-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2014; 4(1): 15-19

doi:10.5923/j.food.20140401.03

Comparison of Physicochemical Properties of Spray-dried Camel’s Milk and Cow's Milk Powder

Abdel Moneim E. Sulieman1, Osama M. Elamin2, Elamin A. Elkhalifa2, Loouis Laleye3

1Department of Biology, faculty of Science, University of Hail, Kingdom of Saudi Arabai

2Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Wad-Medani, Sudan

3Department of Food Science, Faculty of Agriculture, University of Al-Ain, United Arab Emirates

Correspondence to: Abdel Moneim E. Sulieman, Department of Biology, faculty of Science, University of Hail, Kingdom of Saudi Arabai.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

In the present study, fresh raw camel and cow's milk were concentrated to 20-30% total solids, and then dried using a pilot spray-dryer. The effect of direction of feed on physicochemical properties camel milk powderson physicochemical characteristics of the various spray-dried milks were determined. Some of the examined parameters of spray dried milks were affected, such as the water activity which had low values (0.154 - 0.208). Moreover, the degree of lightness was affected by direction of feeding, where co-current feeding gave the highest degree of lightness (97.73), when compared to counter current (93.82). The spray-drying samples also affected the solubility which recorded higher values of tested milk powder samples. The flowability was affected by the direction of feeding; the co-current feeding gave high values, when compared to counter-current feeding which gave less values (1.21-1.37). The yield was also affected, the spray-dried samples gave (68.84-88.20). The chemical analysis indicated that moisture, protein, fat, ash and acidity ranged 1.01-2.41%, 23.75-26.64%, 27.86-29.82% and 0.1-029%, respectively. The results show the importance of optimizing the drying process, in order to obtain products with better functional and physicochemical properties.

Keywords: Spray drying, Solubility, Flowability, Bulk density, Hygroscopicity

Cite this paper: Abdel Moneim E. Sulieman, Osama M. Elamin, Elamin A. Elkhalifa, Loouis Laleye, Comparison of Physicochemical Properties of Spray-dried Camel’s Milk and Cow's Milk Powder, International Journal of Food Science and Nutrition Engineering, Vol. 4 No. 1, 2014, pp. 15-19. doi: 10.5923/j.food.20140401.03.

Article Outline

1. Introduction

- According to FAO[1] there were 19 million camels in the world, out of which 15 million in Africa, 4 million in Asia. According to FAO[1] statistics, the annual camel milk production was around 1.300.000 tons. The camel milk is a potentially important source of food to nomads. In some countries, camel milk is one of the main components of human diet. The present knowledge about camel's milk production potential is very limited. In traditional pastoral systems, camel milk is used for feeding calves and human consumption, two quarters of the udder are usually selected for milking and segregated with ropes while the calf suckles the other two quarters[2].Camel milk differs from cow milk in its chemical composition, however, it contains all essential nutrients as cow milk[3] (Elagamy, 1988). Camel milk is highly nutritious, contains lower fat and lactose, higher levels of potassium, iron and vitamin C and large amounts of insulin like protein. It has high contents of whey proteins such as lactoferrin and immunoglobulin confer to it the high antimicrobial properties. In average, camel milk contains more proteins and whey protein than cow milk[4][5] (Farah, Z. 1993; Walstra et al., 1999). It is rich in essential amino acids, which explain the health benefit of camel milk for human nutrition.Carmel's milk have been consumed for thousands of years in Africa and the Middle East, it's medical benefits toward modern diseases were not known until recently.Spray drying is a method of producing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals. A consistent particle size distribution is a reason for spray drying some industrial products such as catalysts. Air is the heated drying medium; however, if the liquid is a flammable solvent such as ethanol or the product is oxygen-sensitive then nitrogen is used[6]. Spray drying is the most used commercial method for drying milk, because the very short time of heat contact and the high rate of evaporation that give a high quality product with a relatively low cost[7].A dry powder product is highly desirable since it possess long shelf life, requires relatively low transportation cost and storage capacity and the product can be distributed over a wide area, thus a process for producing a dried camel's milk powder that is soluble and without loss of nutritive value is highly desirable. A spray drying system for cow milk powder has been characterized by various factors such as inlet air temperature, feed rate, atomizer speed, out let air temperature product temperature, thermal and evaporative efficiencies[8].The production of milk powder based on the cow milk powder quality standards such as solubility, flowability, color and moisture content, process development must be conducted using the various parameters such as set temperature, inlet temperature, outlet temperature, product flow rate, and the direction of the product versus the drying air. Based on these processing parameters, the best conditions could be selected for the production of excellent milk powder. The major reason for production of milk powder is to prolong shelf life and to facilitate storage and handling. When stored in appropriate storage conditions under dry and cool condition, whole milk powder has a shelf life of 12 months and skim milk powder in excess of 2 years. The shelf life of milk powder is generally established to warrant microbiological safety and to keep acceptable sensory characteristics such as color and flavor. Although milk powder is microbiologically stable and acceptable, many physicochemical changes, such as lactose crystallization, particle caking, oxidation of fat, maillard and enzymatic reactions, may occur during storage and these modify physical and functional properties such as flowability, reconstitution properties, emulsifying and foaming properties of the powder[9]. The extent of these changes is strongly dependent on the storage condition such as temperature, relative humidity and time. Therefore an understanding of the physicochemical changes that occur under storage conditions will be very useful to predict the behavior of powder during its end use[9].The objectives of the present study were to compare the physicochemical and functional properties of spray dried camel's milk powder with spray-dried cow's milk powder.

2. Materials and Methods

2.1. Materials

- Fresh camel’s milk and cow’s milk were supplied by Al Ain Dairy Company during the year (2008). In addition, commercial cow milk powder samples were bought from a local supermarket in Alain, United Arab Emirates to be used in the study.

2.2. Methods

- Production of milk powder was completed in two stages evaporation and spray drying, as follows:Raw camel’s milk and cow’s milk was concentrated to 20% - 30% total solids using rotary evaporator (Rotavapor R II, Buchi , Switzerland ) at 80°C. The camel milk concentrate was dried using a spray dryer (FT 80 Tall from Spray Dryer, Arm field Ltd., UK). Different drying conditions were employed. Air inlet temperature was set at (200°C – 220°C), air outlet temperature was between (98°C -105°C), pump speed was set at (3 - 5) arbitrary units and the outlet air relative humidity ranged between (1.2 - 5.8) percent.

2.3. Effect of Direction of Feed on Physicochemical Properties Camel Milk Powders

- The effect of direction of feed on physicochemical properties of camel milk were determined as follows:Water activities of spray dried powders were measured using a water activity analyzer (Rotronic SW with hydrolyte VD sensor, Rotronic Instrument Corp., Huntington, NY).The flowability (Hausner ratio) is the ratio of un-tapped bulk density and tapped bulk density. Un-tapped bulk density was determined by sifting milk powder into a 100 ml cylinder and then weighing. Tapped bulk density was determined by reading the volume after tapping the cylinder 100 times[10].For determination of solubility, 10 g of whole milk powder was mixed with 100 ml of water at approx 24 °C in mixer at high speed for 90s.The milk then was left for 15 min. After which it is stirred with a spatula. 50ml was filled in to a graduated 50 ml centrifuge glass with conically graduated bottom. The glass was spun in a centrifuge for 5 min, the sediment free liquid is sucked off, the glass was filled up again with water and the content is stirred up. Then the glass was put in to the centrifuge and spun for 5 min after which the sediment was read. The sediment was expressed in ml and is termed insolubility index. It usually below 0.2 ml in powder from good quality milk dried in designed dryers.Process yield was calculated as the relation between total solids content in the resulting powder and total solids content in the feed mixture.Hygroscopicity (determined by moisture gain by two grams of powder samples) were measured under saturation solution of Na2SO4. After 1 week, hygroscopic moisture was expressed as g of moisture per100 g dry solids (g/100g) to determine hygroscopicity.Hygroscopicity (g/100g) = ( Wf – Wi )X100)/(Wi X(100-moisture/100)Where:Wf = final weight .Wi = initial weight.

2.4. Colour Determination

- The color of different samples was measured using a colorimeter (Hunter lab).The results were expressed in the CIE L, a, b. which determined the degree of lightness, redness and yellowness characteristics of the various milk powder samples Where L = is an indication of lightness. A = is an indication of redness.B = is an indication of yellowness.

2.5. Chemical Analyses

- The contents of moisture, ash, protein, total soluble solids, fat and titratable acidity were determined according to AOAC[11] methods. The pH value was determined using a pH meter (model HANNA pH 211 micro processor) according to AOAC[12] method. The ascorbic acid (vitamin C) content was determined in spray dried milk powder samples according to the AOAC[12].

3. Results and Discussion

3.1. Effect of Direction of Feed on Physicochemical Properties of Camel Milk Powders

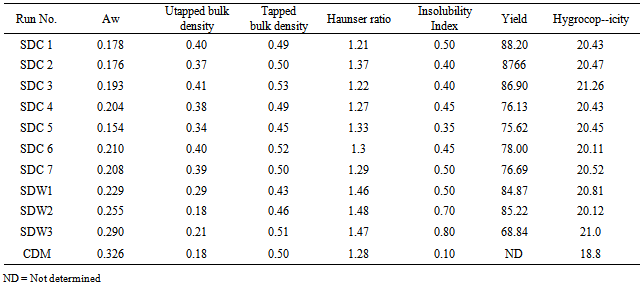

- The data in Table (1) show the water activity values of different spray-dried camel's milk (SDC), spray-dried cow's milk (SDW) and commercial milk powder (CDM). The water activity (AW) was influenced by type of milk, such that water activity was less in spray-dried camel milk samples (0.154 to 0.208), while AW of SDW ranged between 0.229 - to 0.255 and CDM contained the highest value (0.326). The concentration, temperature, direction of feed and type of milk did not affect water activity of spray-dried milk powder, but it gave different results for spray dried cow milk and commercial milk powder samples.The data in Table (1) show untapped bulk density of different spray-dried camel's milk, cow milk and commercial powder milk. The untapped bulk density was affected by the type of drying, spray-drying produced heavier powder with higher bulk density (0.46- 0.53). Commercial samples had density similar to spray dried powder (0.38). It was found that the direction of feeding did not affect the untapped bulk density of spray-dried camel milk powders. However, commercial samples had less density than the powder that produced co-current feeding.The tapped density of different spray-dried camel's milk, spray-dried cow milk and commercial milk powder is indicated in Table (1). The tapped density was affected by type of milk, the spray-dried powder (0.43- 0.43) and commercial samples (0.50) had better results. Drying temperature, direction of feed, type of milk and concentration did not affect the tapped density of spray-dried, freeze-dried and commercial milk powders.The Hausner ratio (flowability) was affected by the direction of feeding; it was found that the co-current gave a lower Hausner ratio (1.27) than counter current (1.37). This shows that powder produced by co- current drying was more flowable. Concentration, temperature of drying, type of drying and type of milk did not affect Hausner ratio. The Hausner ratio is the untapped divided by the tapped bulk density. A hausner ratio of 1 to 1.25 indication the powder had free flowing, hausner ratio of 1.25 to 1.4 indicate fairly free flowing powder, and powder with hausner ratios greater than 1.4 are cohesive and do not flow well.Solubility is an important feature in judging the physical characteristics of milk powder. It refers to the ability of desiccated milk when mixed with water to form a solution, suspension or emulsion which will simulate the physical characteristics of natural milk, which is measured as in-solubility index[13]. The insolubility index of the different spray-dried milk powder samples is presented in Table (1). It was found that the concentration of 20% and 30% total solid did not affect the insolubility index. However, spray-dried had relatively lower insolubility index (0.4). On the other hand, the commercial milk powder was found to has less insolubility index than that of both spray-dried camel milk and spray dried cow’s milk, this may be due to additions of certain addaitives to facilitate the solubility. Milk powder has to be soluble in water, however, not all of components in the powder are soluble when reconstituted in water. In powder produced in modern dryers, this amount is very small and approaching 100% solubility. Nevertheless, powder with a bad solubility is still produced. Dryer can be mal-operated resulting in powder with bad solubility.It was found that the yield of dried powder was affected by type of drying. The yield of spray-dried milk samples ranged between (68.84 -88.20). The type of milk had no effect on yield of powder.The data in Table (1) also show the hygroscopicity of different spray- dried milk powder samples. It was found that the hygoscopicity of different powder milk was not affected by type of milk, it ranged between 18.8 - 21.26, with the low values in commercial milk powder.

|

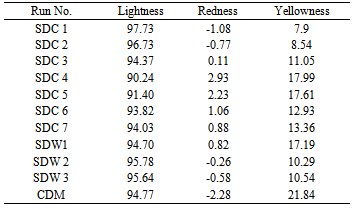

3.2. Colour of Spray Dried Milk

- L value is an indication of lightness and blackness. If the value is 100 the color is white, and if the value is 0 the color is black. The data in Table (2) and Fig 1 show the lightness of different milk powder samples. The lightness of spray dried camel milk (SDC) and spray-dried cow milk (SDC) ranged between was and Commercial milk powder (CDM) ranged between 90.24- 97.73 and 94.70-95.78, respectively (Table 1). On the other hand, the lightness of the milk powder was affected by the direction of feeding, when the direction of feeding was co-current, it produced lighter color, while, the lightness of milk powder was less when the direction of feeding was counter current. It was also found that if high temperature was used in the spray dryer, the lightness of the milk was less as compared to low temperature. Lightness of the milk powder was not greatly affected by the type of milk.

|

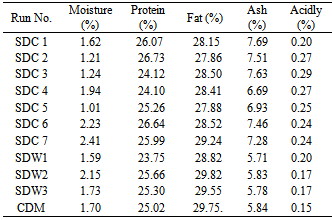

3.3. Chemical Composition of Spray-dried Milk Powder

- The data in Table (3) indicate some of the chemical components of different spray-dried camel's milk (SDC), spray-dried cow milk (SDW) and commercial powder milk (CDM). The moisture content ranged between (1.01-2.41). When drying temperature increased, the moisture of the spray dried milk powders decreased. The moisture content of the commercial sample (1.70) was closely related to those of spray dried camel's milk and cow milk samples. These values are within the recommended standards of powder milk in the Sudan[9] and USA[10] which are <3% and <5%, respectively. The fat content of different samples ranged between (27.86-29.82%). The drying temperature affected the fat content of spray-dried powder, with production of high fat content at low temperature in the powder if compared to high temperature. Using high temperature in spray drying may result in adhesion occurrence or overlap between the lipid and protein molecules. However, the fat content was not affected by concentration and, type of milk, but it is known that cow milk naturally contains more fat than camel milk.The data in Table (3) show the protein content of different spray-dried camel's milk and cow milk which ranged (23.75-26.64%) while that of commercial sample was 25.02%. However, these values were in agreement to those of the Sudanese Standard value[9] and the USA Standard value[10] which were <27% and <28%; respectively. The protein concentration levels had an inverse effect on protein, when high concentration was used protein level decreased. The direction feeding was another factor that affects protein content, such the co-current it was produced high protein levels than counter-current mode of direction feeding.

|

4. Conclusions

- With an increase in temperature a decrease in % water activity was observed in the spray-dried camel's milk samples to as low as 0.18%, indicating the possibility of a longer shelf life. It was also observed that an increase in temperature resulted in higher values of insolubility index mainly due to denaturation of proteins; this irreversible change can limit the usage of these camels' milk powders in the form of re constituted milk. The flowability of all camel's milk powder were below 50°C thus promoting a fairly good flow, however this trend was also observed in spray-dried cow's milk powders, but the color of spray dried camel's milk powders was lighter yellow. Further investigations are required to validate the prospects of camel milk powder on an industrial scale and to encourage usage of camel's milk powder as food ingredients in snacks, chocolates, ice cream and infant formulae.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML