| [1] | FAOSTAT.http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor1 Accessed 30/2/14, 2013. |

| [2] | H. Qiwei and L. Qingdian, ‘‘Research & development of Shangdong taro for high-value products and exports’’ In: D. Zhu, P. V. Eyzaguirre, M. Zhou, L. Sears and G. Liu (eds) Ethnobotany and genetic diversity of Asian taro: focus on China. Proceedings of the symposium on ethnobotanical and genetic study of taro in China: Approaches for the conservation and use of taro genetic resources. Laiyang Agricultural College, Laiyang, Shangdong, China. International Plant Genetic Resources Institute, Rome, 2000. |

| [3] | A. D. R. Arnaud-Vinas and K. Lorenz, ‘‘Pasta products containing taro (Colocasia esculenta L. Schott) and Chaya (Cnidoscolus chayamansa L. McVaugh)’’, Journal of Food Processing and Preservation, Vol. 23, 1999, pp. 1-20. |

| [4] | V. Lebot, ‘‘Tropical root and tuber crops: cassava, sweet potato, yams, aroids’’, CAB International, Oxfordshire, UK, 2009, pp. 279-360. |

| [5] | G. Vinning, ‘‘Select markets for taro, sweetpotato and yam’’ In: Rural Industries Report for Research and Development Corporation. RIRDC Publication No. 03/052, Kingston Act, 2003. |

| [6] | T. Agbor-Egbe, ‘‘Study on the factors affecting storage of edible aroids’’, Annals of Applied Biology, Vol. 119, 1991, pp. 121-130. |

| [7] | L. U. Opara, ‘‘Storage of edible aroids’’, In: F. W. Bakker-Arkema, (ed), CIGR Handbook of Agricultural Engineering, Vol. IV, Agro Processing Engineering, American Society of Agricultural Engineering, 1999. |

| [8] | M. S. Ammar, A. E. Hegazy and Bedeir, S. H, ‘‘Using of taro flour as partial substitute of wheat flour in bread making’’, World Journal of Dairy and Food Sciences, 4, 2009, pp. 94-99. |

| [9] | Y. N. Njintang and C. M. F. Mbofung, ‘‘Development of taro (Colocasia esculenta (L.) Schott) flour as an ingredient for food processing: Effect of gelatinization and drying temperature on the dehydration kinetics and colour of flour’’, Journal of Food Engineering, 58, 2003, pp. 259-265. |

| [10] | Y. N. Njintang, C. M. F. Mbofung, G. K. Moates, M. L. Parker, F. Craig, A. C. Smith and W. K. Waldron, ‘‘Functional properties of five varieties of taro flour, and relationship to creep recovery and sensory characteristics of achu (taro based paste)’’, Journal of Food Engineering, Vol. 82, 2007, pp. 114-120. |

| [11] | M. Kaur, P. Kaushal and K. S. Sanhu, ‘‘Studies on physicochemical and pasting properties of taro (Colocasia esculenta L. Schott) flour in comparison with a cereal, tuber and legume flour’’, Journal of Food Science and Technology, Vol. 50, 2013, pp. 94-100. |

| [12] | J. Rodriguez-Miranda, I. Ruiz-Lopez, E. Herman-Lara, C. E. Martinez-Sanchez, E. Delgado-Licon and M. A. Vivar-Vera, ‘‘Development of extruded snacks using taro (Colocasia esculenta) and nixtamalized maize (Zea mays) flour blends’’, LWT – Food Science and Technology, Vol. 44, 2011, pp. 673-680. |

| [13] | M. S. Sajeev, M. R. Manikantan, A. R. P. Kingsly, S. N. Moorthy and J. Sreekumar, ‘‘Texture analysis of taro (Colocasia esculenta L. Schott) cormels during storage and cooking’’, Journal of Food Science, Vol. 69, 2004, pp. E315-E321. |

| [14] | A. Aprianita, U. Purwandari, B. Watson and T. Vasiljevic, ‘‘Physicochemical properties of flours and starches from selected commercial tubers available in Australia’’, International Food Research Journal, Vol. 16, 2009, pp. 507-520. |

| [15] | C. A. Jaleel, R. Gopi, P. Manivannan, A. Kishorekumar, M. Gomathinayagam and R. P. Vam, ‘‘Changes in biochemical constituents and induction of early sprouting by triadimefon treatment in white yam (Dioscorea rotundata Poir.) tubers during storage’’, Journal of Zhejiang University, Science B, Vol. 8, 2007, pp. 283-288. |

| [16] | Z. D. Osunde and B. A. Orhevba, ‘‘Effect of storage conditions and storage period on nutritional and other qualities of stored yam (Dioscorea spp.) tubers’’, African Journal of Food Agriculture Nutrition and Development, Vol. 9, 2009, pp. 678- 690. |

| [17] | A. T. Osunsami, J. O. Akingbala and Oguntimein, G. B, ‘‘Effect of storage on starch content and modification of cassava starch’’, Starch/Starke, Vol. 41, 2006, pp. 54-57. |

| [18] | V. Ravi and J. Aked, ‘‘Review on tropical root and tuber crops, II. Physiological disorders in freshly stored roots and tubers’’, Critical Reviews in Food Science and Nutrition, Vol. 36, 1996, pp. 711-731. |

| [19] | M. R. Bikomo and J. K. Brecht, ‘‘Curing, washwater chlorination and packaging to improve the post-harvest quality of Xanthosoma cormels’’, Scientia Horticulturae, Vol. 47, 1991, pp. 1-13. |

| [20] | J. A. Bartz, and A. Kelman, ‘‘Reducing the potential for bacterial soft rot in potato tubers by chemical treatments and drying’’, American Potato Journal, Vol. 63, 1986, pp. 481-494. |

| [21] | J. E. Rickard. ‘‘Post-harvest management of taro (Colocasia esculenta var esculenta)’’, Alafua Agriculture Bulletin, Vol.8, 1983, No.2 |

| [22] | I. Malaki, D. Hunter, N. Tuivavalagi, M. W. Ullah and F. Amosa, ‘‘The effects of sodium hypochlorite dipping, temperature and duration of storage, on the quality of fresh taro corms destined for overseas markets’’, Journal of South Pacific Agriculture, Vol. 10, 2003, No.1-2. |

| [23] | N. Badrie and W. A. Mellowes, ‘‘Cassava starch or amylase effects on characteristics of cassava (Manihot esculenta Crantz) extrudate’’, Journal of Food Science, 57(1), 1992, pp. 103-107. |

| [24] | Z. Bainbridge, K. Tomlins, K. Wellings, and A. Westby, ‘‘Methods for assessing quality characteristics of non-grains starch (Part 3.Laboratory methods)’’, Natural Resources Institute, Chatham, UK, 1996. |

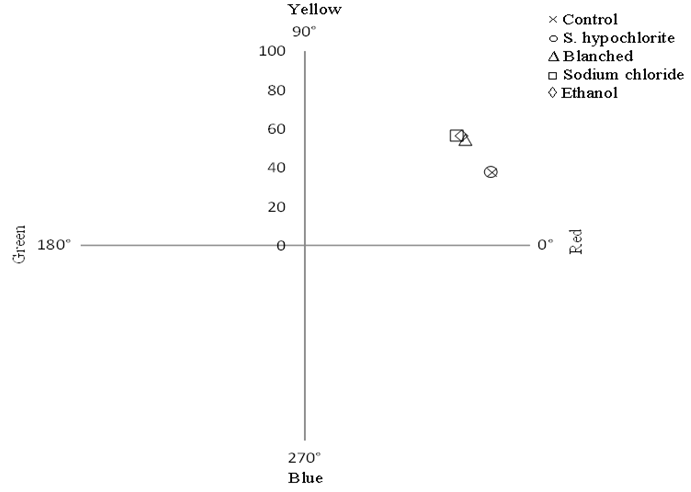

| [25] | C. Saricoban and M. T. Yilmaz, ‘‘Modelling the effects of processing factors on the changes in colour parameters of cooked meatballs using response surface methodology’’, World Applied Sciences Journal, Vol. 9, 2010, pp. 14-22. |

| [26] | D. J. Pejin, O. S. Grujic, J. D. Pejin and S. D. Kocic-Tanackov, ‘‘Effect of yeast storage temperature and flour composition on fermentative activities of baker’s yeast’’, Proceeding of National Science, Matica Sroka Novi Sad, Vol. 116, 2009, pp. 305-313. |

| [27] | W. Hue, T. Shun-ichiro and Yoshiaki, H, ‘‘Effect of heat treatment on quality of sweet potato in wrapper type cold store during long-term storage’’, Journal of the Faculty of Agriculture, Kyushu University, Vol. 49, 2004, pp. 129-138. |

| [28] | M. Van-Hal, ‘‘Quality of sweet potato flour during processing and storage’’, Food Reviews International, Vol. 16, 2000, pp. 1-37. |

| [29] | M. Villamiel, ‘‘Non-enzymatic browning for cookies, crackers and biscuits’’, In: Y. H. Hui (ed), Bakery Products, Science and Technology, Blackwell Publishing, Iowa, 2006, pp. 433-442. |

| [30] | S. S. Sahi and K. Little, ‘‘Quality Control’’, In: Y. H. Hui (ed), Bakery Products Science and Technology, Blackwell Publishing, Iowa, 2006, pp. 319-336. |

| [31] | J. Chirife and J. A. Fontana, ‘‘Introduction: Historical Highlights of Water Activity Research’’, In: G. Barbosa- Canovas, J. A. Fontana, S. J. Schmidt and T. P. Labuza, (eds), Water Activity in Foods, Fundamentals and Applications. Blackwell Publishing and the Institute of Food Technologists, 2007, pp. 3-14. |

| [32] | E. Maltini, D. Torreggiani, E. Venir and G. Bertolo, ‘‘Water activity and the preservation of plant foods’’, Food Chemistry, Vol. 82, 2003, pp. 79-86. |

| [33] | J. M. Aguilera, J. M. del Valle and M. Karel, ‘‘Caking phenomena in amorphous food powders’’, Trends in Food Science and Technology, Vol. 6, 1995, pp. 149-155. |

| [34] | N. Abdullah, A. Nawawi and I. Othman, ‘‘Fungal spoilage of starch-based foods in relation to its water activity (aw)’’, Journal of Stored Products Research, Vol. 36, 2000, pp. 47-54. |

| [35] | L. De Bry, ‘‘Wheat flour of the third Millennium’’. In: Y. H. Hui (ed), Bakery Products, Science and Technology, Blackwell Publishing, Iowa, 2006, pp. 87- 96. |

| [36] | M. Le Meste, D. Lorient and D. Simatos, ‘‘L’eau dans les aliments’’, Paris: Lavoisier Tec et Doc Editions. |

| [37] | D. F. Day, ‘‘Microbiological Control in Sugar Manufacturing and refining’’, In: C. C. Chou (ed), Handbook of Sugar Refining: A manual for the design and operation of sugar refining facilities, John Wiley and Sons, New York, 2000, pp. 505-522. |

| [38] | J. M. Aguilera and D. W. Stanley, ‘‘Microstructural principles of food processing and engineering’’, 2nd edition, Aspen Publishers Inc., Maryland, 1999, pp. 403. |

| [39] | J. B. Hutchings, ‘‘Food colour and appearance’’, Aspen Publishers, Gaithersburg, Madison, 1999. |

| [40] | R. E. Wrolstad and D. E. Smith, ‘‘Colour Analysis’’, In: S. Nielsen, (ed), Food Analysis, 4th edition, Springer Science and Business Media, LCC, New York, 2010, pp. 573-586. |

| [41] | B. J. Dobraszczyk, ‘‘Wheat and flour’’, In: D. A. V. Dendy and B. J. Dobraszczyk, (eds), Cereals and Cereal Products, Chemistry and Technology, Aspen Publishers, Maryland, Vol. 35(1), 2001, pp. 71-76. |

| [42] | M. Maskan, ‘‘Kinetics of colour change of kiwi fruits during hot air and microwave drying’’, Journal of Food Engineering, Vol. 48, 2001, 169-175. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML