-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2013; 3(5): 101-104

doi:10.5923/j.food.20130305.05

Development of Rice Flour Pasta for Gluten Induced Enteropathy Patients

Janayna P. da Silva, Monica R. S. Scapim, Antonio R. G. Monteiro, Edna R. N. de Oliveira, Grasiele S. Madrona

Department of Food Engineering, State University of Maringá, Colombo 5790 Avenue, 87020-900, Maringá, Paraná, Brazil

Correspondence to: Grasiele S. Madrona, Department of Food Engineering, State University of Maringá, Colombo 5790 Avenue, 87020-900, Maringá, Paraná, Brazil.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The objective of this study is to develop alternative food for celiac disease bearers, an autoimmune illness trigged by gluten ingestion. Two pasta formulations were developed using polished rice flour and potato starch replacing wheat flour having their chemical composition and sensory analysis (hedonic scale) verified. A comparison between gluten-free pasta and wheat flour pasta was established considering the results for chemical analysis. This research found that the gluten free pasta produced has lower values, including moisture, lipids, proteins, and carbohydrates compared to the regular wheat flour pasta. The only exception was the ashes value that is slightly high in the gluten free formulation. There was no meaningful difference (p<0.05) in sensory analysis among the samples in any of the attributes under analysis (color, smell, texture and taste). Finally, tasters provided the product with good acceptance.

Keywords: Gluten, Sensory Analysis, Celiac Disease

Cite this paper: Janayna P. da Silva, Monica R. S. Scapim, Antonio R. G. Monteiro, Edna R. N. de Oliveira, Grasiele S. Madrona, Development of Rice Flour Pasta for Gluten Induced Enteropathy Patients, International Journal of Food Science and Nutrition Engineering, Vol. 3 No. 5, 2013, pp. 101-104. doi: 10.5923/j.food.20130305.05.

Article Outline

1. Introduction

- Genetically predisposed individuals who ingest cereals containing gluten have great chance of developing an autoimmune condition known as celiac disease. Gluten consumption and genetic susceptibility are the only factors necessary for the disease to appear, the presence of immune and environmental factors also contributes to trigger the condition[1].Gluten is an amorphous protein found in wheat, rye, barley oat, and their derivatives. It is widely used in products due to its great adherent, insoluble, and elastic properties and constitute an inexpensive option to provide pasta stiffness and shape. When patients are diagnosed with coeliac disease, they are asked to follow a gluten free diet. Given the wide range of products that contains gluten, their dietary options become very restricted. On top of that, gluten free products are substantially pricier. Coeliac disease in now regarded as a common disorder, possibly affecting 1:300 of population in general. The condition is presented by many patients during adulthood with minimal symptoms, with hardly no gastrointestinal manifestations. Tests for endomysial autoantibodies have dramatically facilitated both diagnosis and screening for coeliac disease. Treatment with a gluten-free diet is effective but requires good patient compliance and monitoring to succeed[2].Currently, 1:200–350 people in Europe, 1:250–500 in USA and 1:300–500 in Turkey are estimated to suffer from the disease[3].According to Drenowski and Gomez-Carneros[4], food functionality enhancement poses a dilemma for functional food designers due to possible adverse consumer reactions to the resulting taste, resulting in low sensory acceptance. Thus it´s interesting to develop new gluten free pasta. Replacing gluten in cereal-based products presents a major technological challenge[5]. Thus, to develop alternative gluten-free pasta using rice flour and potato starch is very important to improve these innovative products.The rice flour extrusion process has been on the spotlight of food industry since it brings many advantages when compared to traditional processing systems. It is an alternative technology to exploit great quantities of products and by-products which favors both human and animal nutrition with enriched mixtures, contributing to an improvement in foods nutritional values.Rice is recommended as a safe food for celiac patients since it possesses no gluten and can be used to produce pasta. The lack of gluten may cause some technological issues when producing pasta from rice. Both gliadin and glutenin are very important to perform technologically fundamental functions, which consequently prevents the absorption of water[6].Developing countries seeking technology to produce nutritious foods at low cost may have great interest in supplementary nutrition programs to reach undernourished populations[7]. Alternative ingredients have increasingly been of great interest for the pasta industry providing different products from the ones offered in the market.The addition of pseudo-cereal flours to semolina is becoming more and more popular to improve the nutritional quality of the resultant pasta[8].Pasta has become more popular due to its easy preparation, desirable sensory attributes, long shelf-life[9, 10], along with diversity and nutritive values. Therefore, pasta may function as a suitable food for fortification and/or enrichment purposes. As the world food market is being diversified, studying for the development and improvement of new and acceptable pastas satisfying consumer demands are imminent[11].Pastas were incorporated into Brazilian culture and cuisine through European immigration, especially the Italians. Factors such as simple processing, easy storage and handling turned pasta into a common option for Brazilians from all social backgrounds.Given this, pasta was chosen to be the focus in this study and provide gluten-induced enteropathy bearers with an alternative, helping them to suffer less intensely from the difficulties the disease brings out. It is important to give appropriate attention to any groups with dietary restrictions to prevent them from being isolated in both their social and personal lives.Thus, this study aims at elaborating and providing physical, chemical and sensory evaluation of pasta produced with rice flour.

2. Materials and methods

2.1. Materials

- Polished rice flour (Oryza sativa) used to produce the pasta, potato starch, salt and xanthan-agar gome were obtained at the local market in Maringá-PR.

2.2. Production

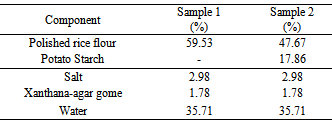

- The pasta was produced at the Cereals Technology Laboratory with appropriate equipment in the main campus of State University of Maringá (UEM).The formulations were produced according to Ciacco and Chang[12]; the proportion is shown on Table 1.

|

2.3. Centesimal Composition

- Both moisture and ash analyses were carried out according to[13]. Crude protein, total fats and crude fiber were carried out according to the Aoac[14]. Carbohydrates content was calculated through the difference between the remaining constituents (moisture, protein, total fats and ash). All analyses were carried out in triplicate applying ANOVA at 5% significance through Microsoft Excel software.

2.4. Sensory Analysis

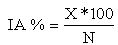

- Sensory analysis was carried out with 50 non-trained tasters both male and female at the ages of 18 to 60. The parameters analyzed were color, smell, texture and taste based on a nine-point hedonic scale (1 for really dislike it and 9 really like it). The tests were carried out according to the conditions for acceptance tests. Data were analyzed through ANOVA, double-factor without repetition. For the Tukey test it was also applied 5% significance. The pasta offered to the tasters was cooked with water for 10 minutes.The rate of acceptance test[15] for the samples was calculated through the following mathematical expression Eq. (1).

| (1) |

3. Results and Discussions

3.1. Centesimal Composition

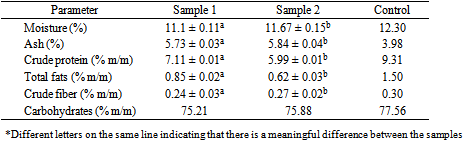

- The moisture content of a product is related to stability, quality and composition. Accurate measurements for moisture is difficult to be conducted since water present in food is not entirely in an open condition, that is, in a form easily lost by evaporation.Ash concerns the inorganic waste remaining in foods after burning organic matter without coal waste. Generally, ash contains calcium, magnesium, iron, phosphorus, lead, chloride and other mineral components.Analyses of crude protein, total fats, crude fiber and carbohydrate are greatly relevant regarding foods since they are associated to the nutritional value. These analyses along with moisture and ash analyses are named proximate analysis. These values are shown on Table 2.

|

3.2. Sensory Evaluation

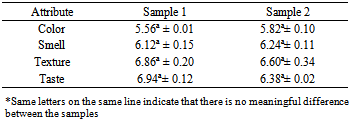

- Sensory analysis is of great relevance once it evaluates the acceptance and quality of the product, being an inherent part of the quality control plan and the development of a new product. Table 3 shows the sensory analysis results for all its different parameters.Sensory analysis revealed no meaningful difference (p<0.05) between the samples for any of the attributes analyzed. However, tasters pointed out meaningful difference for attributes color, smell and texture. Scores were between 5.56 and 6.94, corresponding to slightly liked it.The acceptance rate (IA%) was calculated considering the score for the attribute taste and the result was of 86.75% for Sample 1 and 79.75% for Sample 2, indicating great acceptance from tasters. According to Teixeira[20], in order to have a product accepted and it must obtain a rate of acceptance above 70%.

|

4. Conclusions

- The production of gluten-free pasta was proved easy and nutritionally feasible. Results show that the gluten-free pasta produced has better nutritional parameters, including moisture, lipids, proteins, and carbohydrates when compared with regular wheat flour pasta. The ashes contents were the only exception, being slightly lower for the gluten-free formulation. Finally, tasters provided the product with good acceptance, characterizing it as suitable not only for celiac disease bearers but for everyone who desires a gluten-free diet.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML