-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2014; 4(1): 1-8

doi:10.5923/j.food.20140401.01

Physicochemical, Proximate and Sensory Properties of Organic Side-stream Pineapple (Ananas sp.) Flour

C. Tortoe1, P-N. T. Johnson1, T. Slaghek2, C. Oduro-Yeboah1, P. Addo1, A. Nyarko1, I. Tamakloe1

1CSIR-Food Research Institute, P. O. Box M20 Accra, Ghana

2TNO, P. O. Box 718, 2130 AS Hoofddorp, The Netherlands

Correspondence to: C. Tortoe, CSIR-Food Research Institute, P. O. Box M20 Accra, Ghana.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

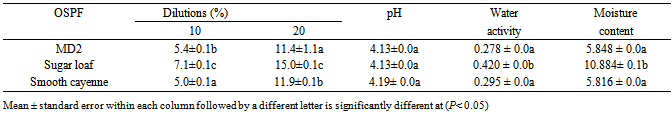

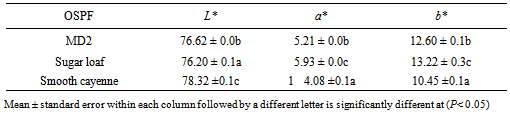

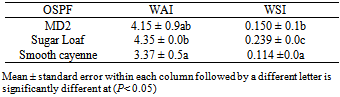

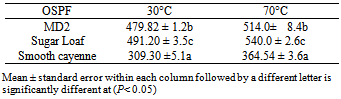

Physicochemical, proximate and sensory properties of organic side-stream pineapple flour (OSPF) developed from three pineapple varieties were evaluated. The OSPF prepared from Sugar loaf had the highest moisture content (10.88) with a corresponding water activity (0.42).Colour changes for OSPF within the three varieties were significant (P < 0.05) for L*, a* and b*. A more positive a* value (5.93) was observed for Sugar loaf indicating browning had occurred. Sugar loaf had 7.1 - 15.0°Brix for 10 - 20% dilutions. Water Absorption Index (WAI) and Water Solubility Index (WSI) were in the ranges of 3.37 - 4.35 and 0.114 - 0.239, respectively. Swelling capacity of OSPF was more significant for Sugar loaf at 70°C (540%) and 30°C (491.20%) than MD2 and Smooth cayenne. Cake prepared from OSPF of Smooth cayenne recorded the highest overall acceptability when 3% flour was used, whereas MD2 had the highest when 6% flour was used. The OSPF of Smooth cayenne used at 15% in bread presented the highest overall acceptance. In both products the sensory properties of appearance, colour, aroma, taste, texture, crust, mouth feel and overall acceptance varied significantly (P < 0.05). Thus, cake and bread incorporated with OSPF was sensory acceptable.

Keywords: Physicochemical, Sensory, Organic Side-stream, Pineapple, Flour, MD2, Sugar Loaf, Smooth Cayenne

Cite this paper: C. Tortoe, P-N. T. Johnson, T. Slaghek, C. Oduro-Yeboah, P. Addo, A. Nyarko, I. Tamakloe, Physicochemical, Proximate and Sensory Properties of Organic Side-stream Pineapple (Ananas sp.) Flour, International Journal of Food Science and Nutrition Engineering, Vol. 4 No. 1, 2014, pp. 1-8. doi: 10.5923/j.food.20140401.01.

Article Outline

1. Introduction

- Pineapple (Ananassp.) is a tropical fruit native to Central and South America[1, 2]. Total pineapple production worldwide is around 16 to 19 million tons[3].Pineapple mainly contains water, carbohydrates, sugars, vitamins A, C and beta carotene. It contains low amounts of protein, fat, ash and fibre and antioxidants namely flavonoids. It also has the enzyme complex protease (bromelain). Bromelain contains peroxidase, acid phosphate, several protease inhibitors and organically bound calcium[4]. Pineapples offer additional advantages for a whole utilization, in particular as a fibre source. Among the qualities of the fibre is the texture, its length (60 cm), high water and dye holding capacity, high whiteness, brightness, resistance to salt and tension strength. Pineapple is largely consumed around the world as canned pineapple slices, chunk and dice, juice, fruit salads, sugar syrup, alcohol, citric acid, pineapple chips and pineapple puree. It is also exported to other countries as fresh produce.Sixty precent of fresh pineapple is edible[5]. Average yield in processing ranges from 45 to 55%. Processing residuals ranges from 45 to 65%, an indication of serious organic-side streams disposal challenges[6]. Alternative solution is the development of organic-side stream pineapple flour from pineapple pulp as composite flour for the bakery and confectionary industries. Composite flour had often been a mixture of flours from roots and tubers rich in starch (cassava, yam, plantain, sweet potato, cocoyam, taro) and/or protein-rich flours (soya, groundnuts) and or cereals (maize, rice, millet, sorghum) with or without wheat flour. However, the introduction of fruit based composite flour is novel, as recently, fruits and vegetables have received much attention as a source of biologically active substances because of their antioxidant, anticarcinogenic and antimutagenic properties[7].Bakery products consumption had increased continuously due to increase in population, changes in eating habits, urbanization and increase in incomes, which meant that a larger proportion of incomesare spent on food.The advantages of using composite flour included the following: a saving on incomes, utilization of underutilized plants, promotion of high yielding indigenous plant species, product diversification, a good supply of carbohydrate, protein, vitamins and minerals for human nutrition and better overall use of domestic agriculture production[8, 9]. Trials with composite flours in bread and other confectionary making have been carried out in Africa in countries such as Senegal, Niger and Sudan[8] and Nigeria[10]. The proportion of the wheat flour varied greatly, the maximum being 70%. In Nigeria, the Federal Government in 2005 mandated the use of composite cassava-wheat flour for baking by adding minimum of 10% cassava flour to wheat flour in order to support the local cassava crop and reduce hard currency loss[10]. Significant commercial breakthroughs for fruits composite flours are limited in literature. Often available composite flour of individual crops differs greatly in sensory and physical qualities which require further research to establish standard parameters.Success is only to be expected if all the rheology of the dough, sensory attributes, shelf-life and marketability indices for composite flours are established. Despite the lower prices of composite flour products the populations often decline to buy such products due to its unfamiliar flour and its sensory properties, which often differ from those of the wheat flour. In order to ensure the success of commercialization of composite flour products, systematic studies need to be conducted to fully understand the best way to formulate products and to determine the optimal processing conditions required to realize high quality baked products. Therefore, the objectives of the study was to develop pineapple organic side-steam, which is economic waste into pineapple organic side-steam flour (OSPF) as a composite flour with wheat, analysis its physicochemical and proximate properties and further conduct its sensory evaluation in cake and bread products.

2. Materials and Methods

2.1. Pineapple Fruitsand Production of Organic Side-steam Pineapple Flour (OSPF)

- Freshly harvested physiological matured Smooth cayenne, Sugar loaf and MD2 pineapple varieties were obtained from local growers in the Central and Eastern regions in Ghana. A total of 394.65 kg of pineapples were sorted, de-crowned, washed in 1 % chlorine and subsequently washed in tap water, peeled, crushed and pulps collected at different times. The pineapple juice was pressed out using a manual presser (Manual Presser, FuroEngineering, Lagos, Nigeria). The pulps were then washed in tap water at 100kg/50L, secondly pressed and dried at 50℃ for 7 hr using a mechanical dryer (Apex Royce Ross, London, United Kingdom). The dried pulp was milled using a commercial hammer mill (Commercial Hammer Mill, Pfeuffer, Germany) and sifted with a 250 micron sieve (Meinzer 11 Sieve Shaker, CSC Scientific Company Inc., Virginia, USA) to get a fine flour of desired particle size. The OSPF(48.10 kg) obtained was immediately vacuum sealed using a vacuum sealer, Audion-Vac VM 150H (A1 Packaging Ltd., London, England) in air-tight polyethylene bags and stored at 27 ±3ºC and relative humidity (RH) of 79 ±2% in a hermetically sealed glass container until subsequent use[11, 12].

2.2. Physicochemical Properties Determination

2.2.1. Moisture Content, Water Activity, Total Soluble Solids and pH

- The moisture content was determined according to standard methods[13].Water activity (aw) of the OSPF was measured in triplicate using a RotronicHygroLab 2 (Rotronic AG, Bassersdrof, Germany). A portion (8.0 g) of OSPF was weighed (Sartorius Portable, PT600, Sartorius GMBH, Gottingen, Germany) and transferred into the chamber of the RotronicHygroLab 2 for water activity measurement. The Brix value of the smooth cayenne, sugar loaf and MD2 samples were determined at the various dilution levels, 10%, and 20% using a Grant RefractometerRB62 (Hanna Instruments, Germany). The pH of the flours was measured using a 3330 Research pH Meter (Jenway Ltd., Essex, UK) by weighing 10.0 g of flour and dissolved in 100ml of distilled water. The mixture was allowed to stand for 1 hr and stirred before electrode was inserted for pH values.

2.2.2. Colorimetry

- Colour measurement was performed on OSPF using a Minolta Chroma Meter (Model CR 310, Minolta Camera Co. Ltd. Japan), using the L* a* b* colour system in duplicates. The Chroma meter was calibrated with a standard white background. (L* = 97.63 a*=-0.48 b* = +2.12) as described in the Hunter Laboratory Manual[14, 15].

2.2.3. Water Absorption Index (WAI) and Water Solubility Index (WSI)

- The Water Absorption Index (WAI) and Water Solubility Index (WSI) were performed according to Jin, Hsieh and Huff[16] with minor modifications. The organic side-stream pineapple flour (5.0 g) was passed through a 250 mesh screen and was combined with 30 ml of distilled water in a tarred centrifuge tube. The mixture was sealed, vortex, and allowed to hydrate for 10 min. The sealed tube was inverted 3 times at both 5 and 10 min to ensure proper mixing. After 10 min samples were centrifuged for 15 min at 3000 rpmusing a Sorvall RC-5B Fixed Angle Rotor (DuPont Instruments, Wilmington, Del., U.S.A.) and the supernatant was decanted into a pre-weighed aluminium dish. The tube was inverted for 5 min over the dish to catch residual moisture. The dish was allowed to dry overnight in a drying oven at 70℃ and the centrifuge tube was reweighed to determine the weight of the sediment. WAI was calculated by dividing the sediment weight by the dry sample weight while WSI was calculated by dividing the dried supernatant weight by the dry sample weight[16].

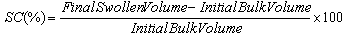

2.2.4. Swelling Capacity

- The method of Fleming, Sosulski, Kilara and Humbert[17] was used with modification. Organic side stream pineapple flour (10.0 g) was weighed into a 100 ml graduated cylinder and tapped gently at the base for a few minutes to allow the flour to settle properly at the base. After noting the bulk volume, 100 ml of water at room temperature (~ 30℃) was added, mixed well and allowed to stand. The volume of sample was read after 1, 5, 10, 15, 25, 30, 45 and 60 min. The experiment was done in triplicates and repeated using water at 70℃. The swelling capacity SC (%) was calculated as below:

2.3. Proximate Composition Determination

- The proximate composition and chemical characteristics of the organic side-stream pineapple flour measured were protein (N × 6.25), crude fibre, fat, ash, carbohydrate and additionally, energy. Total crude fibre was determined using the methodology described by Kirk andSawyerr[18]. Ash, fat, protein and crude fibre content of the blends were determined according to standard methods[13]. Caloric content (Energy) was determined using the Atwater Factor and total carbohydrate was determined by difference[18].

2.4. Ascorbic Acid Content Determination

- Ascorbic acid (vitamin C) content was determined by using 2, 6-dichloro[18] similar to quantitative determination of vitamin C content[19].

2.5. Sensory Evaluation

- Cake and bread baking were carried out with a composite flour blend of (OSPF) and wheat flour at different substitution levels.A typical cake recipe consisted of soft wheat flour (485.0 g), granulated sugar (400.0 g), margarine (450.0 g), baking powder (8.4g), egg (260.0 g) and OSPF (15.0 g) for 3% OSPF incorporated cake. The 6% OSPF incorporated caked had 470.0 g soft wheat flour and 30.0 g OSPF. The bread recipe consisted of strong wheat flour (510.0 g), granulated sugar (40.0 g), margarine (100.0 g), baker’s yeast (3.55g), warm diluted milk (500mls), salt (2.5g) and OSPF (90.0 g) for 15 % OSPF incorporated bread. Cake baking was done according to Ihekoronye and Ngoddy[20] with modification on baking temperature.Sensory evaluation of the OSPF developed from the three varieties of pineapple employed at 3 and 6% in cake and 15% in bread as composite flour with wheat flour was conducted by twenty trained panellist using a 9-point Hedonic scale to assess attributes of appearance, colour, crispness, aroma, taste, texture, mouth-feel and overall acceptability. The sensory evaluation was conducted at the CSIR-FRI Nutrition and Socio-economic Division’s Test Kitchen. An atmosphere of complete quietness and privacy was provided for each panellist. The sensory evaluation was conducted between 10:30am and 11:30am and samples were coded with 3-digit random numbers and a randomized complete block design was used in which the samples were randomly assigned to each panellist[21, 22]. The 9-point Hedonic scale was rated as 9 = like extremely, 8 = like very much, 7 = like moderately, 6 = like slightly, 5 = neither like nor dislike, 4 = dislike slightly, 3 = dislike moderately, 2 = dislike very much, 1 = dislike extremely[23]. .

2.6. Statistical Analysis

- The data obtained for all treatments were statistically analysed using Statistical Analysis Systems version 9.1 SAS 2003 software package. Significance of treatment means was tested at 5 % probability level using Duncan’s New Multiple Range Test (DNMRT).

3. Results and Discussion

3.1. Physicochemical Properties of OSPF

3.1.1. Moisture Content, Water Activity, Total Soluble Solids and pH

- The moisture conditions of products are influenced by differences in variety, maturity, and environmental conditions. Water is an important player in component mobility and in reaction rate is often measured as the water activity (aw) and moisture contents of foods[24, 25]. The OSPF prepared from MD2, Sugar loaf and Smooth cayenne pineapple varieties showed varying significant differences (P < 0.05) in water activity (Table 1). Sugar loaf had the highest moisture content with a corresponding water activity, whereas Smooth cayenne recorded the lowest with a corresponding water activity, with no statistically significantly different at 95% confidence level between the water activities of Smooth cayenne and MD2. The microbial loads, shelf life, texture, aroma and smell, moisture migration, caking and clumping are affected by water activity. Most products are safe if the water activity level are 0.7 - 0.9[26]. Lower water activity of a food product gives a better stability and shelf-life of the product[26]. This affirms increases in stability and shelf-life for MD2 with the lowest water activity. Sugar loaf OSPF recorded the highest total soluble solids and was statistically significantly different (P<0.05) between the other two varieties in both 10 and 20% dilutions(Table 1). This indicates high sugar molecules in OSPF from Sugar loaf. However, the pH of three varieties of OSPF did not differ statistically (P<0.05), indicating their acidic nature (Table 1). Similar results have been reported for pineapple core dietary fibre in studies reported by Prakongpan et al.[27] and Sreenath et al.[28] working on Ananascamosus.

3.1.2. Colour Changes

- The colour changes for OSPF within the three varieties were significantly different (P < 0.05) for L*, a* and b* (Table 2). A more positive a* value was observed for Sugar loaf indicating browning had occurred.This is due to the high sugar molecules which caramelize when exposed to heat, which is buttressed by the high total soluble solids in 10 and 20 % dilutions of Sugar loaf (Table 1).

|

|

3.1.3. Water Absorption Index (WAI) and Water Solubility Index (WSI)

- Water Absorption Index (WAI) and Water Solubility Index (WSI) for OSPF were between 3.37 - 4.35 and 0.114 - 0.239, respectively (Table 3). Similarly, ranges of 457-525% were reported for pineapple, guava and soursop fruit flours by Ramirez and de Delahaye[33]. The OSPF prepared from Sugar loaf showed the highest water adsorption index with a corresponding water solubility index. Among the three types of OSPF there were significant differences (P < 0.05) within water absorption and water solubility indices. The high WAI and WSI for Sugar loaf OSPF is due to its high soluble sugars (Table 1), which is hygroscopic absorbing more water for uniform consistency and swelling faster than the others. The Water Absorption Index (WAI) is the ability of the OSPF to absorb water. Baked, mashed and extruded snack products depends on higher WAI for improved properties, while lower WAI values are more desirable for making thinner gruels. Kulkani et al.,[34] repoted that WAI is an important functional characteristic in the development of ready-to-eat foods since high water absorption capacity may assure product cohesiveness. The OSPF obtained from Smooth cayenne recorded the lowest WAI and WSI corresponding to its lowest soluble solids (Table 1). Jin et al., [16] reported that Water Solubility Index (WSI) is a measure of the extent of solubilisation during hydration of a sample and is largely dependent upon sugars, small polysaccharides and minerals. WSI is influenced by soluble sugars, starch content and water-soluble components like proteins.

|

3.1.4. Swelling Capacity

- The swelling capacity of OSPF was highest for Sugar loaf than MD2 and Smooth cayenne at both 30 and 70℃ (Table 4). The highest swelling capacity of Sugar loaf OSPF corresponds to its highest WAI and WSI (Table 3) and highest soluble sugars (Table 1) recorded. This indicates that the swelling capacity is influenced by the total soluble solids present in the OSPF. However, the amount of soluble solids present is influenced by the variety and stage of maturity of produce. The swelling capacity of the OSPF at 70℃ was higher than 30℃. There were significant differences (P < 0.05) within 30℃ and 70℃ of the swelling capacity of OSPF. Swelling capacity is the expansion accompanying the uptake of water by soluble sugars, starch or protein cells. The ability of soluble sugars, protein and starch to absorb and retain water, depending on the temperature influences the sensory quality of food products. High swelling capacities are associated with relatively disorder arrangement of polymer within granules[35]. Small granules have more elevated resistance compared to the larger granules and swelling capacity occurs when these granules acquire their maximum size[17, 36, 37].

|

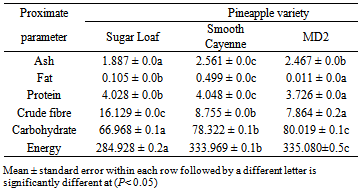

3.2. Proximate Properties

- The crude fibre yield of the OSPF were 16.13, 8.76 and 7.86 g /100 g, for Sugar loaf, Smooth cayenne and MD2, respectively, which are similar to waste pulp of pineapple (Ananascamosus) reported by Sreenathet al.[28]. High fibre content cleanses the digestive system by removing potential carcinogens from the body and prevents the intake of excess cholesterol. Fibre improves the bulk density of food and assists the intake of excess starchy food and prevents metabolic conditions such as hypercholesterolemia and diabetes mellitus[38]. Further, fibre helps in keeping blood sugar levels under control and binds to cancer-causing chemical, keeping them away from the cells lining the colon to prevent cancer[38].

|

3.3. Ascorbic Acid Content

- Ascorbic acid(vitamin C) was significantly abundant in Sugar loaf (6.86 mg/ 100 g) compared to Smooth cayenne (1.53 mg/ 100 g) and MD2 (0.72 mg/ 100 g). High content of vitamin C (ascorbic acid) is appropriate for arresting free radicals and oxidation that causes many digestive disorders [38]. Ascorbic acid is important in the fortification of children foods[18].

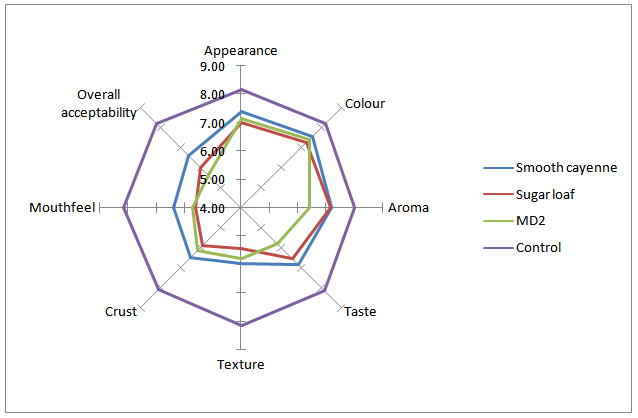

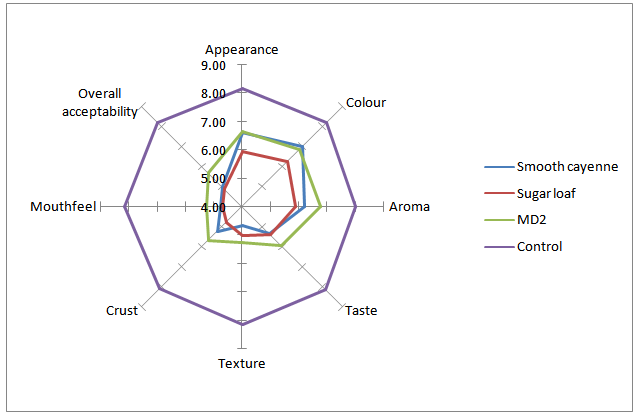

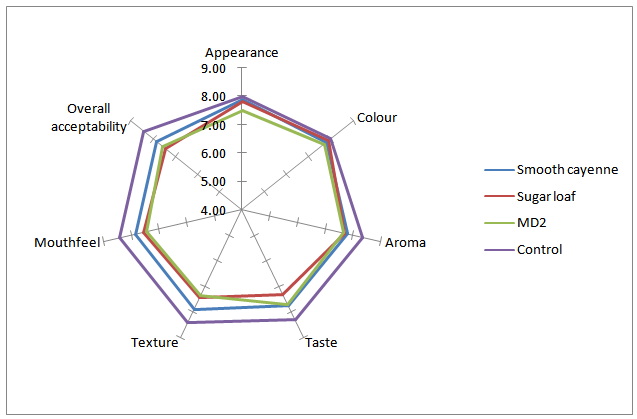

3.4. Sensory Properties

- Figures 1-3 represent the sensory analysis conducted on OSPF in cakes and bread onattributes of appearance, colour, aroma, taste, texture, crust, mouth feel and overall acceptance. The mean scores of the control samples was adjudged best for all the sensory attributes of 3 and 6% OSPF incorporated in cakes. However, 15% OSPF incorporated in bread, the OSPF preformed similar as the control sample. In cake, among the three varieties of pineapple flour, smooth cayenne recorded the highest percentage overall acceptability when 3% flour was used, whereas MD2 had the highest percentage when 6% flour was used. However, pineapple flour of Smooth cayenne used at 15% in bread presented the highest overall acceptance. In all cases, the control consisting of wheat flour was judged best for cake and bread. In similar study reported by Ramirez and deDelahaye[33] due to its hydration properties and flavour the pineapple flour was recommended in the preparation of crackers and as ingredients in desserts. Prakongpanet al.[27] reported good sensory functions for pineapple core fibre incorporated in cake-type doughnuts, golden layer cake and beef burgers. Interestingly, Sreenath et al.[28] reported sensory quality evaluation for Ananascamosuspineapple flour incorporated in sponge cakes as similarly acceptable to control sponge cakes, which is similar to cakes prepared with OSPF in this study.Naturally, the extent to which the wheat flour could be replaced by other flours depended on the nature of the bakery products to be prepared.Major component of wheat flour in bakery is the protein of the gluten that plays a decisive role in dough formation, gas retention and the structure of the crumbs, which is lacking in composite flours. Therefore, when bakery products are made from composite flour, their overall quality such as odour and flavour, taste and texture, chewing properties, appearance and shelf-life should be similar as far as possible to those of products made from wheat flour.

| Figure 1. Sensory attributes of 3% OSPF incorporated in cake |

| Figure 2. Sensory attributes of 6% OSPF incorporated in cake |

| Figure 3. Sensory attributes of 15% OSPF incorporated in bread |

4. Conclusions

- The development of Organic Side-stream Pineapple Flour (OSPF) from pineapple pulp is feasible from all three varieties of pineapple used. However, the physicochemical properties of the OSPF for Sugar loaf varietywere more significant than MD2 and Smooth cayennevariety .Cake prepared from OSPF of Smooth cayenne recorded the highest overall acceptability at 3% flour and MD2 at 6% flour incorporated as composite flour with wheat flour. In addition, OSPF of Smooth cayenne used at 15% bread as composite flour with wheat flour presented the highest overall acceptance

ACKNOWLEDGEMENTS

- The authors gratefully acknowledge the sponsorship from TNO-Netherlands.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML