-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2014; 4(5): 113-117

doi:10.5923/j.food.20140405.01

Influence of Halal and Non-Halal Slaughtering on the Quality Characteristics of Broiler Chicken Burger

Safa Mustafa Ibrahim1, Mutaman Ali Abdelgadir1, Abdel Moneim Elhadi Sulieman2, Abdalla Bilal Adam3

1Centre for Biosciences and Biotechnology, Faculty of Engineering and and Technology, University of Gezira, Wad-Medani, Sudan

2Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

3Department of Physics, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

Correspondence to: Abdel Moneim Elhadi Sulieman, Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

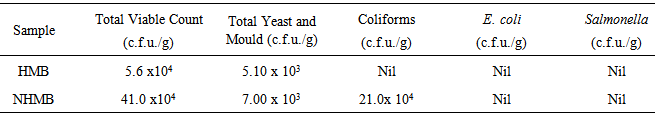

This study aimed to compare between the quality characteristics of burger prepared from meat of chicken slaughtered according to Islamic rules (Halal method) and non-Islamic rules (non-halal method). Twenty hydroid strains of broiler chickens weighing between 1.5 -1.75 kg were used. Burger was prepared using both types of meat. Microbiological, chemical methods and sensory methods were used to assess the quality characteristics of burger. The results indicate that slaughtering did not affect most of the chemical components of the two types of burger. Halal meat burger samples which contained lower microbial load in comparison to those prepared from non-halal poultry meat. The total viable count of halal meat burger (HMB) and non-halal meat sausage (NHMB) was 5.6 x 104c.f.u./g and 41.0 x104 c.f.u./g, respectively. However, the yeast and mould count of HMB and NHMB was 51.0 x 103(c.f.u./g) and 7.0 x 103 (c.f.u./g), respectively. Halal meat burger samples were not contaminated with either Coliforms, E. coli or Salmonella, while the non-halal meat burger samples contained 21.0x 104 c.f.u./g of Coliforms. On the other hand, all burger samples prepared from halal poultry meat were highly accepted by panelists. The sensory evaluation results showed that there was a significant difference (P≥0.05) between the different samples with regard to appearance, tenderness, taste and overall acceptance in comparison with the commercial burger. It is highly recommended to follow the Islamic rule in slaughtering poultry and to apply hazard analysis and food hygiene to reduce the risk of cross contamination with foodborne pathogens in poultry farms.

Keywords: Burger, Halal and non-halal, Tenderness, Taste

Cite this paper: Safa Mustafa Ibrahim, Mutaman Ali Abdelgadir, Abdel Moneim Elhadi Sulieman, Abdalla Bilal Adam, Influence of Halal and Non-Halal Slaughtering on the Quality Characteristics of Broiler Chicken Burger, International Journal of Food Science and Nutrition Engineering, Vol. 4 No. 5, 2014, pp. 113-117. doi: 10.5923/j.food.20140405.01.

Article Outline

1. Introduction

- Halal "permissible" is a term designating any object or an action which is permissible to use or engage in, according toIslamic law. The term is used to designate food seen as permissible according to Islamic law. The opposite of this word isharaam. Halal foods are foods that Muslims are allowed to eat under Islamic dietary guidelines. The criteria specify both what foods are allowed, and how the food must be prepared. The foods addressed are mostly types of meat/animal tissue [1].The low intake of poultry in Sudan can be explained by the price of meat. Traditionally, the price of red meat from sheep and cattle has been low, but during the last decade, a rise has been noted. In the past, poultry meat production has been dependent on the importation of production inputs such as feed, vaccines and parent stock [2]. As the industry is growing and the agribusinesses establish themselves, the agribusinesses tend to be able to produce chicken more efficiently. For Sudanese poultry producers, the cost of environmental regulation systems and feed are the two major expenditures affecting the producers’ final profit. Feed cost itself stands for 50-70% of the producers’ total costs. Depending on the production system used, air condition can be the second largest expense [3]. Poultry meat contributes substantially to the human diet [4]. In many Arabic countries, poultry meat is an important, low-cost source of animal protein. This encourages the consumption of poultry products by a large number of consumers. The consumption of poultry meat has increased by most of the people in these countries.Processed raw poultry meat naturally harbors bacteria, most of which are responsible for the spoilage of poultry meat. However, poultry products can harbor food-borne pathogens, like Salmonella stereotypes, Campylobacter jejuni, Listeria monocytogens, C. perfringens and S. aureus [5]. Poultry and poultry products rank first or second in foods associated with disease in most of the countries all over the world which in the USA ranked third of the reported food-borne disease outbreaks [5].The selling of beef-burger becomes a profitable business in most of Islamic countries. High meat prices prompted the meat producers in many countries to produce various meat products using non-meat ingredients. However, maintaining the nutritional value, organoleptic and texture properties of such products are a big challenge, which necessitates more effort to protect the product integrity, taste, flavor, and textural sensory attributes. To obtain healthy meat products, it is recommended to reduce high fat content to appropriate limits and increase the levels of other substances with beneficial properties.Burger is prepared from minced meat usually in a disc-like shape with diameters of 80-150 mm and 5-20 mm thickness. In commercial fast-food outlets the common name is hamburgers or simply burgers. Originally, burgers were made from beef (preferably lean cow meat), but in recent years chicken and mutton burgers have become more common. Other animal tissues such as fats or connective tissue/tendons can also be part of the mixture, with quantities depending on the type and quality of the products. Burgers are often served on bread rolls or buns with slices of cheese, mayonnaise, mustard, green salad [7]. The objective of this study was to investigate the effect of Islamic (Halal) and non-Islamic (non-halal) slaughtering method of chicken in quality characteristics of burger prepared from these meats.

2. Materials and Methods

2.1. Collection of Samples

- Twenty broilers chicken were collected from Wad Almajzoob farm (central Sudan). These chickens are hydroid strains and their weights ranging between 1.5 -1.75 kg. Each sample was taken immediately after slaughtering in a sterilized container, and transported under aseptic conditions to the Meat Technology Laboratory at the Department of Food Science and Technology of the University of Gezira.

2.2. Methods of Slaughtering

2.2.1. Halal Slaughtering

- The chickens were divided into two groups; each group contained ten broilers chicken. The first group was slaughtered according to Islamic rule (Halal slaughtering). The Halal slaughtering method started with holding the right foot, the feet of the broiler chicken was held. With the left foot, the wings were held down. The boiler chicken was given a drink water so that it relaxed as by this time it was under a lot of stress. The feathers were picked off from the front of the neck so that the knife did not have to cut through the feathers and takes too long. The process started at the beginning by reciting Allah's name and Tasmiyah (Bismillah Allahu Akbar). Then with a very sharp knife, the neck of the chicken was cut till reaching the bone, to ensure that the neck was properly cut for bleed out. The jugular veins and windpipe were cut. To ensure the quality of proper cutting as required by Halal processing, if the knife missed the chicken, cut the chicken neck would be cut by hand.

2.2.2. Non-Halal Slaughtering

- For non-Halal slaughtering, all steps followed in Halal slaughtering were followed with exception to beginning by reciting Allah's name and Tasmiyah (Bismillah Allahu Akbar).

2.3. Preparation of Meat Samples

- Poultry meat samples were prepared for analysis, these samples included: Halal and Non-halal chicken meat samples. The meat samples were transported immediately to the Department of Food Science and Technology laboratory pending.

2.4. Manufacture of Burger

- The burger products were processed in the laboratory, and the recipe for each sample was composed of 3 kg minced chicken meat (either halal or non-halal), 300g chick peas, 300gm rice flour, 300 g peas flour, 150 ml water, 10 g salt 10g, 50g onion, 30g garlic, and seasoning mixtures. All these ingredients were mixed and transferred to then a burger machine which formed burger with an average weight of 70 g weight of the piece, with diameters of 120 mm and 12 mm thickness.

2.5. Microbiological Analysis

- The microbiological analysis was carried out for burger produced from various chicken samples according to Harrigan and McCane [8].Appropriate dilutions of the respective burger samples in 0.1 gm aliquots were spread on pre-poured plates of Plate count agar for the presumptive enumeration of total viable count, Baird-Parker agar for staphylococci and MacConkey agar for coliforms. Inoculated plates were incubated for 24-48 h at 37℃. Characteristic colonies appearing on the respective selective agar media were counted, multiplied by the dilution factor and expressed as colony forming units per ml c.f.u/ml.

2.5.1. Salmonella Detection

- Ten grams sample were weighed aseptically and mixed well with 100 ml sterile nutrient broth. This was incubated at 37℃ for 24 hours. Then 10 ml were drawn aseptically and added to 100 ml selenite broth. The broth was incubated at 37℃ for 24 hours. Then with a loopful streaking was done on dried Bismuth sulphite agar plates. The plates were then incubated at 37℃ for 72 hours.Black metallic sheen discrete colonies indicated the presence of salmonella. A confirmatory test was carried out by taking a discrete black sheen colony and sub culturing it in a Triple sugar iron agar tubes.Production of black colour at the bottom of the tube confirms the presence of salmonella.

2.6. Proximate Chemical Composition

- The proximate chemical composition of burger samples was determined according to AOAC method AOAC [9] to determine the contents of moisture content, protein, fat, crude fibre, ash and carbohydrates. Moisture content was determined by using the air oven drying method. The Protein content was analyzed by the Kjeldahl method, the Fat content was determined by the Soxhlet method and carbohydrates content was determined by subtracting 100 from moisture, protein, fat, crude fibre and ash.

2.7. Sensory Evaluation

- Samples for sensory evaluation were conducted in the sensory evaluation facilities of meat laboratory, Faculty of Animal Production University of Khartoum. The samples to be used for sensory evaluation were randomly selected and cooked in a pan for 5 minutes and kept warm by using aluminum foil. 20 semi-trained panelists were used to evaluate the sausage samples. The evaluation included; colour, tenderness, flavour, juiciness and overall acceptability using an 8- point scale score (hedonic scale) card as described by Cross and Overby [10], in which the highest score of 8 being extremely desirable and 1being extremely undesirable.

2.8. Statistical Analysis

- Data were analyzed as with a 4x3 factorial arrangement of treatments using analysis of variance, treatments means were compared by Duncan's multiple range tests and ANOVA table by using SPSS version 15 computer programs.

3. Results and Discussion

3.1. Microbiological Characteristics of Burger Samples

- The microbiological characteristics of burger prepared from halal and non halal poultry meat is shown in Table (1). The total viable count of halal meat burger (HMB) and non-halal meat burger (NHMB) was 5.6 x 104c.f.u./g and 41.0 x104 c.f.u./g, respectively. On the other hand, the total yeast and mould count of HMB and NHMB was 5.10 x 103(c.f.u./g) and 7.0 x 103 (c.f.u./g), respectively. This indicates that halal slaughtering method resulted in lowering microbial viable counts. However, the counts of coliforms was 21.0x 104 c.f.u./g in NHMB and was not found in HMB. In addition, Salmonella was not detected in all tested samples. The consumption of these types of burger is safe according to European Commission [11] Regulation (EC) No 2073/2005 which requires absence of Salmonella in 10g of minced beef or beef burgers intended to be eaten cooked. If Salmonella spp. are detected, the affected batch must be withdrawn or recalled from the market.

|

3.2. Chemical Composition and pH of Burger Samples

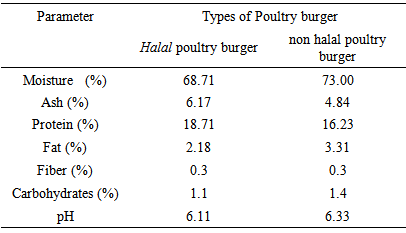

- The proximate chemical composition (%) and pH value of burger samples is present2 in Table (2). The moisture content of burger prepared from non halal poultry meat (73.00%) was higher than that prepred from halal meat which was 68.71%. This could be attributed to the slaughtering method, as a lesser amount of blood is shed during non-halal slaughtering. The obtained results were close to those reported by AL-Dughaym et. al. [13] who found that moisture content of burger ranged (66.01 and 68.60%).

|

3.3. Sensory Evaluation of Burger

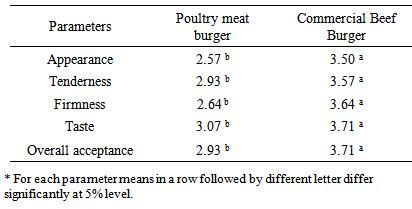

- Table (3) shows the sensory evaluation of burger prepared from halal poultry meat) and commercial beef burger.

|

4. Conclusions

- The present study aimed to compare between the quality of burger product prepared from chicken slaughtered according to Islamic rules (halal method) with that of chicken slaughtered according to non-Islamic rules (non-halal method). Generally, the microbial analysis indicated that halal slaughtering method resulted in lowering the various microbial loads of burger samples. However, the contamination of these samples with various microbial groups could reflect contaminated supply, cross contamination, and/or poor hygiene practices. Lower initial microbial levels of burger raw materials, effective heat treatment during cooking, careful handling of cooked burger and maintenance of adequate cooling temperature during storage would improve the microbiological quality and enhance the shelf life of burger product.The chemical analysis indicates that the slaughtering method does not adversely influence the chemical composition of burger product with a relative increase of some of those components in burger prepared from Halal chicken meat.The sensory evaluation of burger prepared from halal poultry meat indicated a significant difference (P≥0.05) between the different samples with regard to appearance, tenderness taste, and overall acceptance, and the highest scores of all sensory attributes were given to the commercial beef burger.

ACKNOWLEDGEMENTS

- Authors acknowledge with gratitude the technical assistance by the staff and technicians of the Department of Food Science and Technology, Faculty of Engineering and Technology, Gezira University.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML