-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2013; 3(5): 81-84

doi:10.5923/j.food.20130305.01

Extraction of Pectin from Lemon and Orange Fruits Peels and its Utilization in Jam Making

Abdel Moneim E. Sulieman1, Kawther M. Y. Khodari2, Zakaria A. Salih2

1Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia

2Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Wad Medani, Sudan

Correspondence to: Abdel Moneim E. Sulieman, Department of Biology, Faculty of Science, University of Hail, Kingdom of Saudi Arabia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This study aimed to extractpectin from orange and lemon peels and its utilization use in the production of jam. Jam was processed using the extracted pectin as well as commercial pectin, then physicochemical characteristics and sensory evaluation were determined for the products. The amount of pectin extracted from orange peel and lemon peels on fresh basis was 15.25% and 20.75%, respectively. Jam made using pectin extracted from orange pectin jam OPJ and lemon pectin jam LPJ contained 60%, 61% total soluble solids, respectively, while the reducing sugar content, pH, moisture and ash values were; 2.96% and 5.027%, 4.2 and 3.5, 29% and 28%, 0.36% and 0.35%, respectively. However, the contents of sodium, and calcium were 188 and 160, 148 and 153 and 35, 24 mg/100g in OPJ and LPJ, respectively. The content of vitamin C of OPJ and LPJ were 35, 51 mg/100g, respectively. The sensory analysis indicated that all types of jams were accepted by panelists. It is recommended to encourage production of jam at home level using local raw materials under strict conditions as well as the using of natural pectin from local fruits for the production of jams.

Keywords: Pectin, Waste Products, Processing, Lemon, Orange

Cite this paper: Abdel Moneim E. Sulieman, Kawther M. Y. Khodari, Zakaria A. Salih, Extraction of Pectin from Lemon and Orange Fruits Peels and its Utilization in Jam Making, International Journal of Food Science and Nutrition Engineering, Vol. 3 No. 5, 2013, pp. 81-84. doi: 10.5923/j.food.20130305.01.

Article Outline

1. Introduction

- One of the major problems challenging the food industry throughout the world is how to make full utilization of the waste material. These waste materials, as citrus peels and other residues from 60% to 65% of bulk citrus fruit after processing[1] in Sudan, such residues are normally thrown as waste during processing.Citrus waste contains many useful components which can be extracted and utilized in different products. One of these components is pectin. Hence, citrus peel has become one of the most important sources of commercial pectin[2].Sudan possesses great potentialities for citrus industry. Many citrus varieties are grown in the Sudan such as: lime, grapefruit, sweet orange, lemon and mandarins. However, the most widely citrus species grown commercially in Sudan is sour orange (Citrus aurantium, L.). Presently, commercial citrus production spreads to many regions of the country [3][4].Pectin is a heteropolysaccharide found in the primary cell walls of many plants. It is a white to light brown powder, mainly extracted from citrus fruits, and is used as a gelling agent particularly in jams and jellies, and used also in medicines, sweets, as a stabilizer in fruit juices and milk drinks[5].The main use for pectin is as a gelling agent, thickening agent and stabilizer in food. The classical application is giving the jelly-like consistency to jams or marmalades, which would otherwise be sweet juices. For household use, pectin is an ingredient in gelling sugar (also known as "jam sugar") where it is diluted to the right concentration with sugar and some citric acid to adjust pH. In some countries, pectin is also available as a solution or an extract, or as a blended powder, for home jam making[6]. Since no pectin industry exists in the Sudan, the utilization of citrus peel as a source of pectin might be economically sound and reduces it’s importation. On the other hand increase of waste value of citrus peel as a source of pectin could be achieved through extraction of other components from the waste. With respect to food processing, the common trend in this country is to study the use of pectin (different sources) in jam processing. The objectives of the study included the extraction of pectin from orange and lemon fruit peels as well as the utilization of extracted pectin in the production of jam and assessment of the product chemical and sensory quality.

2. Materials and Methods

2.1. Materials

- In this study two kinds of orange (abusamaka cultivar) and lemon (baladi cultivar) fruits (10 each) were sold from Wad Medani (central Sudan) vegetables and fruits market randomly, transported to the Food Quality Control laboratory of the Department of Food Science and Technology, University of Gezira in baskets pending extracting of pectin to be used jam production. The foreign materials were removed manually and fruits of both types were washed clearly by distilled water. The other materials included: pumpkin fruits, sucrose, clean potable water, acetone, ethanol, distilled water, commercial pectin, pineapple flavor, citric, sodium benzoate and acetic acid (MSHACO company).

2.2. Extraction of Pectin

- Total pectin was determined as g/100 g on fresh weight basis sample. Orange and lemon were peeled and dried for four days and powdered. Orange powder (500 g) and from lemon powder (500 g) were used. Then 5 liter distilled water and 50 ml HCL were added for each blend and then mixed and left for 24 hours, then filtered in separation device. One liter of filtrate was added to 1 liter ethanol (95%), the mixture was put into centrifugation apparatus. Ten left one hour and filtered through Buchner funnel. Acidified ethanol was added to residues. The filtrate was washed with 250 ml acetone for drying and filtrate was dried at room temperature for 24 hours. The product was ground into fine powder and sieved by 40 mesh sieve to separate pectin from fiber. The pectin powder was then collected, weighed and packed in plastic container pending jam production.

2.3. Processing of Jam

- Jam was produced according to the traditional method using pumpkin as a raw material. The formula consisted of pumpkin fruit pulp (1 kg), sugar (1 kg) and pectin (8 g). The prepared fruit peels and 500 g sugar were placed in a cooker and mixed well. The mixture was cooked under continuous stirring for 12-15 minutes during which the remaining sugar was added. When the total soluble solids reached 60 Brix, then 8 grams of the extracted pectin or commercial pectin were added. Then the mixture was cooked until the total soluble solids reached 67 Brix. After that, the heat was turned off and the Jam was cooled to 87℃, filled in sterilized dry jars, labeled and stored for about 2 weeks at room temperature 25℃.

2.4. Physicochemical Analysis of Jam Product

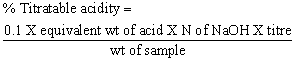

- The jam produced either extracted pectin from orange or lemon or commercial pectin samples were analyzed chemically and by sensory evaluation. The chemical methods included determination of the pH and the contents of total soluble solids (TSS), moisture, ash and total carbohydrates according to the AOAC methods[7]. The reducing sugars contents were estimated according to AOAC[8]. Reducing sugar was determined by dissolving 2 g of sample in 250 ml of distilled water. 1 ml of solution was diluted with 100ml of distilled water in a beaker. 1 ml of the diluted solution was pipetted into a test-tube and 1 ml of 5% phenol was added drop by drop. The test-tube was allowed to stand for 10 min before the content was transferred into clean, grease-free cuvette and read with spectrophotometer at a wavelength of 490 nm. A blank was prepared as above to set the equipment to calibrate the equipment. Titratable acidity of the jam samples was determined using methods as described by Ruck[9]. 25g of jam samples were transferred to 400 ml beakers containing hot water, which was made up to the 200 ml mark, boiled gently for 15 min and filtered through filter paper. 50 ml of the filtrates were pipetted into 250 ml beakers; 100 ml of water was added to each of them. They were titrated with sodium hydroxide to pH 8.1 using a pH meter. Total acidity was calculated as follows:

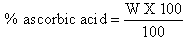

Ascorbic acid was determined by the 2,6-dichlorophenol indophenol titration procedure[9]. Ascorbic acid was extracted using an acetic acid (70%) and metaphosphoric acid (30%) solution. The extracts were transferred with distilled water into a 50 ml volumetric flask and made up to the mark with more water and filtered rapidly. The filtrate was run from a burette into a test tube containing one drop of dilute acetic acid and 1ml of the redox dye, 2,6 dichlorophenol indophenol solution. The volume of extract required to decolorize the dye was noted. The titration was repeated using standard ascorbic acid solution (1 mg pure vitamin per 100 ml) in place of the jam and fruit extracts.

Ascorbic acid was determined by the 2,6-dichlorophenol indophenol titration procedure[9]. Ascorbic acid was extracted using an acetic acid (70%) and metaphosphoric acid (30%) solution. The extracts were transferred with distilled water into a 50 ml volumetric flask and made up to the mark with more water and filtered rapidly. The filtrate was run from a burette into a test tube containing one drop of dilute acetic acid and 1ml of the redox dye, 2,6 dichlorophenol indophenol solution. The volume of extract required to decolorize the dye was noted. The titration was repeated using standard ascorbic acid solution (1 mg pure vitamin per 100 ml) in place of the jam and fruit extracts. W = volume of dyeDetermination of potassium (K), sodium (Na) and calcium (Ca) concentrations were accomplished by means of flame photometer (Model Corning, 400) according to the AOAC [9].

W = volume of dyeDetermination of potassium (K), sodium (Na) and calcium (Ca) concentrations were accomplished by means of flame photometer (Model Corning, 400) according to the AOAC [9].2.5. Sensory Evaluation

- Jam products were subjected to sensory evaluation (Hedonic scale) using 10 trained panelists to assess the texture, flavour, appearance and color. The tests were carried out in a room free from disturbing noises, with uniform intensity levels of lightening. Fresh air was provided with water for rinsing. All those conditions were equally used for all tests. The order of presentation of samples was randomized and the samples were given codes before being tested, the results were recorded and analyzed.

2.6. Statistical Analysis

- All scores of the sensory evaluation were analyzed by the analysis of variance (ANOVA), to determine whether there were significant differences between means for each variable .least significant difference (LSD) test was used .

3. Results and Discussion

3.1. Extraction of Pectin

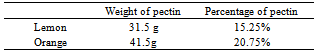

- The amount of pectin extracted from orange peels (Table 1) was 31.5g which was equivalent to 15.25% of total orange peel weight, and the amount of pectin extracted from lemon peels was 41.5g which was equivalent to 20.75% as total lemon peels weight. It has been reported that typical levels of pectin in fresh apples, 1–1.5%, apricot, 1%, cherries, 0.4% , oranges, 0.5–3.5%, carrots approx. 1.4% and citrus peels 30%[10].

|

3.2. Chemical Characteristics

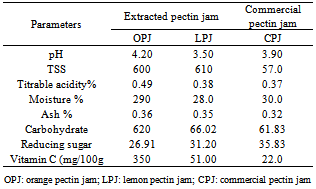

- The data presented in Table (2) show the results of the chemical composition of jam prepared using pectin and pumpkin as raw materials.The pH of jam made using pectin extracted from oranges (OPJ), jam made using pectin extracted from lemon (LPJ) and commercial pectin jam (CPJ) were 4.2, 3.5 and 3.9 respectively. These results are similar to that required for quality control of jam referring to the international standard of pH jam with a range of (3.2 – 3.5)[11]. On the other hand, total soluble solids (TSS) of OPJ, LPJ, and CPJ were 60, 61 and 57 Brix, respectively. These values were lower than the standard TSS values which range between (65 – 70) Brix[12]. The relatively low TSS contents in comparison with the standard values could be attributed to the smaller amount of sugar used, which also affected the total carbohydrate contents. The Brix value of and pH 3.44 recorded for jam in the present study conform to values recommended for jam to hinder microbial growth and maintain keeping quality[13]; The pH value determined in the current study is close to the reported pH 3.2 for optimum gel formation.

|

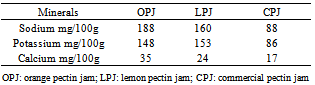

The ash contents of OPJ, LPJ and CPJ were 0.36, 0.35 and 0.32% respectively. These results are similar to the standard of the jam made by the standard pectin. The variation of pectin ash contents extracted from the different fruits could be due to the type or chemical constituents of cell fruits or the pectin of the fruit itself and the methods of collection and drying of the fruit.The reducing sugar content of OPJ, LPJ and CPJ is indicated in Table (2) were 26.9%, 31.2% and 35.83%, respectively. The results were less than the standard because of the method used for pectin extraction (standard value 6) (Joseph, 1986)[12]. Reducing sugar content was within the values (20-40%) acceptable in commercial jams[14].Vitamin C (ascorbic acid) contents of OPJ, LPJ and CPJ were 35 mg/100g, 51 mg/100g and 22 mg/100g, respectively. These results were similar to the standard (50 – 80 mg/100 g.The mineral contents (mg/100g) of OPJ, LPJ and CPJ were presented in Table (3). The content of sodium was 188, 160 and 88 mg/100g in OPJ, LPJ and CPJ respectively. While the content of potassium was 148, 153 and 86 mg/100g, respectively. And the contents of calcium were 35, 24 and 17 mg/100g respectively.The variations found in some of the physicochemical properties of jam samples compared with those of other authors could be due to the different sources of the fruits used, the effects of storage and processing methods.

The ash contents of OPJ, LPJ and CPJ were 0.36, 0.35 and 0.32% respectively. These results are similar to the standard of the jam made by the standard pectin. The variation of pectin ash contents extracted from the different fruits could be due to the type or chemical constituents of cell fruits or the pectin of the fruit itself and the methods of collection and drying of the fruit.The reducing sugar content of OPJ, LPJ and CPJ is indicated in Table (2) were 26.9%, 31.2% and 35.83%, respectively. The results were less than the standard because of the method used for pectin extraction (standard value 6) (Joseph, 1986)[12]. Reducing sugar content was within the values (20-40%) acceptable in commercial jams[14].Vitamin C (ascorbic acid) contents of OPJ, LPJ and CPJ were 35 mg/100g, 51 mg/100g and 22 mg/100g, respectively. These results were similar to the standard (50 – 80 mg/100 g.The mineral contents (mg/100g) of OPJ, LPJ and CPJ were presented in Table (3). The content of sodium was 188, 160 and 88 mg/100g in OPJ, LPJ and CPJ respectively. While the content of potassium was 148, 153 and 86 mg/100g, respectively. And the contents of calcium were 35, 24 and 17 mg/100g respectively.The variations found in some of the physicochemical properties of jam samples compared with those of other authors could be due to the different sources of the fruits used, the effects of storage and processing methods.

|

3.3. Sensory Evaluation

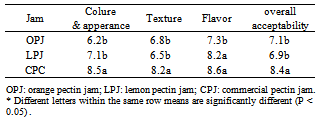

- A sensory evaluation was carried out by the senses of taste, smell, touch and hearing when food is eaten. The complex sensation that results from the interaction of the senses was used to measure food quality in programmes for quality control and new product development[14].The results of the sensory evaluation of jam product using pectin extracted from orange, lemon as well as commercial pectin is indicated in Table (4). The panelists gave high scores (5.8) for the appearance of jam made from commercial pectin which differed significantly from that of extracted pectin jam samples. The low scores of appearance of jam made from extracted pectin could be due to the dark color formation. As indicated in the table there was non – significant difference in texture of the two jam samples, also the panelists preferred the texture of the commercial pectin jam and gave it high scores (8.2) in comparison to that of jam prepared from orange (6.8) and lemon (6.5). In contrast, the color and flavor were significantly different when different jam samples were compared. The flavor of orange pectin jam was non-significantly different from that of commercial pectin jam. However, there is insignificant difference in overall acceptability of the two samples (OPJ and LPJ) while those jam types differed significantly from commercial pectin jam. However, all jam products were accepted by the panelists who preferred jam produced using commercial pectin.

|

4. Conclusions

- It could be concluded that both lemon and orange can be used in making jam. The low gel strength of the jam can be improved by the addition of pectin during processing to attain the commercially acceptable gel strength or a combination of fruits rich in pectin can be used to make up for the deficiency. The combination with other fruits could serve to improve the flavour and the colour.It is highly recommended to encourage production of jam using local raw materials like (sugar beet) at household level and strict conditions must be available while making jam at home. More research is recommended on the use of natural pectin from local fruits for the production of jams.

ACKNOWLEDGEMENTS

- The authors express their gratitude to the Ministry of Higher Education and Scientific Research of Sudan who sponsored this research. Thanks are extended to the staff members and technicians of the Department of Food Science and Technology for their support.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML