-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Food Science and Nutrition Engineering

p-ISSN: 2166-5168 e-ISSN: 2166-5192

2011; 1(1): 1-4

doi: 10.5923/j.food.20110101.01

Chemical and Microbiological Characteristics of Fermented Milk Product, Mish

Abdel Moneim E. Sulieman , Hadeel O. Abd Elgadir, Elamin A.

Department Food Science and Technology, Faculty of Engineering and Technology, University of Gezira

Correspondence to: Abdel Moneim E. Sulieman , Department Food Science and Technology, Faculty of Engineering and Technology, University of Gezira.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This study aimed to assess the quality aspects of commercial mish samples collected from Khartoum State through determination of the chemical and the microbiological characteristics, in addition to the production of mish at laboratory level from cow’s milk (C) and goat’s milk (G) and assessment of the product quality. The chemical analyses of both commerical and laboratory made mish samples revealed a range of pH: 4.4 – 4.49, acidity: 1.5 – 2.0, total soilds: 33.38 – 37.21, soilds non-fat: 25.3 – 29.9, fats: 6.2 – 7.13, protein: 7.0 – 8.03, ash: 1.41 – 1.99, and moisture: 75.95 – 83.78. The micobiological analysis indicated that the total count of the commercial samples ranged between 3.98-4.1 log10 cfu/ml, while the laboratory made mish from goat milk (LMMG) and cow milk (LMMC) recorded 14.5 log10 cfu/ml and 13.5 log10 cfu/ml, respectively. The yeast count in the commercial mish samples ranged between 3.9-3.96 log10 cfu/ml, while they were 3.8 log10 cfu/ml in LMMG and 4.0 log10 cfu/ml in in all tested samples. The laboratory made mish samples were highly accepted by the panelists.

Keywords: Mish, Chemical Composition, Acidity

Cite this paper: Abdel Moneim E. Sulieman , Hadeel O. Abd Elgadir, Elamin A. , "Chemical and Microbiological Characteristics of Fermented Milk Product, Mish", International Journal of Food Science and Nutrition Engineering, Vol. 1 No. 1, 2011, pp. 1-4. doi: 10.5923/j.food.20110101.01.

Article Outline

1. Introduction

- Fermentation is defined as a process leading to the anaerobic breakdown of carbohydrates. Other major compounds than carbohydrates, such as organic acids, proteins and fats, are fermentable in the broader view that fermentation is an energy-yielding oxidation-reduction process[1,2]. To the microbiologist, fermentation refers to any anaerobic metabolic pathway that yields energy from organic molecule (the initial food), utilized a different an electron transport system[3].Fermentation transform the original food by producing acids, alcohols and volatile compounds that add flavor and aroma, some of these chemicals are antimicrobials. They inhibit the growth of undesirable pathogens and spoilage microbes. Thus fermentation preserves food. Generally, fermentation is a self-limiting process. The accumulating acids and/or alcohols eventually kill even the fermenting microorganisms themselves.Mish is a fermented milk food a most known to all regions of the Sudan and may be similar product but in different names in some regions as Bija tribes (Haloom), it is spiced fermented milk product and intensity of spicing may differ from region to another and even from family to another within the same district as it depends one spices availabilityand the taste of people. Mish made at homes by adding previous sour milk to the heated (boiled) milk and then spices, such as black cumin, hot red-pepper, fenugreek ands salt are added and left for a picking period (2-3 days) after which it is ready for eating[4].The mish of Darfur, nomads of Dinder and the Northern States are closely related to the Egyptian products like laban-zeer, karish cheese and mish cheese[5]. The spices used in the same as those used in Darfur, namely black cumin and red pepper[6]. Judging by the consistency of the product, mish fall fermented milks and cheese.The objectives of the present study include: the assessment of the quality of mish samples collected from different markets in Khartoum State through determination of their chemical composition and microbiological characteristics, and production of mish at laboratory level from cow’s milk and goat’s milk and assessment of the product quality.

2. Materials and Methods

2.1. Materials

- The samples of mish (Alrawaby “R”, Capo “C”, and Daima “D”) were obtained from Alshakerren market in Khartoum Bahri, during the period (January – February, 2011). The samples were kept at low temperature by using refrigerator to suppress microbial growth. Five pounds of each cow;s and goat’s milk were brought from Bika village (Gezira state). The milk samples were transferred to the diary laboratory, Faculty of Engineering and Technology, where the production of laboratory made mish was done.

2.2. Microbiological Analysis

- The microbiological analyses were carried out in all mish samples to determine the total viable count, yeasts count, coliforms count, E.coli test and moulds count according to the methods described by Harrigan and Mccance[7].

2.3. Chemical Analysis of Mish Samples

- The chemical analyses were carried out in all mish samples to determine the pH values and the contents of titratable acidity (TA), ash, protein, total soluble solids (TSS), solids non fat (SNF), moisture and fat according to AOAC[8] methods.

2.4. Preparation of Laboratory made Mish (LMM)

- Five pounds of each of cow’s and goat’s milk were heated at 90oC and cooled to 40oC. Capo yoghurt , 500 ml (as a starter), were added to the milk samples, and they were let to be fermented for 8 hours. Each mixture was drained using clean cloth for 3-4 hours, so as to remove the excess whey. The samples were kept in a refrigerator for 24 hour, then aproppriate amount of fenugreek and cumin seeds, green pepper and commercial salt, were added. Each sample was then kept in a plastic container for 24 hours, so as to insure its homogenity, and kept al low temperature (6oC) pending microbiological and chemical analyses.

2.5. Assessment of LMM

- The quality of laboratory made mish (LMM) was determined using chemical, microbiological and sensory methods.

2.6. Sensory evaluation of laboratory made Mish

- The cow’s and goat’s mish were subjected to sensory evaluation using 10 panelists at the third day of production. The panelists were asked to rate or to judge samples to be tasted under 9 scales, about the appearance, texture, color, flavour, and the overall acceptability. Each panelist was provided with water for rinsing. The samples were given codes before being tested.

2.7. Statistical Analysis

- The data obtained from sensory evaluation were subjected to a simple descriptive statistics and least significant difference (LSD) test, so as to determine whether there were significant differences in the data or not.

3. Results and Discussion

3.1. Micobiological Characteristics

- The micobiological characterestics of the commical mish and laboratory made mish samples are shown in Table (1), the total count of the commercial samples Alrawby (R), Capo (C) and Dima (D) mish samples ranged between 3.98-4.1 log10 cfu/ml, while the laboratory made mish from goat milk (LMMG) and cow milk (LMMC) recorded 14.5 log10 cfu/ml in goat’s mish and 13.5 log10 cfu/ml in cow’s mish. The higher microbiological load of laboratory made mish samples could be attributed to conduction of the microbiological analysis for LMM after 3 days, while the commercial mish samples were analyzed immedially after production. The same table also showed that the coliform count was 3.37 log10 cfu/ml, 3.89 log10 cfu/ml, and 1.24 log10 cfu/ml in R, D and C samples, respectively. While the coliform count of 9.5 log10cfu /ml in LMMG and 10.5 log10 cfu/ml in LMMG. The yeast count in the commercial mish samples ranged between 3.9-3.96 log10 cfu/ml, while they were 3.8 log10 cfu/ml in goat’s and 4.0 log10 cfu/ml in cow’s laboratory made mish, respectively. The observable difference was a round 0.06 among the three groups. The mould count ranged between 3.61-3.89 log10 cfu/ml in the commercial samples, while those of the goat’s was 3.4 log10 cfu/ml and the cow’s laboratory made mish was 4.9 log10cfu/ml. The counts of yeast and mould of the commercial and laboratory made mish had relatively closely related values. The low count may be due to the higher acid concentration of mish which was not aproppriate for their growth. The E. coli count was not detected in all mish samples.Generally, the microbiological analyses indicate that mish samples were safe for consumption since all counts of microbiological groups were below the standard levels according to the Sudanese Standards and Metrology Orgnization[9], which states that the acceptable standards of coliform, yeast and mould counts was about 10, the total count was about 50, and, however, the E. coli count was not detected.

|

3.2. Chemical Analysis

- Table (2) shows that the pH of commercial samples ranged between 4.45-4.48, which was relatively similar to the those of laboratory made mish samples (4.49 in goat’s milk mish and 4.40 in cow’s milk mish). The acidity values were also similar and amount to 1.5-2.0, 1.58 and 1.54 (lactic acdi %) in the commercial mish samples, goat’s milk mish samples and cow’s milk mish samples). The increase in acidity was due to the fermentation proccess which resulted in higher acid concentration that reduced the pH values of mish samples. The total soild % ranged between 33.38-37.21 in the commercial mish samples, while they were 34.02 and 34.35 in the laboratory made goat’s milk mish and cow’s laboratory made mish, respectively. The solid-non-fat (SNF) % ranged between 26.9-29.9 in the commercial mish samples, while those of the laboratory made mish were 28.4 in LMMG and 25.3 in LMMG. The Sudanese Standad and Metrology Organazation [9] stated that the value of solids non fat should not exceed 8.2 and the fat should not exceed 3 in yoghurt product, i.e.there were obvious differences between the present study findings and the values recommended by Sudanese Standardization Organization[9]. However, the increase in SNF could be attributed to the solid ingriedients added to the formula such as fenugreek and cumin seeds. The same table showed that fat, protein, and ash ranged between 6.2-7.0%, 7.0-8.0%, and 1.41-1.99%, respectively, in the commercial samples, while they were 6.69% and 7.13%, 7.90% and 8.03%, and 1.6% and 1.76%, respectively, in the laboratory made goat’s and cow’s mish, respectively. The motisure content was 83.68%, 82.15% and 75.92% in C samples, D samples and C samples, respectively, while the LMMC and LMMG contained 78.13% and 80%, respectively. The protein content was found to be 7.0 % in both R and D commercial mish samples and 8.0 in C mish samples. The test for Ash (%), reveald that the R, D and C mish samples contained 1.99 %, 1.41 % and 1.99 %, respectively. On the other hand, the protein (%) was found to be 7.90 in laboratory made mish prepared from cow’s milk, and 8.03 in laboratory made mish prepared from cow’s milk goat’s milk. The test for ash (%), reveald that the various mish samples contained a range of 1.41 to 1-99% indicating relatively lower amounts of minerals in laboratory made mish samples compared with commercial mish samples. All mish samples contanied relatively higher fat contents which ranged between 7.13 to 6.2 %.

3.3. Sensory Evaluation

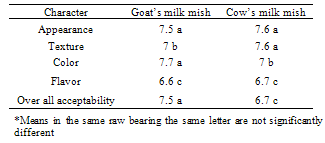

- Table (3) summerizes the mean for sensory attributes as determined by panelists for the two types of laboratory made mish. The results indicated that the panelists mostly preferred the goat’s mish color than that of cow’s mish (i.e. the cow’s milk relatively got a yellow color, and this color may probably reflected in the mish product). The panelists were relatively similar in their judgements about the appearance and flavour of both goat’s and cow’s mish (i.e. the additives acts to improve the unacceptable flavour of the goat’s milk). Generally, the panelists considerably accepted the mish made by goat’s milk than that made by cow’s milk.

|

|

4. Conclusions

- The objectives of the present study were to evaluate the quality charactaristics of mish samples collected from some different markets in Khartoum State and comparing these charactaristics with those of mish samples produced at laboratoray level. The chemical analysis revealed that, the pH in both commercial and laboratory made mish samples were less than that of fresh milk samples. The total solids (%), solid non-fat (%), fat (%) and protein (%) in both commercial and laboratory made mish samples, were greater than that of fresh milk samples. The microbiological analyses revealed that mish product is same to consumption. All samples were accepted by panelists who preferred the goat’s laboratory made mish more than the cow’s laboratory made mish.

ACKNOWLEDGEMENTS

- The authors would like to express their sincere gratitute for the staff of El-Rawabi dairy company for their unlimitted assistance during the research implementation.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML