible coatings oil and improve the shelf life of cheese.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML