-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2012; 2(6): 108-112

doi: 10.5923/j.food.20120206.02

Quality Evaluation of “Ricotta” Cheese Produced at Laboratory Level

Abdel Moneim E. Sulieman1, Aisha S. Eljack2, Zakaria A. Salih2

1Department of Biology, faculty of Science, University of Hail, Kingdom of Saudi Arabai

2Department of Food Science and Technology, Faculty of Engineering and Technology, University of Gezira, Wad-Medani, Sudan

Correspondence to: Abdel Moneim E. Sulieman, Department of Biology, faculty of Science, University of Hail, Kingdom of Saudi Arabai.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Ricotta cheese is made from heat-acid precipitation of protein from whey or whey-milk blend. The study aimed to evaluate the quality characteristics of ricotta cheese produced at laboratory level. The chemical composition of ricotta cheese was as follows: moisture: 72.89%, protein: 72.89%, protein: 0.14%, fat: 0.6%, ash: 5.37%, pH: 5.28, acidity: 1.38%, total solid: 18.41%, Ca: 225mg/100g, K: 120mg/100g and Na: 106mg/100g. On the other hand, the total viable count was 1.0×104 c.f.u/g and yeast and mould count was 2.0×102 c.f.u/g. However, all harmful microorganisms were not detected in cheese samples. The sensory evaluation showed that ricotta cheese was generally acceptable. The study recommends encouraging the local dairy industry to introduce ricotta cheese so as to meet the local need and to use whey in the other dairy products.

Keywords: Chemical Composition, Yeasts And Moulds, Total Viable Count, Sensory Evaluation

Cite this paper: Abdel Moneim E. Sulieman, Aisha S. Eljack, Zakaria A. Salih, "Quality Evaluation of “Ricotta” Cheese Produced at Laboratory Level", International Journal of Food Science and Nutrition Engineering, Vol. 2 No. 6, 2012, pp. 108-112. doi: 10.5923/j.food.20120206.02.

Article Outline

1.Introduction

- Cheese is the name given to a group of fermented milk products produced throughout the world in great variety of flavors, textures and form. Fox et al,[1] suggested that there are more than 1000 varieties of cheese worldwide . Walter and Hargrove[2] described about 400 varieties and list the names of a further 400, while Burkhalfer[3] classifies 510 varieties. Cheese making developed recently with the gradual acquiring of knowledge about the chemistry and microbiology of milk and cheese which makes it possible to gain more control over the cheese making process. Few new varieties have evolved as a result of increased knowledge, but existing varieties have become better defined and their quality has become more consistent. The ricotta cheese is a high moisture soft cheese[4]. This cheese can be produced from whey or milk or mixture of both[5]. Ricotta cheese is very mild and it is used in many Italian dishes. Several methods have been developed for utilization of whey; one of these methods is the manufacture of ricotta cheese. Ricotta cheese, which means “re cooked”, is produced by boiling acidified cheese whey[6];[7]. All whey protein cheese mixture are homogenized and heated at 93oC/15-30 min. The curd is left in the whey for 10 min. and then scooped in plastic frame lined over a drainage table and allows to achieve complete drainage in 24 hr. The curd is placed in plastic container and stored at 4℃.Ricotta cheese is not known or consumed largely in Sudan, and few data is available in this type of cheese, therefore the objectives of the present study were: to evaluate the chemical and microbiological characteristics of whey, to produce of ricotta cheese at laboratory level using whey and to evaluate the microbiological, chemical and sensory quality characteristics of the manufactured ricotta cheese.

2. Materials and Methods

2.1. Preparation of Whey Samples

- The whey samples were collected from local market in Wad Medani, central Sudan during April-May 2011. Whey samples were placed in plastic containers and transported to the Department of Food Science and Technology laboratory, Faculty of Engineering and Technology, University of Gazira at cool temperature (at 6℃).

2.2. Chemical Analyses of Whey

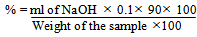

- The pH of whey was measured using digital pH meter (PN9410.GL. Britain). The pH meter was calibrated with buffers of pH 4 and 7. The pH values were recorded according to AOAC[8].The titrimetric determination of acidity of whey was accomplished according to the AOAC[9] method. 10 ml sample were taken, and then diluted in 100ml distilled water, then 10ml were pipetted into two 100ml conical flask. The pipettes were washed with distilled water, and six drops of phenolphthalein indicator then added. The samples were then titrated with 0.1 N. NaOH until a stable pink color was formed. The titrable acidity was expressed as % lactic acid from the following formula:Whey and cheese titrable acidity

Where 90 is the amount of lactic acid reacted with 1.0ml of o.1 N NaOH.The moisture, ash and protein contents of whey samples were determined according to AOAC[8], while fat content of was determined according to the AOAA[9] using Gerber tube. The solid non fat content in whey was determined by using the following formula:Total solid% - fat%

Where 90 is the amount of lactic acid reacted with 1.0ml of o.1 N NaOH.The moisture, ash and protein contents of whey samples were determined according to AOAC[8], while fat content of was determined according to the AOAA[9] using Gerber tube. The solid non fat content in whey was determined by using the following formula:Total solid% - fat%2.3. Microbiological Analyses

- Ten ml of whey were homogenized with 90 ml of distilled water by shaking for several minutes, from this suspension; 1 ml was taken from the dilution and transferred to another tube to make serial dilution up to 106. Total viable count per ml was determined by pour plating of suitable dilution on melted nutrient agar, and incubated aerobically after solidification at 37℃ for 72 hour[10].Yeast and Moulds were enumerated according to Harrigan and MacCance[11] using potato dextrose agar (PDA). The plates were incubated at 25℃ for 3-5 days, plates containing between 30 and 300 colonies were count as colony forming units (cfu/ml).Coliform bacterial count was determined according to Harrigan and MacCance[11] using MacConkey broth. The tubes were incubated at 37℃ for 48 hours. Positive tubes gave gas in Durham tubes. Then the positive tubes were sub cultured into EC broth medium and then incubated at 44℃ for 24 hours, to determine coliform bacteria, the tubes showing gas production were considered positive.Plates showing positive coliform were subjected to the confirmed test for E. coli using Brilliant green bile broth in test tubes with Durham tube. The test tubes were then incubated at 45℃ for 48 hours. Each confirmed positive tube was sub-cultured into E.C broth media and then incubated at 45℃ for 24 hours. Tubes showing any amount of gas production were considered to be positive[12].For salmonella detection, 100 ml of samples were incubated at 37oC for 24 hours. Then 10 ml were drawn aseptically and added to 100 ml selenite broth. The broth was incubated at 37oC for 24 hours. Then with a loopful streaking was done on dried Bismuth sulphite agar plates. The plates were then incubated at 37℃ for 72 hours. Black metallic sheen discrete colonies indicated the presence of salmonella. A confirmatory test was carried out by taking a discrete black.

2.4. Preparation of Ricotta Cheese at Laboratory Level

- Ricotta cheese was made from heated acid precipitation of protein from whey. During heating by using a heater (at 79℃), 7 liters of whey protein were coagulated. The rate of coagulation increases as temperature was raised to 93℃ and thick layer of curd was formed on the surface of the whey. When coagulation was completed and the curd was firm (after 10-20 min. at 93℃), the curd was removed from the heater ordinary plastic mesh.10 ml of lemon juice were immediately added to the resulting curd. After 10 minutes, the mixture was placed in cheesecloth for 2-3 hours. The obtained ricotta cheese was then kept in small plastic container.

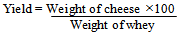

2.5. Cheese Yield

- The resulting cheese was weighed immediately using a weighing balance. The yield of cheese was calculated as follows:

2.6. Assessment of Ricotta Cheese

- The quality of laboratory made ricotta cheese was determined using chemical, microbiological and sensory methods.The pH, acidity, total solid, solids non fat, moisture, protein, fat and ash were determined as described for the whey.The microbiological analyses total viable count, yeast and mould count, coliform count E. coli and salmonella were determined as described for the whey.

2.7. Sensory Evaluation of Laboratory Made Ricotta Cheese

- The ricotta cheese was subjected to sensory evaluation using 10 panelists. The panelists were asked to rate or to judge samples to be tasted under 9 scales, about the appearance, texture, colour, flavour and the overall acceptability. Each panelist was provided with water for rinsing. The samples were given codes before being tested.

2.8. Statistical Analyses

- All scores of sensory evaluation were analyzed by the analysis of variance according to SAS[13]. To determine whether there were significant differences between means for each variable; least significant difference (LSD) test was used.

3. Results and Discussion

3.1. Chemical Compositions of Whey Sample and pH

- Table (1) shows the chemical composition of whey samples. The moisture content was 92.20+0.23%. This value was slightly lower than that found by Kosikowski (1979), which was 93.7%. The protein content was 0.7+ 0.14%, which was lower than that reported by Abozaid[14] who determined a value of 0.9%. The fat content was 0.7+0.1%, which was higher than that reported by Kosikowski[15], which was 0.3%. The ash content of whey is 5.37+0.19%. This value was higher than that found by Kosikowski[15], which was 0.52%. pH value of whey was 5.1+0.30%. This value was higher than that reported by DTU National Food institute[16], which was 5.00.The titratable acidity (expressed as% lactic acid) of whey was 2.35+0.3%. This value was higher than that of http: //www. Dairy forall.com[17], which was 0.4%. The total solid content was 17.9+0.06%. This value was higher than that reported by http: //www. Dairy forall.com[17], which was 10.5%.

|

3.2. Microbiological Analysis of Whey Samples

- Table (2) shows results of the microbiological analysis of whey samples. The total viable count was 9×104 cfu/ml, this result was higher than that reported by http://www.wolframalph .com/entities[18] which was 4×104. The yeast and mould count of whey samples was 6×104 cfu/ml, this result was higher than that reported by http://www.wolframalph .com/entities[18] which was 3×104. However, Coliform, E.coli and salmonella were not detected in whey samples indicated the proper sanitary conditions in which the cheese was made.

|

3.3. Chemical Composition of Laboratory-Made Ricotta Cheese

- The chemical composition of laboratory-made ricotta cheese was presented in Table (3). The moisture content cheese was 72.89+2.6% which was lower than that of whey (92.20+0.23%). This reduction could be attributed to the effect of high heat treatment which evaporated part of water. However, the result obtained in the present study was lower than that reported by http:www.Dairy forall.com[17], which was 93% for ricotta cheese.The protein content of laboratory-made ricotta cheese was 0.6+ 0.1%, while it was 0.7%+0.14% in whey. The result was lower than that reported by DTU National Food institute[15], which was 0.8% for ricotta cheese. The fat content of laboratory-made ricotta cheese was 0.6+ 0.1%, while it was 0.7+0.1% in whey. The difference did not exceed 0.1. The result was lower than that reported by DTU National Food institute[16], which was 0.8% for ricotta cheese.The ash content of laboratory-made ricotta cheese was 5.37 + 0.19%, while it was 6.9+1.4% in whey.pH value of laboratory-made ricotta cheese was 5.28+0.23%, while it was 5.1+0.3% in whey, and this difference could be attributed to the effect of heat treatment which eliminated the microbial load. The result was similar to that reported by DTU National Food institute[16], who found value of 5.00% for ricotta cheese.The titratable acidity was 1.38+0.6%, while it was 2.35+0.06% in whey. The variation in acidity of whey and ricotta cheese may be attributed to storage of whey at room temperature for 12-24 hours before production of ricotta cheese. The result was lower than that reported by DTU National Food institute ([16], who found value of 1.03% for ricotta cheese. The total solid of laboratory-made ricotta cheese was18.41+1.5%, while it was 17.9+0.06% in whey. The difference did not exceed 0.51. The result was lower than that reported by DTU National Food institute[16], who found value of 17.5% for ricotta cheese.

|

3.4. Microbiological Characteristics of Laboratory-Made Ricotta Cheese

- Microbiological analyses of laboratory-made ricotta cheese, as shown in Table (4) revealed presence of 1×104 cfu/ml of total viable count. This result was lower than that found by Rossetti et al.,[19], which was 2.8 ×106 cfu/ml. The lower levels of total bacterial count in laboratory-made ricotta cheese could be attributed to the effect of heat treatment which suppress the growth of microorganisms, and also could be attributed to the proper hygienic conditions of cheese production. The yeasts and moulds count of laboratory-made ricotta cheese was 2×102 cfu/ml. This result was lower than that found by Rossetti[19], which was 8.0 ×103 cfu/ml. The lower levels of yeasts and moulds count of laboratory-made ricotta cheese were probably due to the effect of higher heat.Coliform, E. coli and salmonella were not found in laboratory-made ricotta cheese.The absence of Coliform, E. coli and salmonella in laboratory-made ricotta cheese, were probably due to the effect of heat treatment of whey used for the production of ricotta cheese which suppressed the growth of those microorganisms (pathogenic bacteria).

|

3.5. Sensory Evaluation

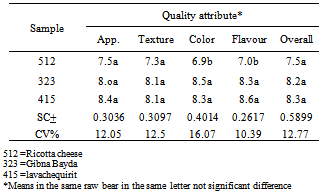

- Table (5) summarizes the mean scores for sensory attributes of the ricotta cheese, Gibna Bayda and lavachequirit. The result indicated slight differences of the various sensory parameters of cheese samples. There were significant differences p> (0.05) of ricotta cheese color and lavor when compared with those of Gibna Bayda and lavachequirit. The low scores of lavor may be attributed to the distraction of certain LAB responsible for generation lavor compound as a result of heat treatment.Generally, the panelist highly accepted ricotta cheese when compared to Gibna Bayda and lavachequirit. However, there were no significant differences in appearance, texture and overall of the various cheese types.

|

4. Conclusions

- In the present study the ricotta cheese was prepared at laboratory level using whey which was collected as a by- product of Gibna Bayda industry. The manufactured ricotta cheese was analyzed chemically, microbiologically and subjected to sensory analysis. Chemical analysis of the manufactured ricotta cheese showed that its main component were 72.89% moisture, 0.6% protein, 0.7% fat, and 6.9% ash. Microbial analysis showed that ricotta cheese is free from pathogenic bacteria. The sensory analysis indicated that the ricotta cheese made from whey was highly acceptable by panelist. From the results of this study it is highly recommended to introduce whey to other food industries, and to encourage the local industry to increase the production of Ricotta cheese so as to meet the local need.

ACKNOWLEDGEMENTS

- The authors express their sincere thanks to all staff members of the Department of Food Science and Technology, Gezira University for their assistance.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML